Space traveling wave tube, collector thereof and preparation method of the connector

A technology of traveling wave tubes and collectors, which is applied in the field of long-life space traveling wave tubes, the preparation of the traveling wave tubes and collectors, can solve the problem of difficult removal of oxide film, achieve low cost, prolong life, and huge economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

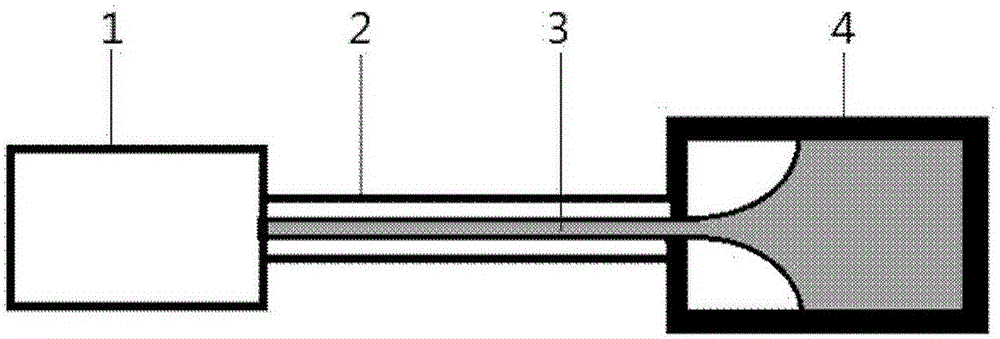

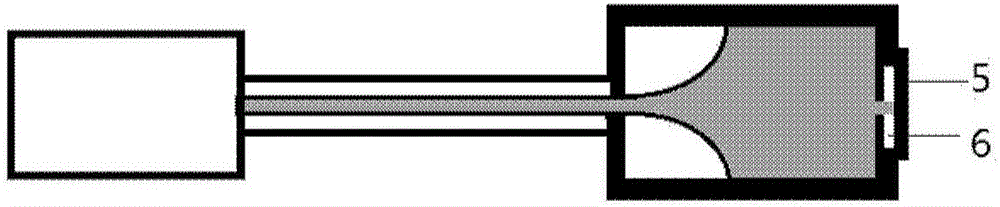

Image

Examples

preparation example Construction

[0039] Based on the same inventive concept, the present invention provides a method for preparing the collector of a space traveling wave tube, including the steps:

[0040] (1) Open a small hole at the bottom of the collector;

[0041] (2) Covering a metal sheet on the small hole to form a hermetic seal between the metal sheet and the small hole.

[0042] Based on the same inventive concept, the present invention provides a method for manufacturing a space traveling wave tube, which is characterized by including the following steps:

[0043] (1) Open a small hole at the bottom of the collector;

[0044] (2) Covering a metal sheet on the small hole to form a closed space between the metal sheet and the small hole;

[0045] (3) Weld the collector covered with the metal sheet with the slow wave component, and weld the slow wave component with the electron gun, and the electron gun is aligned with the metal sheet.

[0046] Further, in the above preparation method, after step (3), it includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com