Three-cavity sliding-vane-type vacuum pump

A vacuum pump and sliding vane technology, applied in rotary piston pumps, pumps, rotary piston/oscillating piston pump components, etc., can solve the problems of low ultimate vacuum, small volume ratio of sliding vane vacuum pumps, etc. Exhaust airflow pulsation, rich profile types, improved vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

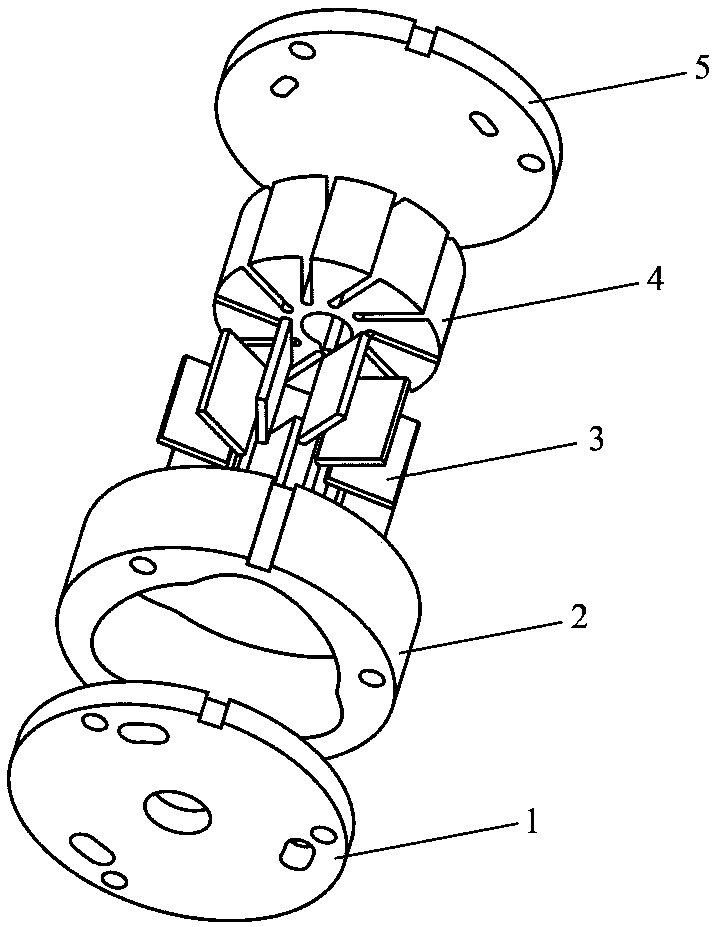

[0038] Such as figure 1 As shown, the exploded view is obtained after moving each component in the assembly drawing of the three-cavity vane vacuum pump along the axial direction.

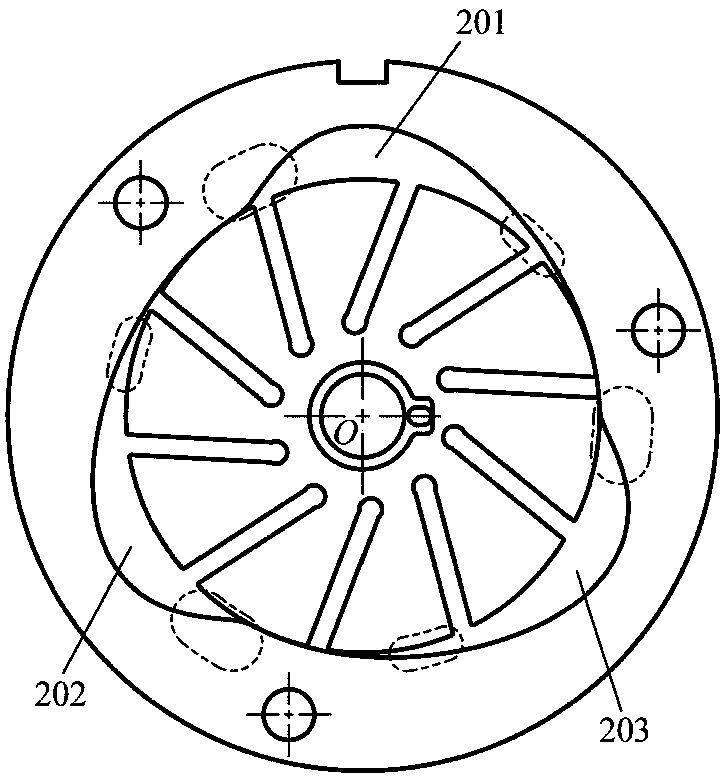

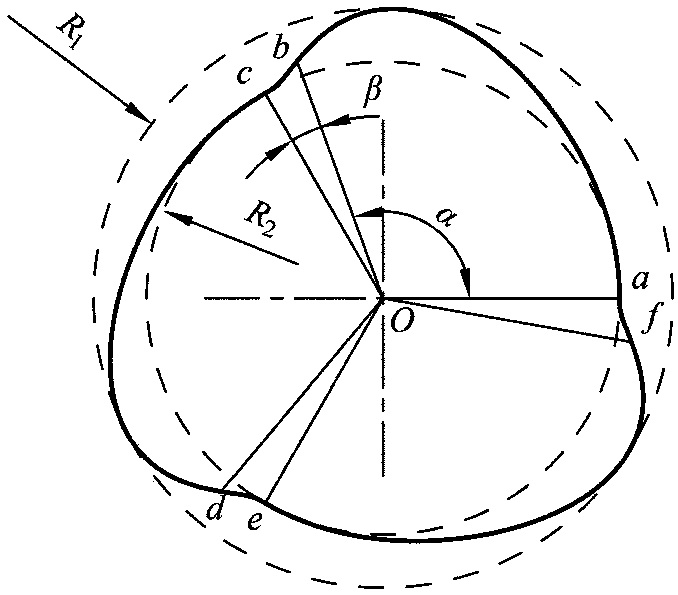

[0039] Such as figure 2 As shown, the suction end cover (1), the pump chamber (2), and the exhaust end cover (5) are all provided with a positioning groove and 3 through holes for fixing; the suction end cover (1), the pump Three identical working chambers are formed between chamber (2), exhaust end cover (5) and rotor (4), including: first working chamber (201), second working chamber (202), third working chamber (203), the three working chambers form 120° rotational symmetry with respect to the center of rotation O point, and are all asymmetrical working chambers; 10 chutes with a certain inclination angle are symmetrically opened on the rotor (4), and the matching chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com