Leak detection device and leak detection method

A technology of leak detection and standard leak hole, which can solve the problem of rising sealing performance index and improve leak detection sensitivity, The effect of reducing the background noise and improving the ultimate vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the application will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the application. .

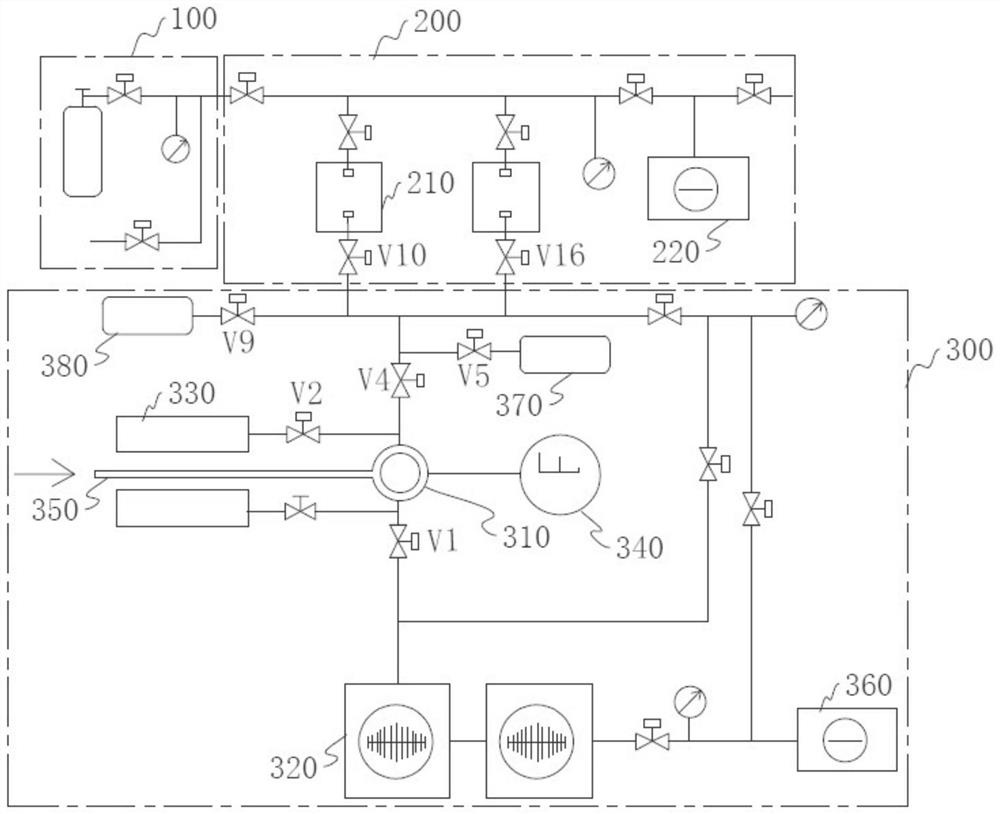

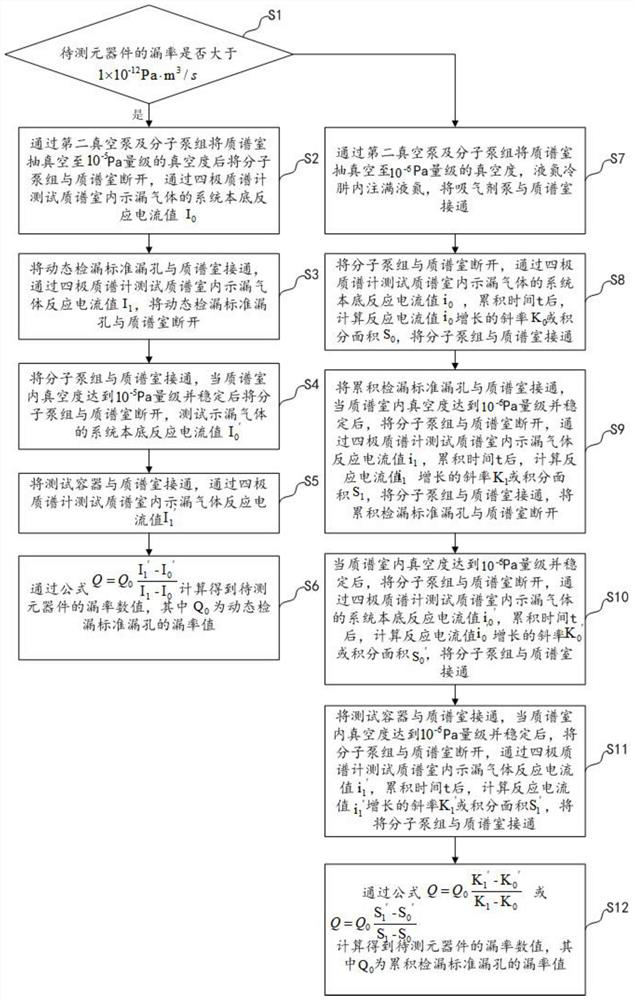

[0035] Such as figure 1Shown is a schematic diagram of the first embodiment of the present application, including an inflatable area 100, a station area to be tested 200 and a test area 300, and the inflatable area 100 is used to inflate and deflate the station area to be tested 200; The station area 200 to be tested comprises a test container 210 and a first vacuum pump 220, the test container 210 is provided with at least one, and the first vacuum pump 220 is connected with the test container 210 for vacuumizing the test container 210; the test area 300 includes a mass spectrometry chamber 310, a molecular pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com