Multilevel floating vortex vacuum pumps and usage method thereof

A vacuum pump and scroll technology, which is applied in the field of multi-stage floating scroll vacuum pumps, can solve the problem of high air compression ratio, large axial and radial separation force and energy consumption, and the inability to increase the number of scroll turns and the ultimate vacuum of vacuum pumps and other problems to achieve the effect of improving the ultimate vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

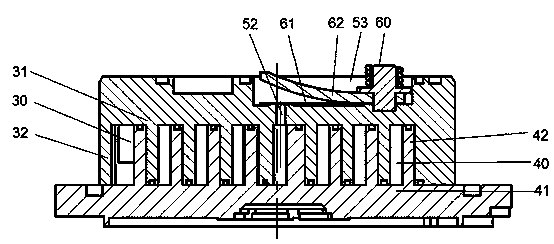

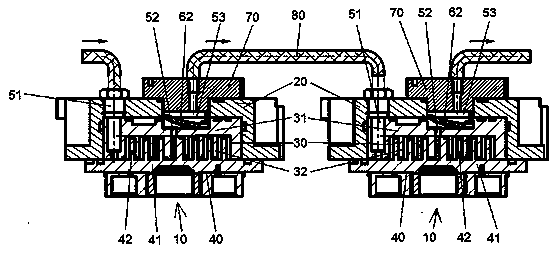

[0030] In the first embodiment of the present invention, please continue to refer to figure 1 , figure 2 and image 3 shown. The exhaust valve assembly 60 includes the above-mentioned reed valve plate 61 and a limiting plate 62 . An air valve chamber 53 is also provided on the first end plate 31 of the fixed scroll 30 , the air valve chamber 53 is connected to the exhaust port 52 , and the air valve chamber 53 runs through the fixed scroll base 20 . One end of the limiting plate 62 is fixedly arranged on the first end plate 31 of the fixed scroll 30 in the air valve chamber 53, and the limiting plate 62 presses down on the reed valve plate 61, and the other end of the limiting plate 62 is bent. Tilt up to limit the opening angle of the reed valve plate 61, so that the opening position of the reed valve plate 61 is limited. At the same time, the reed valve plate 61 fits in the exhaust port 52 located in the middle of the first end plate 31 of the fixed scroll 30 .

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com