Single-head varying-pitch screw rotor with equal tooth top width

A technology of equal tooth tip width and variable pitch, applied in rotary piston pumps, rotary piston machines, components of pumping devices for elastic fluids, etc. Problems such as small utilization coefficient and weak interstage leakage blocking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

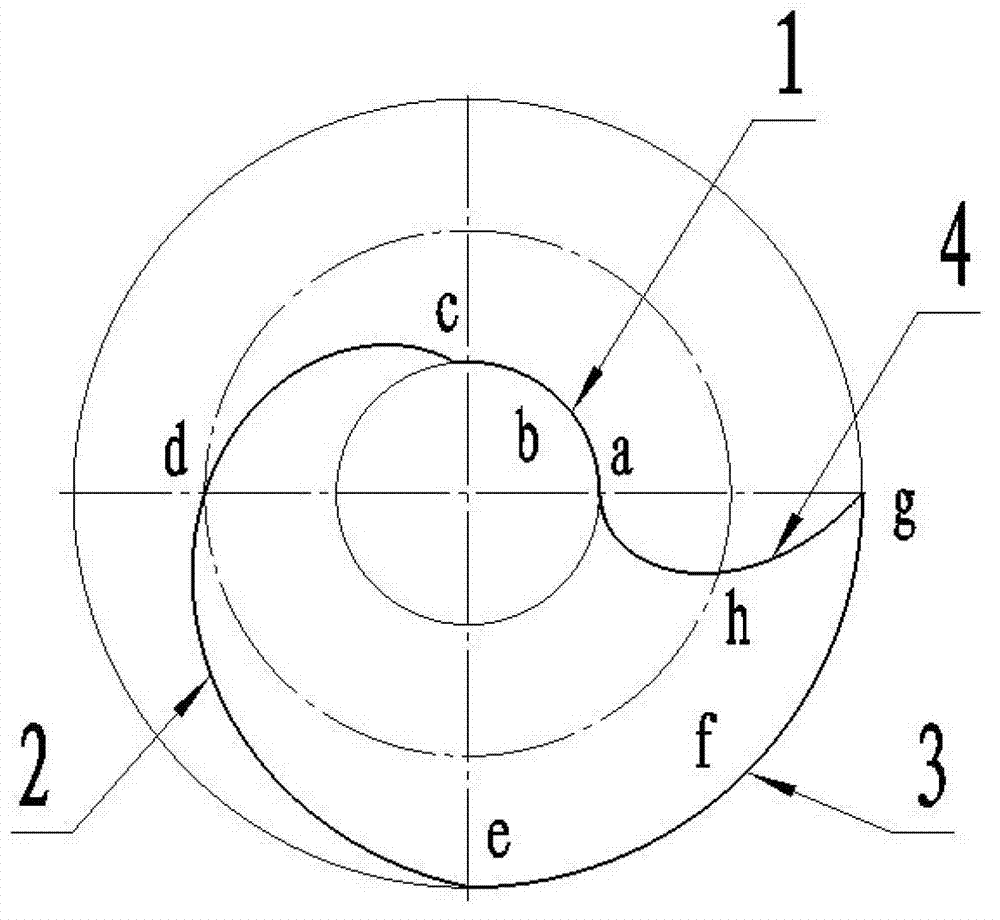

[0048] This embodiment provides a single-head variable-pitch screw rotor with equal addendum width, and the end surface profile at a certain cross-section is as follows: figure 1 shown. The section of curve abc is the dedendum circle curve 1, the section of curve cde is the involute curve 2, the section of curve efg is the addendum circle curve 3, and the section of curve gha is the transition curve 4 composed of a single cycloid. (for example, the end c of the dedendum circle curve abc is connected with the start end c of the involute curve cde, the end e of the involute curve cde is connected with the start end e of the addendum circle curve efg, and the end of the addendum circle curve efg g is connected to the initial end g of the transition curve gha formed by a single cycloid, and the end of the transition curve gha formed by a single cycloid is connected to the initial end a of the dedendum circular curve abc to form an end profile).

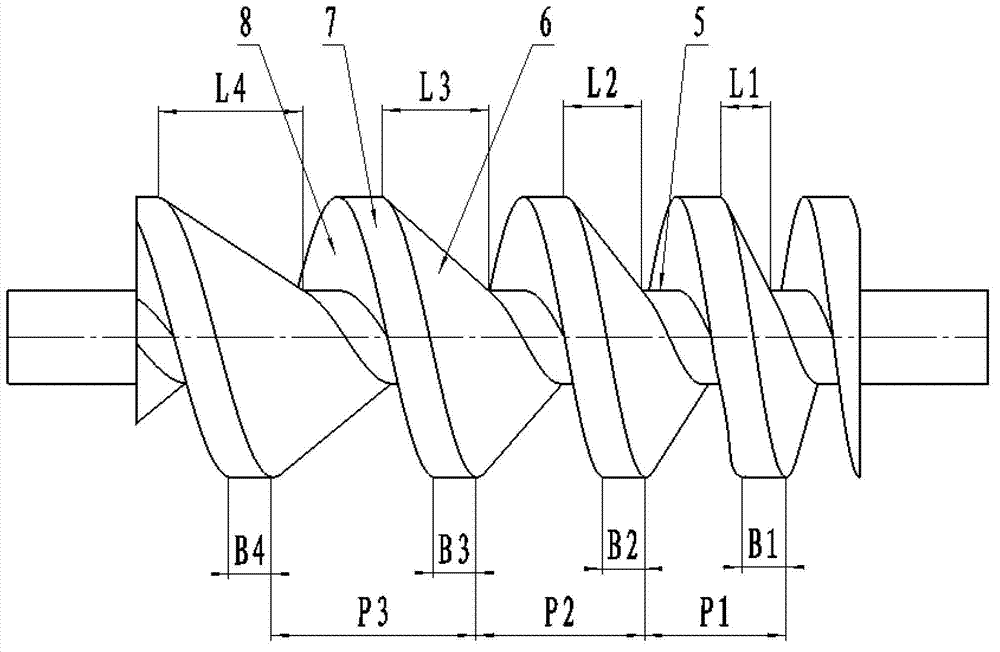

[0049] The structural diagram of ...

Embodiment 2

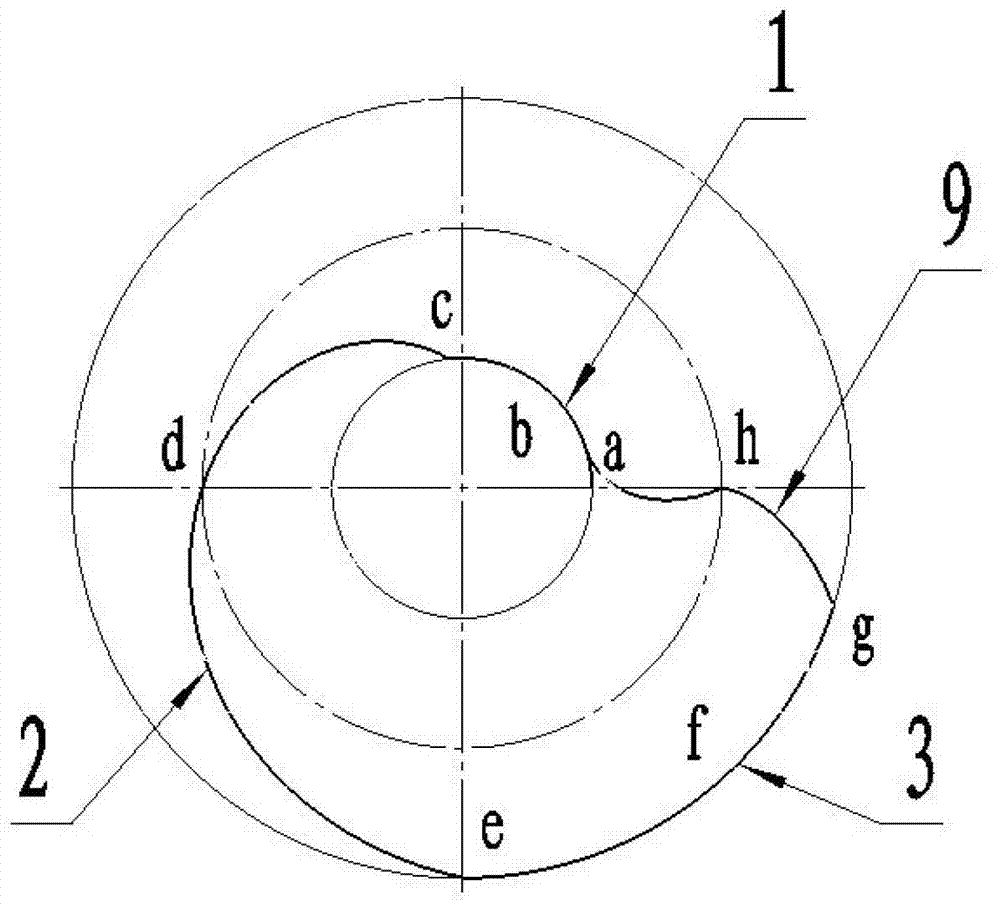

[0052] This embodiment provides a single-head variable-pitch screw rotor with equal addendum width, and the end surface profile at a certain cross-section is as follows: image 3 As shown, the section of curve abc is the dedendum circle curve 1, the section of curve cde is the involute curve 2, the section of curve efg is the addendum circle curve 3, the section of curve gha is the transition curve 9 composed of double cycloids, and the four sections of curve Connect in order (for example, the end c of the dedendum circle curve abc is connected with the start end c of the involute curve cde, the end e of the involute curve cde is connected with the start end e of the addendum circle curve efg, and the addendum circle curve The end g of efg is connected to the initial end g of the transition curve gha formed by a single cycloid, and the end of the transition curve gha formed by a single cycloid is connected to the initial end a of the dedendum circular curve abc to form an end p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com