Photoelectric detection device transfer manufacturing system and method

A photodetector and transfer system technology, applied in the manufacture of electrode systems, electrical components, discharge tubes/lamps, etc., can solve problems affecting the performance of photocathode and the life of the whole tube, and achieve strong economic benefits and social significance. Avoid the effect of desensitization and prevent contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described below in conjunction with the accompanying drawings.

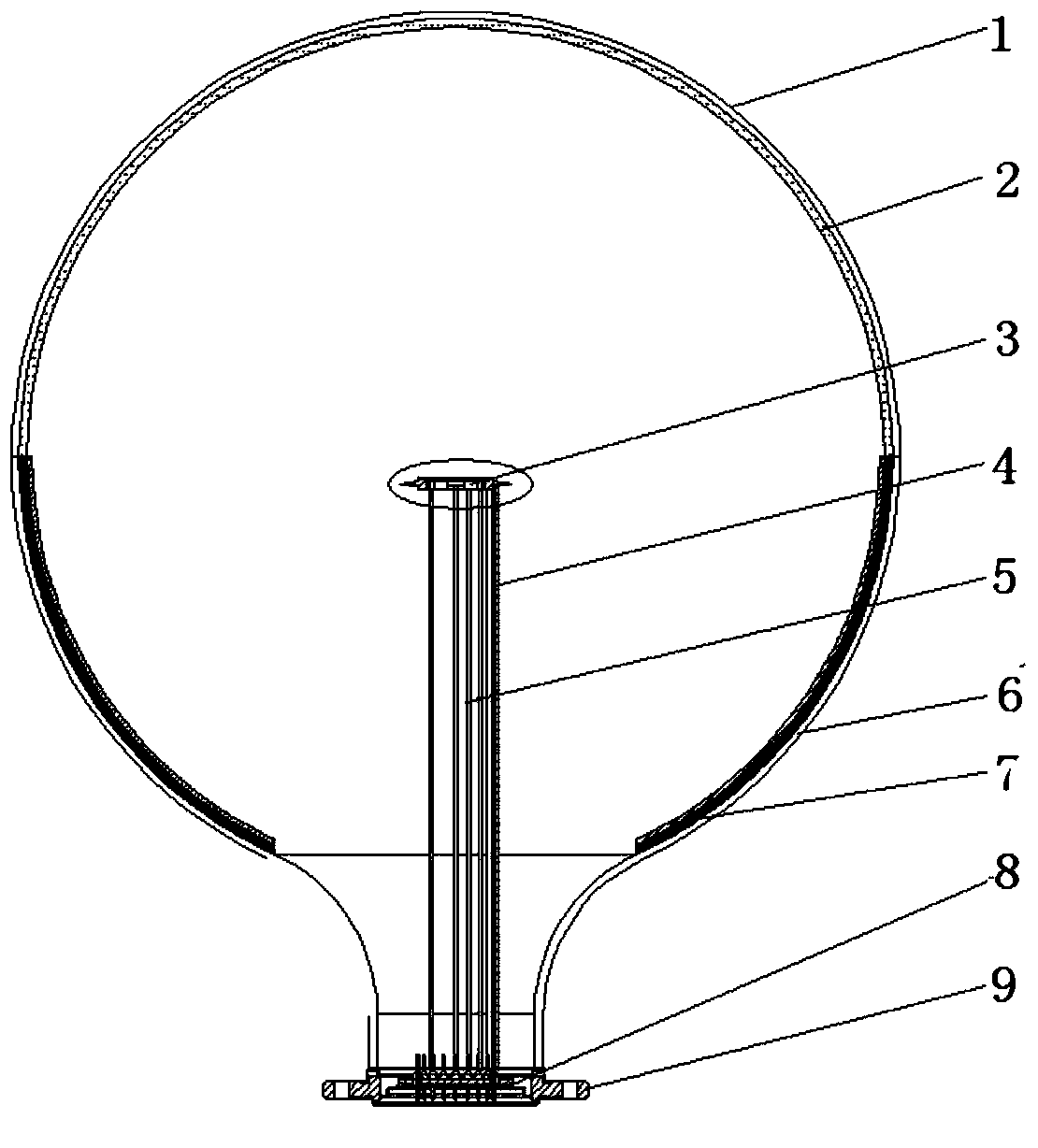

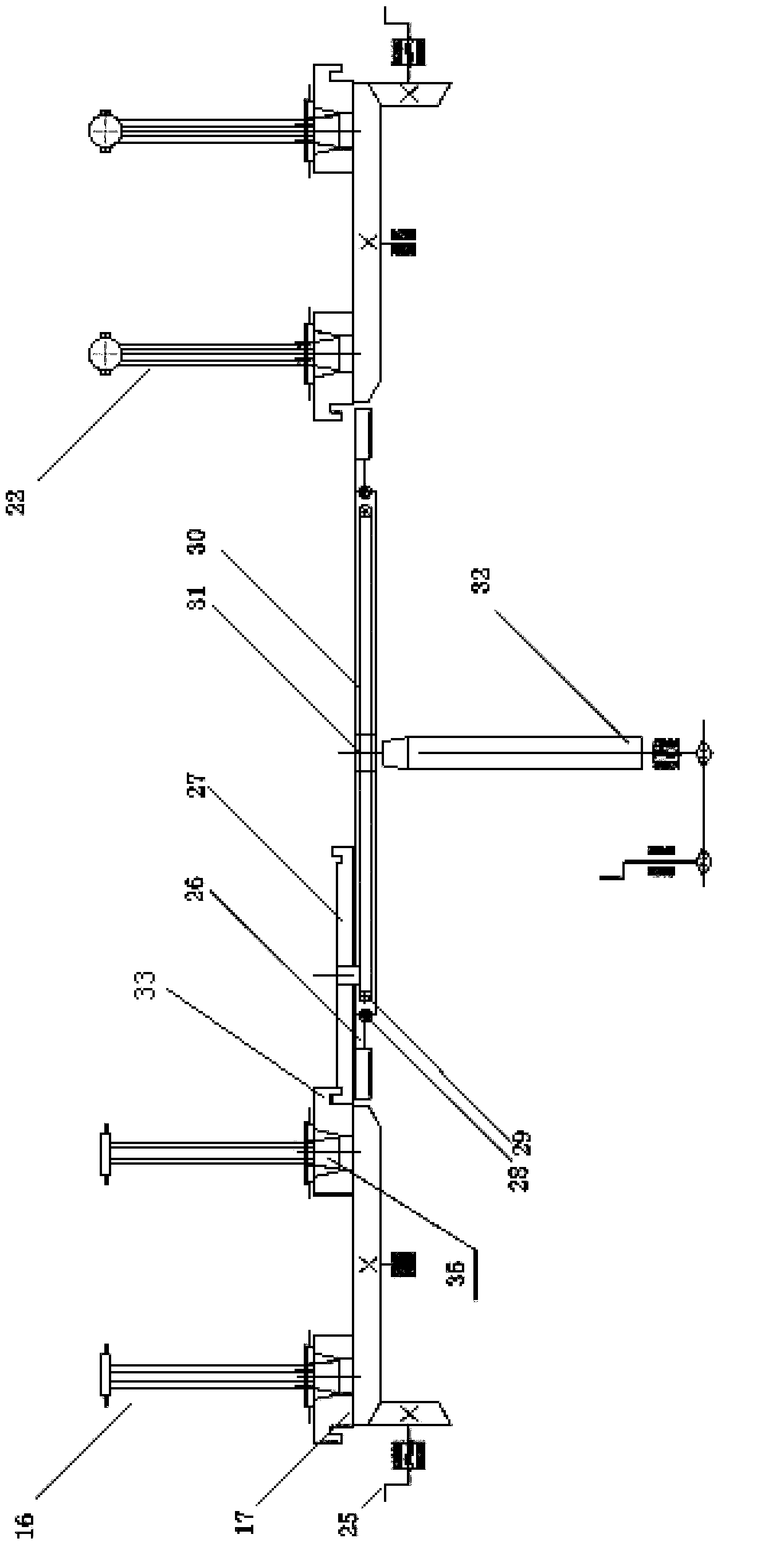

[0053] Such as figure 1 As shown, the present invention adopts the structure of three independent vacuum chambers according to the characteristics of the microchannel plate type large-area photomultiplier tube. There is a flapper valve.

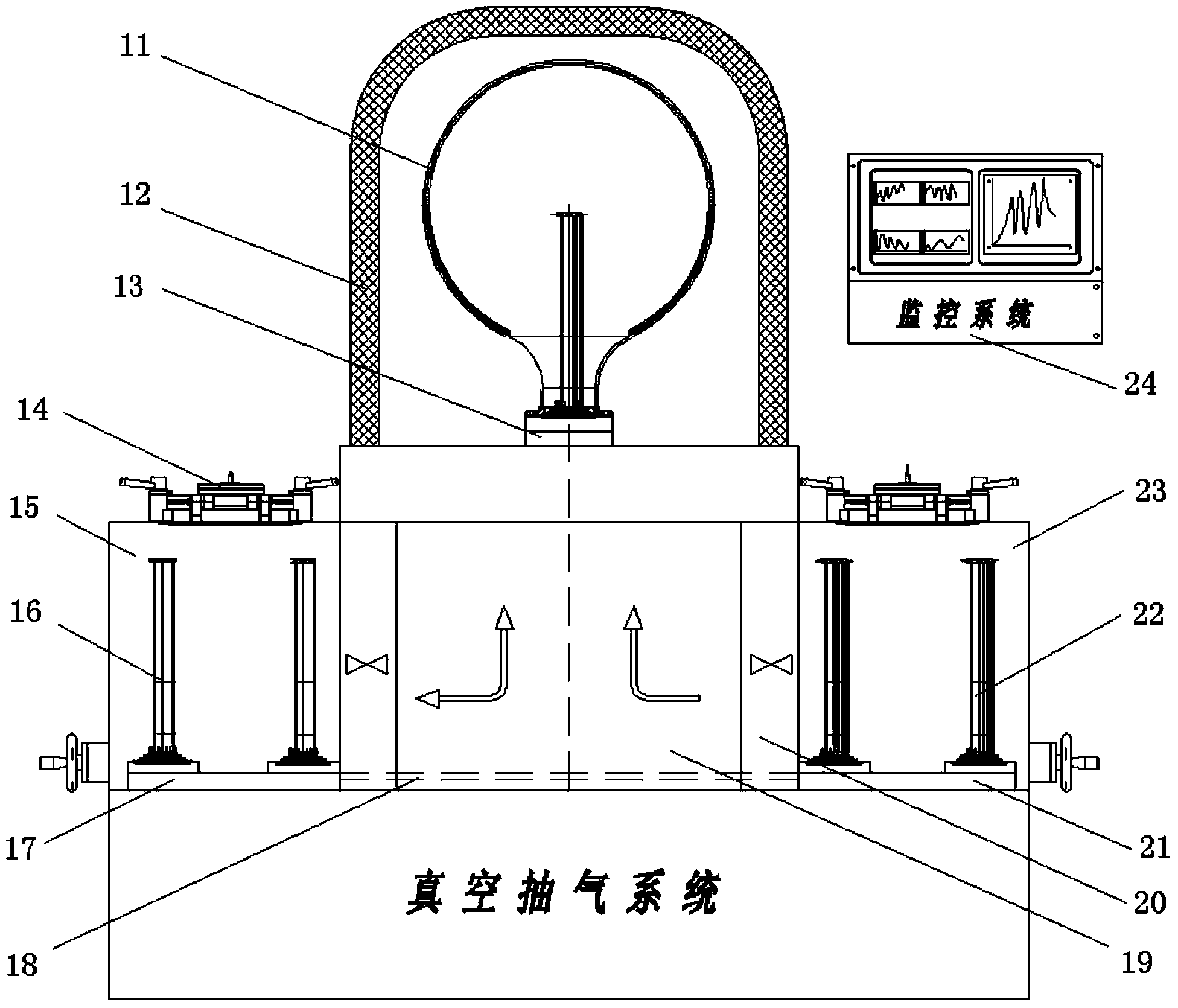

[0054] The schematic diagram of the production system is shown in figure 2 , the functions of each main part are as follows:

[0055] 1) Cathode cavity 15: place the cathode alkali source material and the photoelectron collector for testing cathode sensitivity, glow discharge components and other components. Multiple stations can be set inside to store the cathode component 16 and supply power to the cathode component.

[0056] 2) Anode chamber 23: store the anode MCP assembly 22, install the tungsten halogen lamp and the electron gun, bake and degas the MCP, and also set up multiple stations inside, store the anode assembly to improve ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com