Fully-smooth conical screw rotors of double-screw extruder

A twin-screw extruder and conical screw technology, applied in the field of full-smooth conical screw rotors, can solve the problems of small output torque, poor load resistance, high processing accuracy requirements, etc., to increase the volume of the working chamber, The effect of reducing the working chamber volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawings and examples.

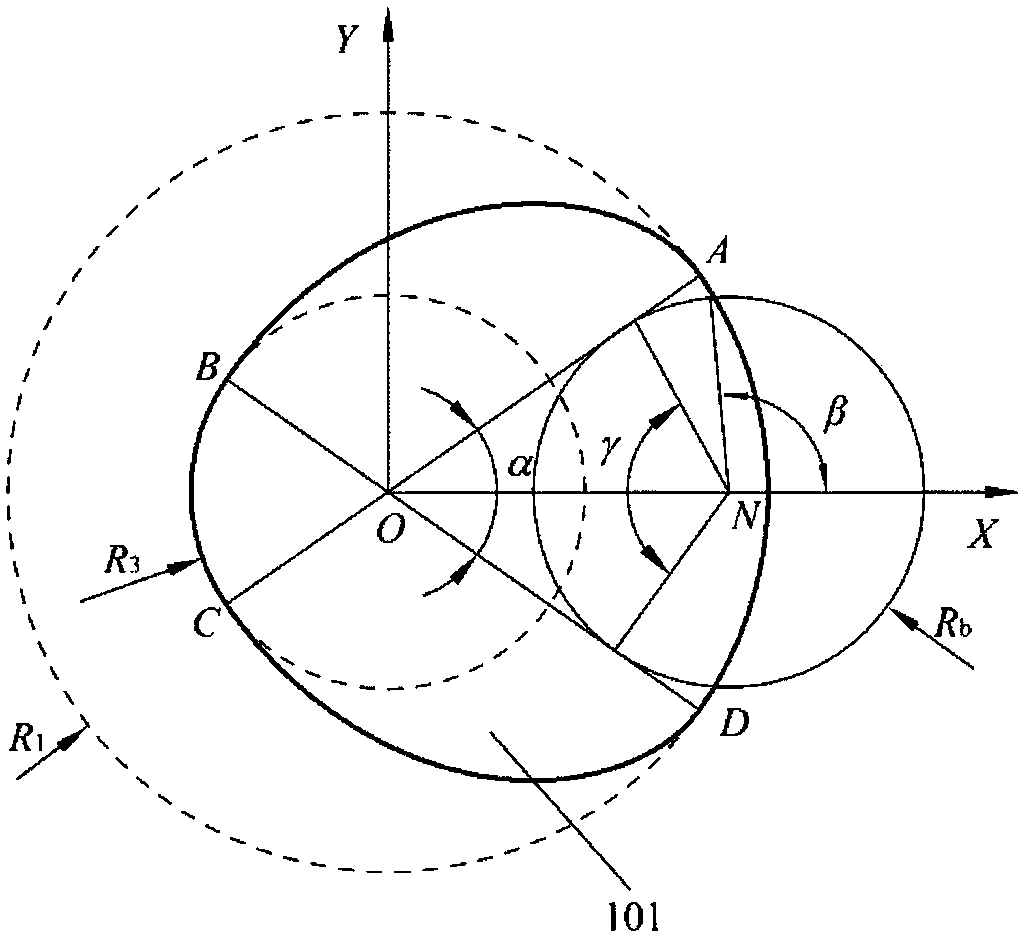

[0045] Such as figure 1 Shown is the cross-sectional profile diagram of the fully smooth conical screw rotor of the proposed twin-screw extruder; the left cross-sectional profile (101) of the left screw rotor (1) consists of four curves, including two arcs and two sections of eccentric involute, counterclockwise as follows: left eccentric involute AB, left dedendum arc BC, conjugate curve CD of left eccentric involute and left addendum arc DA, corresponding The adjacent composition curves are completely and smoothly connected; the shape of the left section profile (101) of the left screw rotor (1) is exactly the same as that of the right section profile (201) of the right screw rotor (2).

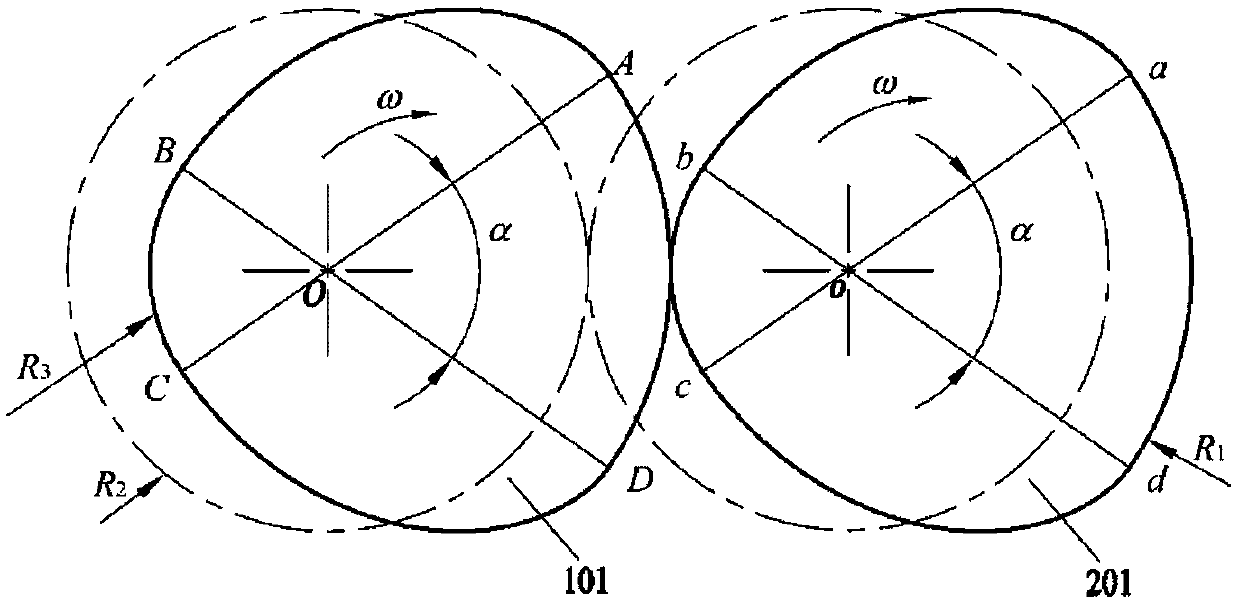

[0046] Such as figure 2 Shown is the meshing diagram of the section profiles of the two screw rotors; the left section profile (101) of the left screw rotor (1) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com