Patents

Literature

42results about How to "Fully meshed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual private network having automatic reachability updating

InactiveUS20050138204A1Easy to createCommunication securityEnergy efficient ICTDigital data protectionPrivate networkReachability

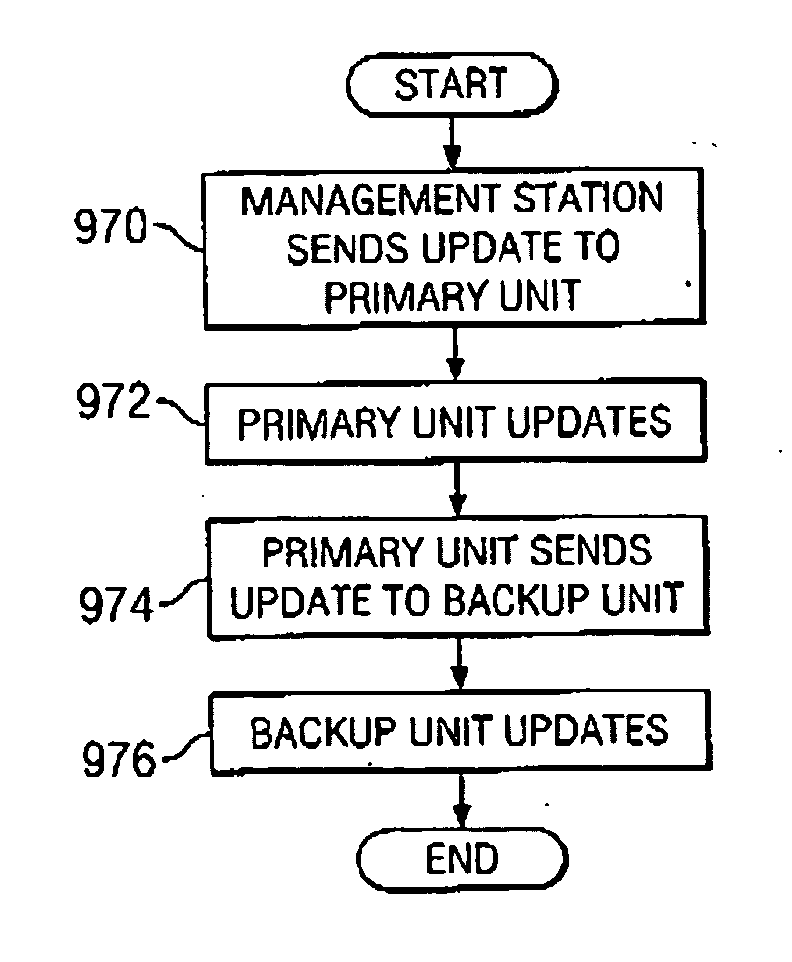

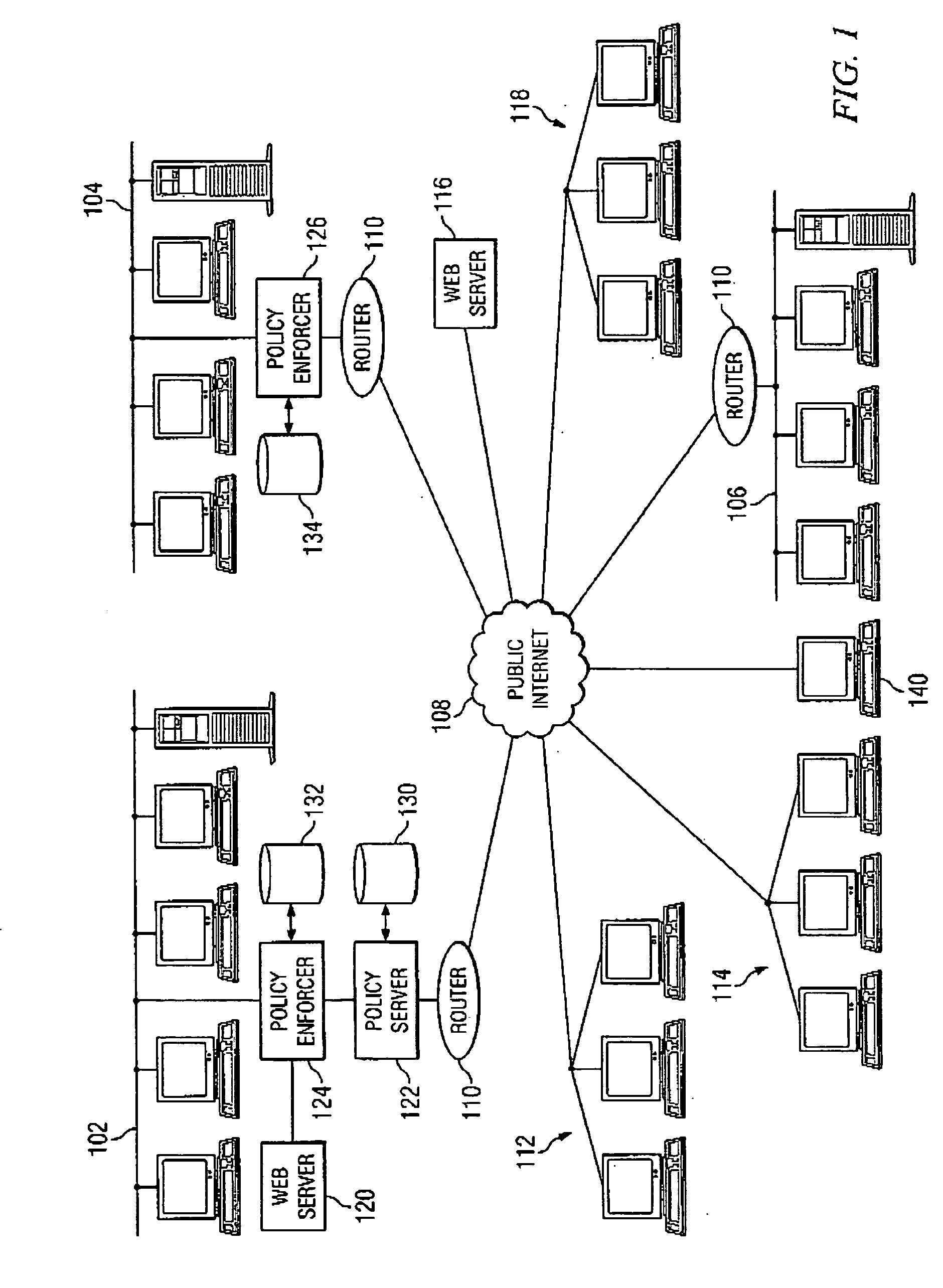

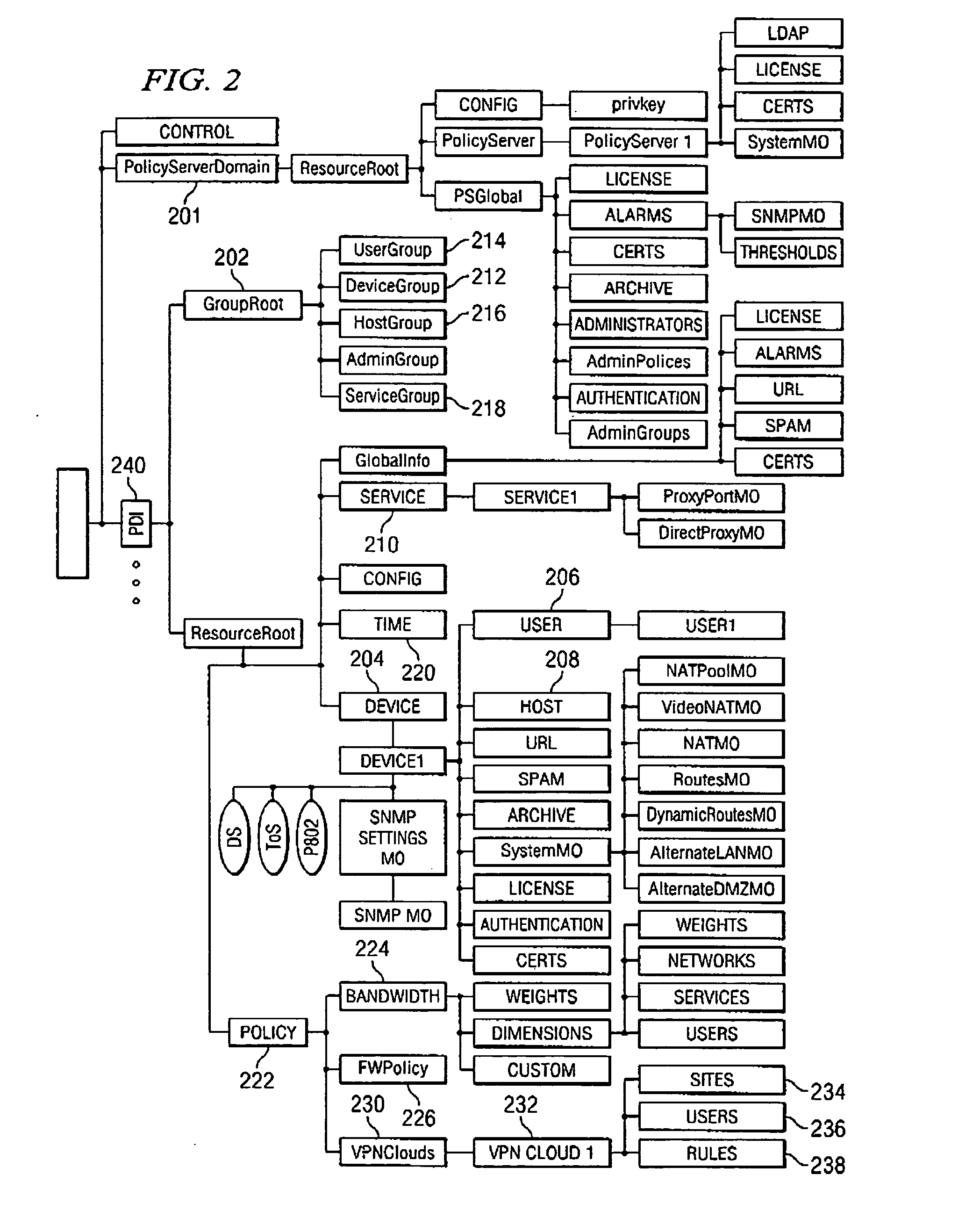

A unified policy management system for an organization including a central policy server and remotely situated policy enforcers. A central database and policy enforcer databases storing policy settings are configured as LDAP databases adhering to a hierarchical object oriented structure. Such structure allows the policy settings to be defined in an intuitive and extensible fashion. Changes in the policy settings made at the central policy server are automatically transferred to the policy enforcers for updating their respective databases. Each policy enforcer collects and transmits health and status information in a predefined log format and transmits it to the policy server for efficient monitoring by the policy server. For further efficiencies, the policy enforcement functionalities of the policy enforcers are effectively partitioned so as to be readily implemented in hardware. The system also provides for dynamically routed VPNs where VPN membership lists are automatically created and shared with the member policy enforcers. Updates to such membership lists are also automatically transferred to remote VPN clients. The system further provides for fine grain access control of the traffic in the VPN by allowing definition of firewall rules within the VPN. In addition, policy server and policy enforcers may be configured for high availability by maintaining a backup unit in addition to a primary unit. The backup unit become active upon failure of the primary unit.

Owner:IYER SHANKER V +3

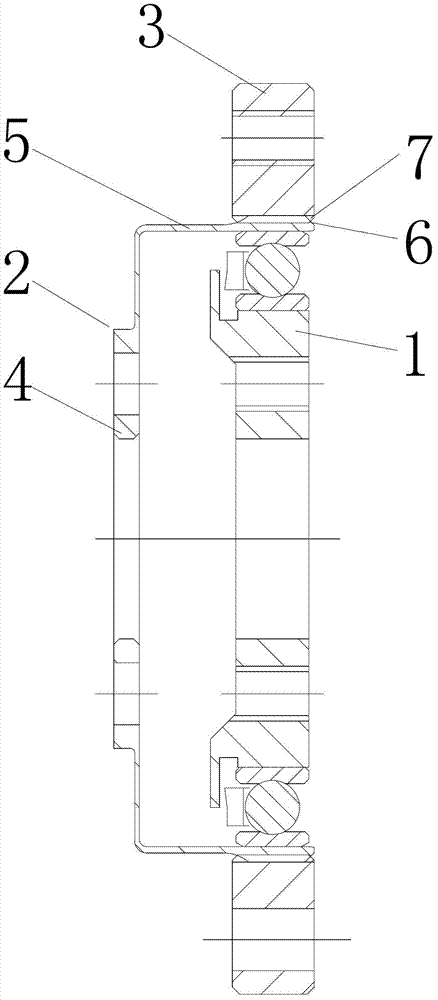

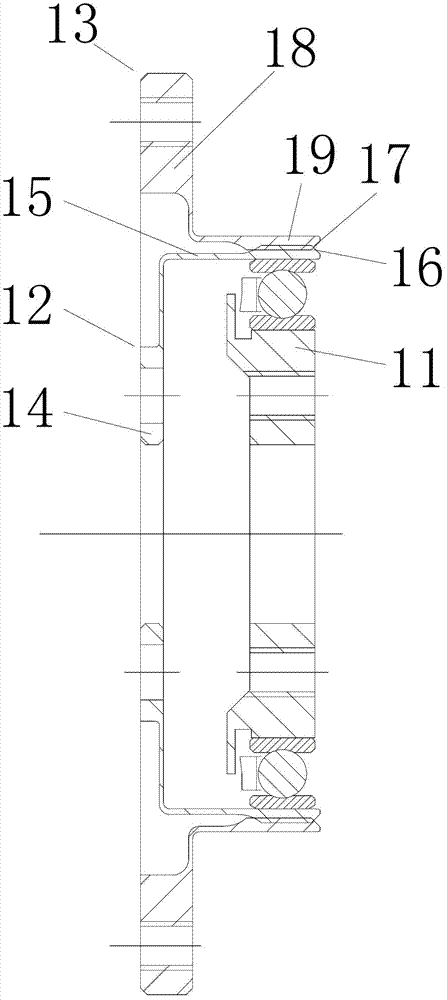

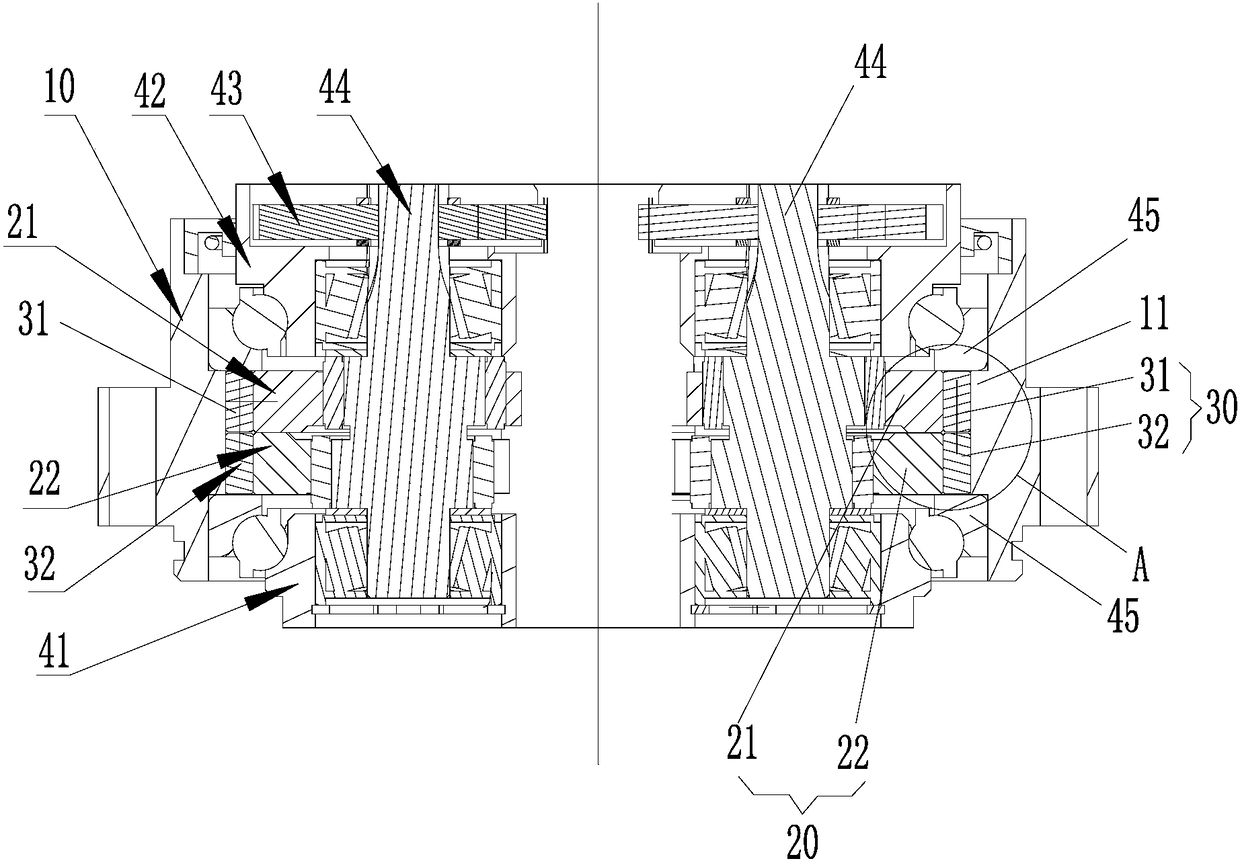

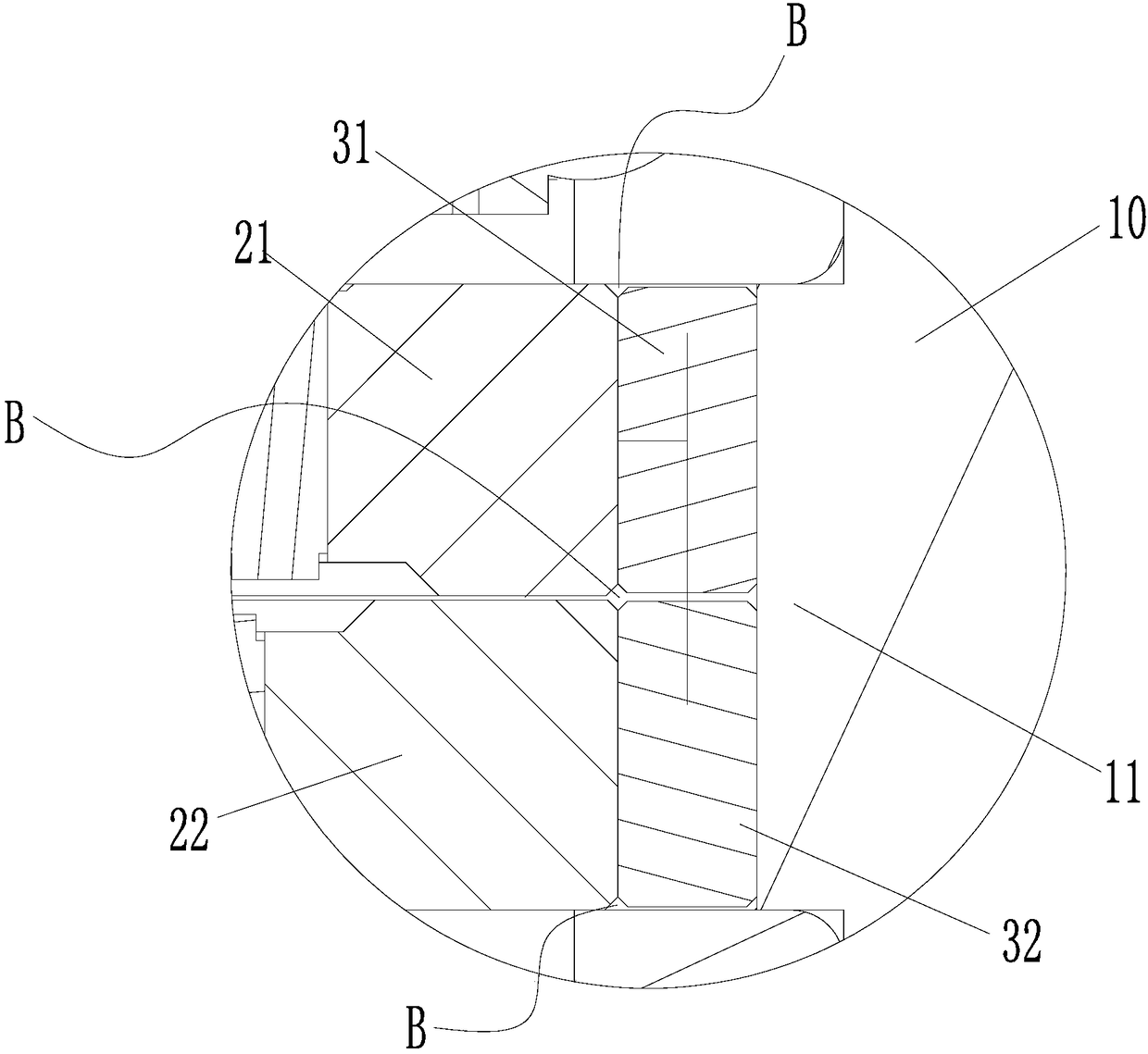

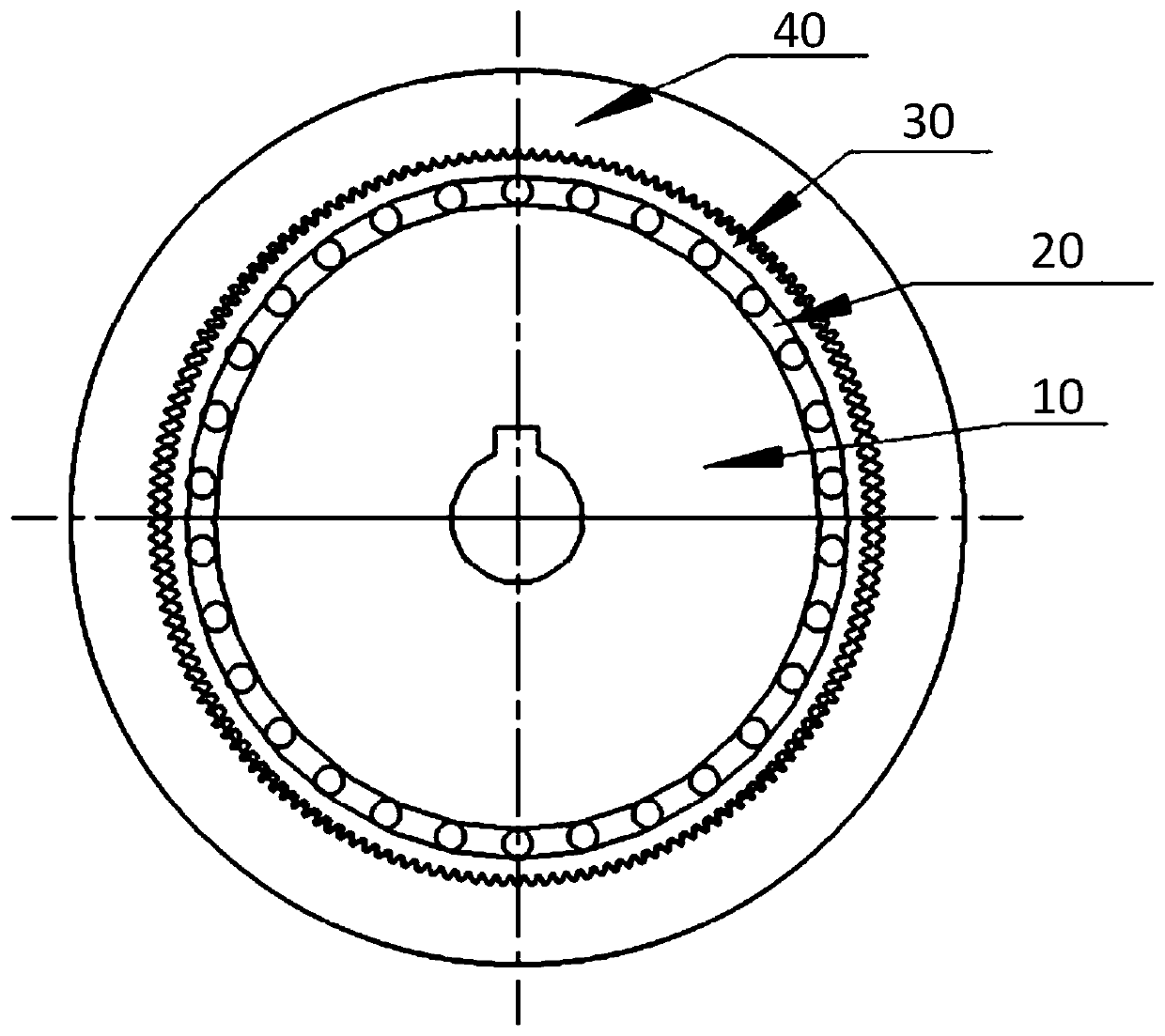

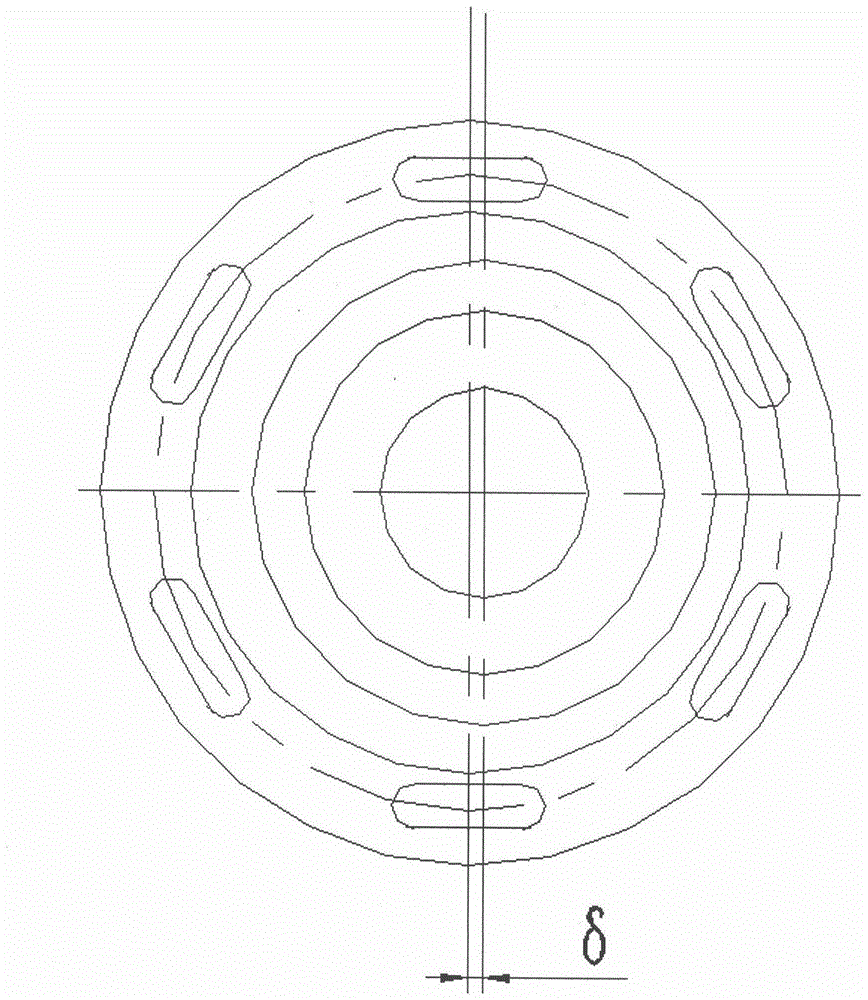

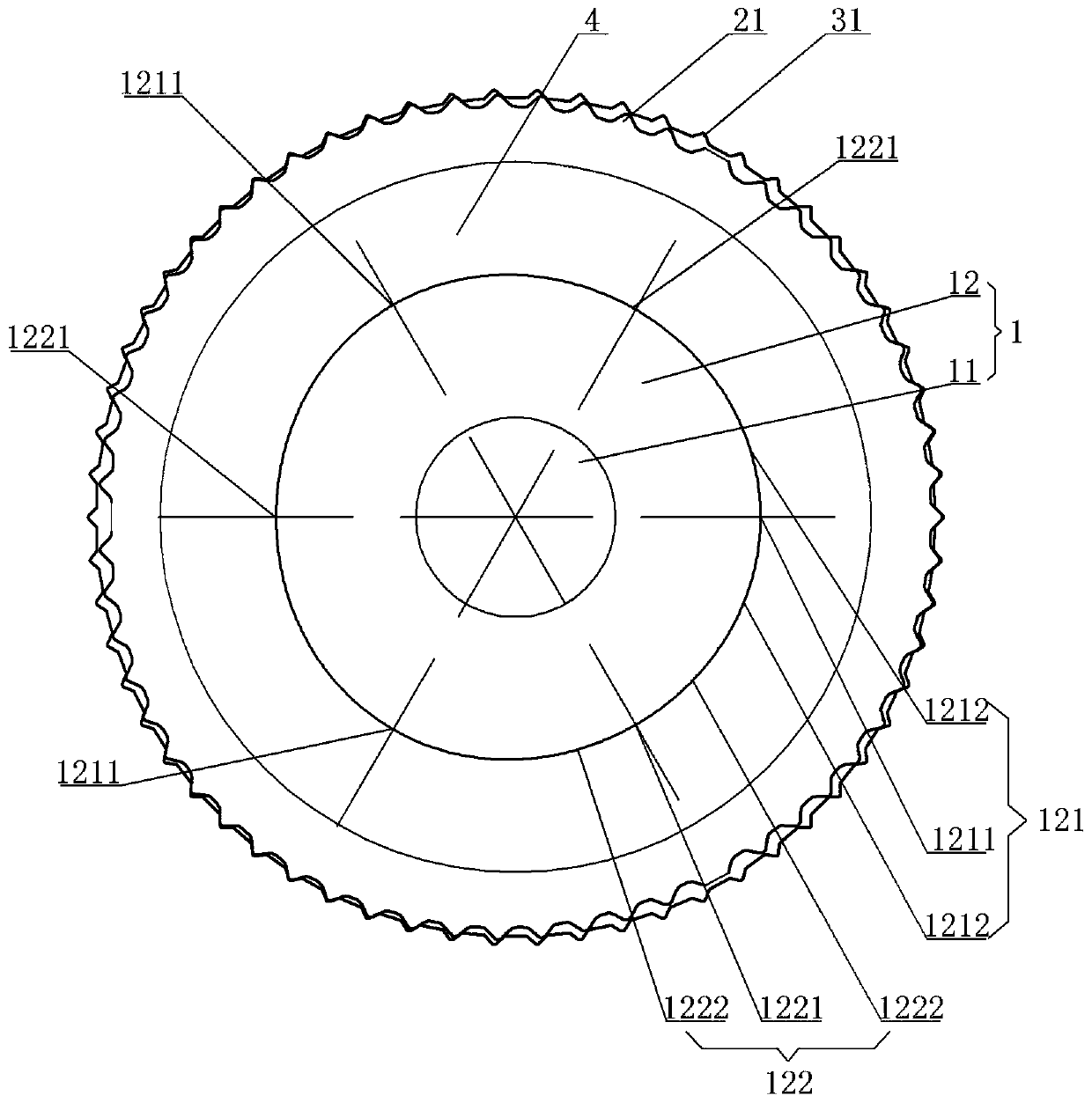

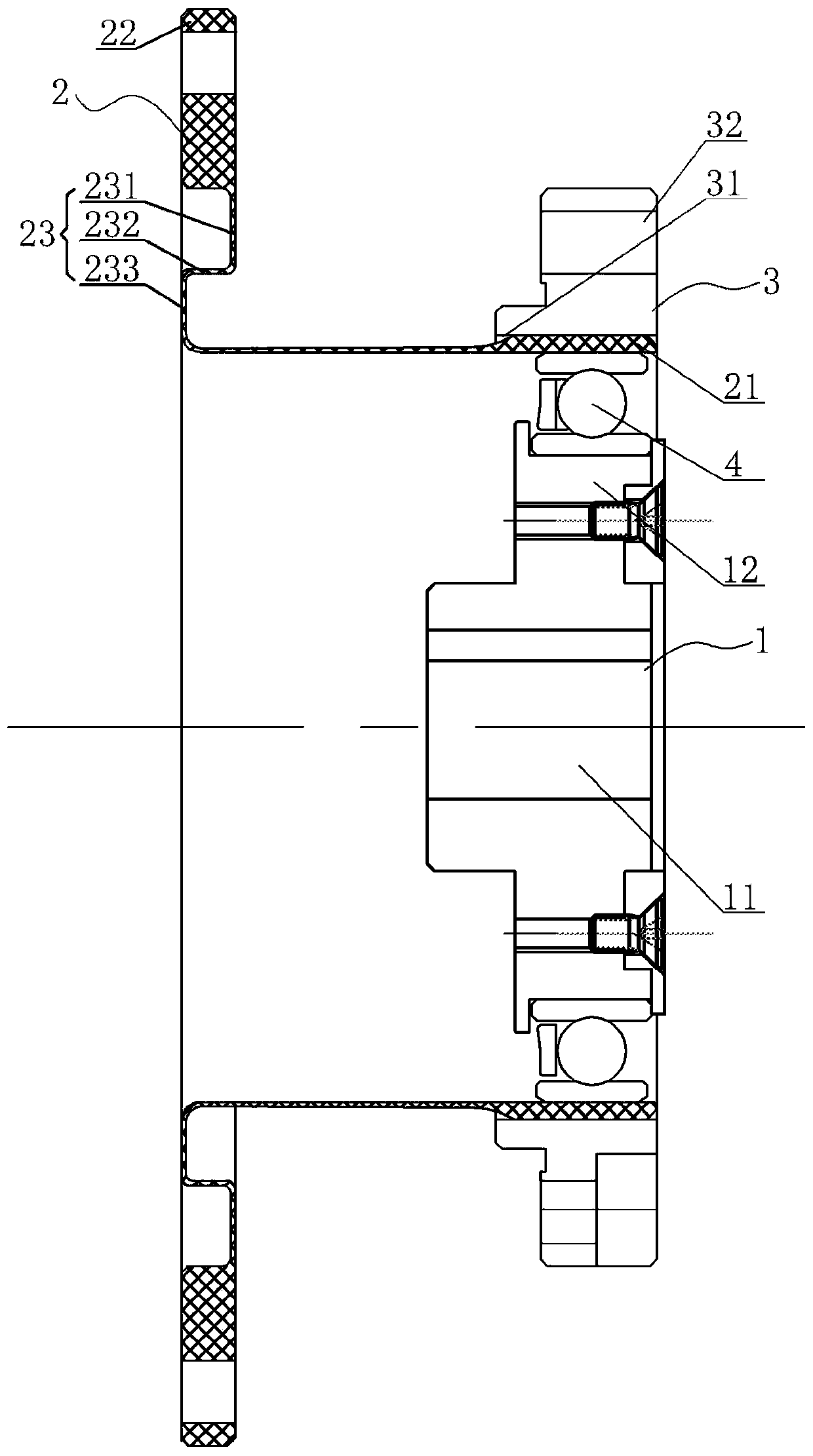

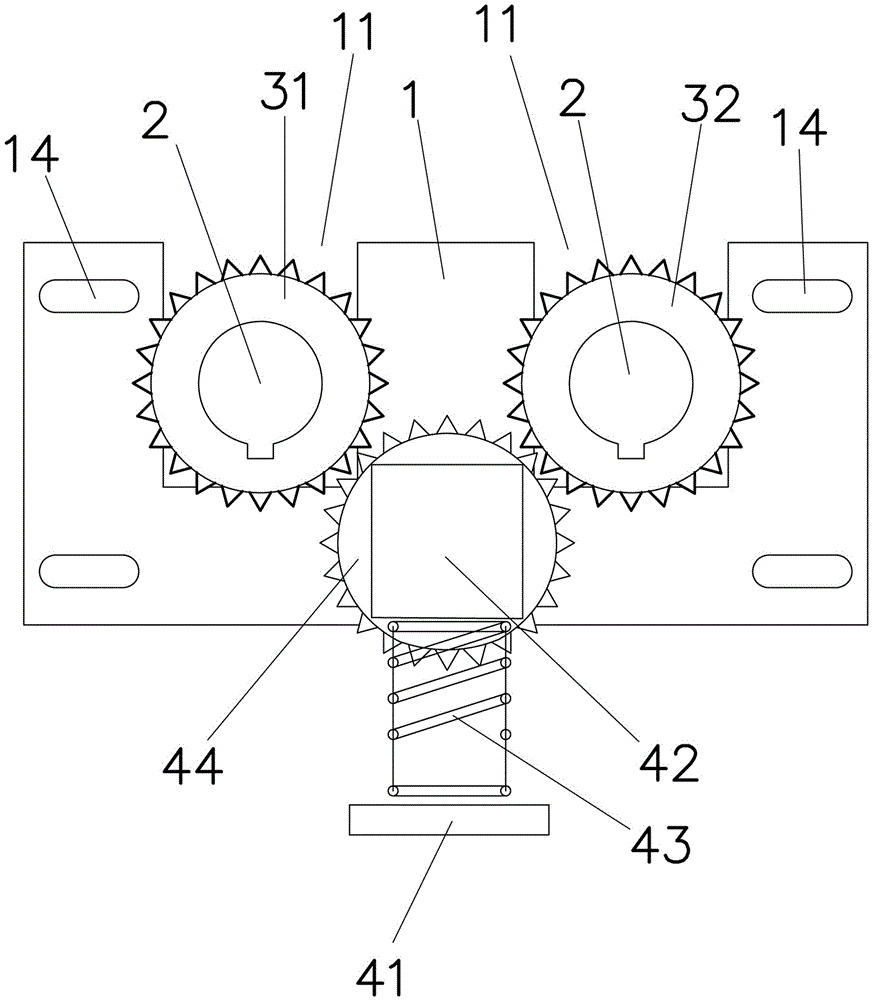

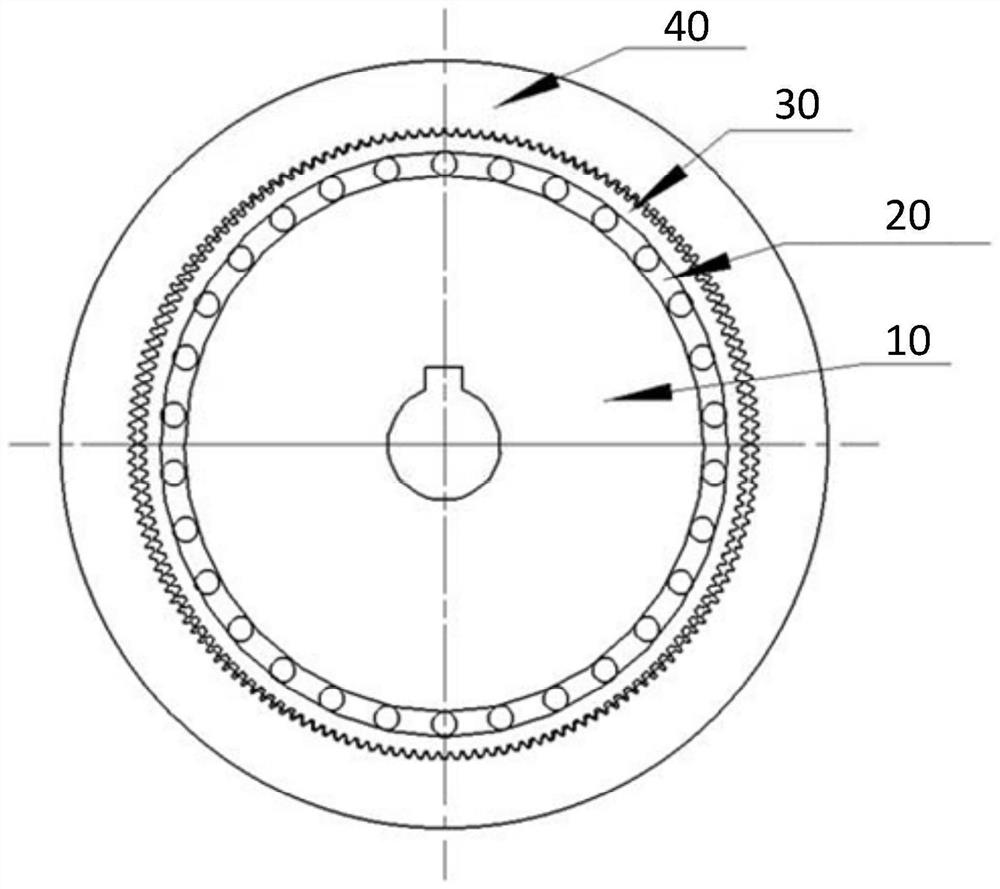

Harmonic speed reducer with flexible felly

The invention discloses a harmonic speed reducer with a flexible felly. The harmonic speed reducer comprises a wave generator, a flexible gear and the felly, wherein the flexible gear comprises a gear body and a gear ring; the gear body is substantially disc-shaped and concentrically arranged on the outer circumference of the gear body; first teeth are formed on the outer circumference of the gear ring; the felly comprises a felly body and a felly ring; the felly body is circular; the felly ring is arranged on the end surface of the felly body; second teeth are formed on the inner circumference of the felly ring; the wave generator is arranged on the inner circumference of the gear ring; the outer circumference of the gear ring is arranged on the inner circumference of the felly ring; the first teeth are meshed with the second teeth; and the felly ring is deformed along with the gear ring. According to the scheme, the number of meshed teeth is relatively large, the transmission precision is relatively high, the output is stable, an impact is not generated, and the service life is long.

Owner:SUZHOU LEADERDRIVE HARMONIC WAVE TRANSMISSION TECH CO LTD

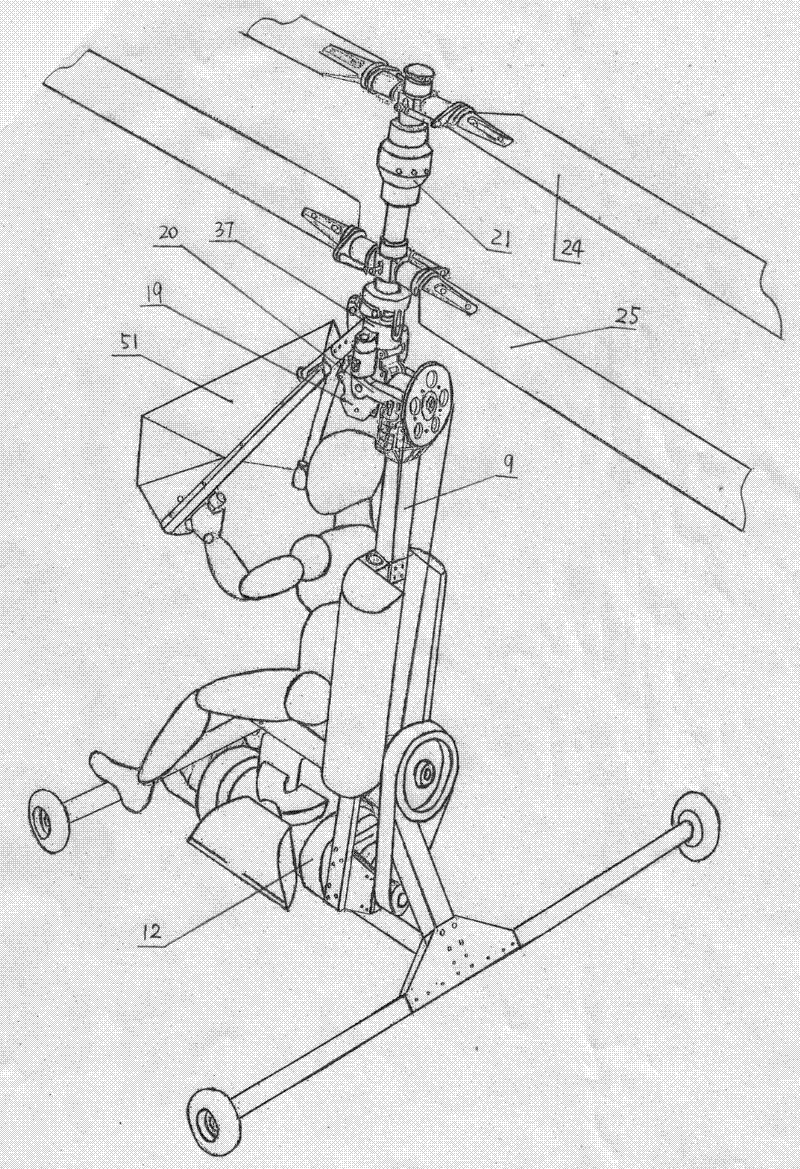

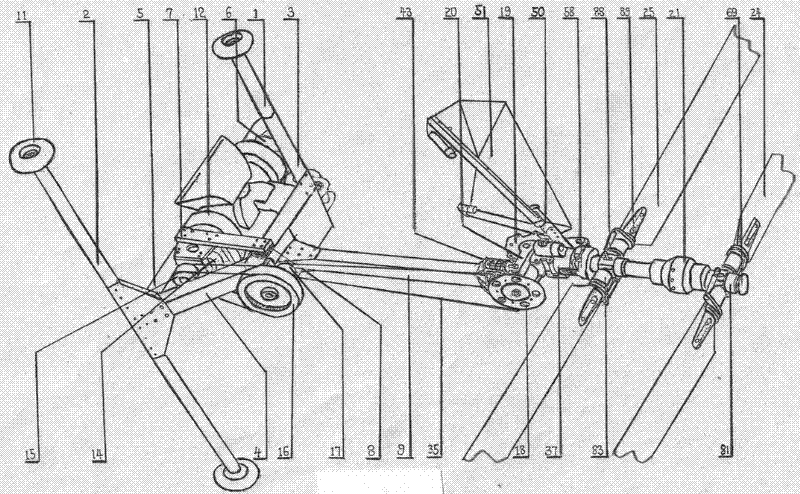

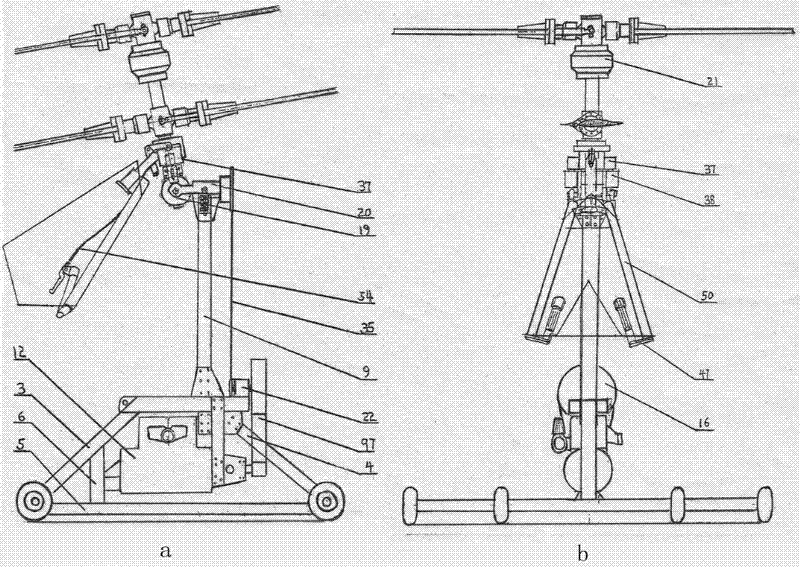

Gear tilting type coaxial machine

InactiveCN102211663AImprove stabilityEasy to controlAircraft componentsRotocraftCounter rotationFuselage

The invention provides a gear tilting type coaxial machine. An engine is connected with a rotor tilting reversing gear mechanism fixed at the upper end of a body upright through a speed reducing mechanism; the rotor tilting reversing gear mechanism comprises a tilting reversing gear box and a tilting reversing support arm; the tilting reversing gear box connects the body with a tilting control rod base on the lower part of a rotor shaft, and is rotatably connected with upper and lower rotors through a rotor shaft variable-pitch control mechanism and a rotor reversing counter gear box; the upper and lower rotors are of a coaxial counter-rotation dual-rotor structure; the rotor shaft variable-pitch control mechanism is matched with the rotor reversing counter gear box; a variable-pitch pullwire of the rotor shaft variable-pitch control mechanism is arranged on a V-shaped wing operation rod of a V-shaped wing operation rod control mechanism; the V-shaped wing operation rod is provided with an engine accelerator regulation handle; the V-shaped wing operation rod control mechanism is connected with the tilting control rod base; and a V-shaped wing fairing is mounted on the V-shaped wing operation rod. The coaxial machine has the advantages of low cost and simple driving mode.

Owner:王略

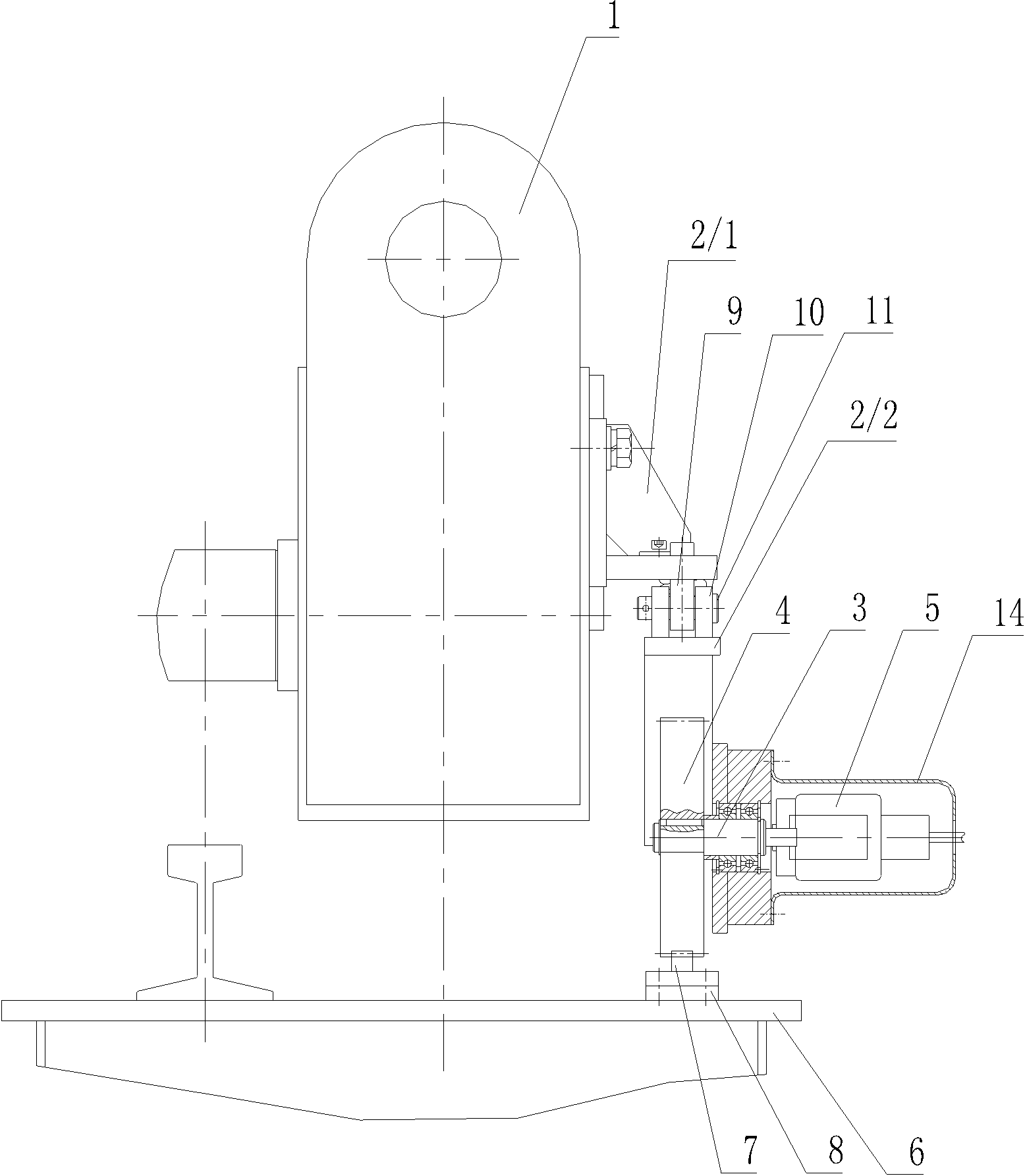

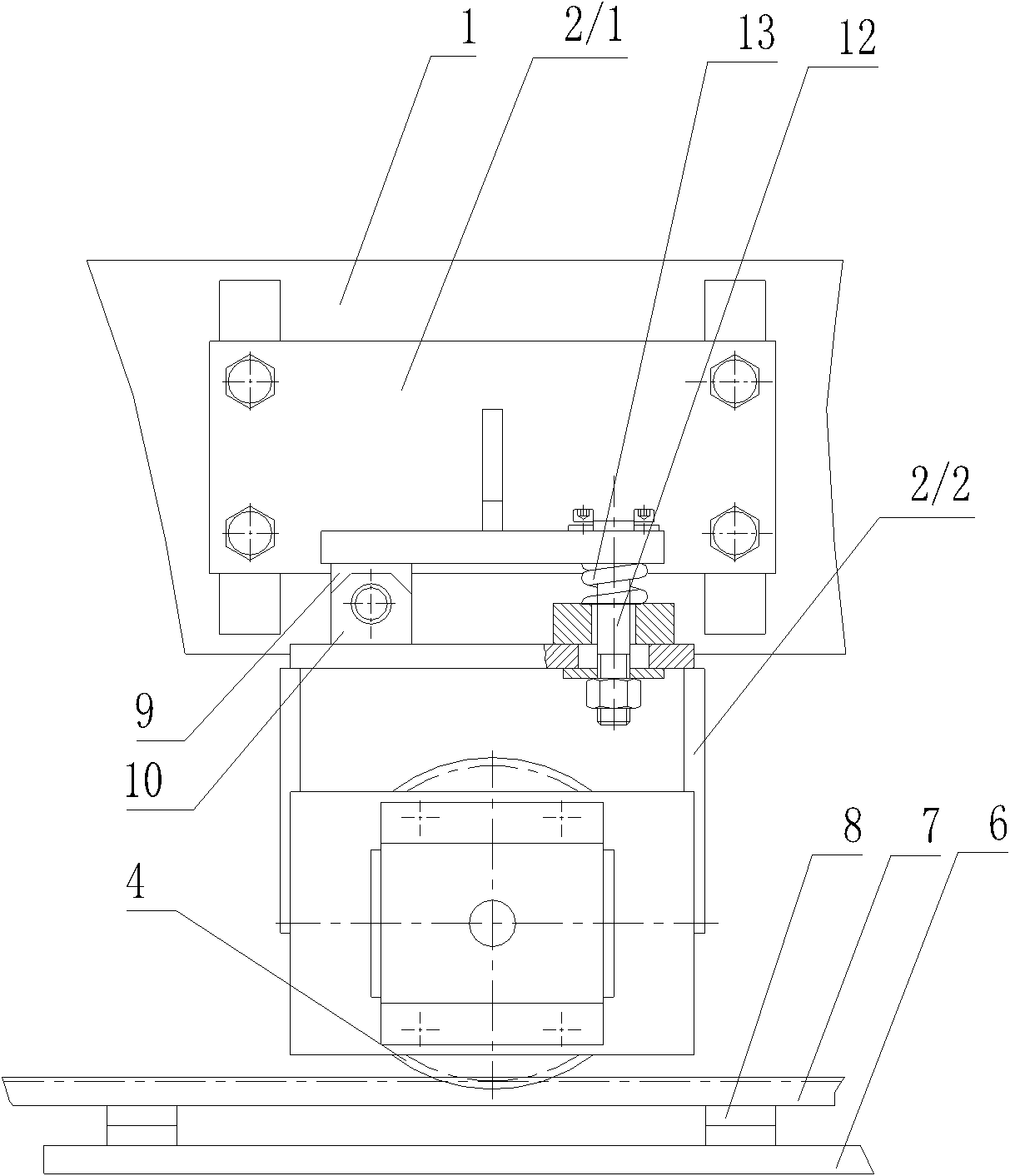

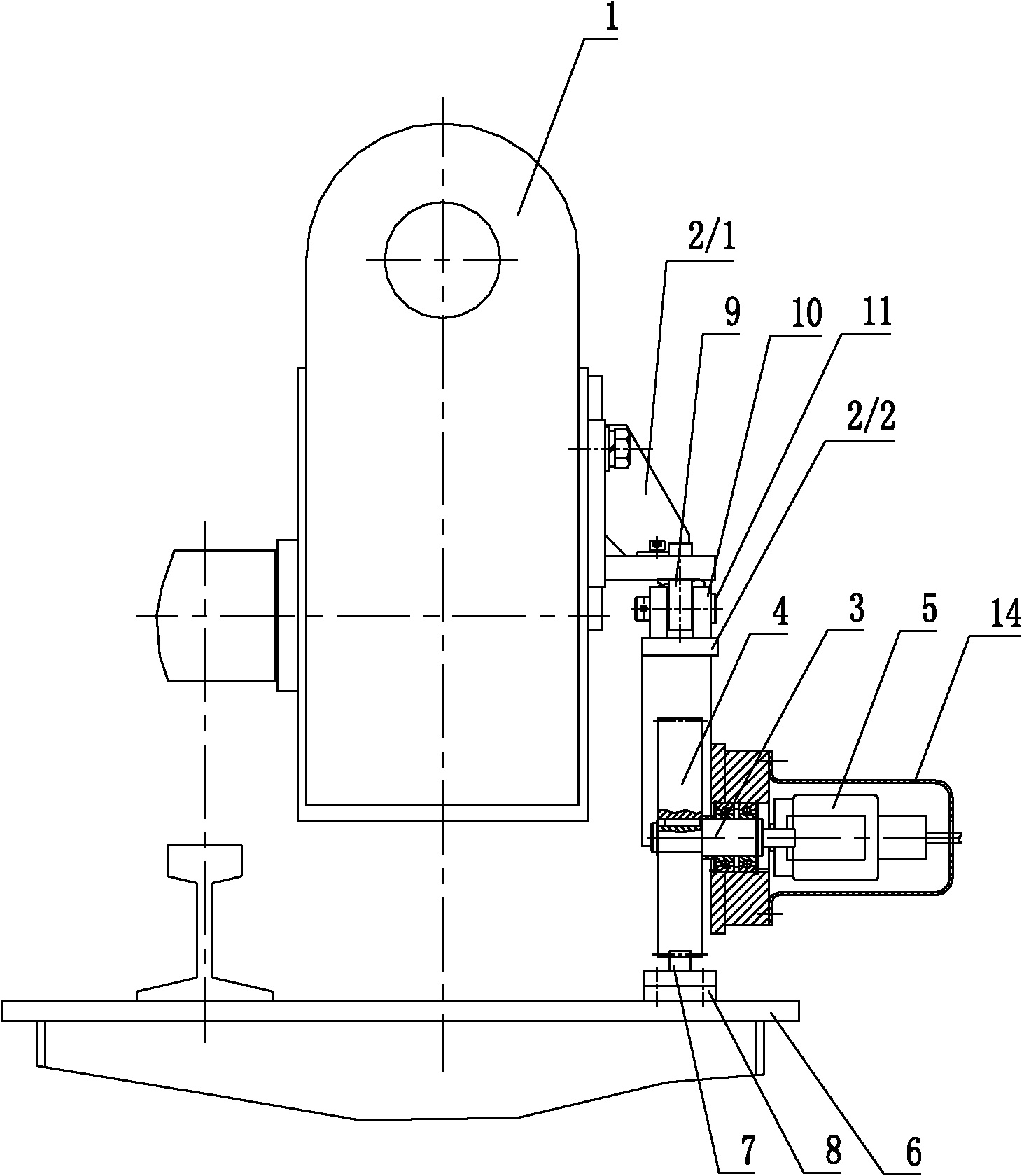

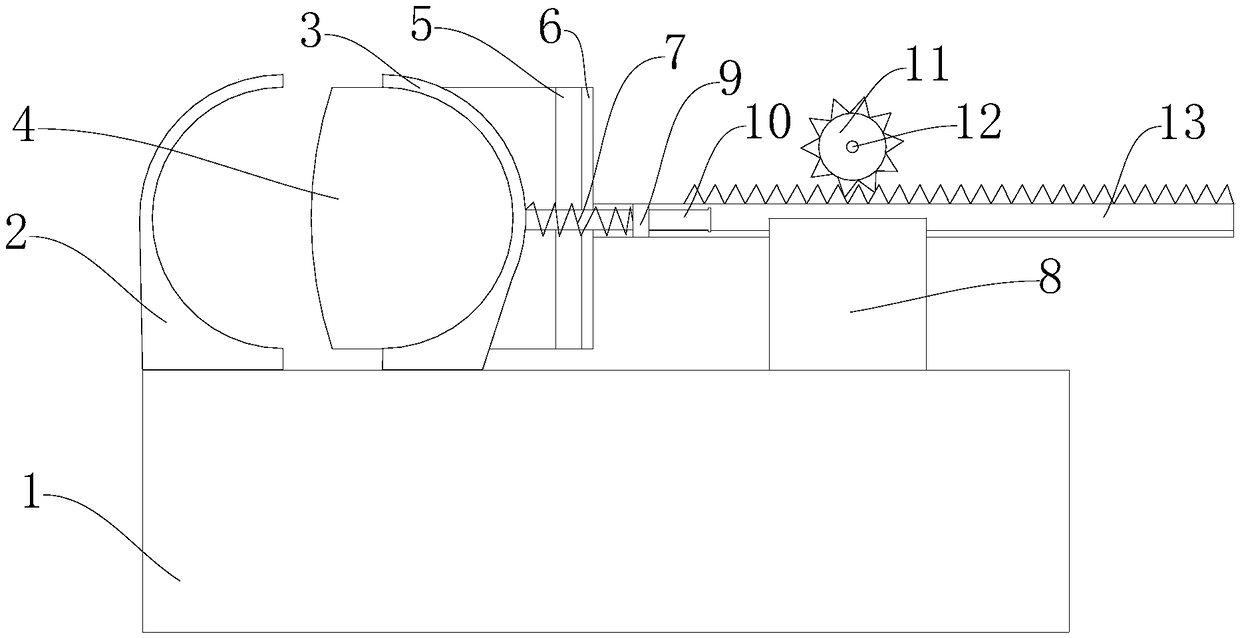

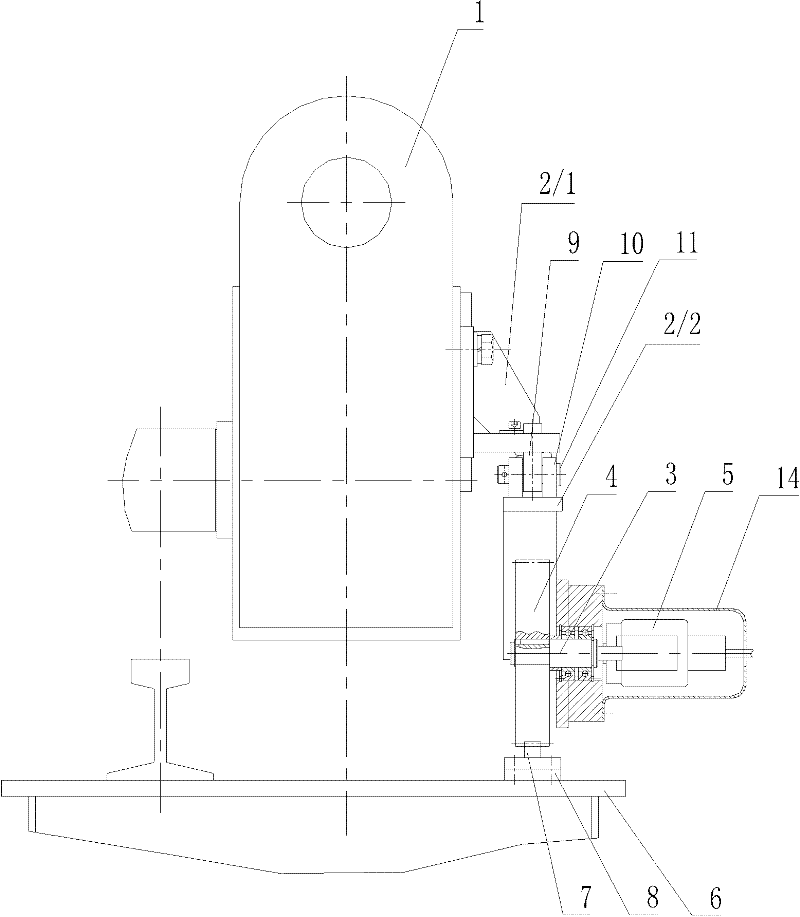

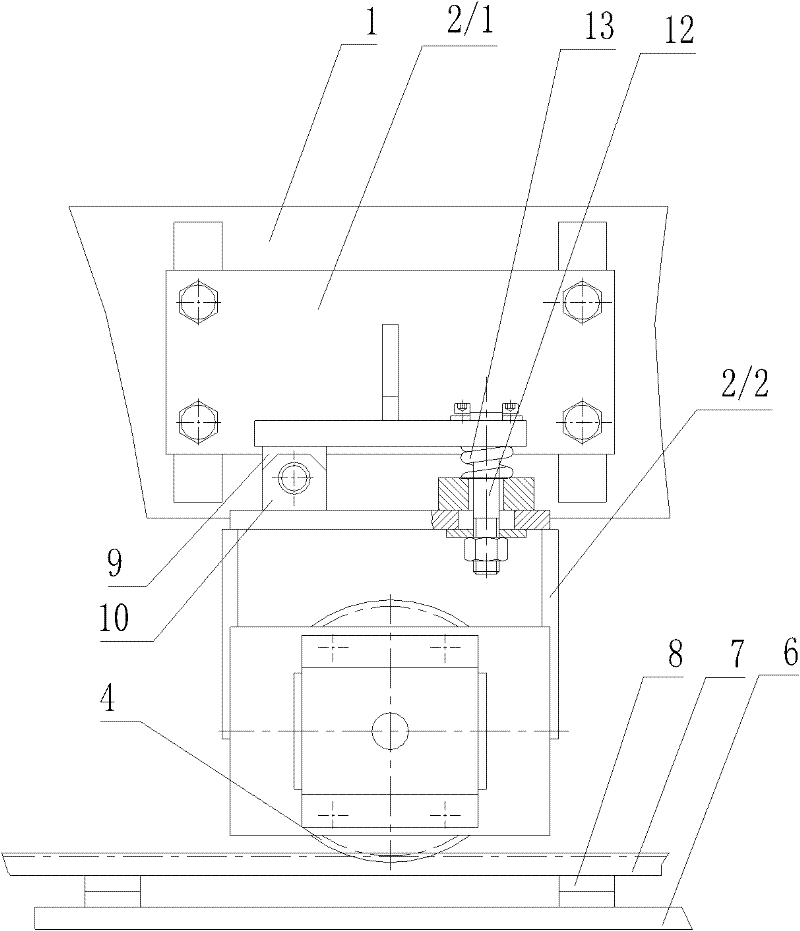

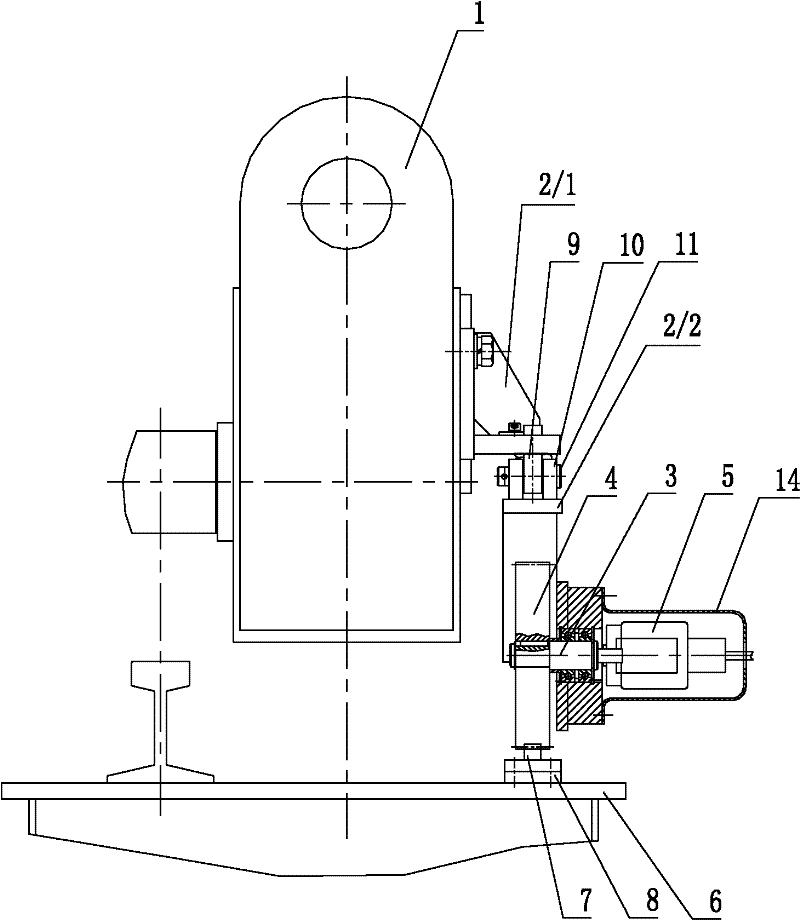

Running positioning device for double-beam trolley of crane

The invention relates to a running positioning device for a double-beam trolley of a crane. The device is characterized by comprising a holder and a support shaft, wherein the holder is fixedly installed on the end beam of the trolley; the support shaft is installed on the holder through a bearing; one end of the support shaft is fixedly equipped with a gear, and the other end of the support shaft is fixedly equipped with a revolution counter; and a rack is fixedly installed on the main beam of the crane and is meshed with the gear. In the invention, the number of meshed teeth of the gear and the rack is captured by the revolution counter, a signal of the number of meshed teeth is transmitted to a control system, then the control system performs variable frequency control on the motor of the trolley according to the signal and an actually measured residual distance signal, the speed of the trolley is gradually reduced, the motor is power off when the trolley arrives at a preset position, and the trolley stops stably.

Owner:杨秀杰

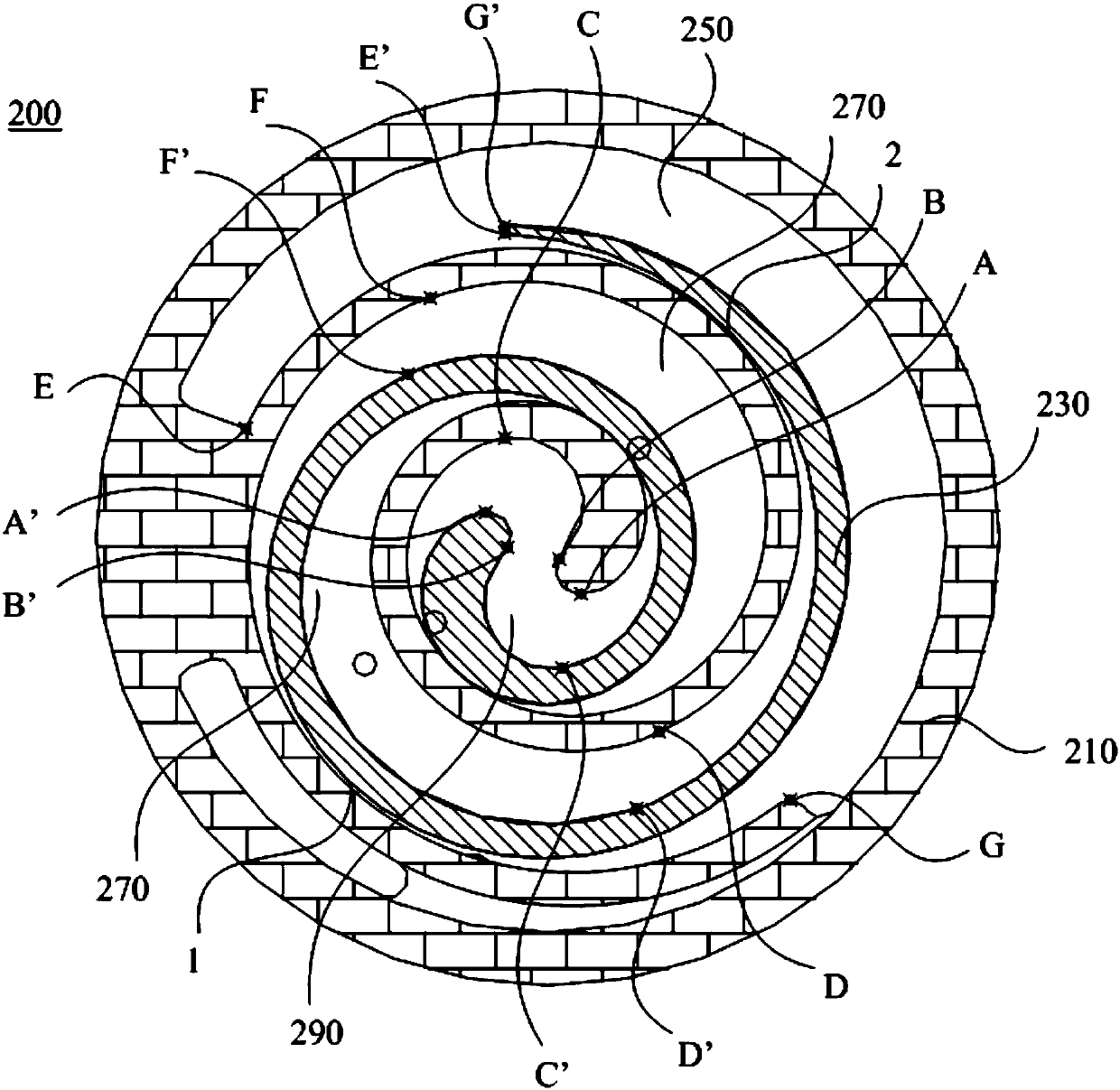

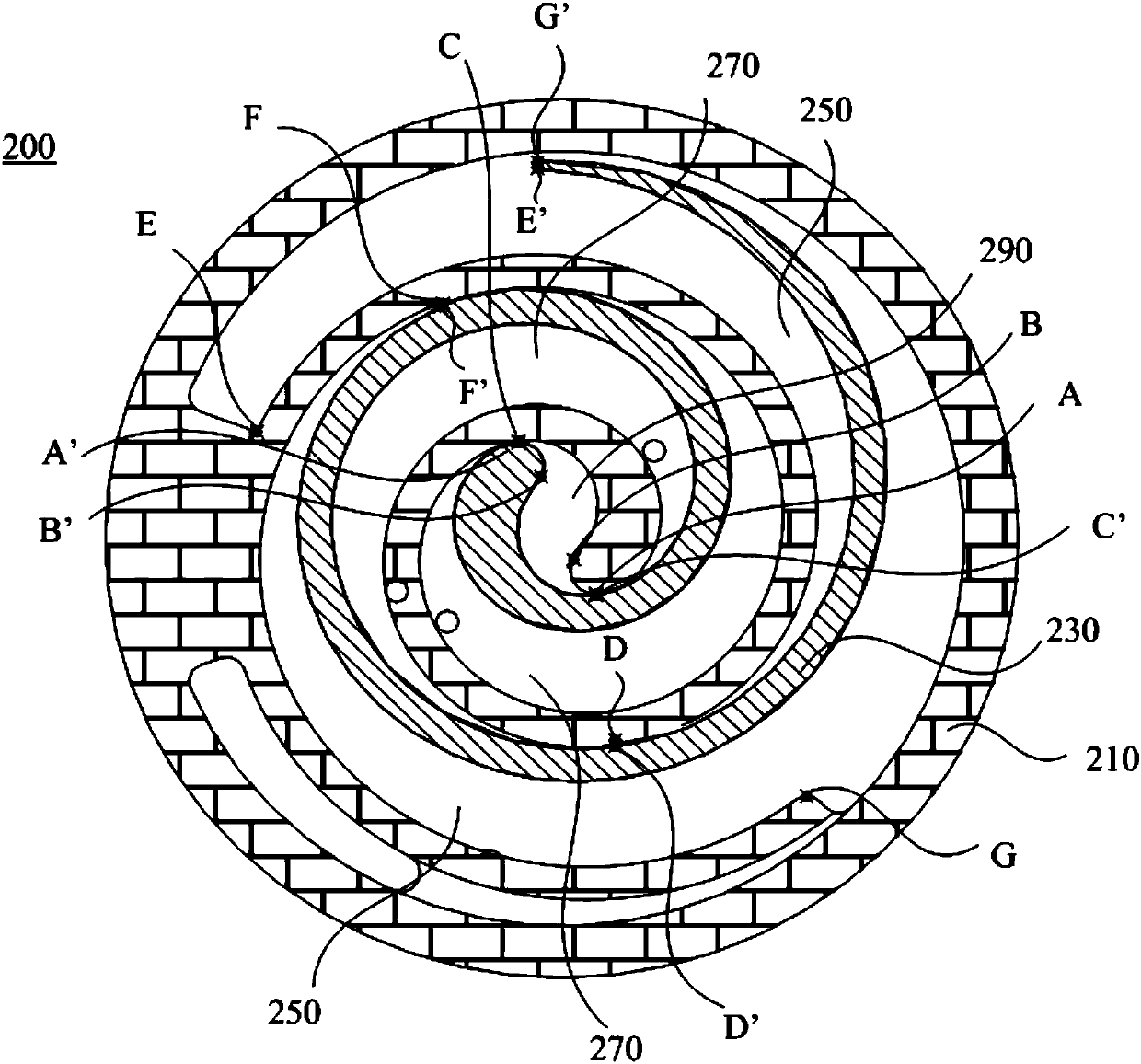

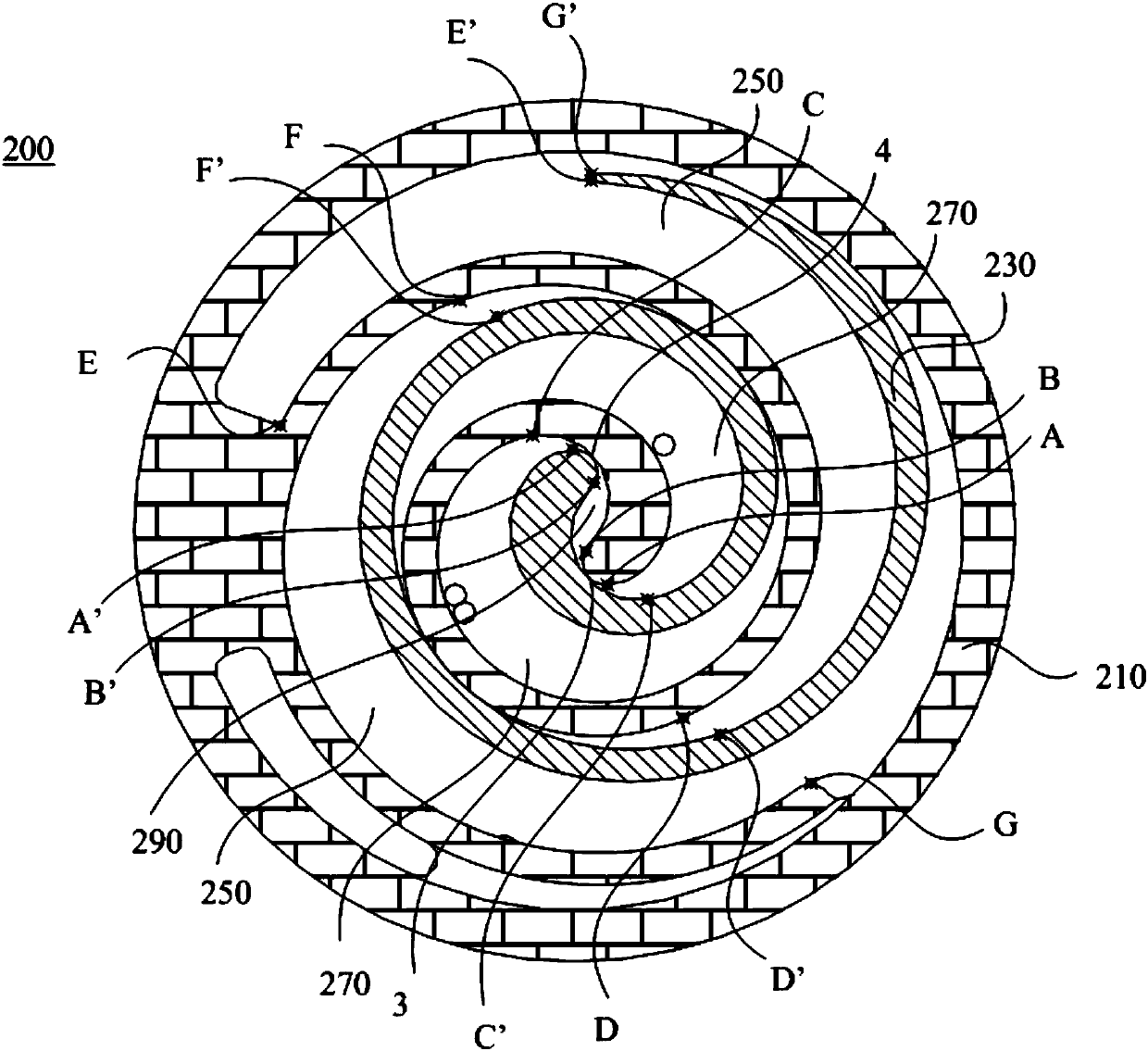

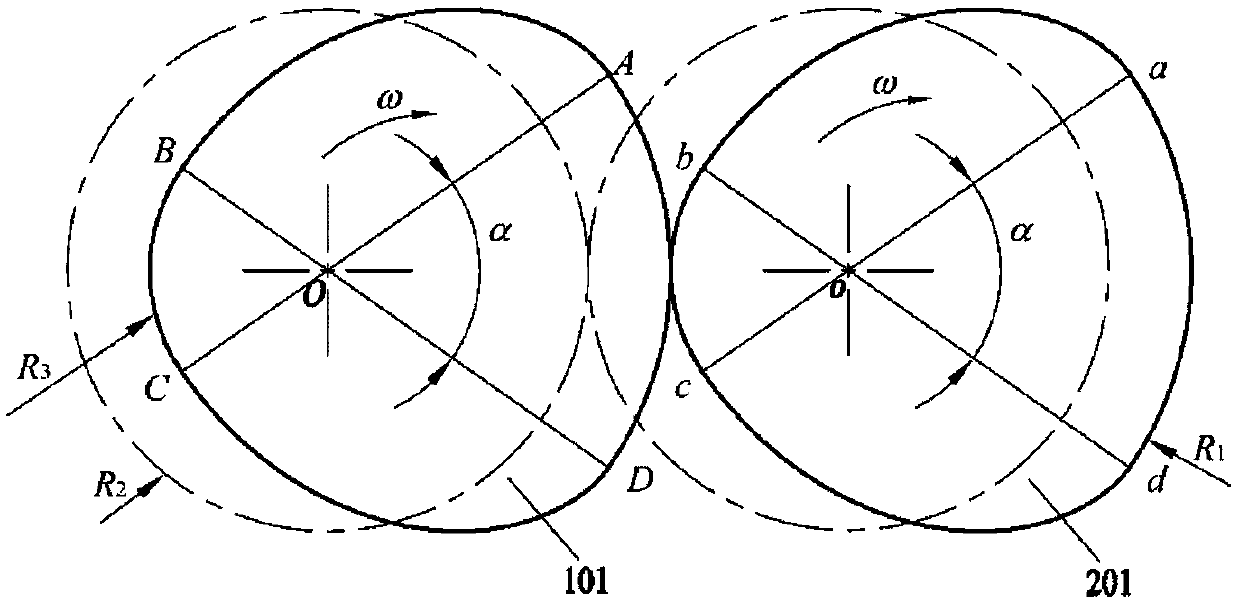

Scroll compressor and correcting method of scroll wrap molded line thereof

PendingCN107559191ANo interferenceFully meshedRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention relates to a scroll compressor. The scroll compressor comprises a static vortex plate and a movable vortex plate. The static vortex plate comprises a first central head section and a first central inner arc-shaped section. The movable vortex plate comprises a second central head section and a second central inner arc-shaped section. In a gradual open process of a suction cavity, scroll wraps of the static vortex plate between a medium pressure cavity and the suction cavity and those of the movable vortex plate form gaps, and the scroll wraps of the static vortex plate and the scroll wraps of the movable vortex plate between the exhaust cavity and the medium pressure cavity are engaged; in a gradual close process of the suction cavity, the first central head section and the second central inner arc-shaped section form a gap, the second central head section and the first central inner arc-shaped section form a gap, and the scroll wraps of the static vortex plate and the scroll wraps of the movable vortex plate between the exhaust cavity and the medium pressure cavity are engaged. The invention also provides a correcting method of a scroll wrap molded line of the scrollcompressor. According to the scroll compressor and the correcting method of the scroll wrap molded line thereof, the compression effect of the scroll compressor is relatively good.

Owner:SHANGHAI GUANGYU AUTOMOBILE AIR CONDITIONING COMPRESSOR

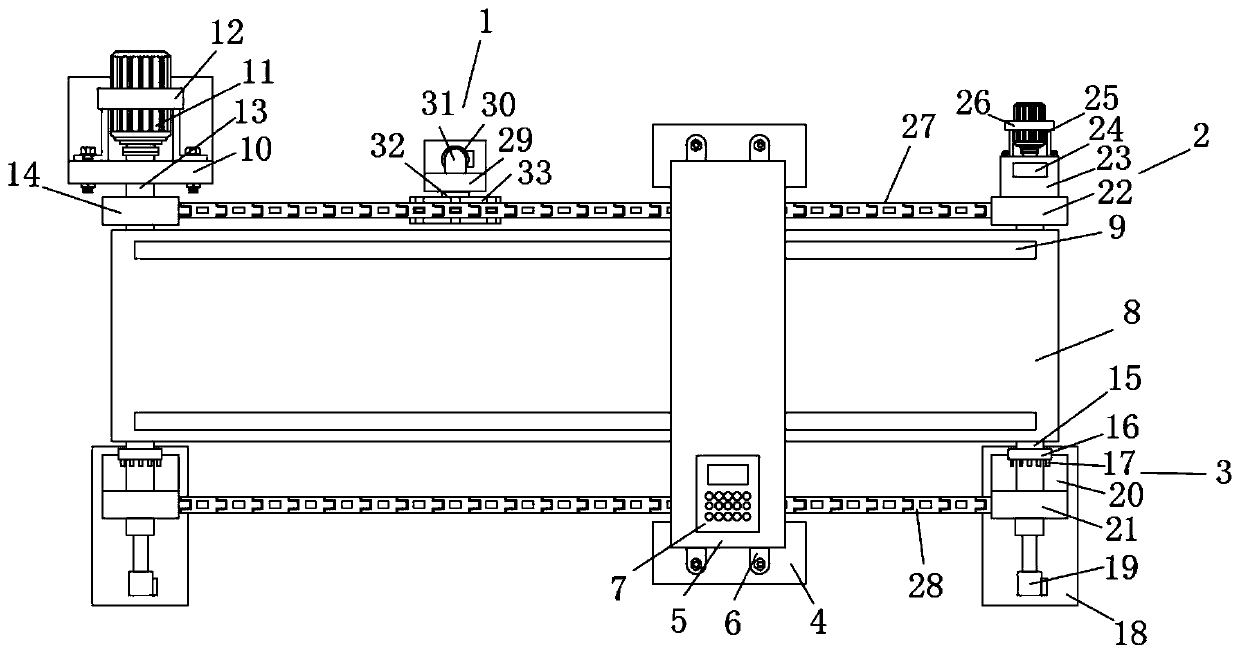

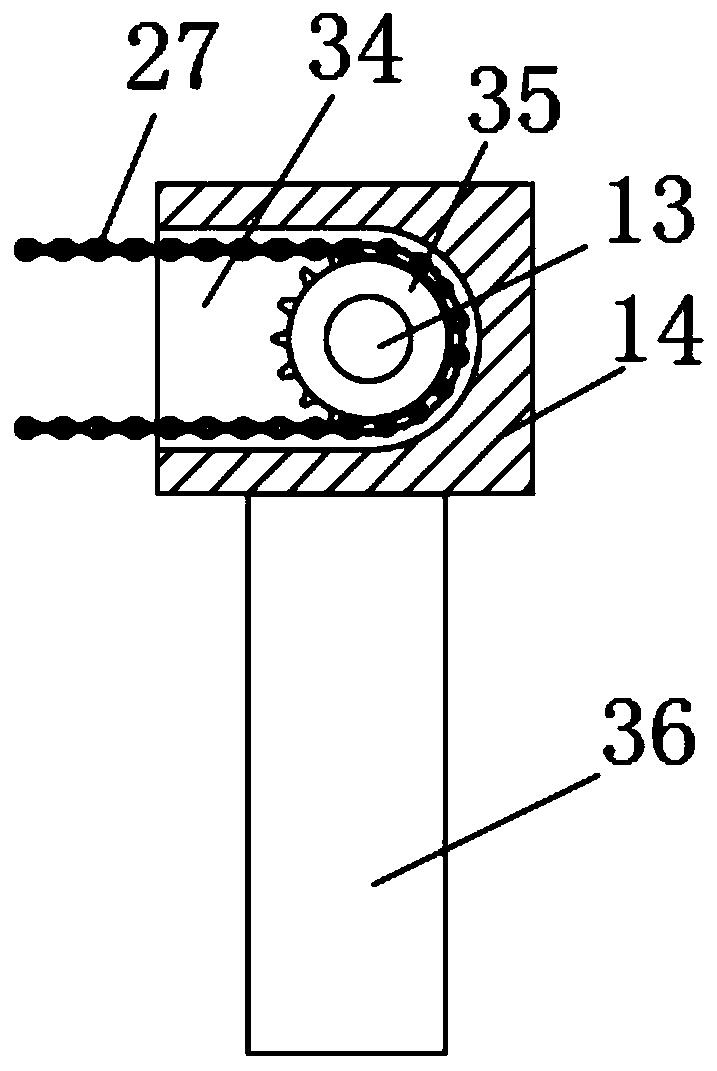

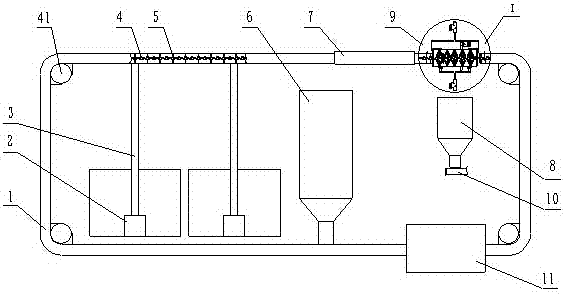

Chain breakage protection device for packaging machinery

InactiveCN110525751AIncrease the distance between the upper and lower chainsGuaranteed chance of broken chainCleaningControl devices for conveyorsContinuous operationPackaging machine

The invention discloses a chain breakage protection device of a packaging machine. The chain breakage protection device comprises a tightening mechanism, a lubricating mechanism, a switching mechanismand a packaging machine body. The lower ends at the two sides of the packaging machine body are each fixedly connected with a pair of connecting tables, a machine base is detachably connected to thebottom end of the packaging machine body and the two pairs of connecting tables through the fixing bolts, one side of the top end of the packaging machine body is fixedly connected with a control panel, and a conveying belt is arranged right below the packaging machine body. According to the invention, the main and auxiliary chains are arranged on the conveying belt, thereby securing the continuous operation of the device, greatly improving the working efficiency, avoiding the influence on the packaging work and greatly shortening the replacement time. Once a main chain is loosened, the tightening mechanism can be used to tighten or loosen a gear, the distance between the upper chain and the lower chain of the main chain can be increased, and the chain breaking probability of the main chain can be reduced. Meanwhile, the lubricating mechanism is arranged at the meshing position of the main chain and the chain gear, so that the chain breaking can be prevented, and a certain protection function is achieved.

Speed reducer structure and robot with same

PendingCN108087501AReduced Skew AngleAvoid deformationToothed gearingsPortable liftingReduction driveEngineering

The invention provides a speed reducer structure and a robot with the same. The speed reducer structure comprises a needle tooth groove, a cycloidal wheel module and a needle tooth part; and the needle tooth groove is formed in the inner wall of the needle tooth groove. The cycloidal wheel module is arranged in the needle tooth groove. The needle tooth part comprises a first needle tooth and a second needle tooth; and the first needle tooth and the second needle tooth are arranged in the needle tooth groove, and are positioned between the outer peripheral surface of the cycloidal wheel moduleand the groove bottom of the needle tooth groove. The needle tooth part adopts split needle teeth: the first needle tooth and the second needle tooth, so that the cycloidal wheel module and the splitneedle teeth are relatively independent during acting, and deflection angles of the needle teeth are effectively reduced. When one cycloid in the cycloidal wheel module is engaged with the needle teeth for stressing, as the lengths of axes of the needle teeth are reduced, the contacted areas of the needle teeth with the cycloids are not influenced by needle tooth holes or cycloidal profile axis machining errors, and full contacted engagement is realized. In addition, the split needle teeth are adopted; and the two split needle teeth form a gap channel in the connecting place to facilitate lubrication of the needle teeth.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Preparation method of insect-preventing plywood

InactiveCN107471364AImprove corrosion resistanceFully meshedOther plywood/veneer working apparatusRadiation/waves wood treatmentPaulowniaAdhesive

The invention belongs to the technical field of plywood machining, and particularly relates to a preparation method of insect-preventing plywood. The preparation method comprises a veneer insect prevention treatment mode and an adhesive insect prevention treatment mode, specifically, the veneer insect prevention treatment mode comprises the steps of treating fluid soaking and paulownia wood fumigation after acid treatment, and according to the adhesive insect prevention treatment mode, composite particles with the insect preventing effect are added into an adhesive. Compared with the prior art, the preparation method has the following advantages that the plywood prepared through the preparation method can well defend against white ants and decay fungi, the erosion resistance of veneer can be improved, the durability of the insect prevention effect is good, and the service life of the plywood is prolonged.

Owner:融安县华荣木业有限公司

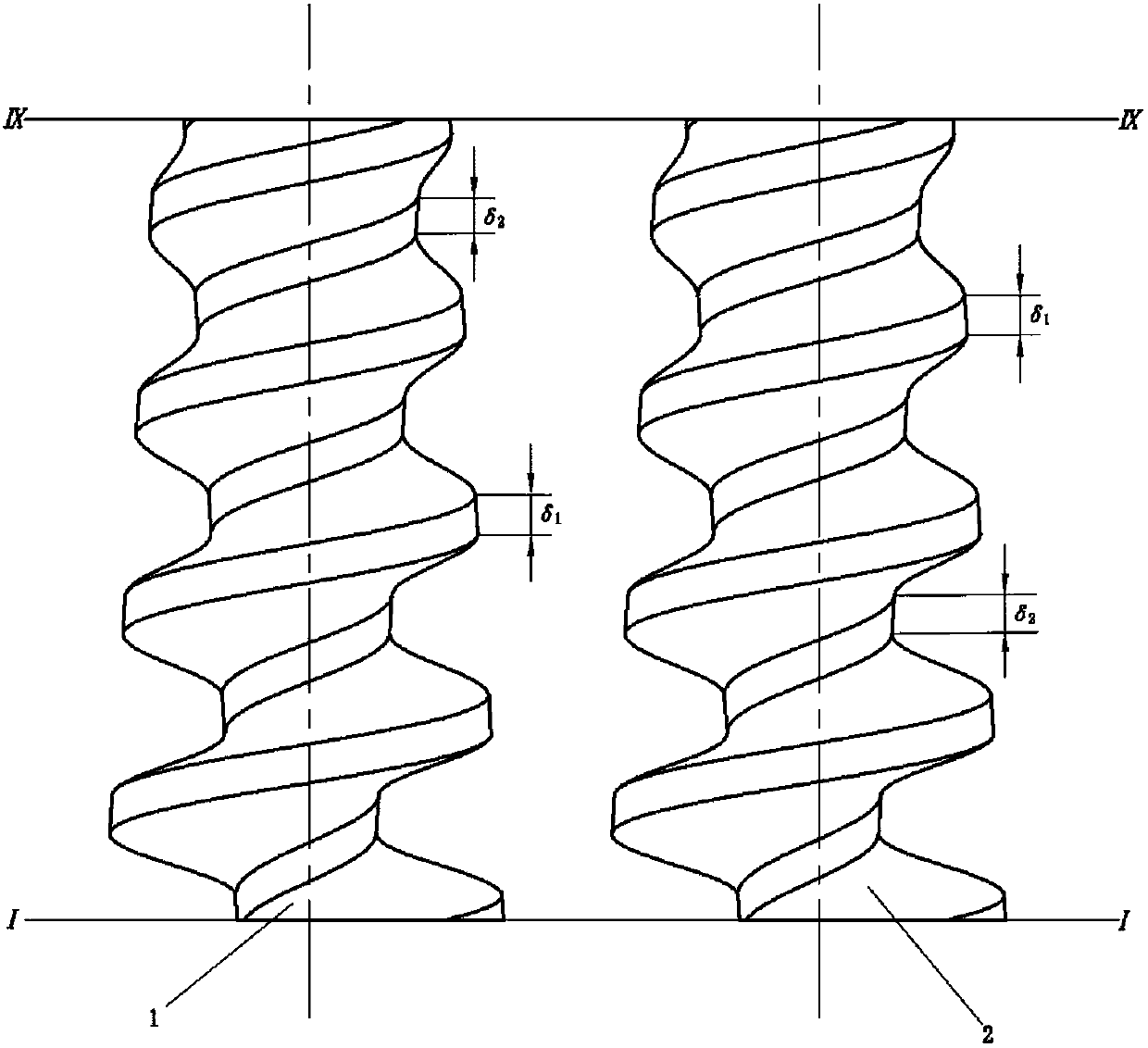

Fully-smooth conical screw rotors of double-screw extruder

The invention discloses fully-smooth conical screw rotors of double-screw extruder. The screw rotors are conical; the screw pitch P of each screw rotor is consistent; from a sucking-in end (I-I) to anemitting end (IX-IX), the addendum arc radius R1 of each cross section profile is gradually reduced, and the dedendum arc radius R3 is gradually increased; the addendum thickness theta 1 and the dedendum arc radius theta 2 of each screw rotor are persistently unchanged and identical in the axial direction; the two screw rotors are completely identical, and the axes of the screw rotors are parallel to each other; by adopting the fully-smooth conical screw rotors of double-screw extruder, the volume of a working cavity at each sucking-in end can be effectively increased, and the volume of the working cavity at each emission end is reduced, so that the screw rotors have a good extrusion function; for cross section profiles of the screw rotors at any axial positions, adjacent composition curves are completely smoothly connected; the screw rotors which are formed by extending from the cross section profiles along helixes can be meshed accurately; and friction abrasion to the screw rotors is reduced, so that the service life of the screw rotors is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

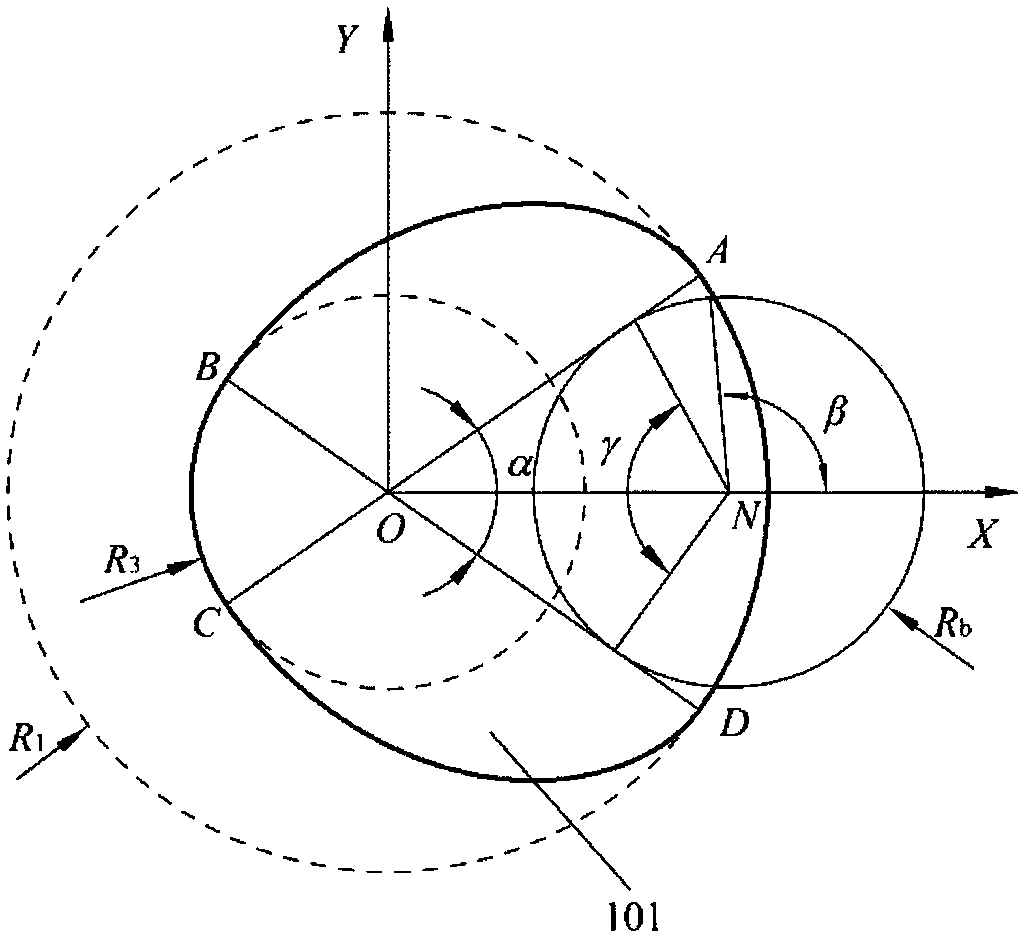

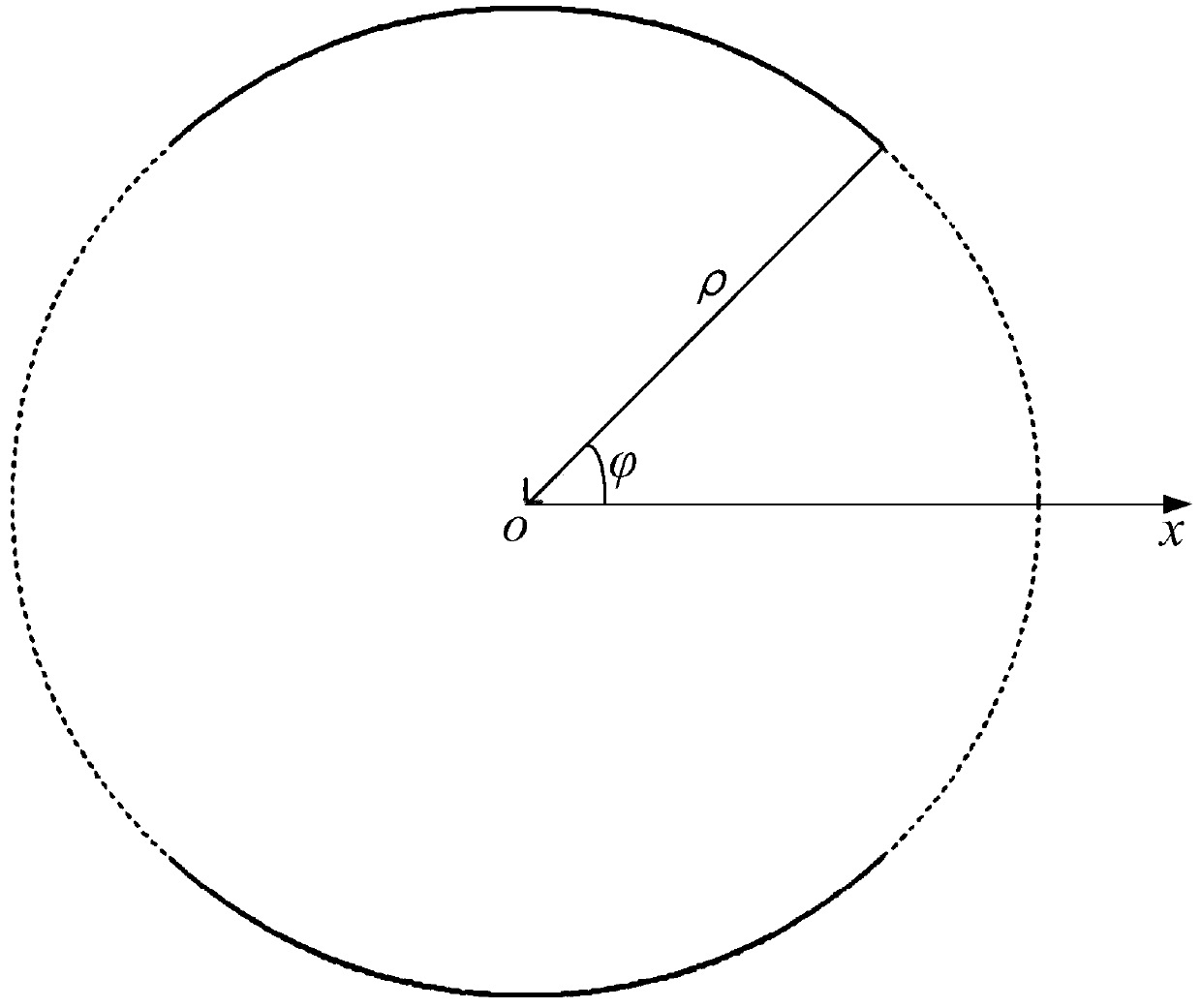

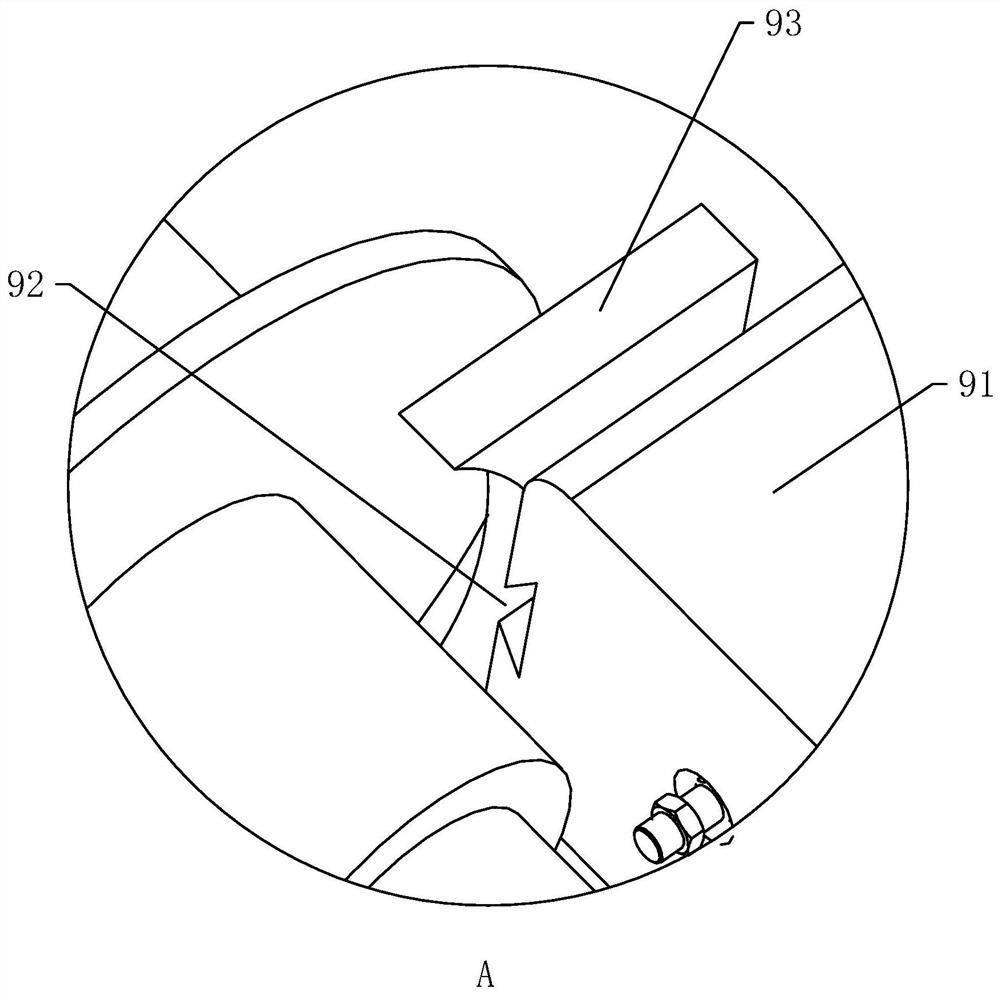

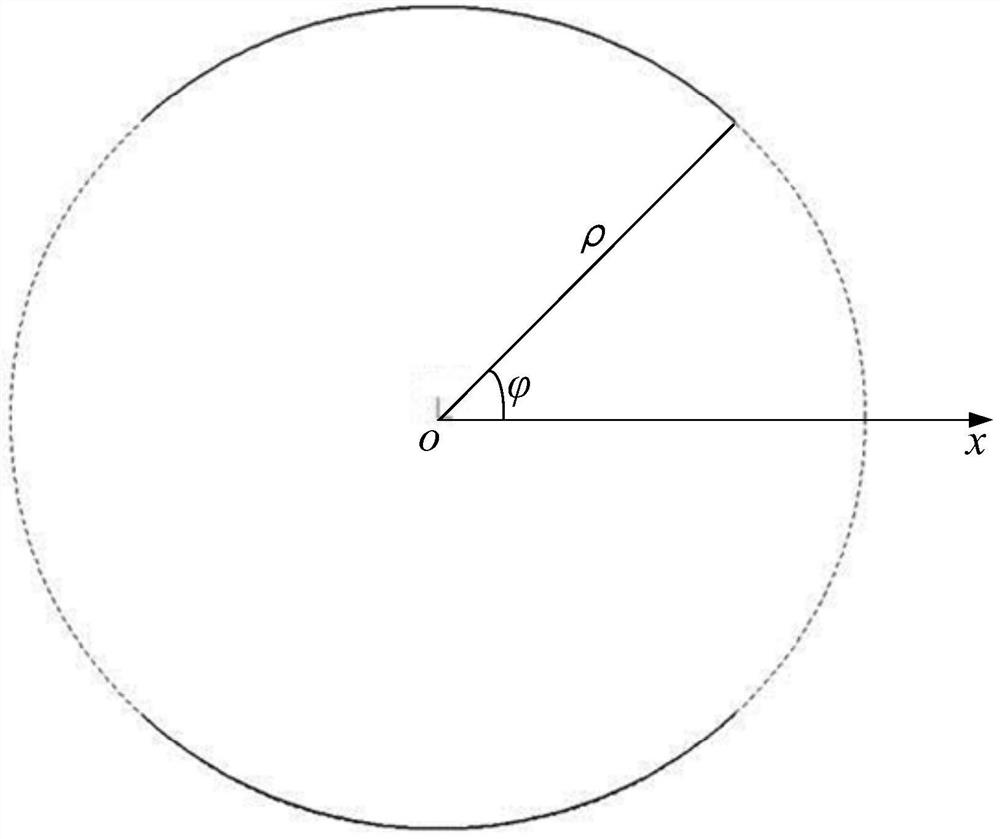

Wave generator, harmonic reducer and drive system

The invention relates to the technical field of speed reducers, and particularly provides a wave generator, a harmonic reducer and a drive system. The wave generator comprises a cam and a flexible neutral layer, wherein an outer edge outline molded line of the cam comprises a first molded line located in a meshing area and a second molded line located in a non-meshing area; the second molded line is a cosine cam molded line; the first molded line has radial increment compared with the second molded line, so that the polar radius, located in the meshing area, of the cam is increased; and the first molded line and the second molded line are continuously and guidably connected in a transition way. According to the wave generator, the harmonic reducer and the drive system provided by the invention, through increasing the polar radius of the meshing area, the radial deformation amount, in a meshing area, of a flexible wheel is increased, flexible wheel teeth and rigid wheel teeth located at a semi-meshing state are sufficiently meshed, and the meshing tooth number of the meshing area is correspondingly increased, so that the meshing stress of the flexible wheel teeth is reduced, and a bearing capacity of the speed reducer is improved.

Owner:合肥凯邦电机有限公司 +2

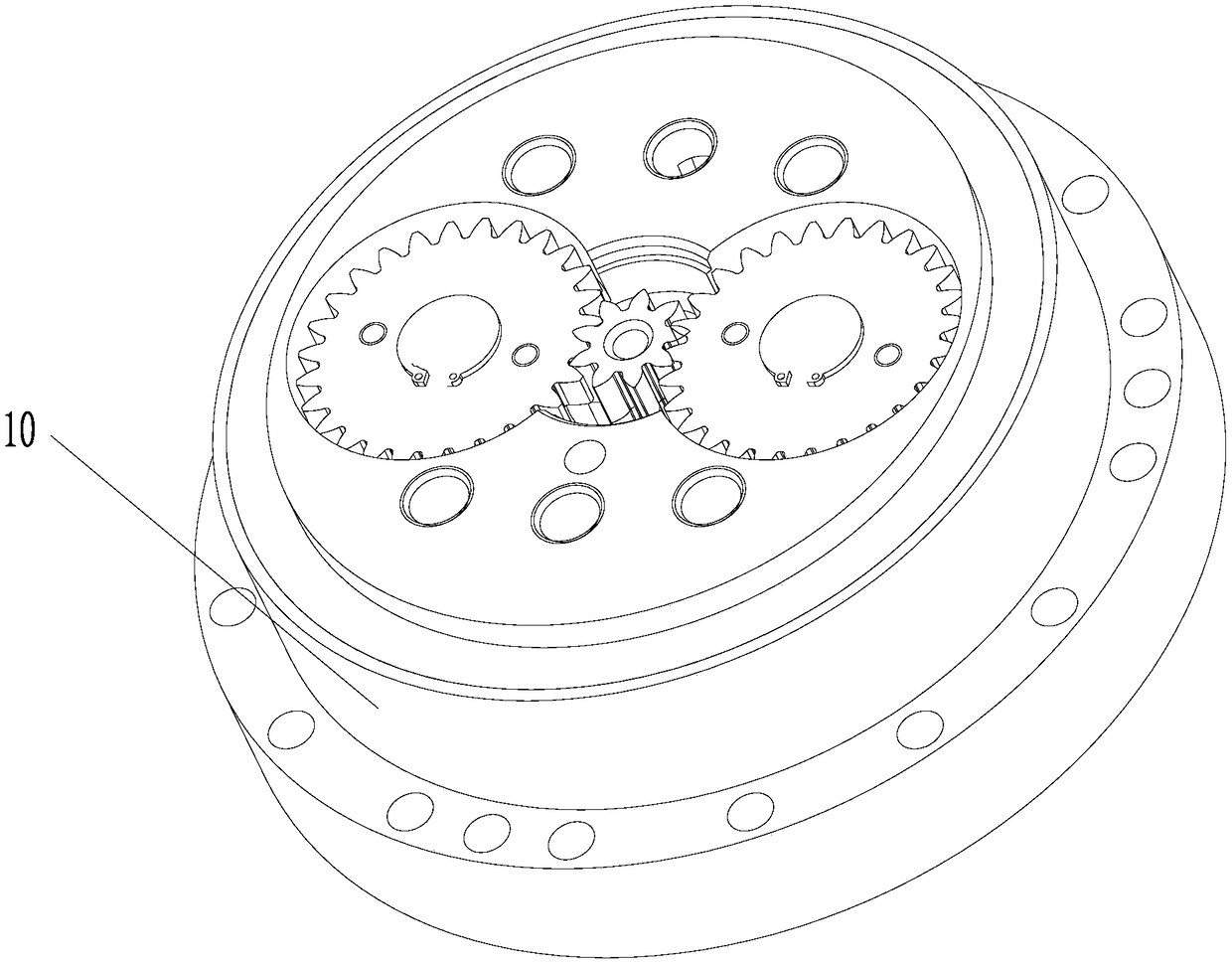

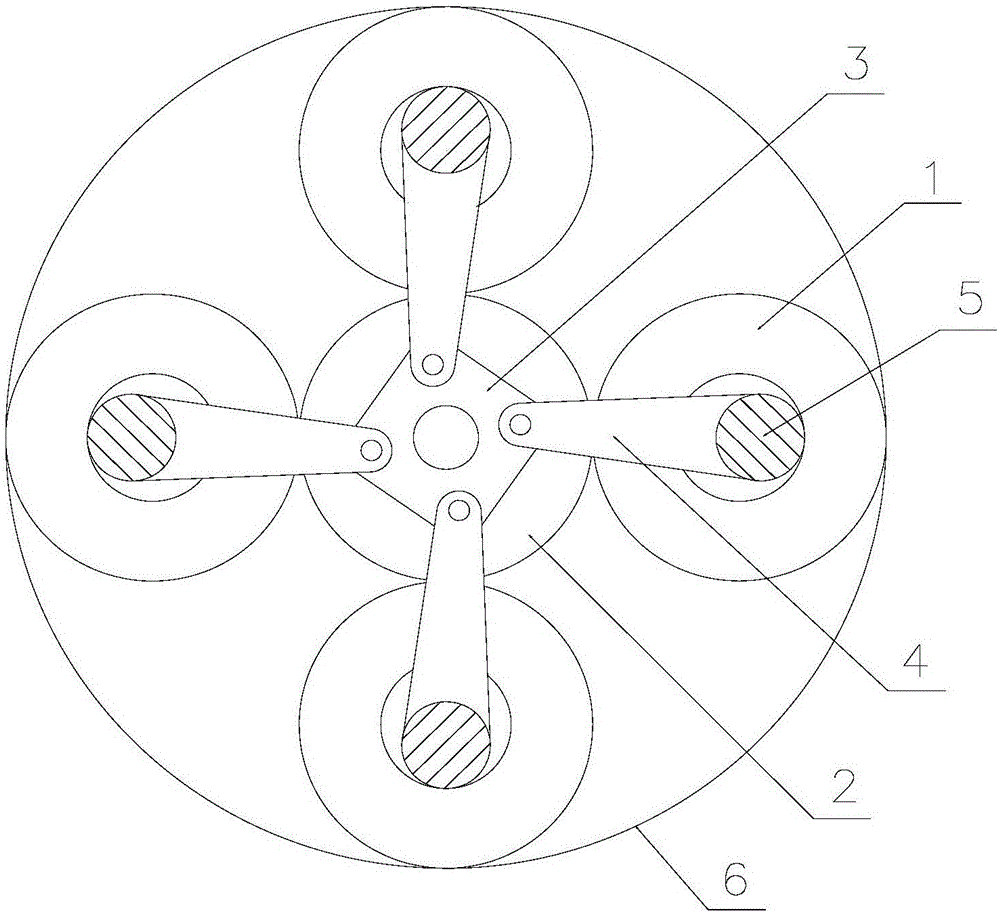

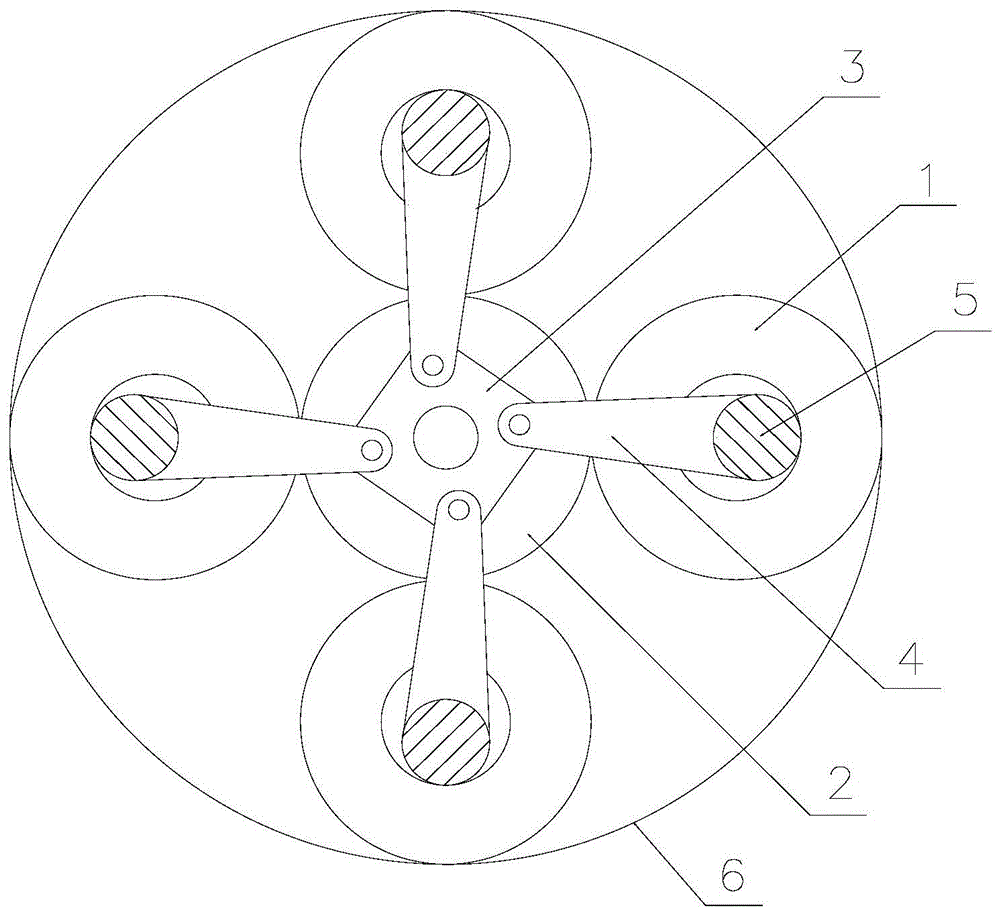

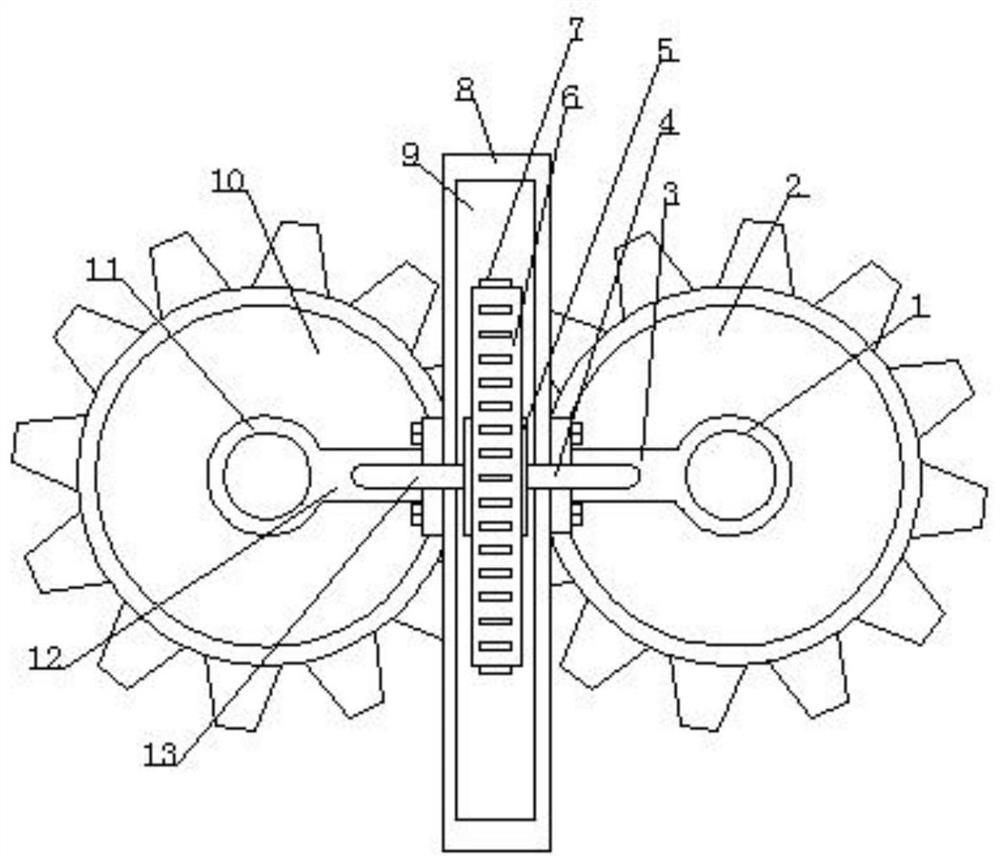

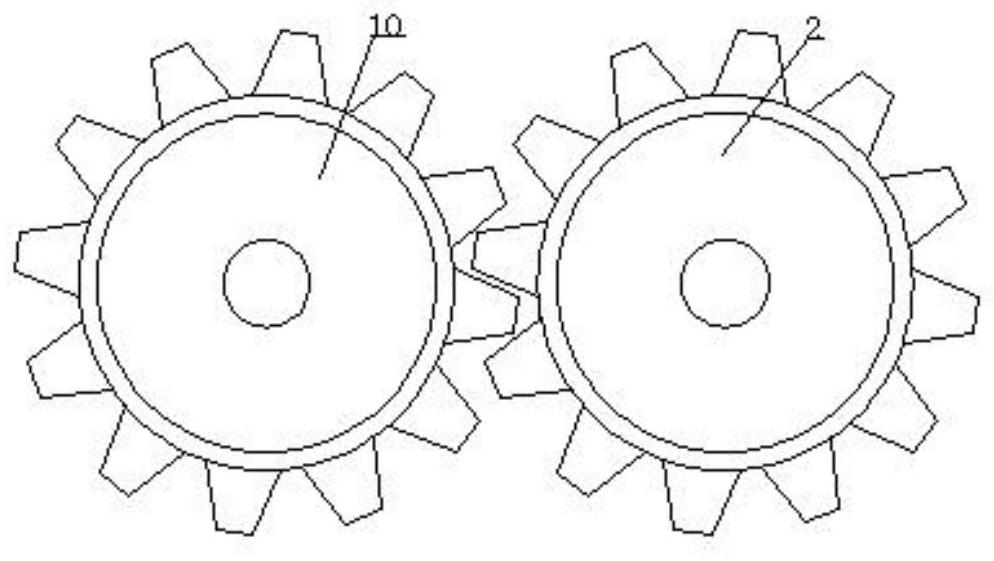

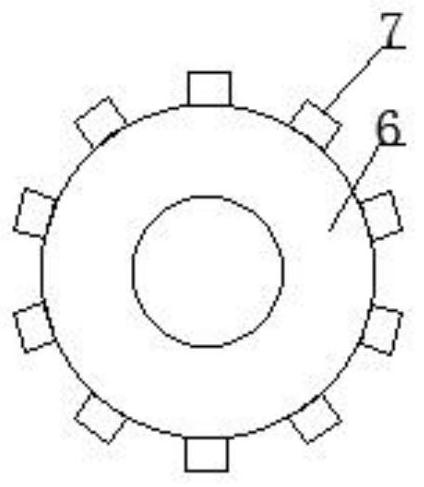

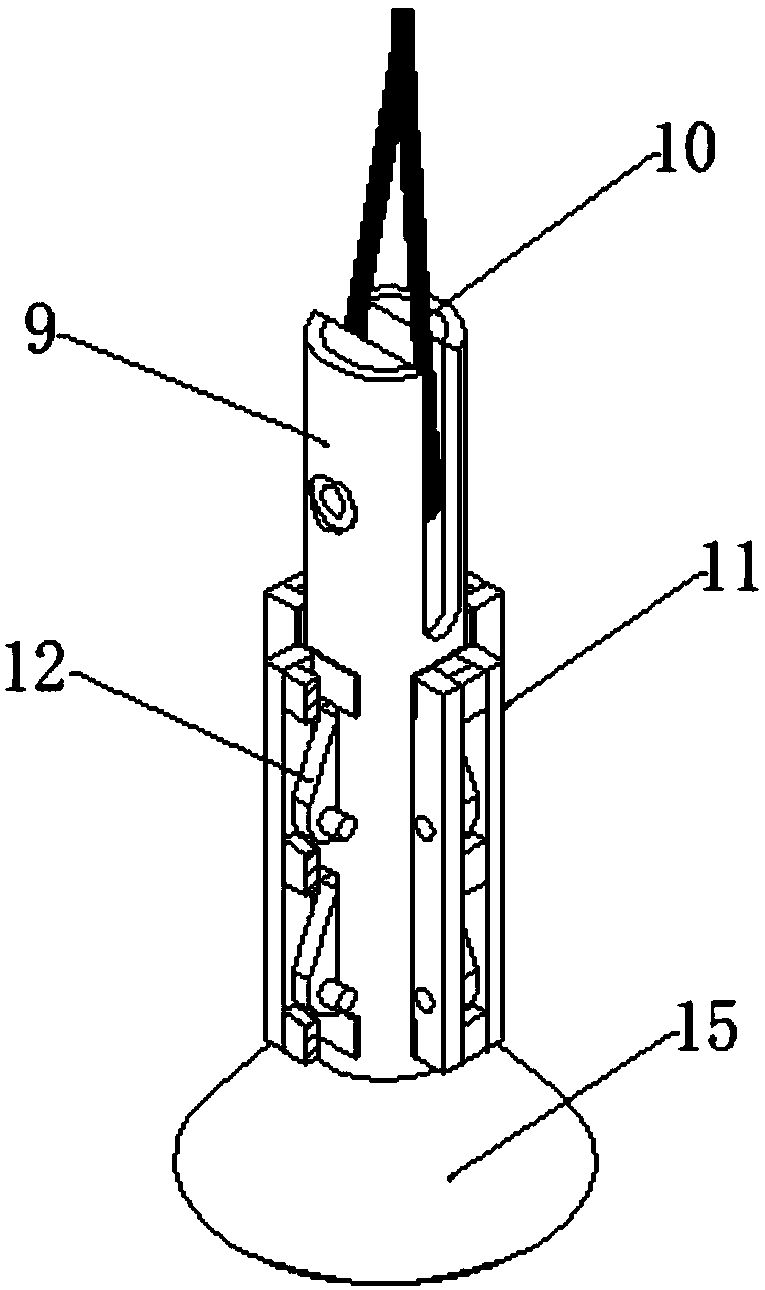

Uniform load system of planet mechanism

The invention discloses a uniform load system of a planet mechanism. The uniform load system comprises a synchronous uniform load mechanism which is in transmission connection to the part among planet wheels in the planet mechanism and is used for synchronously adjusting the positions of the planet wheels to achieve the uniform load. According to the uniform load system of the planet mechanism, after the planet wheels are adjusted to be sufficiently engaged with an inner gear ring and a sun wheel, the synchronous uniform load mechanism is arranged, and the planet wheels synchronously rotate. Accordingly, sufficient meshing among the planet wheels, the inner gear ring and the sun wheel is kept, a meshing gap between the planet wheels in the planet mechanism is eliminated, and the running delay of the planet wheels is avoided.

Owner:CHONGQING UNIV

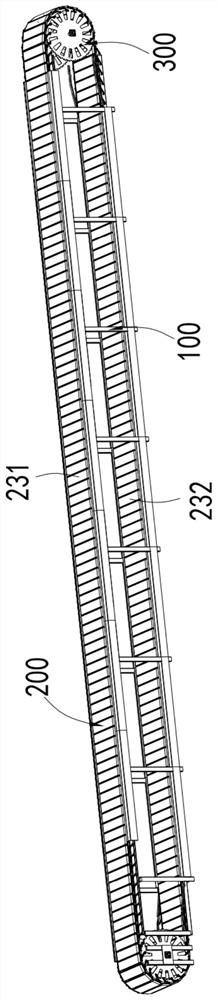

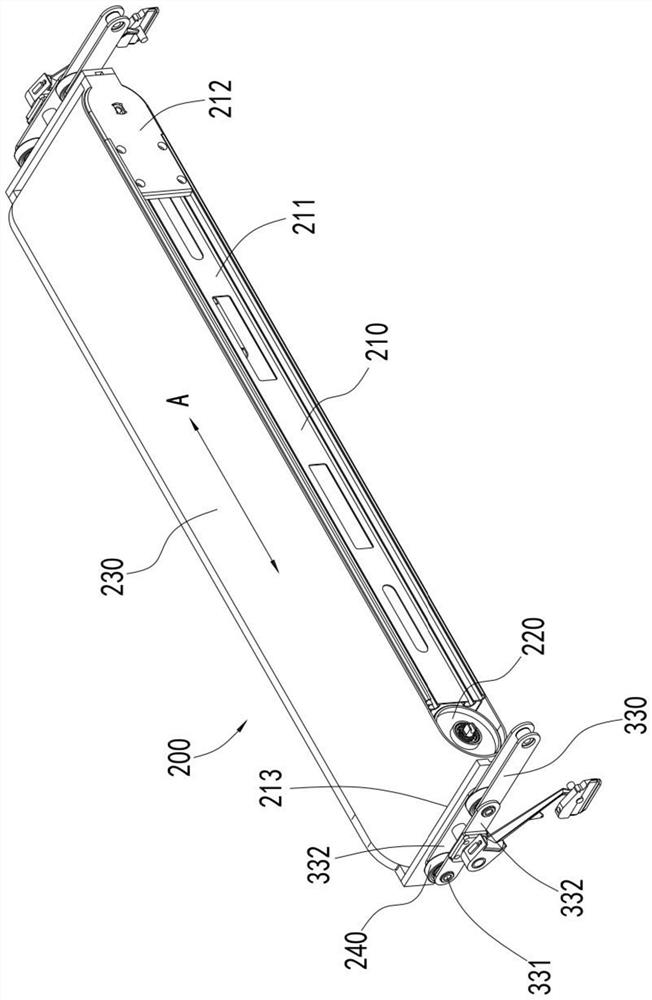

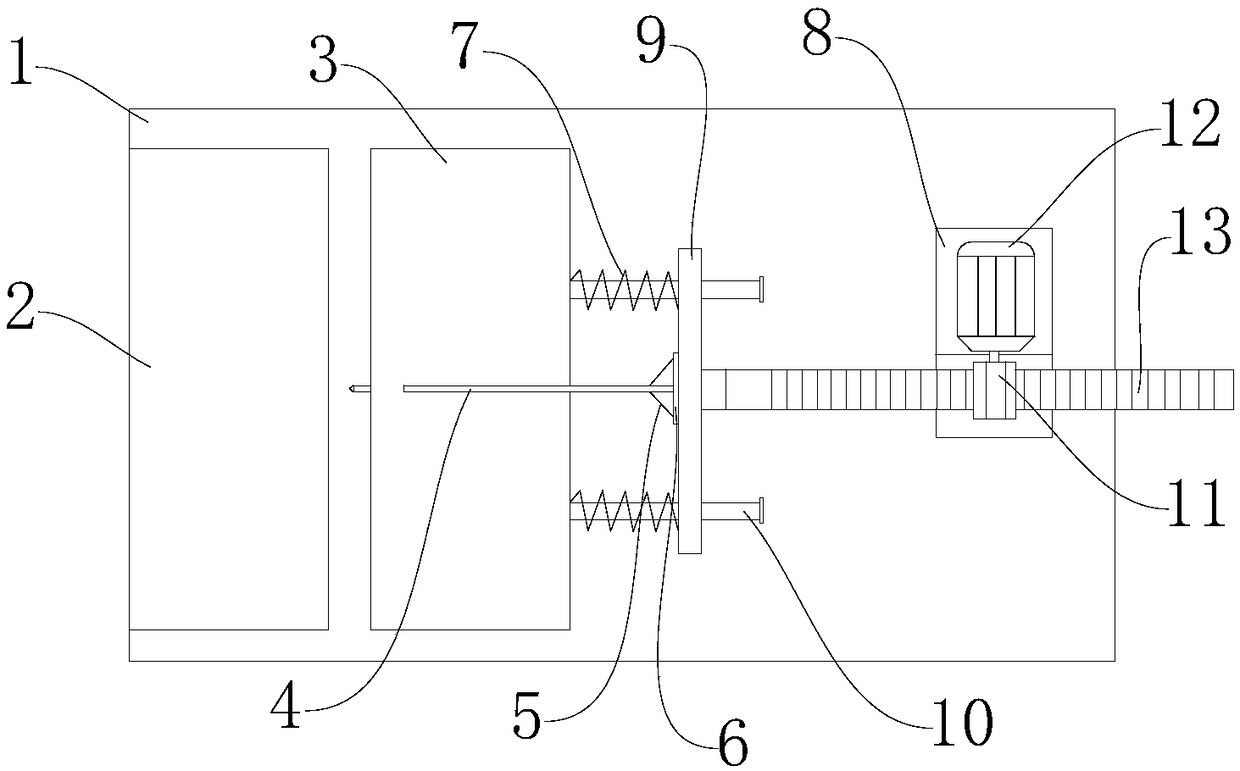

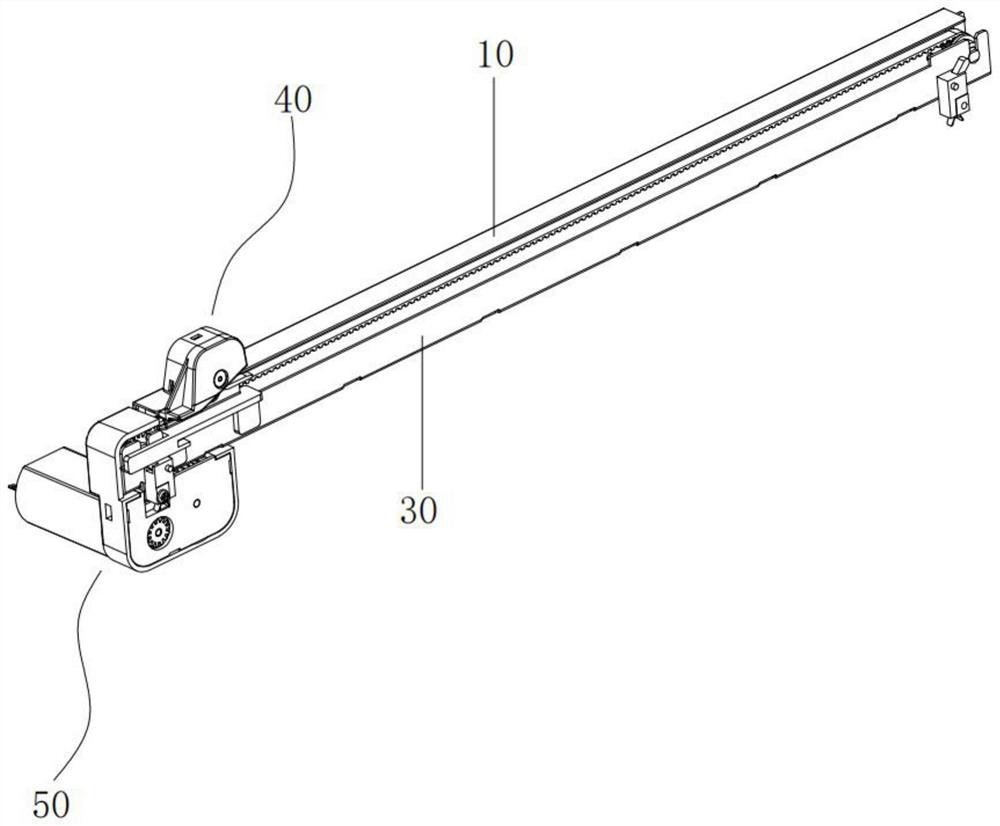

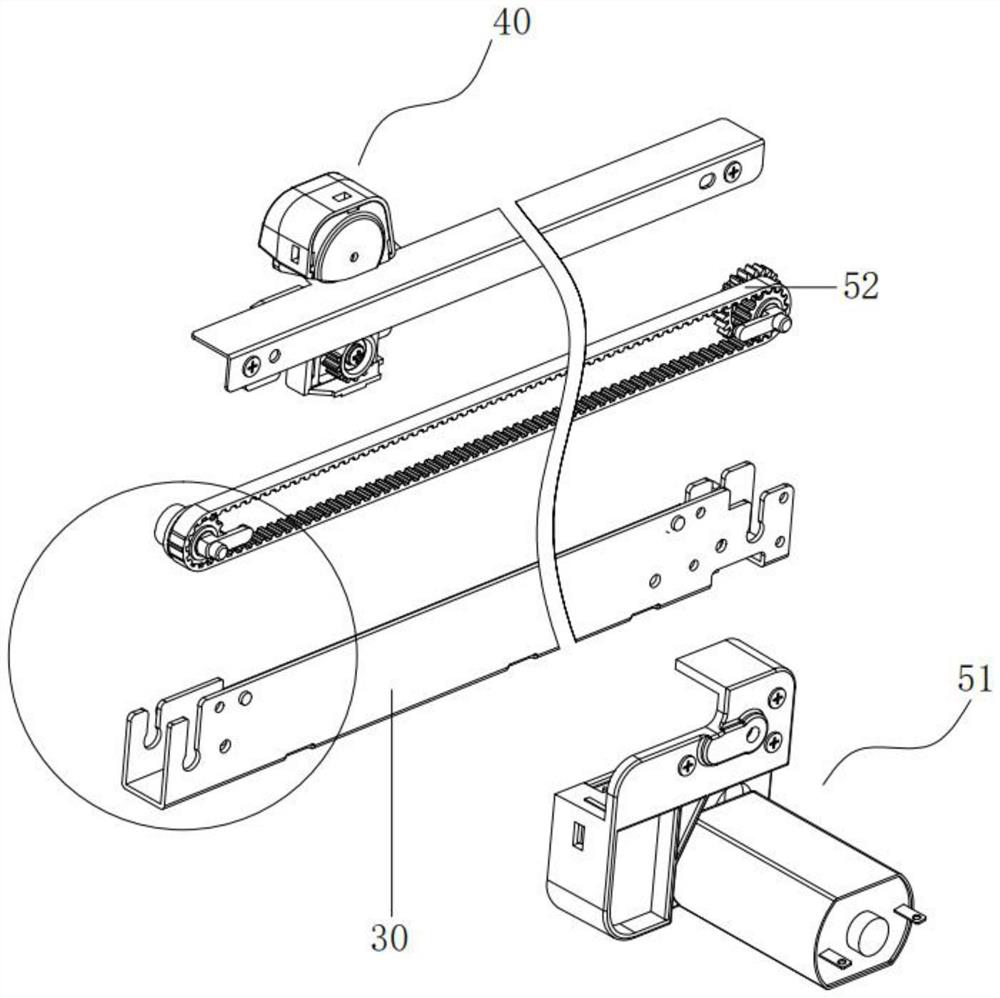

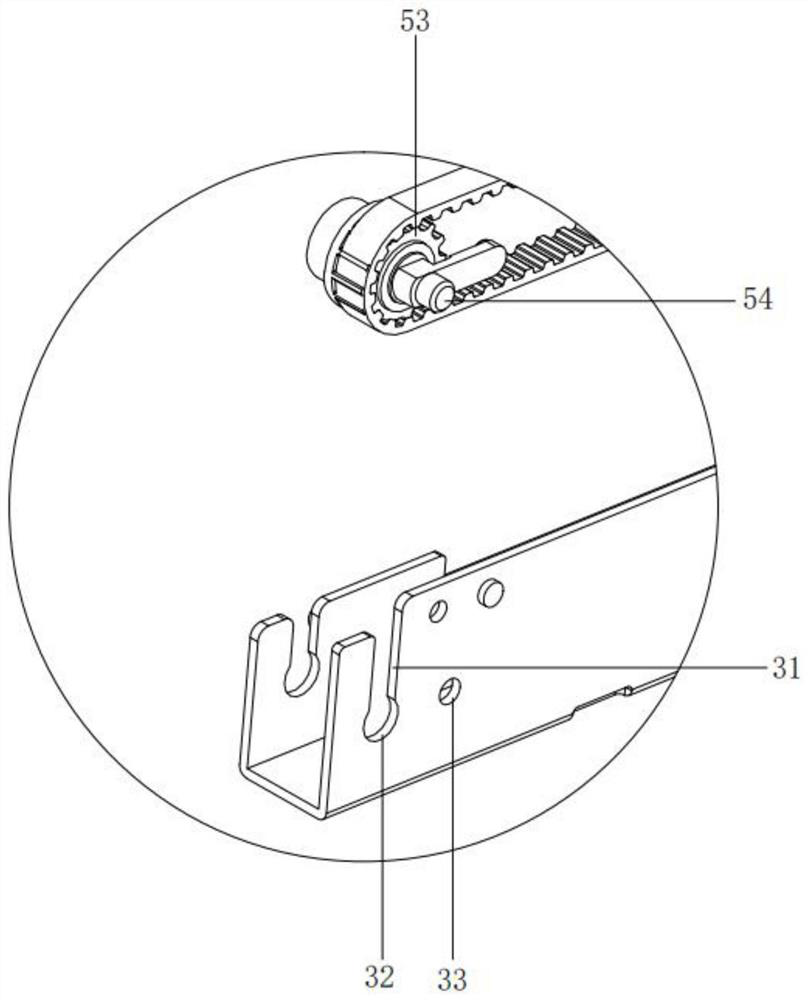

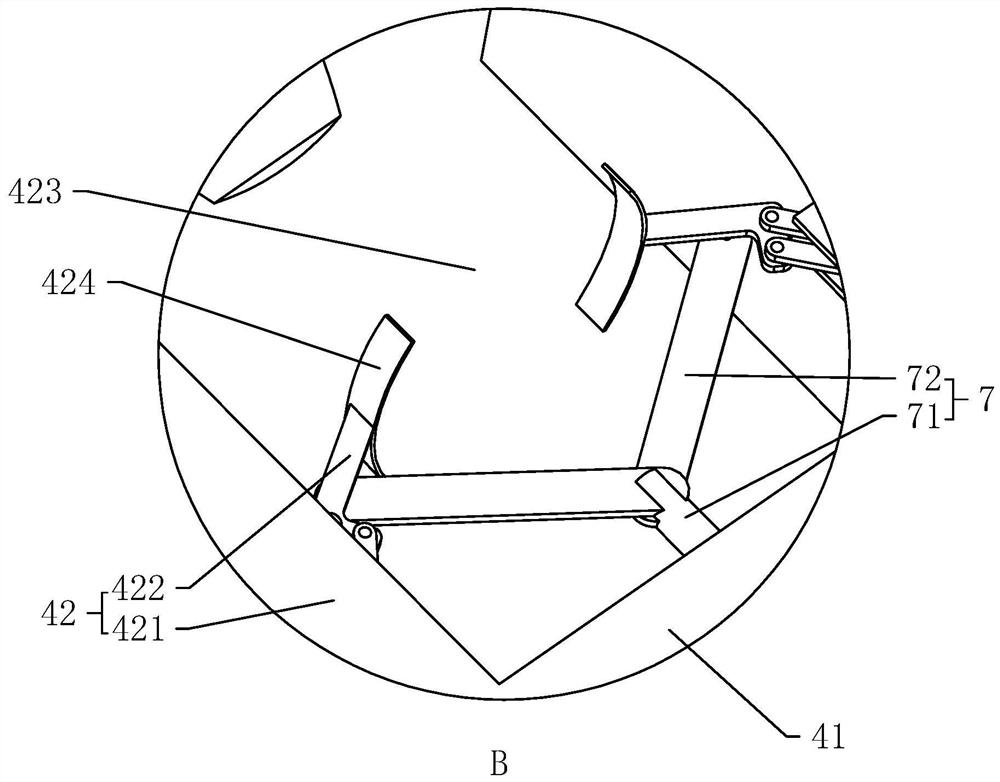

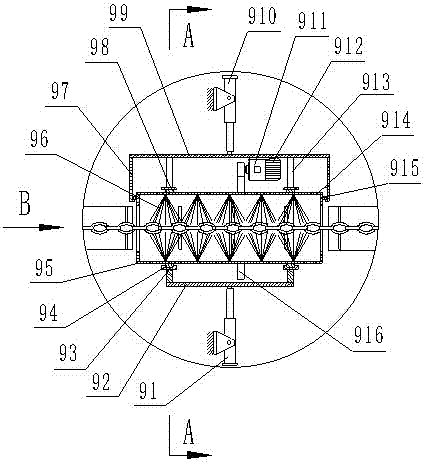

Sorting machine, sorting trolley, sorting system and article sorting method

InactiveCN113522757ASolve the problem that can not be used for sortingImprove efficiencySortingConveyor partsStructural engineeringMechanical engineering

The invention discloses a sorting machine, a sorting trolley, a sorting system and an article sorting method. The sorting machine comprises a frame, the sorting trolley and a driving mechanism, wherein the sorting trolley comprises a trolley frame, a rotating roller and a conveying belt arranged on the rotating roller in a sleeving mode, the trolley frame of the sorting trolley does not shield the surfaces and the ends of a first straight belt section and a second straight belt section of the conveying belt, each sorting trolley rotates along with a trolley loop line until the first straight belt section of the conveying belt faces upwards, and when the second straight belt section faces downwards, sorting is carried out through the first straight belt section; and each sorting trolley rotates along with the trolley loop line until the first straight belt section faces downwards, and when the second straight belt section faces upwards, sorting is carried out through the second straight belt section. According to the sorting machine, the sorting trolley, the sorting system and the article sorting method, the problem that an existing sorting trolley cannot be used for sorting when rotating from an upper layer to a lower layer is solved, the use efficiency of each sorting trolley in the operation process is greatly improved, and the sorting efficiency is improved.

Owner:SUZHOU GP LOGISTICS SYST

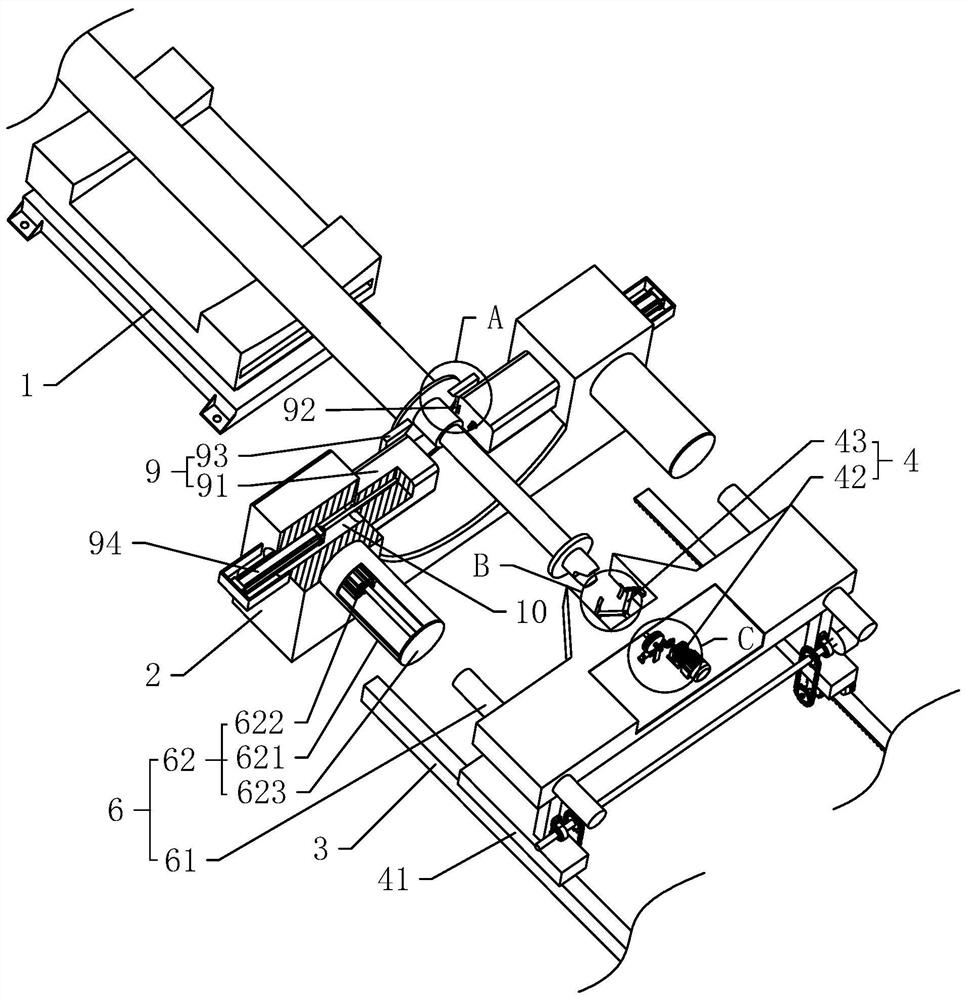

Inter-shaft central distance adjusting mechanism

InactiveCN104455339ARealize micro-adjustmentMachining accuracy adjustmentTransmission elementsGearing detailsDrive shaftEngineering

The invention discloses an inter-shaft central distance adjusting mechanism which comprises a driving shaft and a driven shaft. The two ends of the driving shaft are installed on two driving bearing pedestals respectively. The inner surfaces of the two driving bearing pedestals are non-concentric cylindrical surfaces. The eccentricity exists between the two driving bearing pedestals. By means of the inter-shaft central distance adjusting mechanism, the central distance can be slightly adjusted, the machining errors are reduced, and the assembling accuracy is adjusted.

Owner:杨桂珍

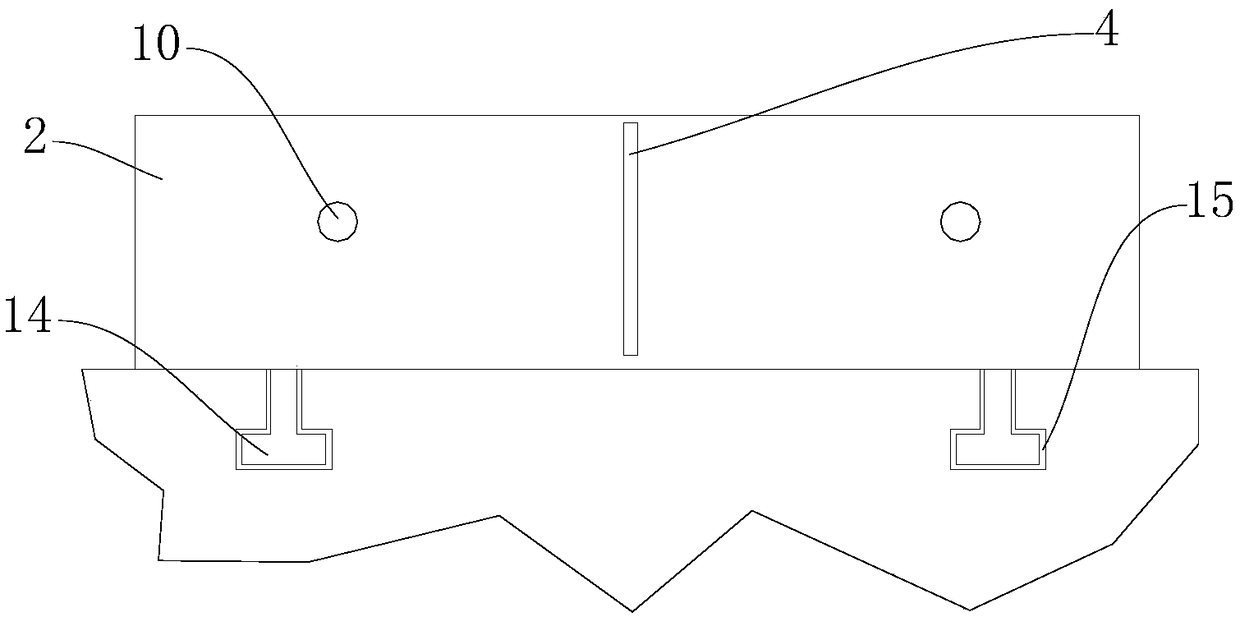

Equipment for cutting off bio-degraded plastic pipes

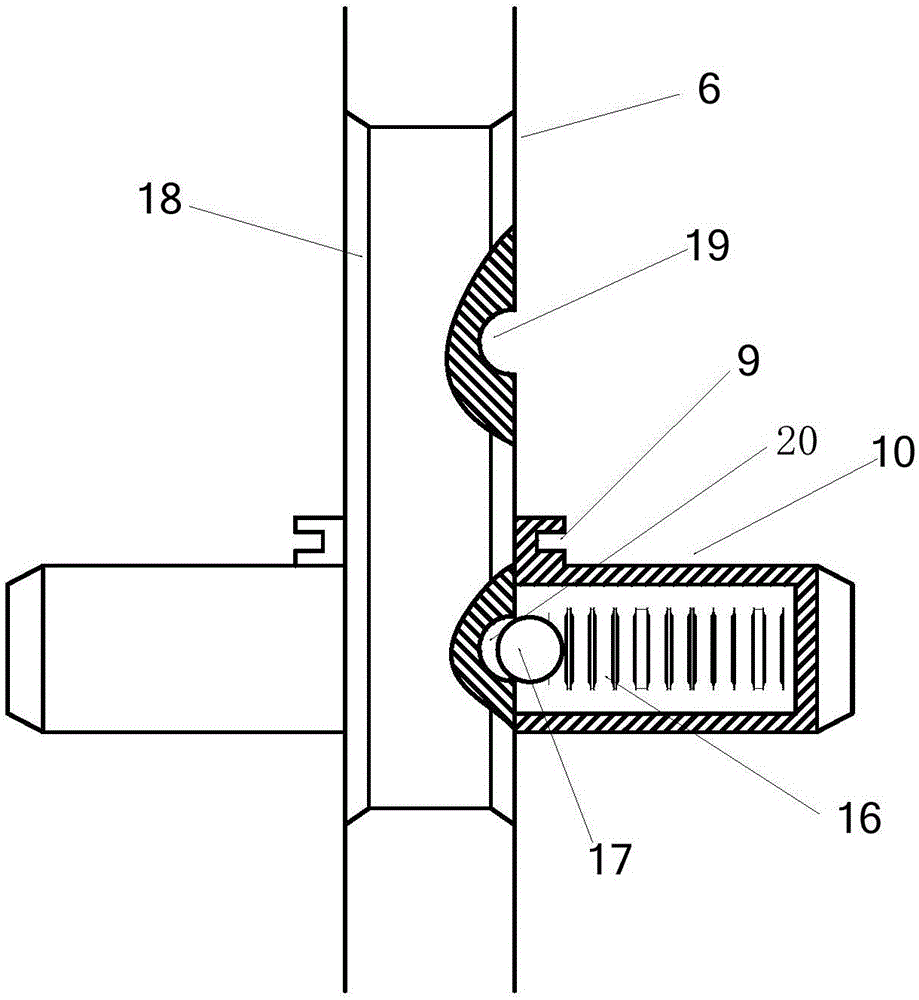

InactiveCN109015779AReliable contactConstant forceMetal working apparatusEngineeringMechanical engineering

The invention discloses equipment for cutting off bio-degraded plastic pipes. The equipment comprises a base. A fixed pressing block is arranged on the left side of the upper end of the base, a movable pressing block is arranged in the middle of the upper end of the base, a T-shaped guide rail is arranged at the bottom of the movable pressing block, a guide groove is formed in the upper end of thebase, the T-shaped guide rail is matched with the guide groove, and the movable pressing block is matched with the fixed pressing block. A cutting-off knife is arranged in the movable pressing block,and penetrates through the movable pressing block, mounting plates are arranged at the right end of the cutting-off knife, a rack is arranged at the right end of a push plate, the rack is in engagedconnection with a gear at the output end of a motor, the motor rotates to drive the gear to rotate, and then the rack is driven to move left and right; and as the rack and a motor table are connectedthrough the cooperation of a sliding rail and a sliding groove, the rack moves left and right more stably, meanwhile, the radial runout during rotation of the gear is small through the fixed connection between the motor and the motor table, full engagement of the gear and the rack is guaranteed, transmission of the equipment is stable, all transmission parts are connected reliably, and the whole equipment is safer and more efficient.

Owner:ANHUI DELIN ENVIRONMENTAL PROTECTION DEV GRP

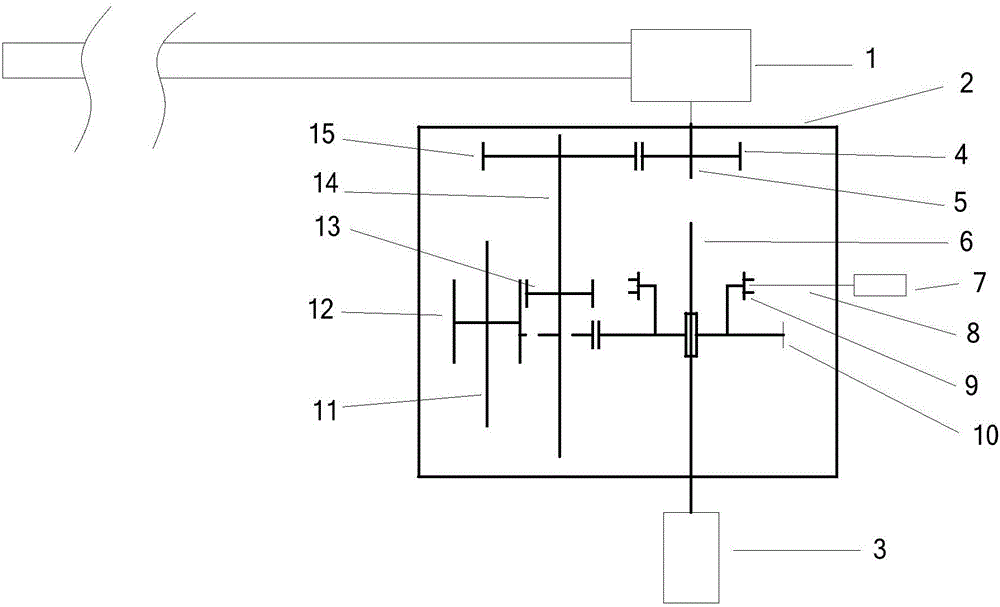

Self force augmentation type bidirectional wrench and operating method thereof

The invention discloses a self force augmentation type bidirectional wrench and an operating method thereof. The self force augmentation type bidirectional wrench comprises a handle, a force-augmentation reversing part, a reversing switch, a shifting lever and a sleeve. The force-augmentation reversing part comprises an input shaft, an intermediate shaft, a reversing shaft, an output shaft, an input gear, a transmission gear, a forward gear, a reverse gear, an output gear, a spring and a steel ball. The output gear can be selected to be engaged with the forward gear or the reverse gear through the reversing switch so that the output shaft and the sleeve can rotate in the same direction as the handle or rotate in the direction opposite to the rotating direction of the handle, and the force moment of the handle can be amplified through two-stage gear transmission. The self force augmentation type bidirectional wrench is simple in structure, convenient to operate, capable of screwing and unscrewing screws in two directions, and capable of saving strength.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

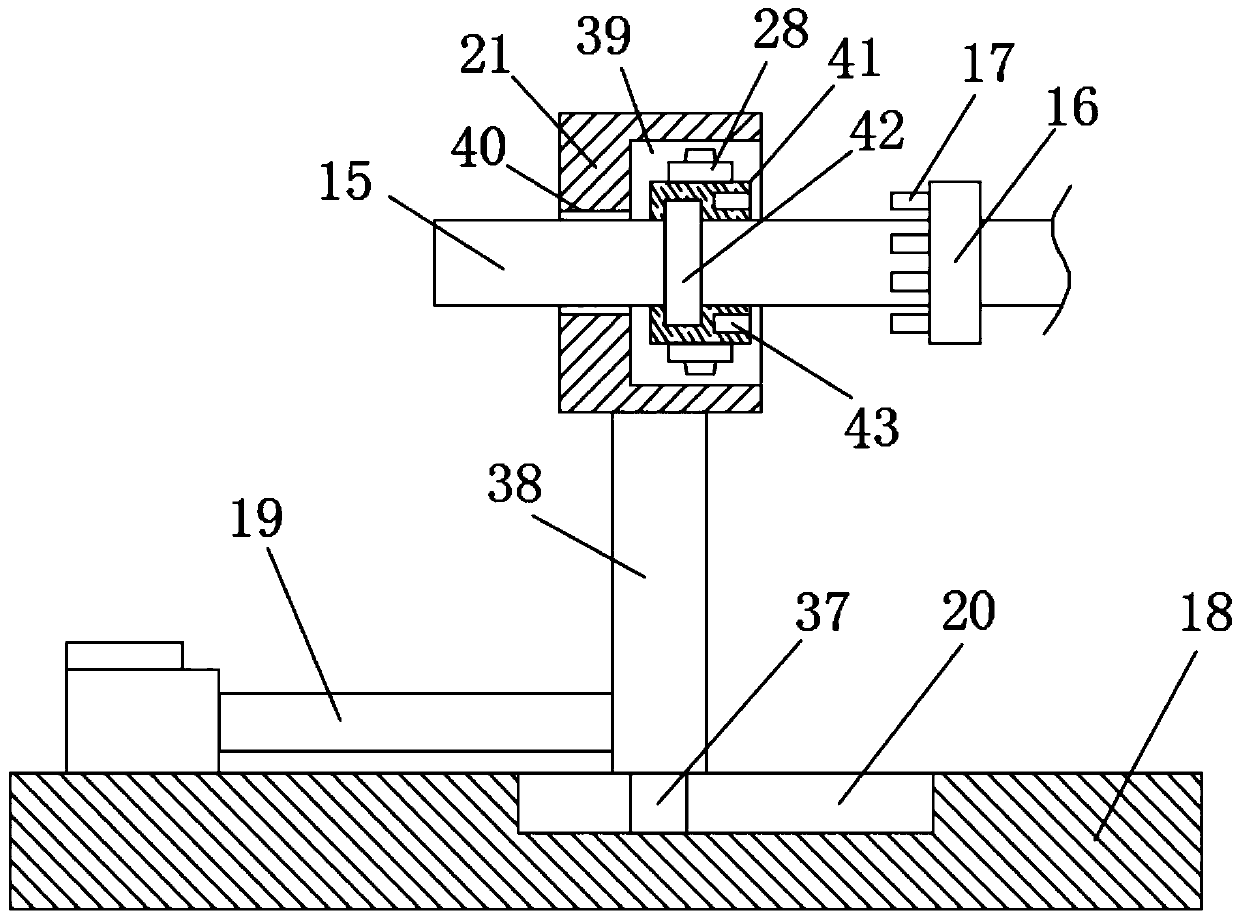

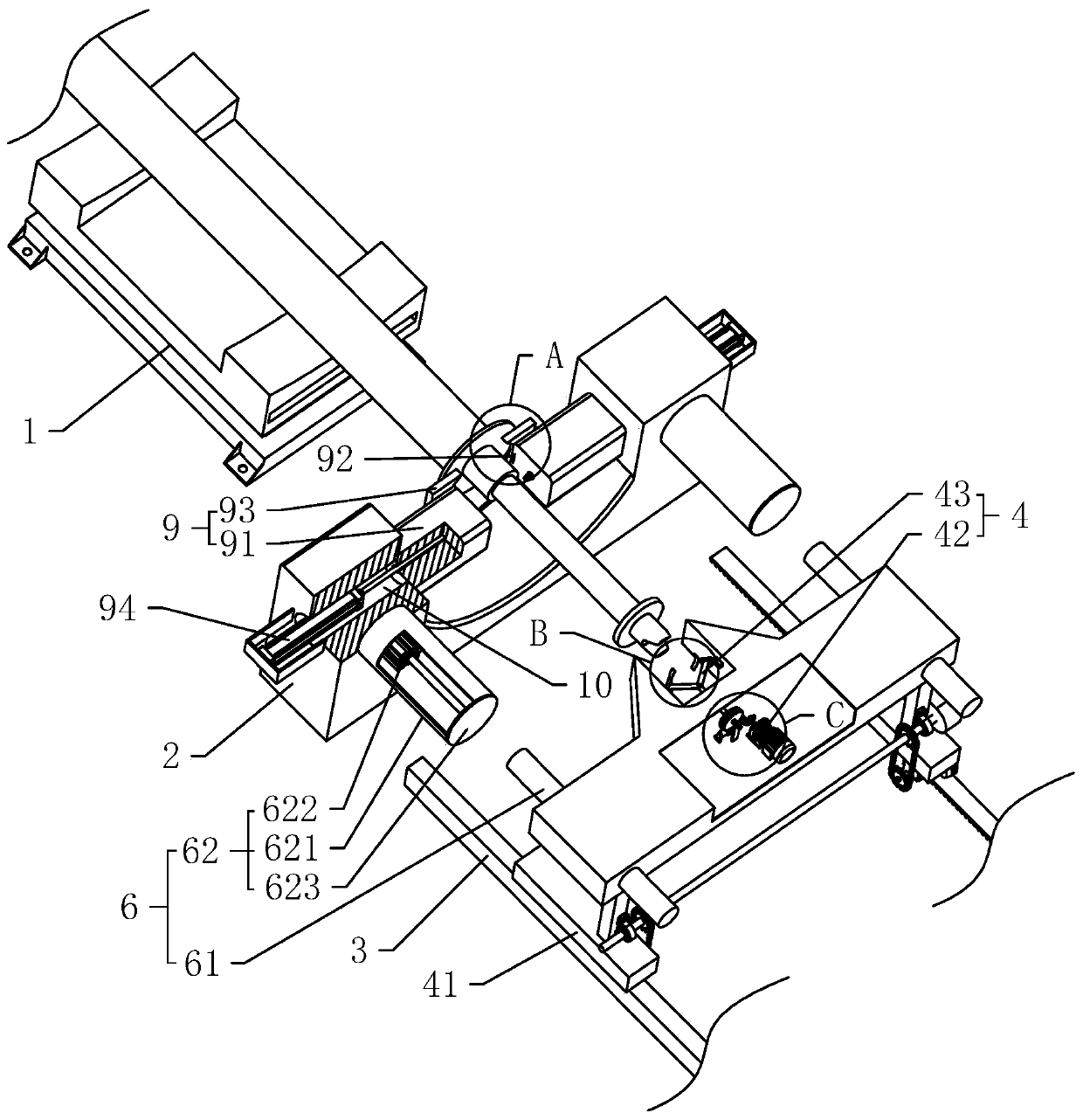

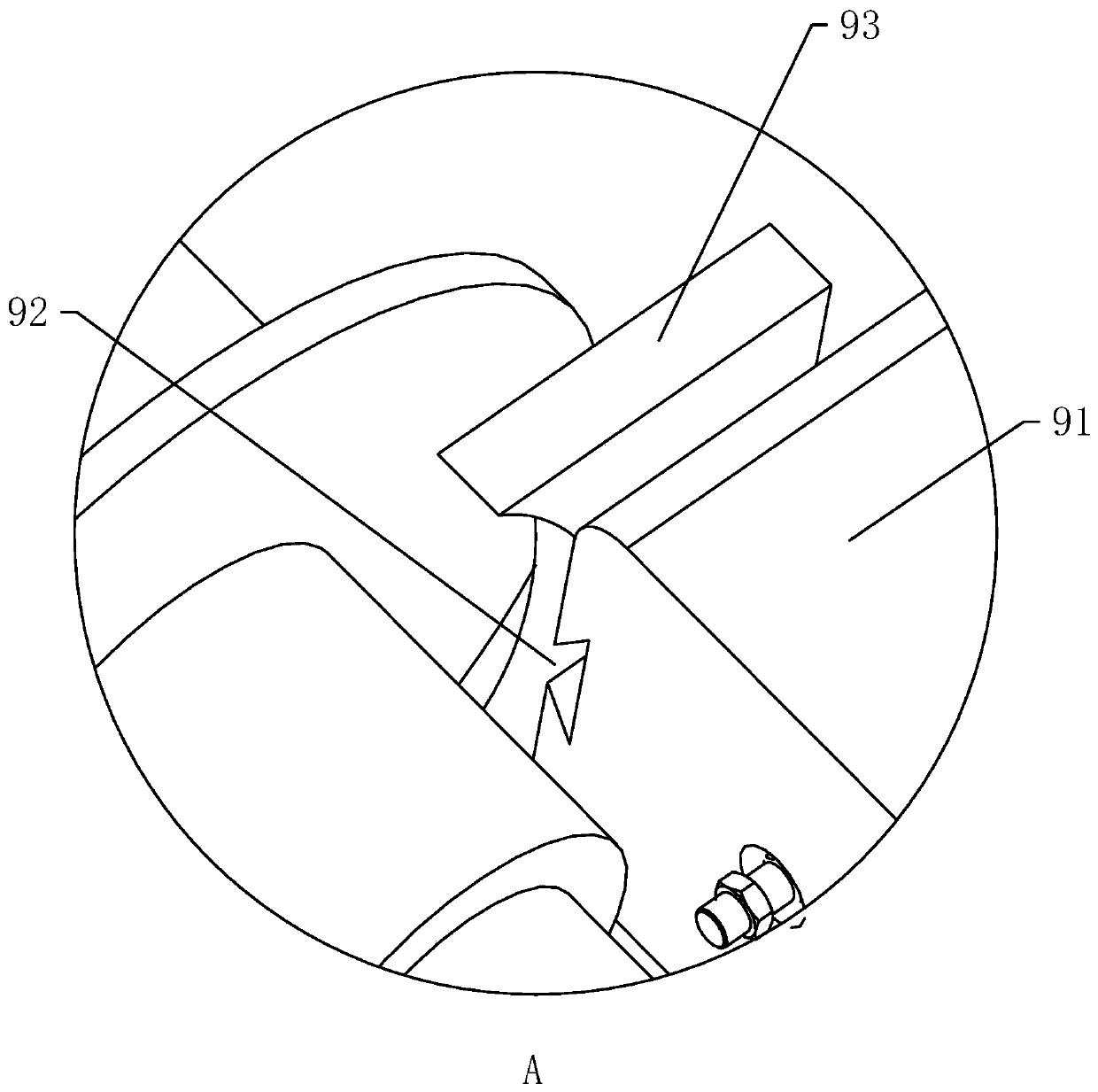

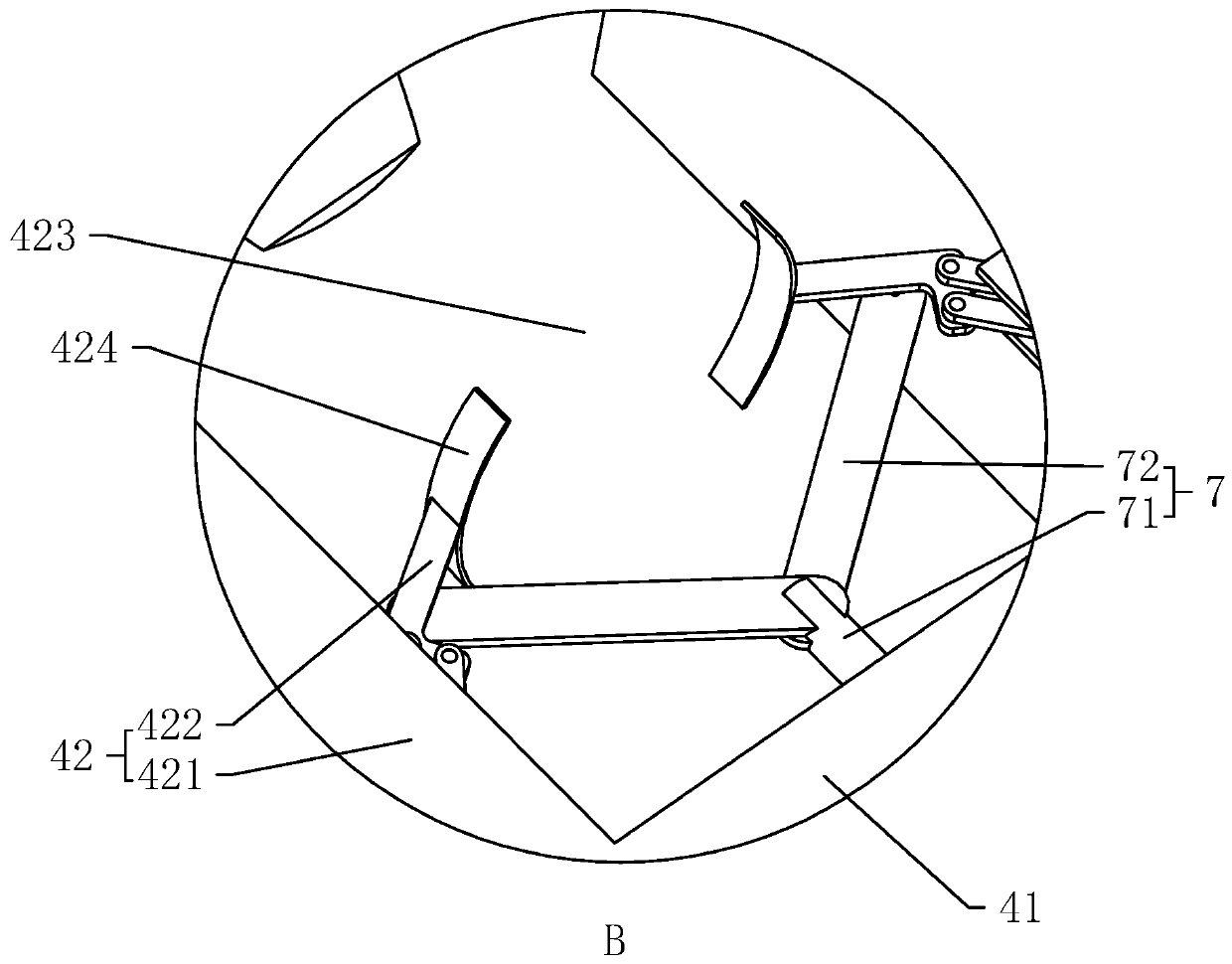

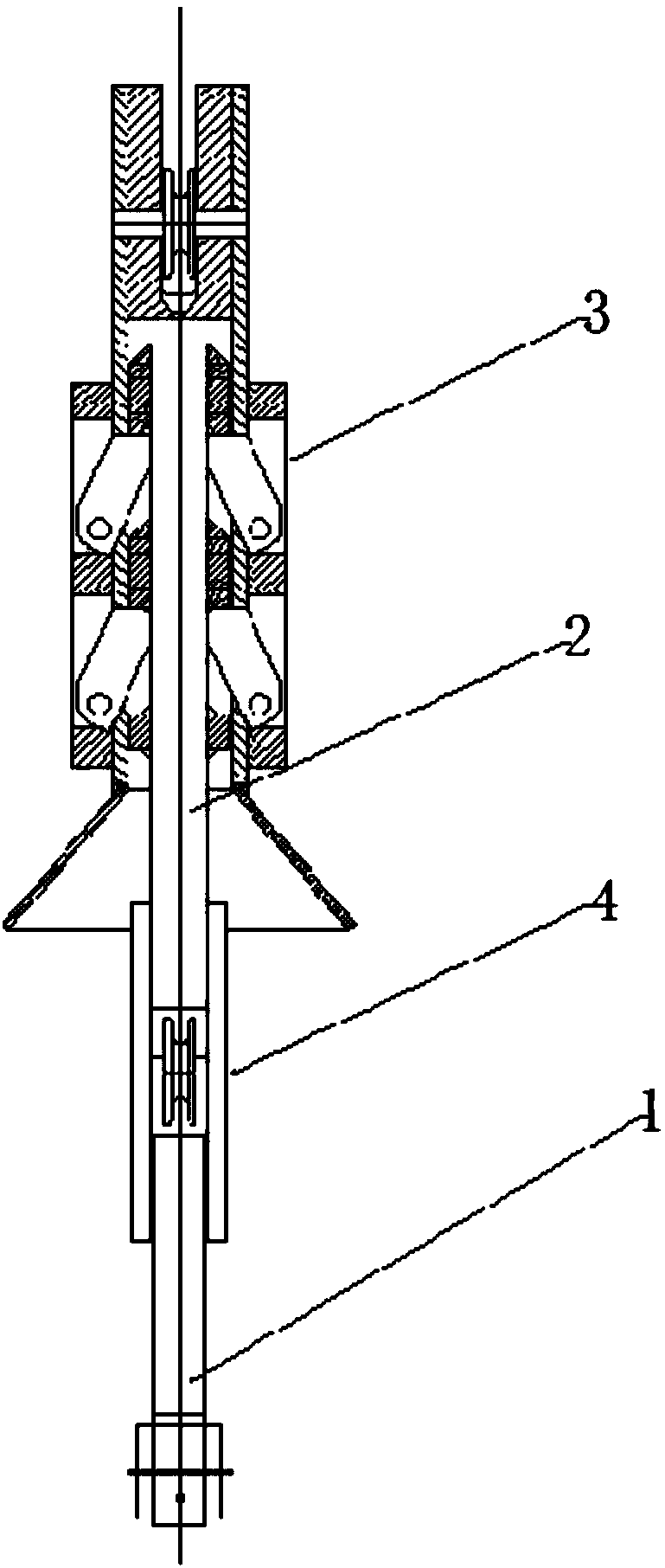

Core pulling machine for smoke conveying pipes

The invention discloses a core pulling machine for smoke conveying pipes, relates to core pulling equipment, and is used for solving the problem of high difficulty of core pulling during production ofrubber pipes. The core pulling machine comprises a bearing frame for bearing the rubber pipes, a positioning frame for fixing the rubber pipes, guiding rails arranged on one side, far away from the bearing frame, of the positioning frame as well as a core pulling device glidingly arranged on the guiding rails; and the core pulling device comprises a sliding frame glidingly arranged on the guidingrails, a clamping mechanism arranged on the sliding frame and used for grasping mold core columns as well as a driving mechanism arranged on the sliding frame and used for driving the sliding frame to move along the guiding rails. The structure that the weight of the rubber pipes and the mold core columns is borne by the bearing frame, then the rubber pipes are fixed by the positioning frame andcore pulling is performed by the core pulling device on the sliding frame finally is adopted, and core pulling operation can be performed on the rubber pipes in various weight and sizes, so that the labor intensity of an operator can be reduced, the operation difficulty caused by the huge sizes of the mold core columns is reduced, and the purpose of facilitating the core pulling operation on the rubber pipes is achieved.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

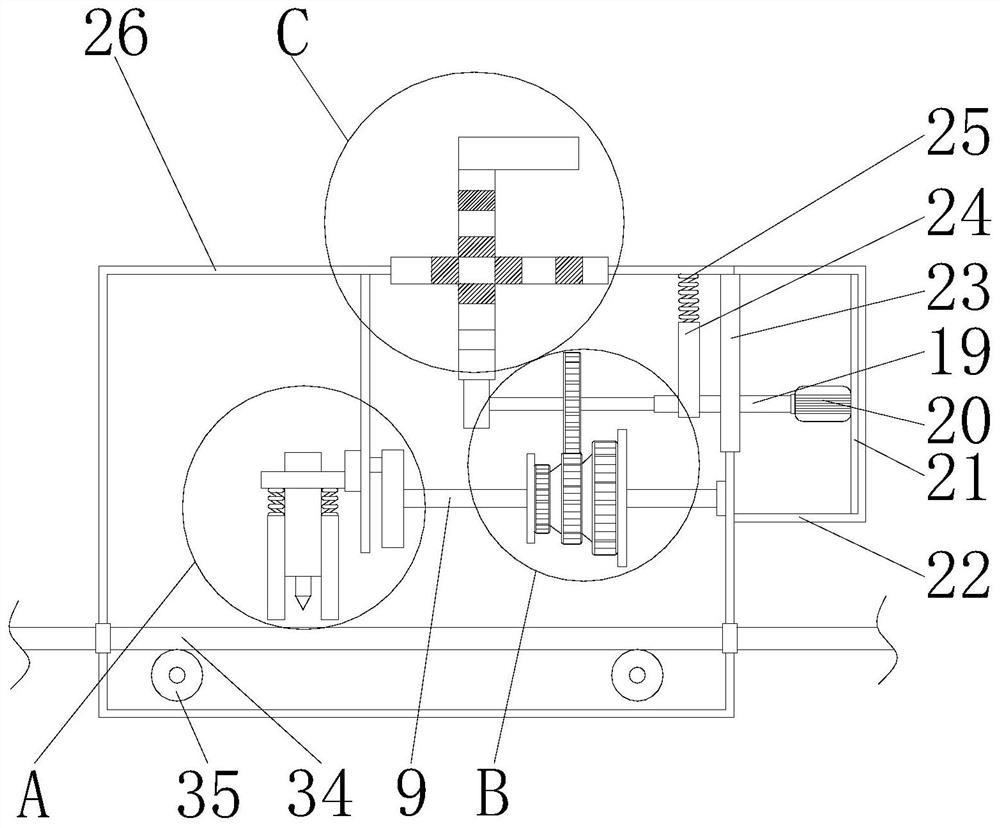

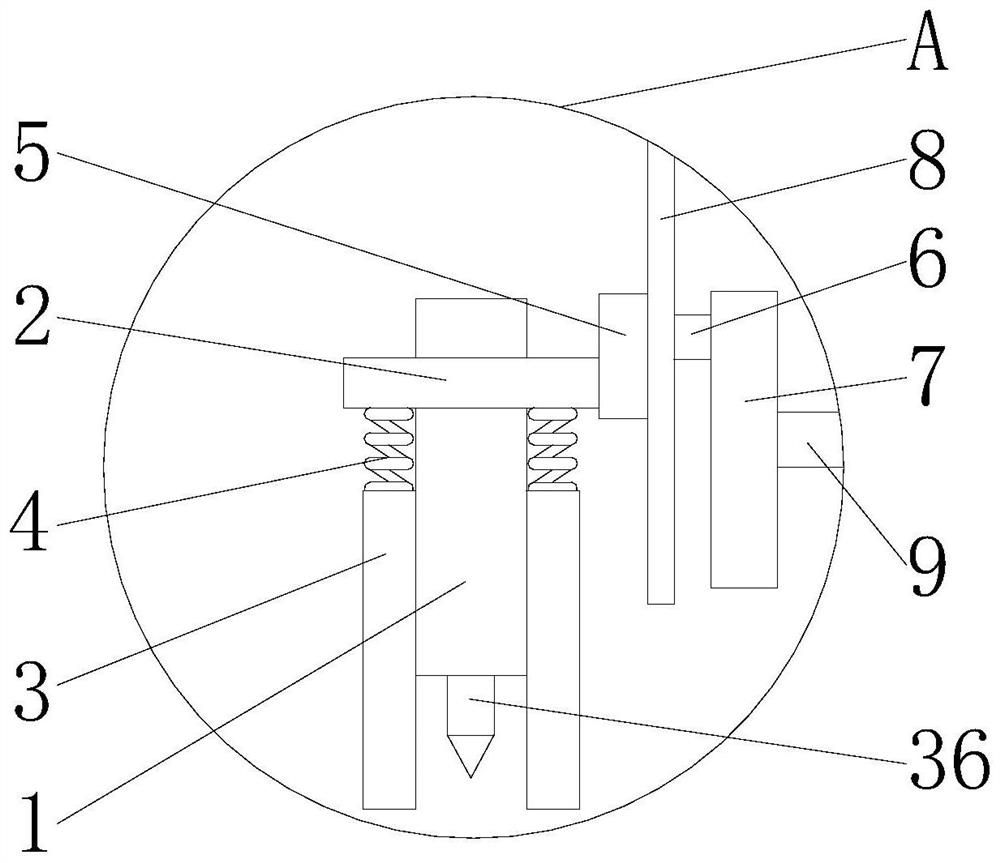

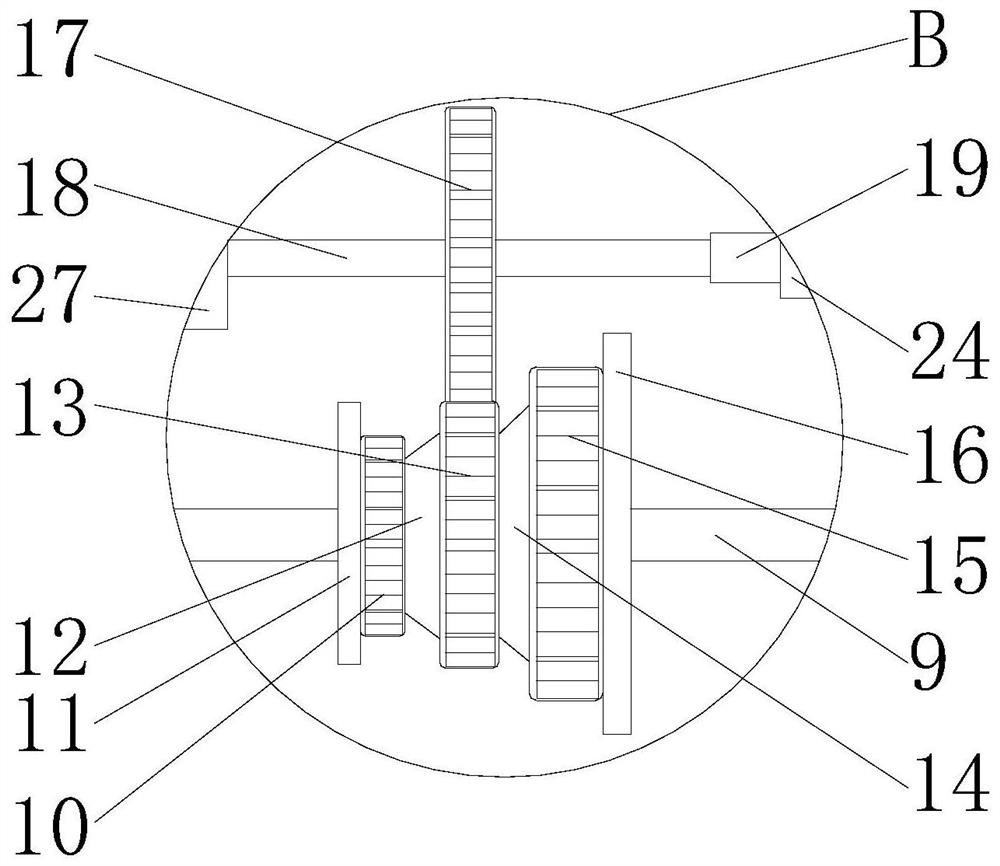

Automatic punching device for engineering paperboard

InactiveCN112743626AImprove work efficiencyAvoid displacement and falling offMetal working apparatusCircular discPunching

The invention discloses an automatic punching device for an engineering paperboard, and relates to the technical field of paperboards. The automatic punching device comprises a punching machine body, wherein the upper end of the punching machine body is fixedly connected with the inner wall of a fixing plate; the outer wall of the left end of the punching machine body is slidably connected with the right ends of sliding plates; the upper ends of the sliding plates are fixedly connected with the lower ends of No. 1 springs; the upper ends of the No. 1 springs are fixedly connected with the left lower end of the fixing plate; and the right end of the fixing plate is fixedly connected with the outer wall of the left end of a hollow rod. According to the automatic punching device for the engineering paperboard, a No. 4 gear is controlled to be engaged with a No. 1 gear, a No. 2 gear and a No. 3 gear through movement of a control rod, so that the rotating speed of a rotating disc can be changed through different gear tooth numbers of the No. 1 gear, the No. 2 gear and the No. 3 gear; and the punching interval can be adjusted by changing the rotating speed of the rotating disc, so that operation needing different punching intervals can be achieved, and the working efficiency of workers is improved.

Owner:江门市恒正自动化设备科技有限公司

High frequency precision harmonic reducer

The invention provides a high frequency precision harmonic reducer. A flexible wheel in a process of being engaged to a cam can counteract and eliminate corresponding vibration, so that vibration of the whole reducer is alleviated, the service life of the whole reducer is prolonged, the noise of the whole reducer is reduced, and the whole reducer is more stable in transmission, more full to engageand improves the precise transmission ability. The high frequency precision harmonic reducer comprises a wave generator, the flexible wheel and a rigid wheel. The flexible wheel comprises a flexibleinner gear, an output flange and a radial connecting part. The wave generator is arranged in an inner mounting cavity of the flexible inner gear. The wave generator comprises an input shaft end and acam. Flexible bearings are annularly distributed between the outer annular circumferential surface of the cam and the inner annular circumferential surface of the flexible inner gear, the cam of the wave generator is specifically of a N-convex structure, N convex ring surfaces are annularly distributed on the outer annular circumference of the cam uniformly, N is a natural number greater than or equal to 2, a progressive transitional annular surface is arranged between two adjacent convex ring surfaces, and the gear part of the flexible inner gear is in engaged connection to a corresponding outer gear of the rigid wheel.

Owner:SUZHOU LEADERDRIVE HARMONIC WAVE TRANSMISSION TECH CO LTD

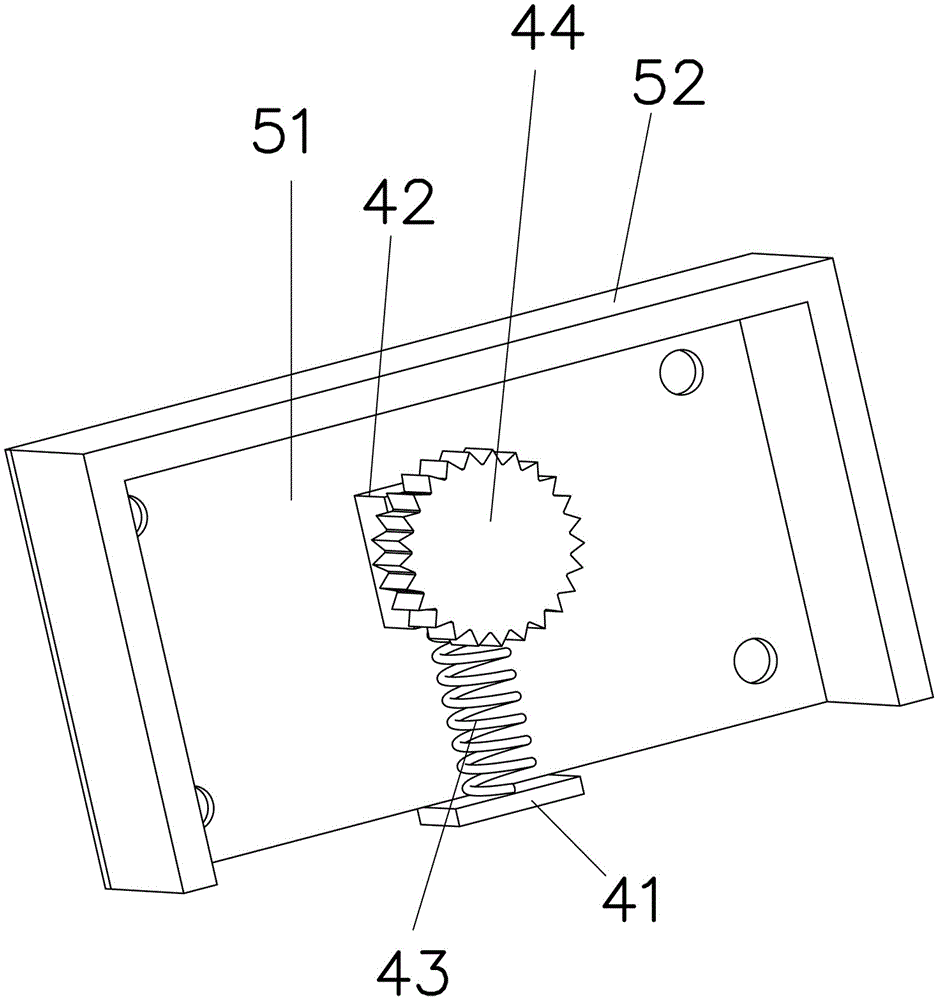

A transmission structure between adjacent conveying rollers

The invention relates to the field of machinery, particularly to an adjacent conveying roller transmission structure. According to the technical scheme, the adjacent conveying roller transmission structure is composed of a frame, two conveying rollers, a first gear, a second gear, a housing and a floating transmission structure, wherein the first gear and the second gear are fixedly connected to the corresponding conveying rollers, the housing is fixedly connected to the frame, and the floating transmission structure is fixedly arranged on the housing. The housing comprises a mounting plate connected to the frame through screws and an abutting plate, which is fixedly connected to the upper portion of one surface of the mounting plate and abuts against the frame on both sides; the floating transmission structure comprises a fixing seat fixedly connected to the low portion of the mounting plate, a floating seat arranged above the fixing seat, springs arranged between the fixing seat and the floating seat, and a third gear which is rotatably connected to the floating seat and engaged with the first gear and the second gear. The adjacent conveying roller transmission structure can effectively avoid jamming of the conveying roller and accordingly improve the stability of an entire conveying system.

Owner:遵化市堡子店兴利铁选厂

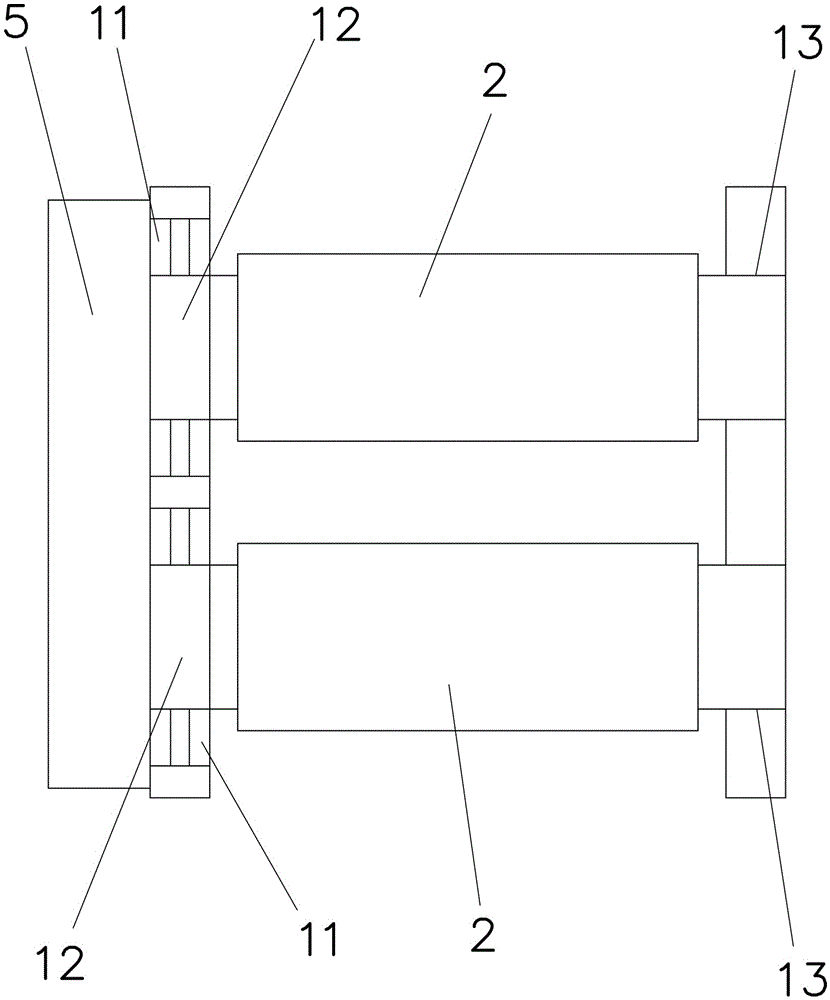

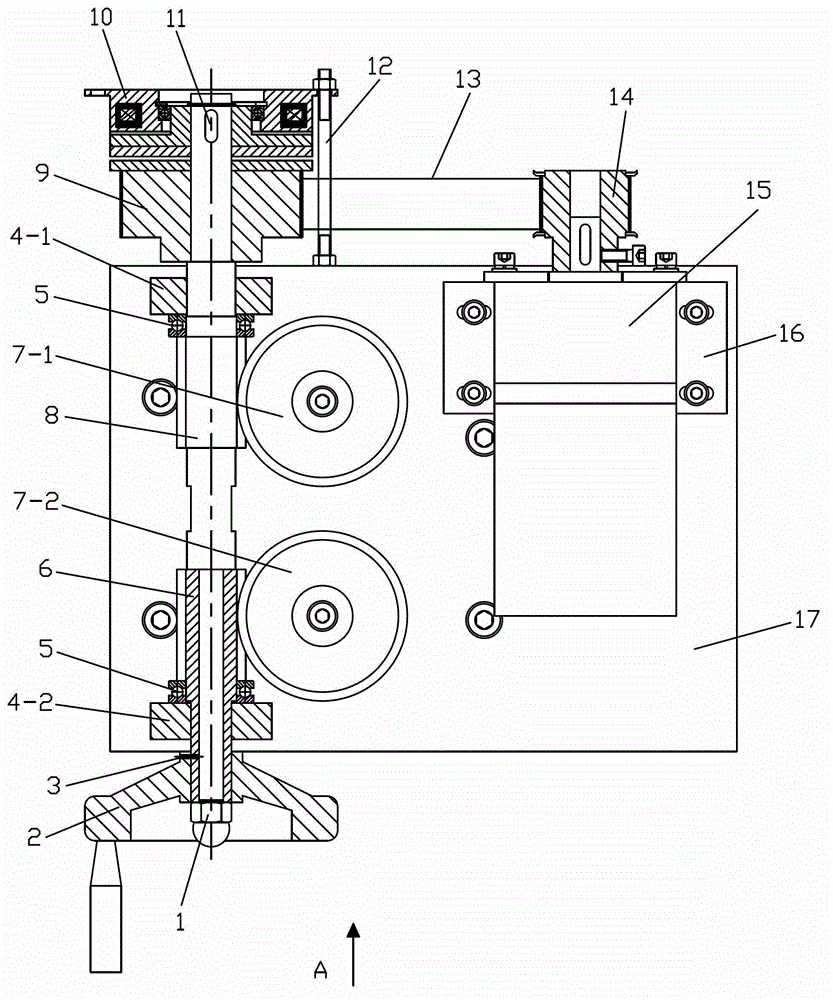

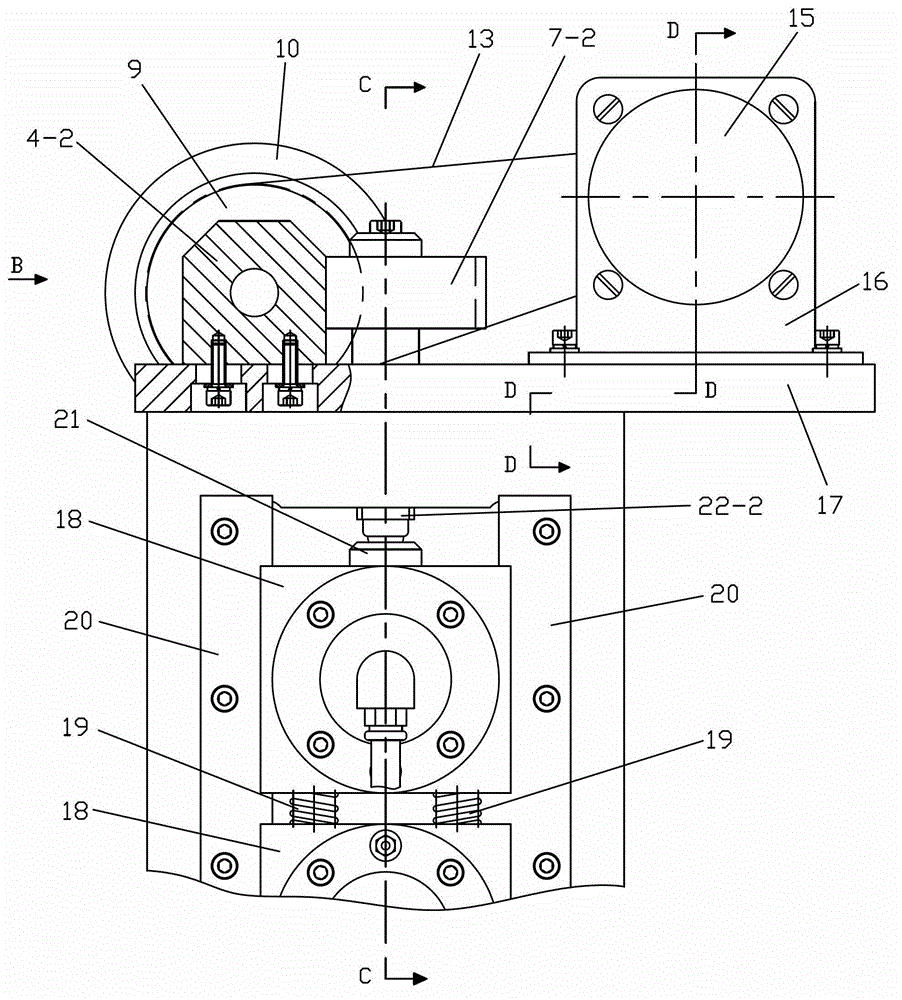

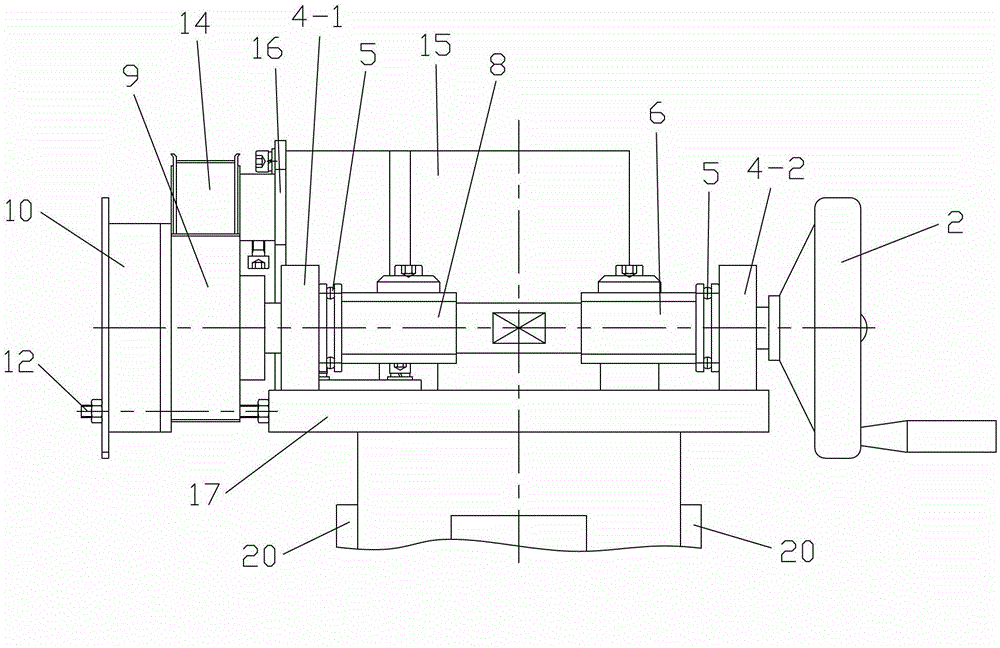

Roller adjusting mechanism of small standard copper belt rolling machine

ActiveCN102909221BCompact structureEasy to useMetal rolling stand detailsMetal rolling arrangementsElectromagnetic clutchEngineering

Owner:THE NORTHWEST MACHINE

Automatic cutter for printer

PendingCN114368023AFully meshedImprove cut paper qualityMetal working apparatusAcute angleComputer printing

The invention provides an automatic cutter for a printer, which comprises a horizontally placed fixed cutter and a circular cutter in sliding connection with the fixed cutter, the fixed cutter inclines downwards and forms an angle less than 90 degrees with the vertical direction, and the front end of the circular cutter along the paper cutting direction is attached to the cutting edge of the fixed cutter. An included angle is formed between the rear part of the cutter blade and the cutting edge of the fixed cutter and is an acute angle; according to the automatic cutter, a certain included angle is formed between the circular cutter body and the fixed cutter body, the circular cutter body and the fixed cutter body are meshed more sufficiently, the paper cutting quality can be improved, parts are reduced, assembling is easy and convenient, the requirements for part machining and manufacturing precision are lower, and the service life is longer.

Owner:XIAMEN RONGTA TECH

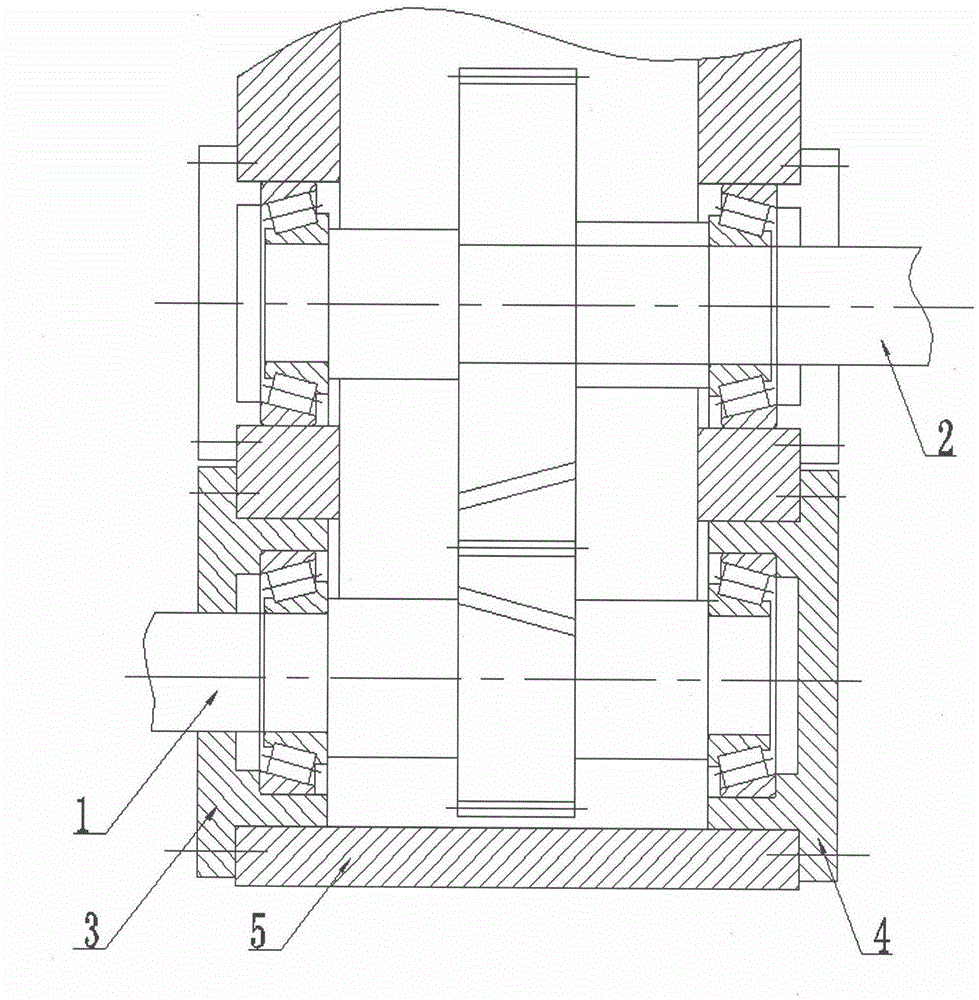

Planetary Mechanism Load Equalization System

ActiveCN105134885BAvoid running delaysFully meshedToothed gearingsGearing detailsGear wheelEngineering

The invention discloses a uniform load system of a planet mechanism. The uniform load system comprises a synchronous uniform load mechanism which is in transmission connection to the part among planet wheels in the planet mechanism and is used for synchronously adjusting the positions of the planet wheels to achieve the uniform load. According to the uniform load system of the planet mechanism, after the planet wheels are adjusted to be sufficiently engaged with an inner gear ring and a sun wheel, the synchronous uniform load mechanism is arranged, and the planet wheels synchronously rotate. Accordingly, sufficient meshing among the planet wheels, the inner gear ring and the sun wheel is kept, a meshing gap between the planet wheels in the planet mechanism is eliminated, and the running delay of the planet wheels is avoided.

Owner:CHONGQING UNIV

Sullage soft soil solidifying base layer external force fracturing repairing method

InactiveCN107447742AImprove integrityHigh strengthSoil preservationSoil scienceUltimate tensile strength

The invention discloses a sullage soft soil solidifying base layer external force fracturing repairing method. According to the sullage soft soil solidifying base layer external force fracturing repairing method, in the repairing method, good connecting and fusion effects are formed between sullage soft soil used for filling and a sullage soft soil solidifying base layer by arranging a strip-shaped slot, so that the integrality of the repaired sullage soft soil solidifying base layer is higher, and the integral strength of the repaired sullage soft soil solidifying base layer is also be improved; and meanwhile, modulating is conducted on the sullage soft soil based on the volume of the strip-shaped slot, a lot of overflowing phenomena can be avoided in the repairing process of the sullage soft soil, and the sullage soft soil can be in full reaction and mesh with the sullage soft soil solidifying base layer better through heating processing on filler.

Owner:JIANGSU NATURE WAY TECH

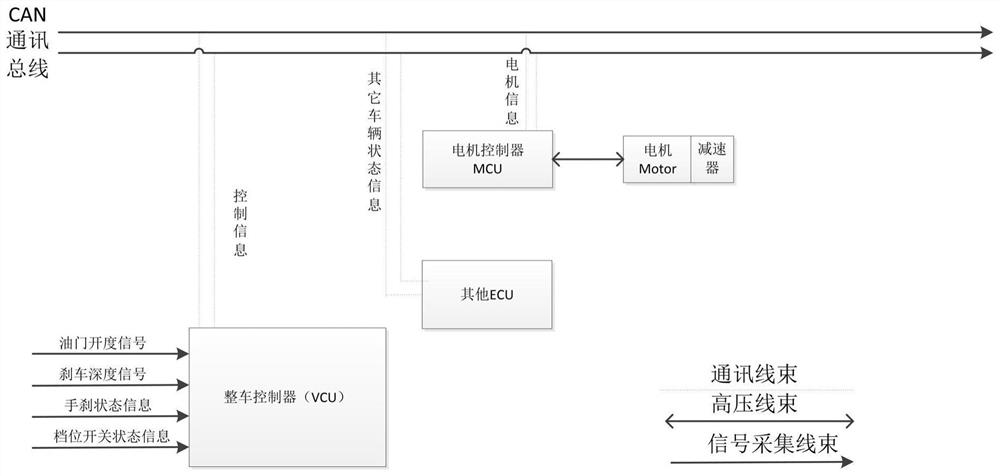

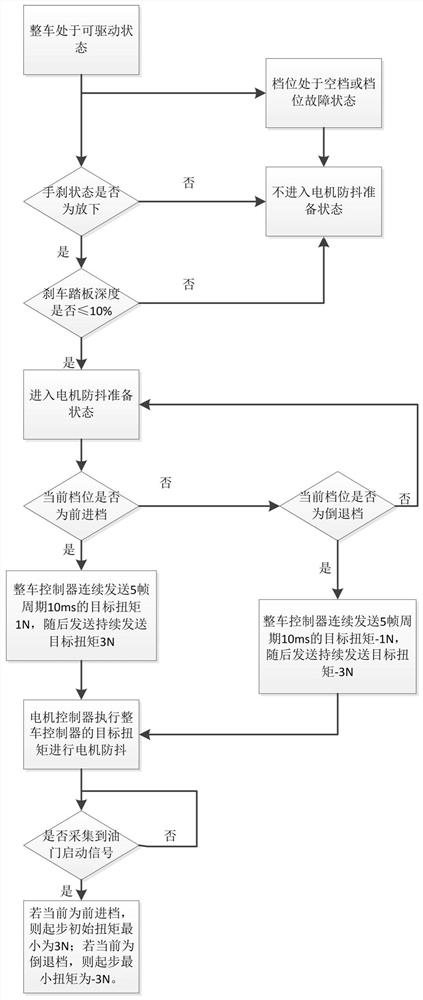

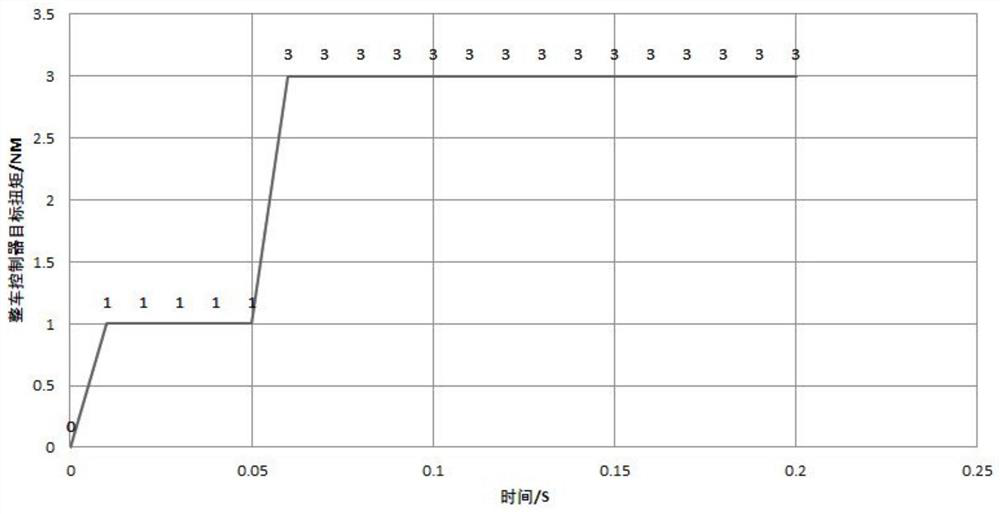

Anti-vibration control method for a motor of a hydrogen fuel cell vehicle

ActiveCN111942173BAnti-shake control implementationAnti-shake control process is simpleSpeed controllerElectric devicesCar drivingDriver/operator

The invention discloses an anti-vibration control method for a motor of a hydrogen fuel cell vehicle. The anti-shake control method includes: the vehicle controller recognizes the driver's operation intention, and judges according to the operation intention whether the vehicle has the conditions for entering the motor anti-shake preparation state; when the conditions for entering the motor anti-shake preparation state are met, the vehicle The controller judges whether the motor needs anti-shake processing according to the collected accelerator opening signal, brake depth signal, gear switch state signal, handbrake state signal and vehicle state information; when it is judged that the motor needs anti-shake processing, the whole The vehicle controller sends a target torque signal to the motor controller, and the motor controller controls the motor to execute the target torque. This method is based on the car's own vehicle controller and motor controller to realize the anti-shake of the motor. The anti-shake control process is simple and does not require additional hardware costs; this method has high reliability and can effectively prevent the motor from shaking and protect the car. Continuity and comfort of driving.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

Running positioning device for double-beam trolley of crane

The invention relates to a running positioning device for a double-beam trolley of a crane. The device is characterized by comprising a holder and a support shaft installed on the holder, wherein two ends of the support shaft are respectively fixedly provided with a gear and rotatable counter, a rack engaged with the gear is fixed mounted on a crane girder, the holder includes an upper holder and a lower holder, the upper holder is fixed on an end beam of the trolley, the left end at a lower part of the upper holder is hinged with the left end at an upper part of the lower holder, the right end at the lower part of the upper holder is connected to the right end at the upper part of the lower holder through a bolt, the bolt is sleeved by a spring which is arranged between the upper and the lower holders, and the support shaft is mounted on the lower holder. The invention transmits the signal to a control system through the rotatable counter catching the engagement tooth number of the gear and the rack, and the control system performs frequency conversion to an electrical machine based on the signal and the actual measurement residual distance signal, the speed gradually reduces from high to a predetermined position, the electrical machine powers off, the trolley stably stops; and the connection mode of the upper and the lower holder ensures the gear and the rack to fully engage through the up and down fluctuation of the lower holder under the condition of unsmooth contact surface of the girder and the rack.

Owner:杨秀杰

Temporary manufacturing and machining equipment for gear for improving matching degree

In order to solve the problem that the matching degree of gears is not easy to increase in the prior art, the invention discloses temporary manufacturing and machining equipment for a gear for improving the matching degree. The temporary manufacturing and machining equipment for the gear for improving the matching degree comprises a first gear, a second gear and a connecting frame; the connectingframe is arranged between the first gear and the second gear; a second connecting rod and a first connecting rod are separately welded to the left side face and the right side face of the connecting frame; a first connecting ring is connected between the first connecting rod and the first gear; a second connecting ring is connected between the second connecting rod and the second gear; material containing films are symmetrically packaged in the connecting frame; and a first supporting shaft is welded to the surface of the first connecting rod. According to the invention, extrusion on the material containing film is reasonably utilized, and the gap between the gears is filled with materials in the material containing film, therefore the gear matching degree is improved; and the temporary manufacturing and machining equipment for the gear for improving the matching degree is suitable for being used for the gears of various damaged shapes, which avoids the situation that the gear falls off due to the fact that the gear damage is not found in time, and greatly improves the gear operation safety.

Owner:呼和牧仁

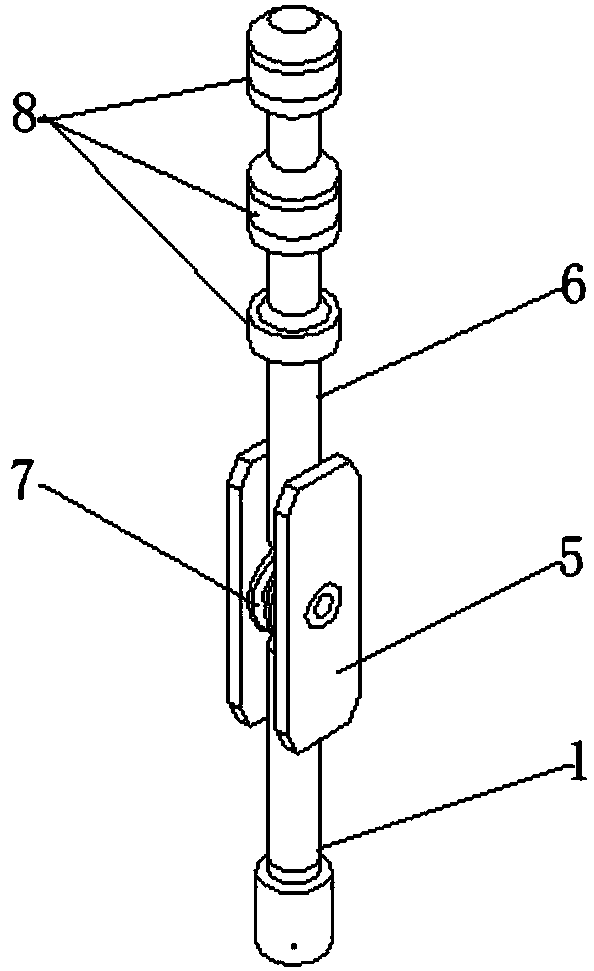

Hammer head salvage connection structure and hammer head salvage device

PendingCN108086321ADoes not affect mating connectionsImprove fishing efficiencyBorehole/well accessoriesBulkheads/pilesEngineeringElectrical and Electronics engineering

The invention provides a hammer head salvage connection structure and a hammer head salvage device. The hammer head salvage connection structure comprises a salvage connecting member arranged on a hammer body, and the hammer body is connected with a hanging rope through a hanging structure; and during the working state, a position, higher than the hanging structure, on the salvage connecting member is provided with a first connecting portion cooperatively connected with a salvage hanging tool. The first connecting portion is arranged on the position, higher than the hanging structure, on the salvage connecting member so as to avoid the problem that sediment covers the salvage connecting member to the greatest extent; and even if the hanging rope breaks, the remaining hanging rope is located below the salvage connecting member, cooperative connection between the salvage hanging tool and the salvage connecting member cannot be affected, and the salvage efficiency is high.

Owner:NENGCHENG GRP

A flue gas conveying pipe core pulling machine

The invention discloses a core-pulling machine for flue gas conveying pipes, which relates to core-pulling equipment and is used to solve the problem of difficult core-pulling in the rubber hose production process, including a bearing frame for carrying the rubber hose, a positioning frame for fixing the rubber hose, The guide rail arranged on the side of the positioning frame away from the bearing frame, the core-pulling device slidably arranged on the guide rail, the core-pulling device includes a slide frame set on the guide rail, set on the slide frame and used to grab the mold The clamping mechanism of the core column, the driving mechanism set on the sliding frame and used to drive the sliding frame to move along the guide rail; the weight of the rubber hose and the mold core column is borne by the carrier frame, and the rubber tube is fixed by the positioning frame, and finally the sliding frame The core-pulling structure of the upper core-pulling device can perform core-pulling operations on rubber hoses of various weights and sizes, which can reduce the labor intensity of the operator and reduce the difficulty of the operation caused by the huge volume of the mold core column, so as to achieve The purpose of facilitating the core-pulling operation of the rubber hose.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

Wave generator, harmonic reducer and transmission system

The invention relates to the technical field of speed reducers, and particularly provides a wave generator, a harmonic reducer and a drive system. The wave generator comprises a cam and a flexible neutral layer, wherein an outer edge outline molded line of the cam comprises a first molded line located in a meshing area and a second molded line located in a non-meshing area; the second molded line is a cosine cam molded line; the first molded line has radial increment compared with the second molded line, so that the polar radius, located in the meshing area, of the cam is increased; and the first molded line and the second molded line are continuously and guidably connected in a transition way. According to the wave generator, the harmonic reducer and the drive system provided by the invention, through increasing the polar radius of the meshing area, the radial deformation amount, in a meshing area, of a flexible wheel is increased, flexible wheel teeth and rigid wheel teeth located at a semi-meshing state are sufficiently meshed, and the meshing tooth number of the meshing area is correspondingly increased, so that the meshing stress of the flexible wheel teeth is reduced, and a bearing capacity of the speed reducer is improved.

Owner:合肥凯邦电机有限公司 +2

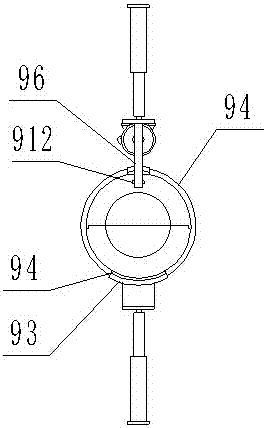

A pig feed conveying device

ActiveCN105230512BAvoid mixingGuaranteed qualityAnimal feeding devicesCleaningCable trayMechanical equipment

The invention discloses a pig feed conveyor. The pig feed conveyor comprises a feeding pipe, troughs, discharge pipes, a conveying chain, cable trays, a material tower and a driving device. A horizontal pipe segment of the feeding pipe is provided with a cable tray cleaning device. The cable tray cleaning device comprises an upper drum and a lower drum, both of which are capable of adjusting upwards and downwards. Hairbrushes are arranged in drums. Open slots are arranged in drum walls. The outer walls of the drums are provided with tooth rings and guide rail rings. When the upper drum and the lower drum are combined as an overall body, the conveying chain and the cable trays are cleaned by means of the hairbrushes. The pig feed conveyor has following beneficial effects: the pig feed conveyor is capable of cleaning the conveying chain and the cable trays on a regular basis in order to prevent caked feed caused by mildew from mixing into fresh feed, thereby ensuring quality of feed and reducing abrasion of attachments to a sprocket wheel; therefore, the conveying chain is fully engaged with a sprocket wheel in order to ensure working stability of mechanical equipment and reduce maintenance frequency of equipment; and the pig feed conveyor is worth prompting and applying.

Owner:云南东恒经贸集团猪育种有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com