Inter-shaft central distance adjusting mechanism

A technology for adjusting the mechanism and center distance, which is applied in the direction of mechanical equipment, transmission parts, components with teeth, etc., can solve the problems of increased meshing gap, affecting transmission accuracy, and difficulty in adjusting the center distance between shafts. Achieve the effect of adjusting assembly accuracy and making up for processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

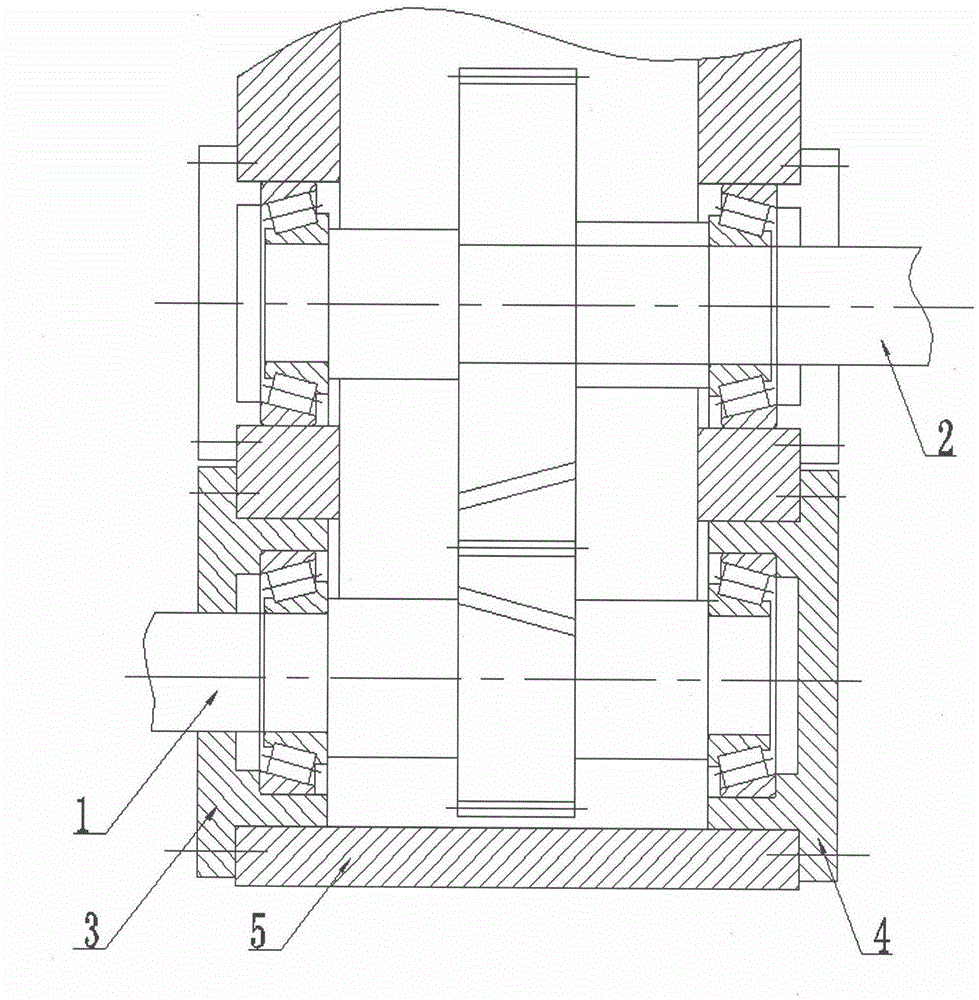

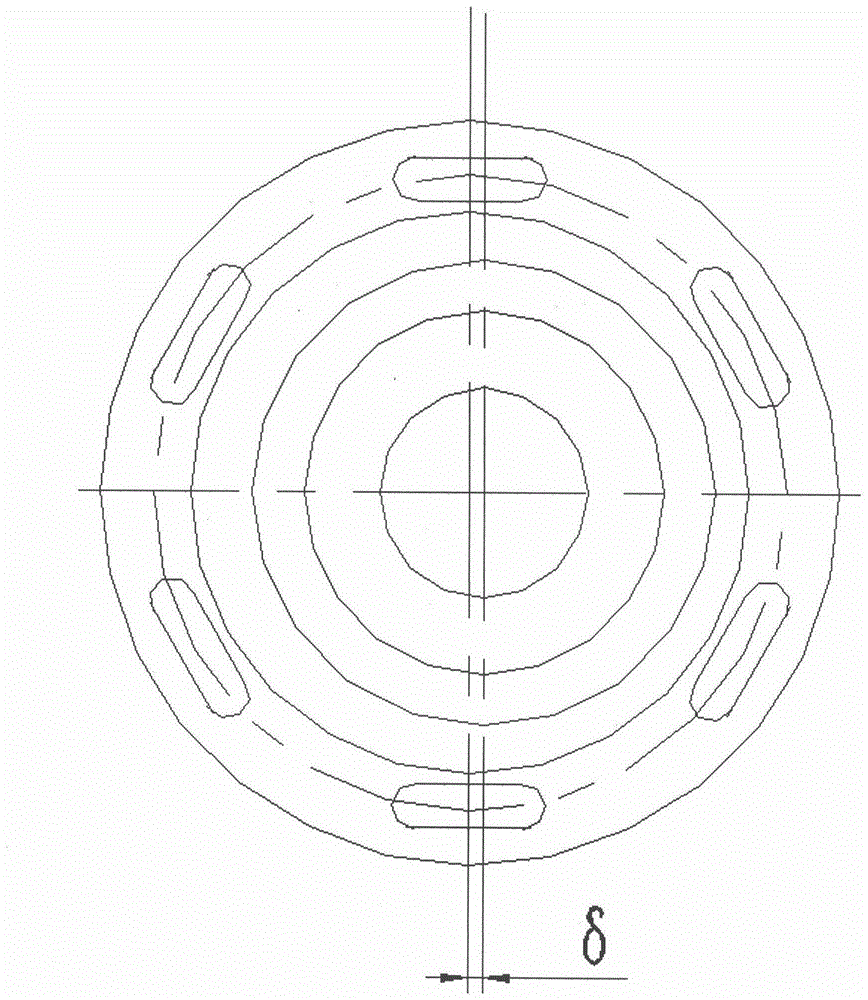

[0012] Such as figure 1 As shown, the present invention provides a center distance adjustment mechanism between shafts, which includes a driving shaft 1 and a driven shaft 2, and the two ends of the driving shaft are respectively installed on two driving bearing seats 3, 4, as shown in figure 2 As shown, the inner surfaces of the two active bearing seats are non-concentric cylindrical surfaces, and there is an eccentricity δ between them.

[0013] Such as figure 1 As shown, the inter-shaft center distance adjustment mechanism is installed in the box body 5 .

[0014] In gear transmission or worm gear transmission, due to the existence of machining accuracy and assembly accuracy, it is difficult to ensure that the center distance meets the design requirements, thus affecting the transmission accuracy. The adjusting mechanism of the center distance between shafts of the present invention can realize micro-adjustment of the center distance, compensate for processing errors, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com