Patents

Literature

79results about How to "Realize micro-adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

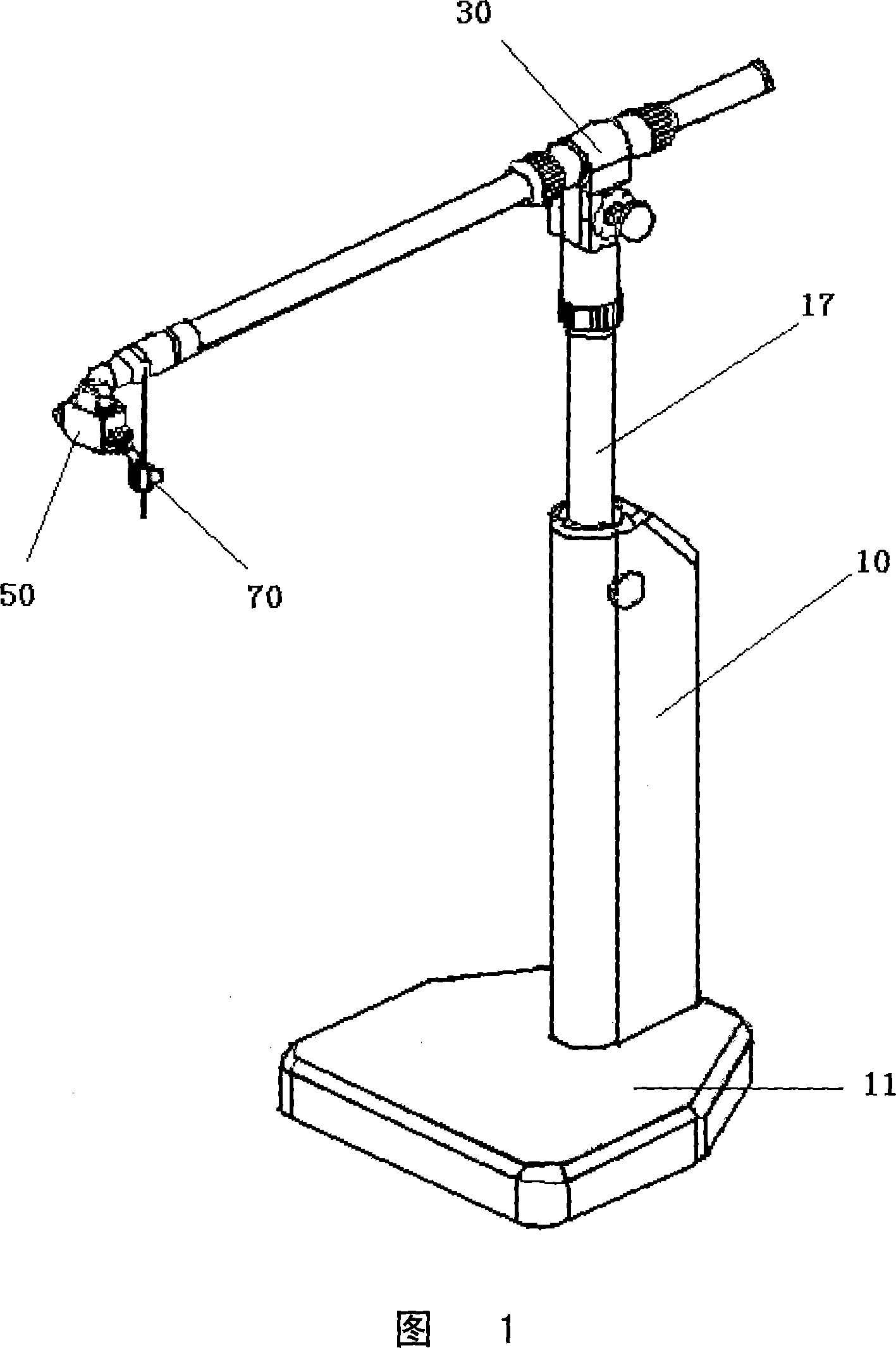

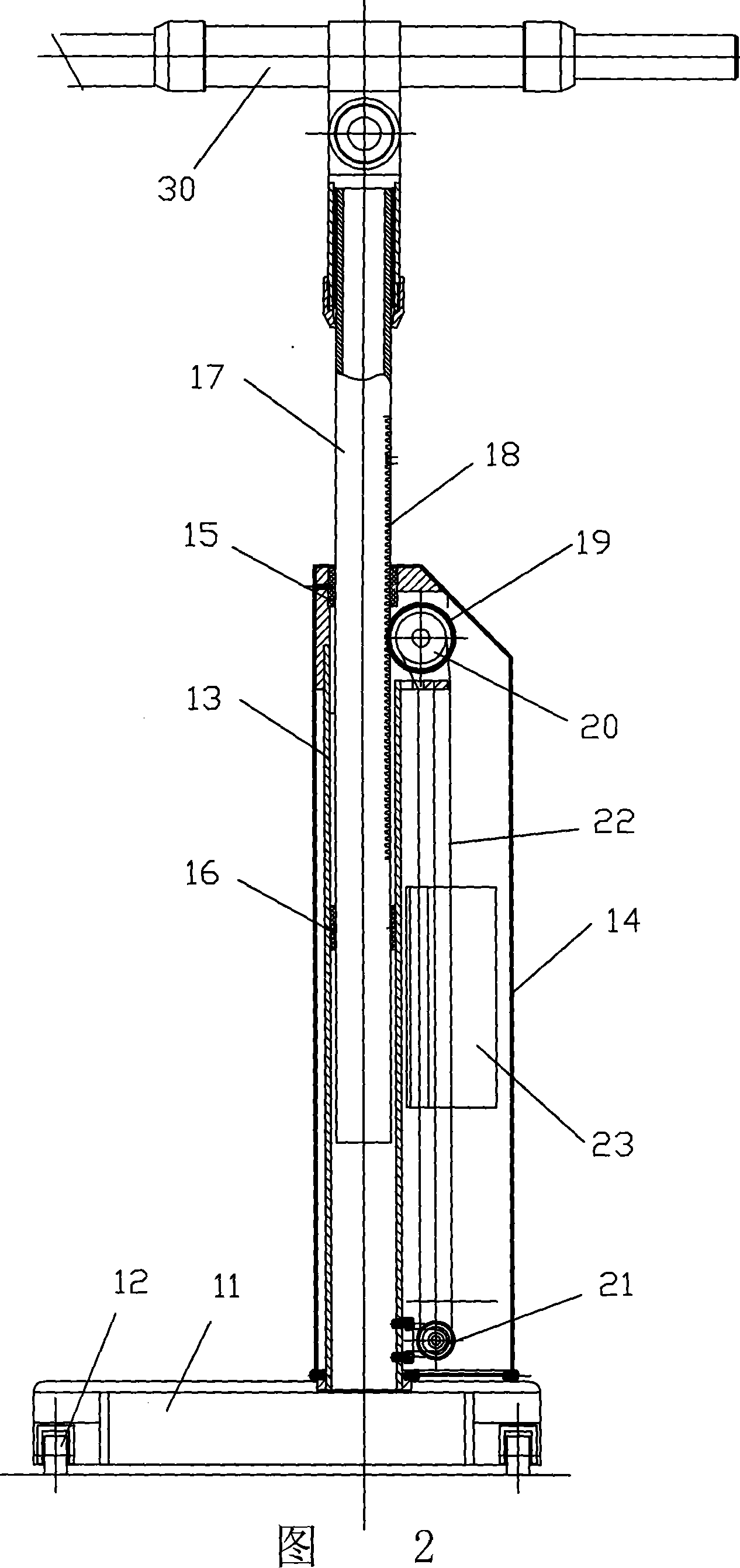

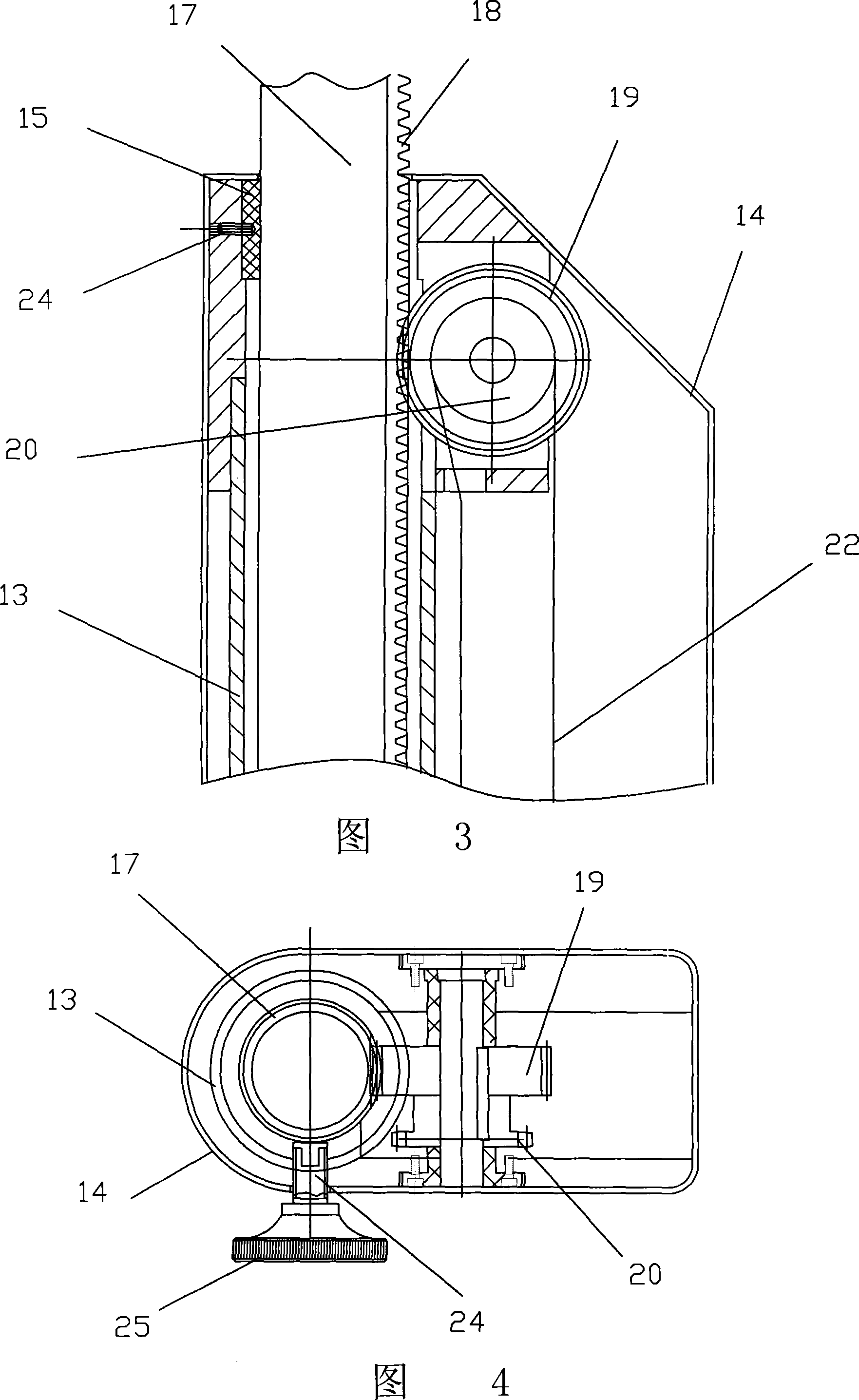

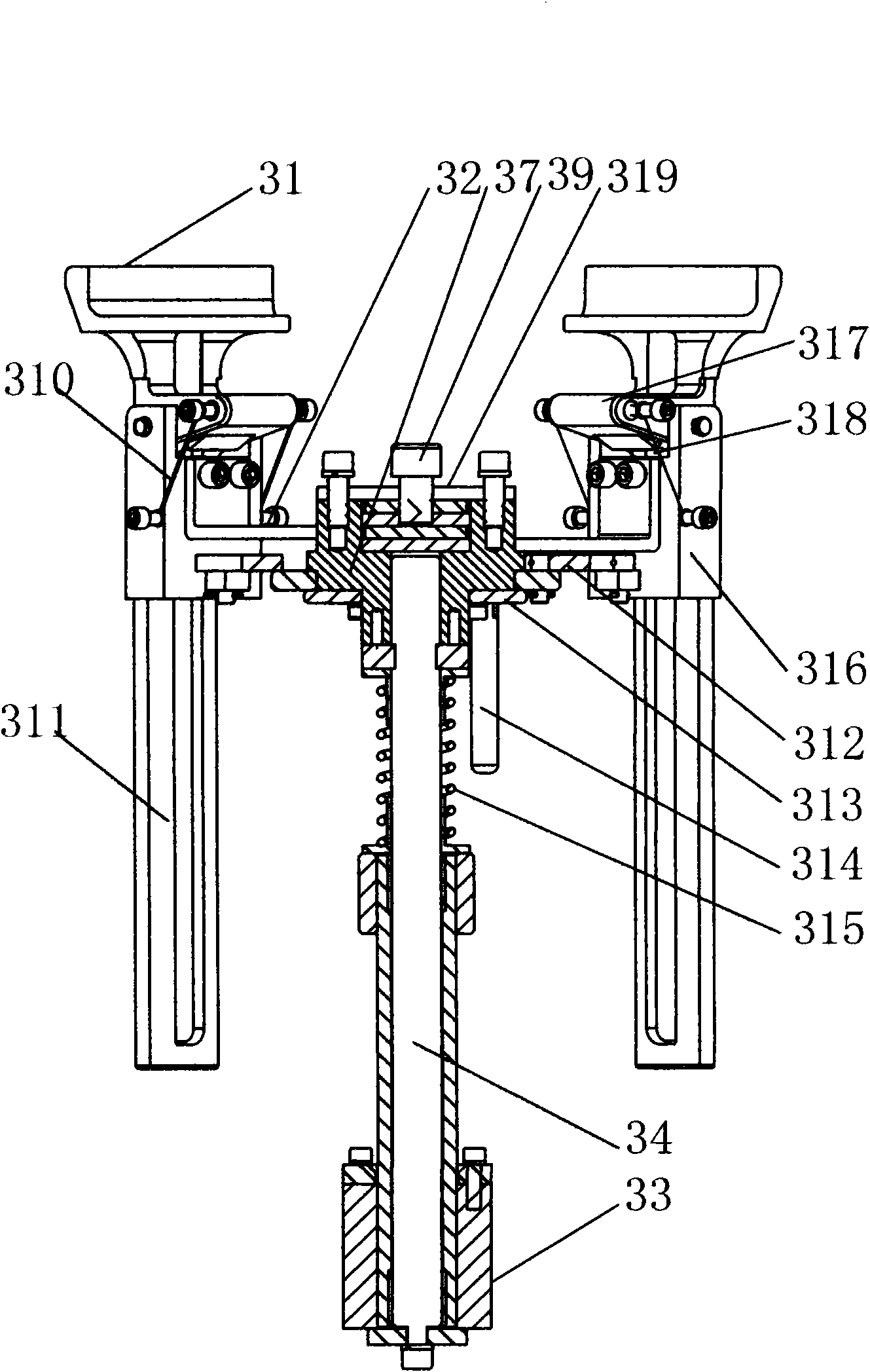

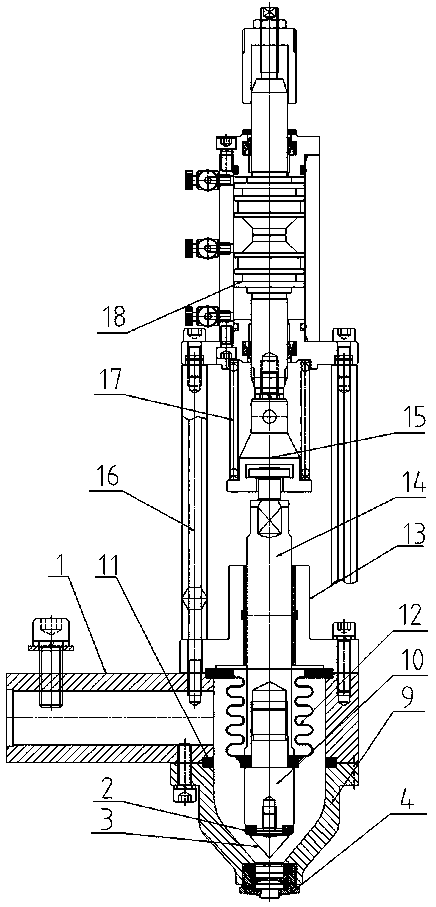

Interventional operation equipment guiding instrument

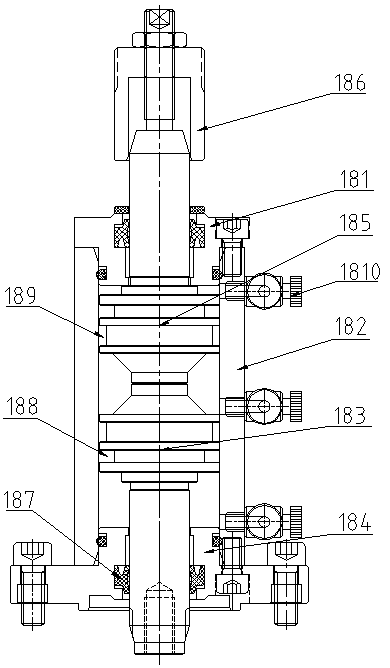

The interventional operation equipment guiding instrument includes one lower support assembly, one upper crossbeam assembly, one angle regulator assembly, and one interventional guide assembly. The lower support assembly includes one bottom seat, one vertical pipe and one upper support pipe; the upper crossbeam assembly includes one T-shaped adaptor, one crossbeam and one union; the angle regulator assembly includes one casing, one spherical shaft, screws and nuts, one hand wheel and one transition board; and the interventional guide assembly includes one outer support, one inner support and one puncture needle. The present invention has at least 10 regulating freedom degrees for aligning the puncture needle to the disease focus and inserting the puncture needle into the disease focus accurately.

Owner:SYMBOW MEDICAL TECH

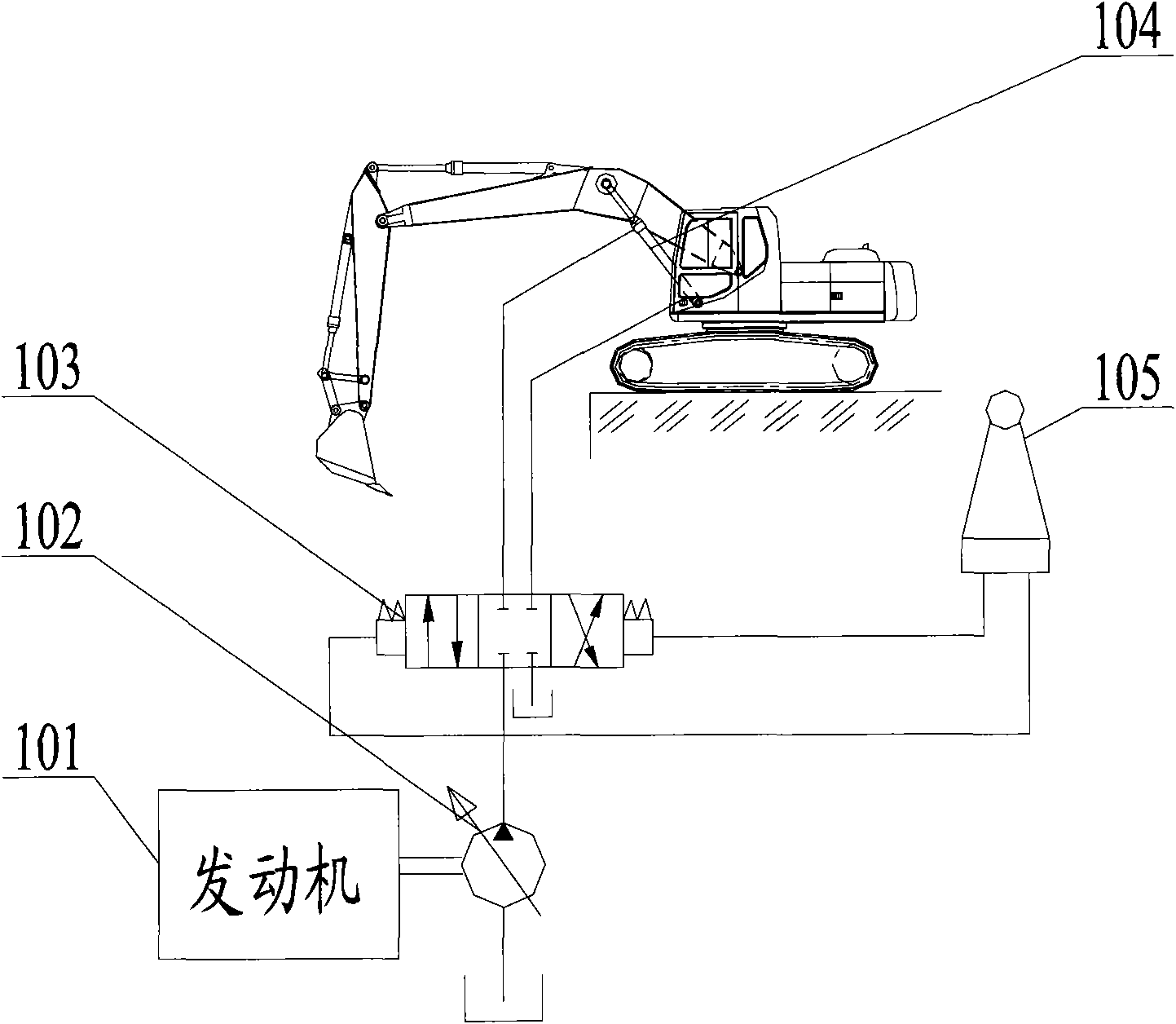

Method and device for detecting efficiency parameters of hydraulic system and engineering machinery having the device

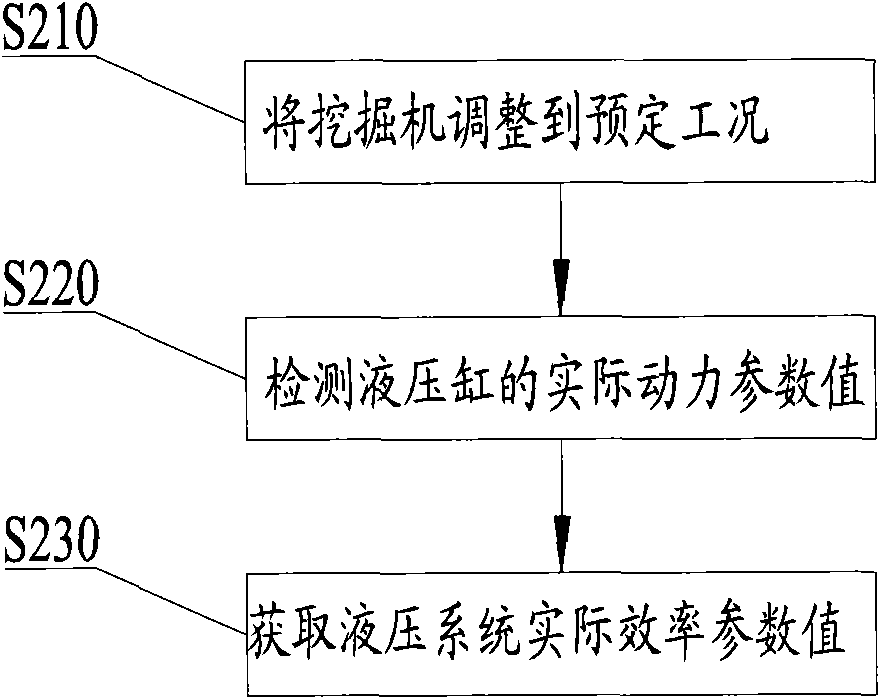

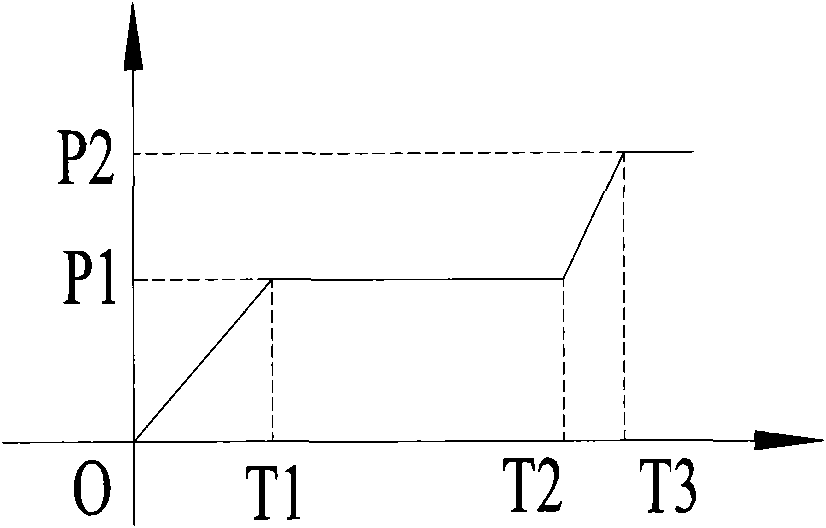

ActiveCN101603559ALarge displacementIncrease the total traffic baseFluid-pressure actuator testingSoil-shifting machines/dredgersPower parameterControl engineering

The invention discloses a method and a device for detecting efficiency parameters of a hydraulic system, and engineering machinery having the device for detecting efficiency parameters of a hydraulic system. The method for detecting efficiency parameters of the hydraulic system comprises: detecting actual power parameter values output by a hydraulic actuator of the hydraulic system; obtaining actual efficiency parameter values according to the actual power parameter values, a predefined power parameter value and a predefined hydraulic system efficiency parameter value, wherein the predefined hydraulic system efficiency parameter value is efficiency parameter value under predefined use state and predefined working condition. Having the device for detecting efficiency parameters of a hydraulic system, a control device of the engineering machinery is capable of calibrating and correcting the control datum, according to actual efficiency parameter values of the hydraulic system obtained through real-time detection, thereby realizing micro-adjustment to the engineering machinery, improving reliability and efficiency of fine action, and guaranteeing quality of fine operation.

Owner:SANY HEAVY IND CO LTD (CN)

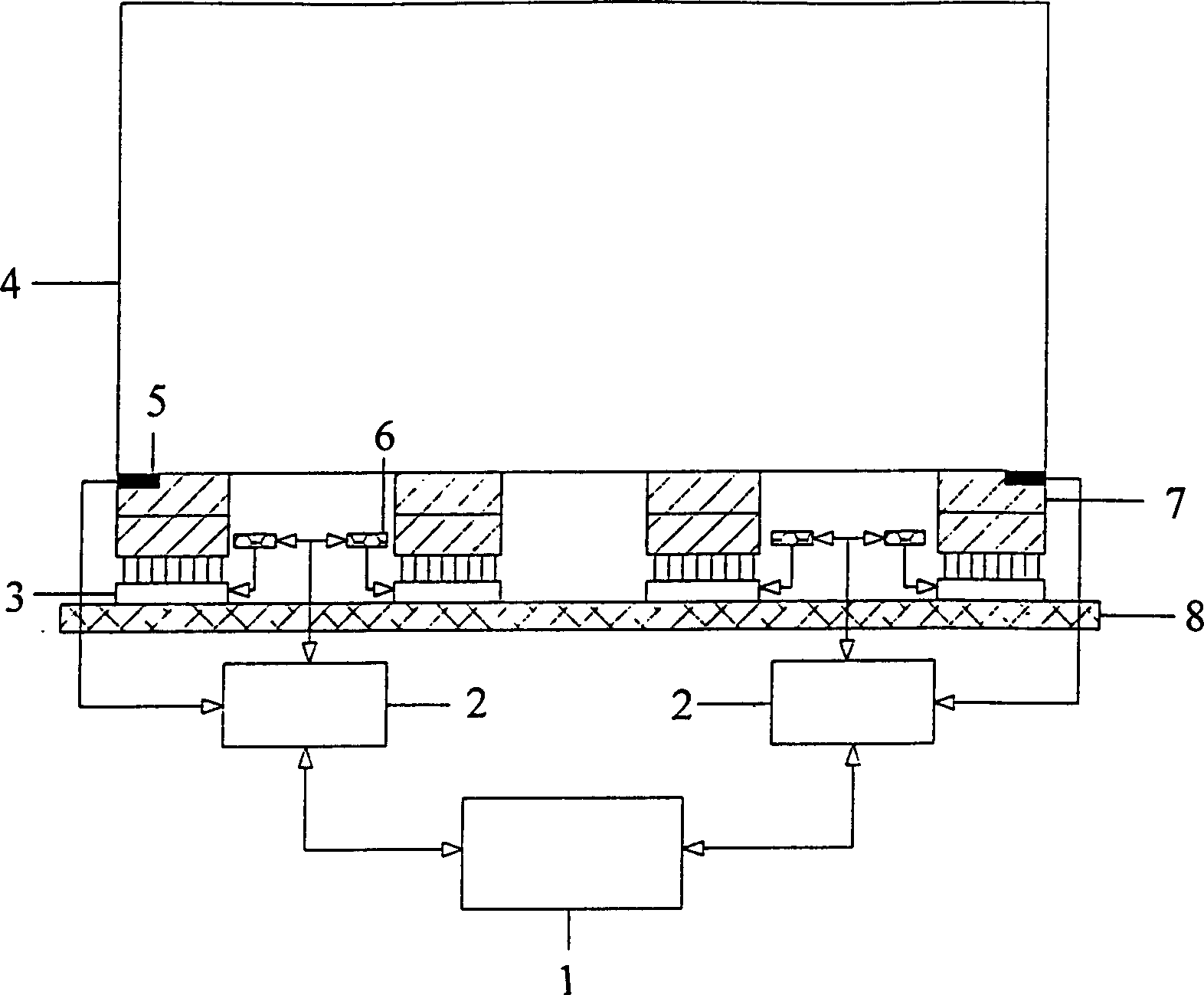

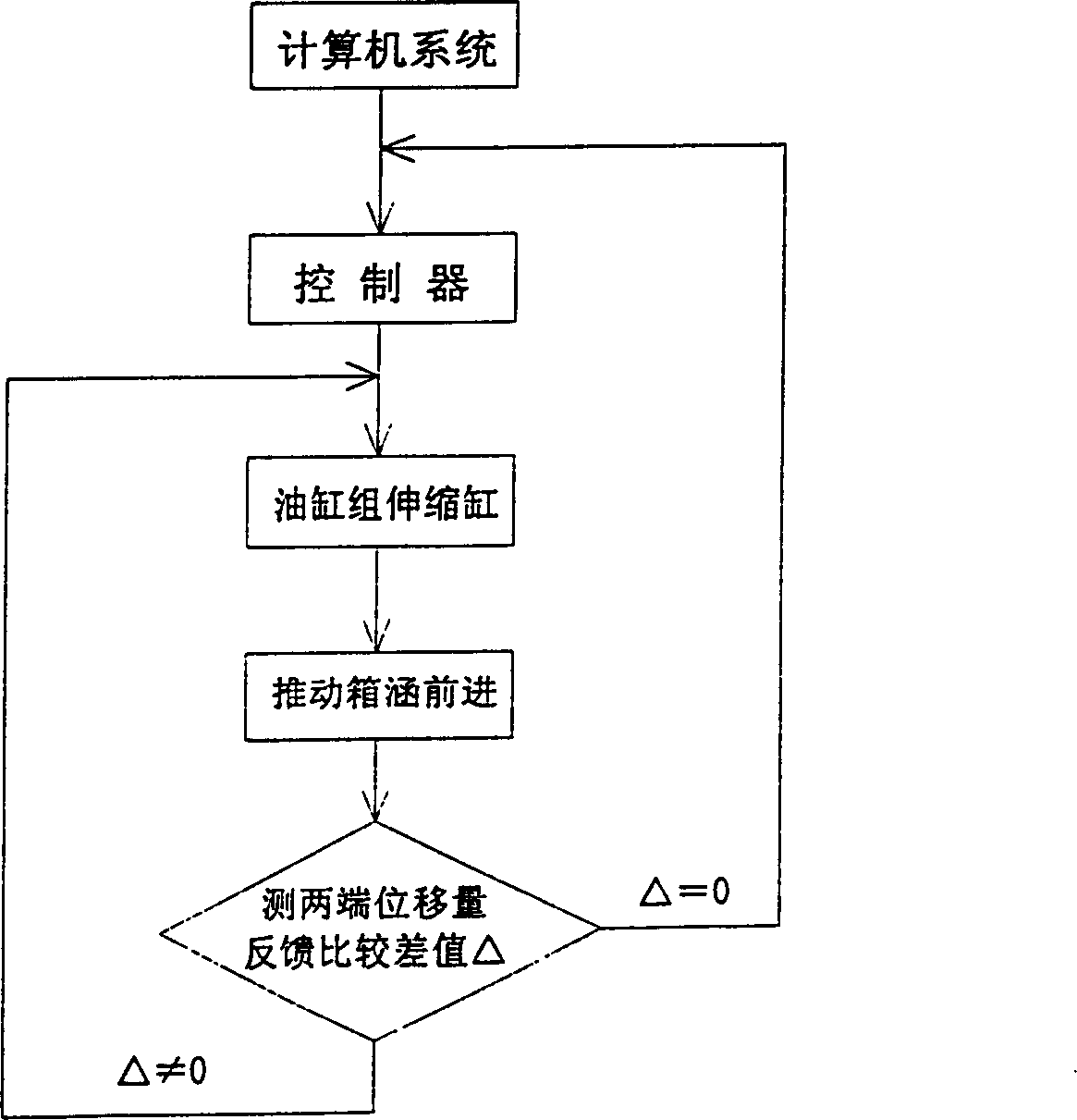

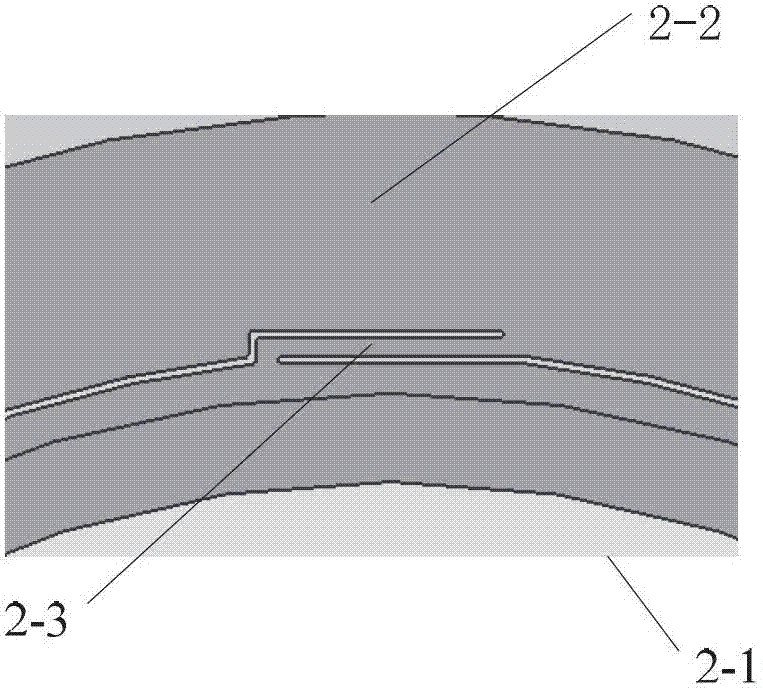

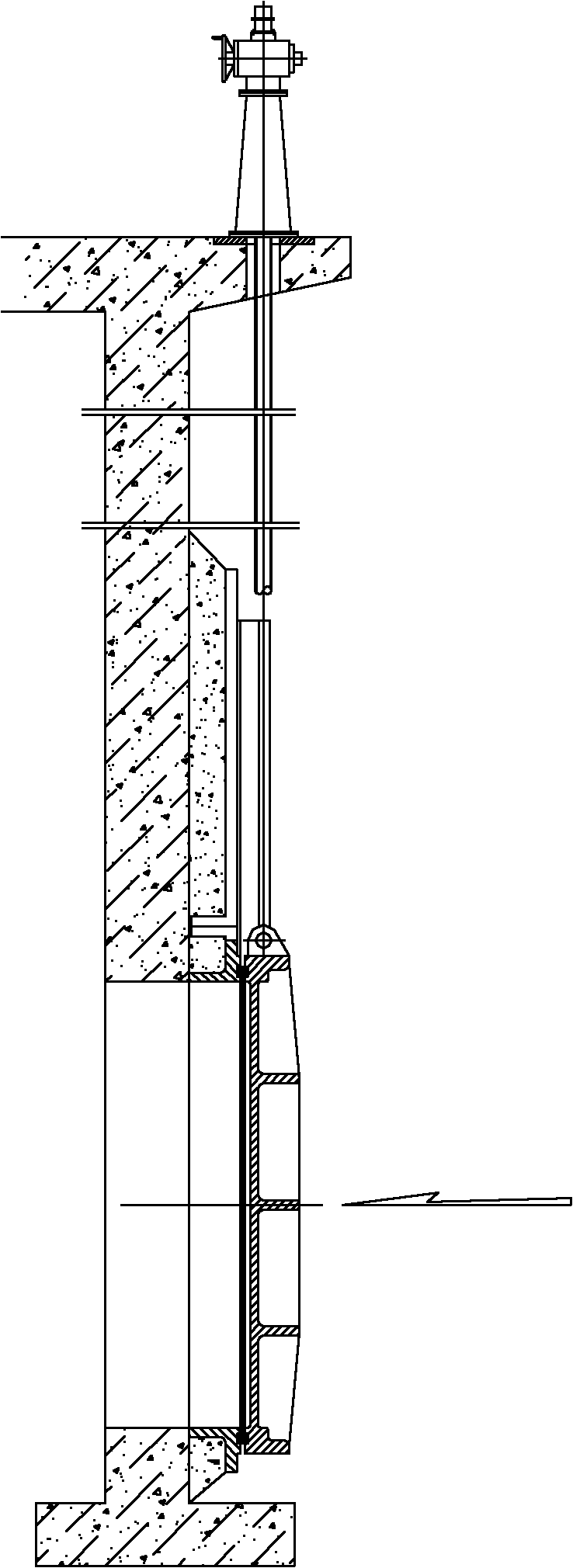

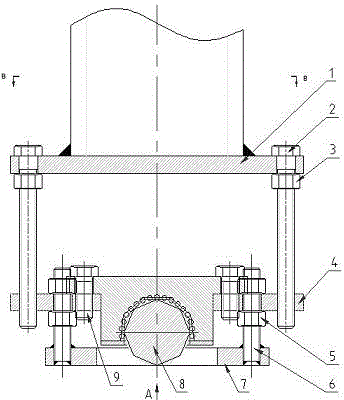

Computer hydraulic synchronous propelling method and apparatus thereof

InactiveCN1800582ARealize micro adjustmentHigh technical contentComputer controlTunnelsControl systemHeel

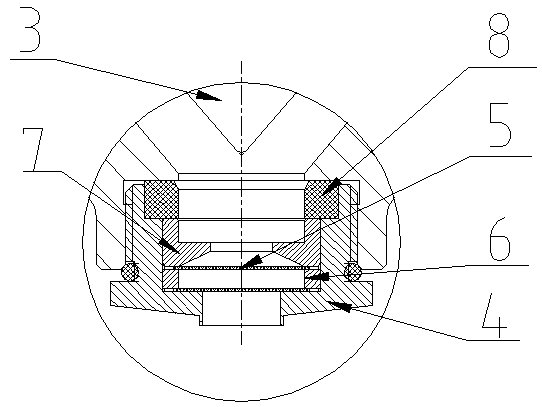

The invention relates to a computer hydraulic synchronous pushing method and relative device, belonging to the underground construction technique, which is characterized in that: the cylinder group (3) has a rigid fixing support (8) clinging its back base; a heel block (7) is arranged between the top arm of the cylinder group (3) and a box (4); the on-site controller (2) is connected to the main control system (1) with a computer, the signal wire of cylinder group (3), the control wire, the displacement sensor (5) mounted on the two sides of box (4) to push the cylinder group step-by-step to the destination. The invention has improved technique, high practicability, saved labor, and shortened operation period.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

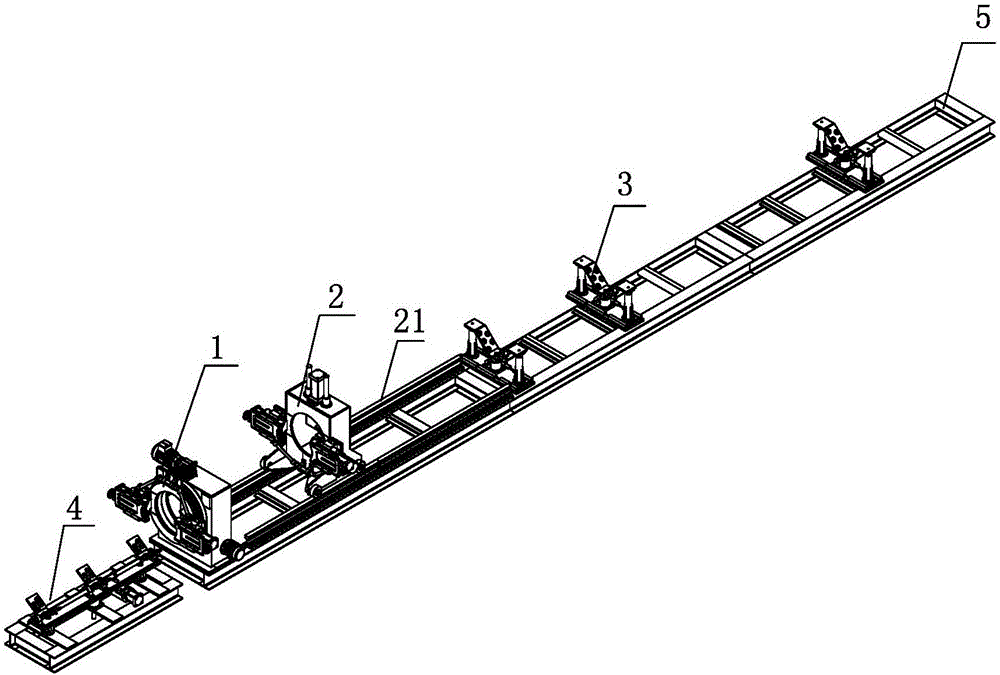

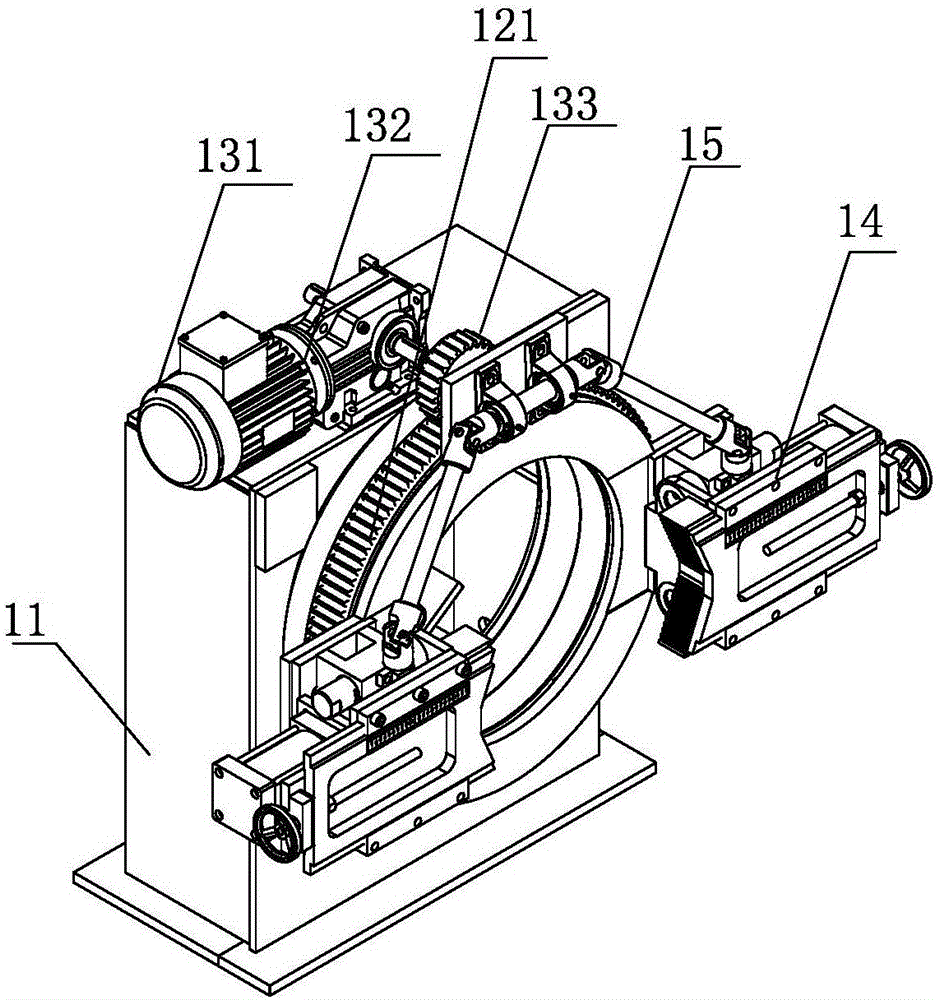

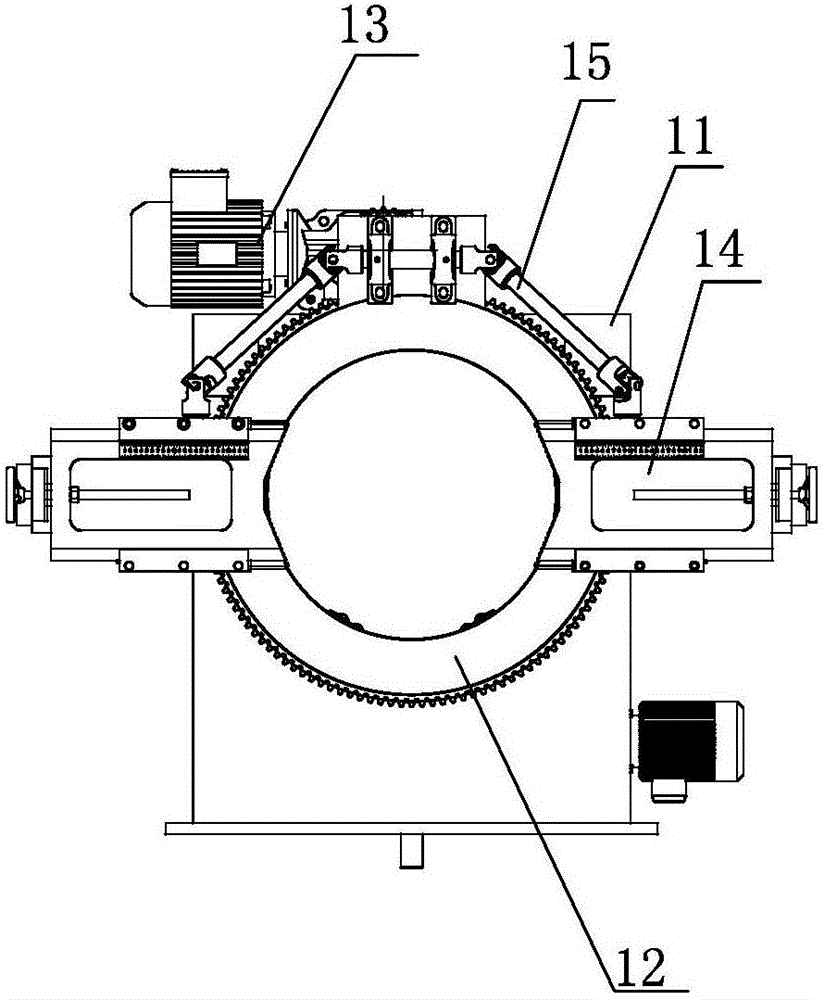

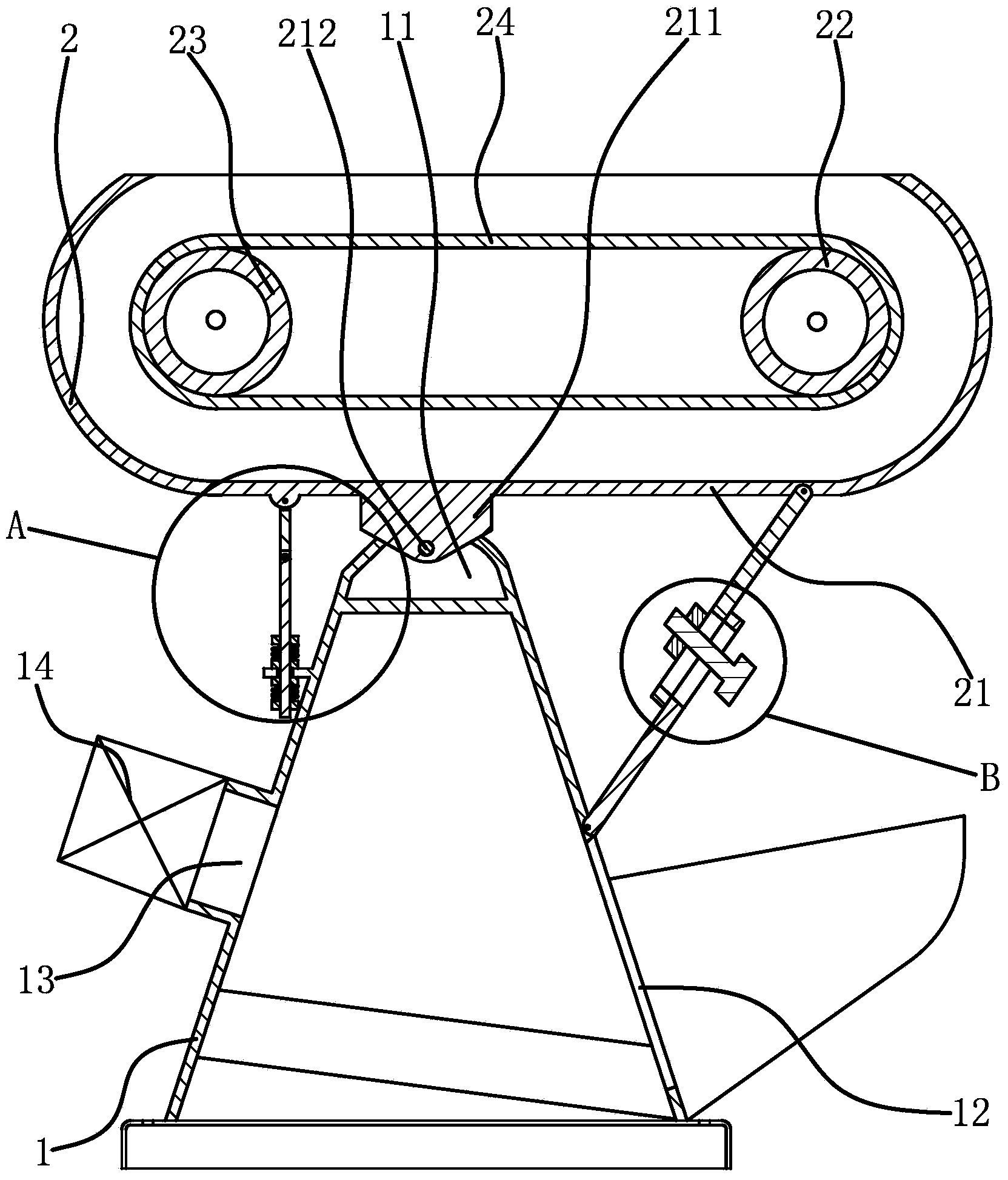

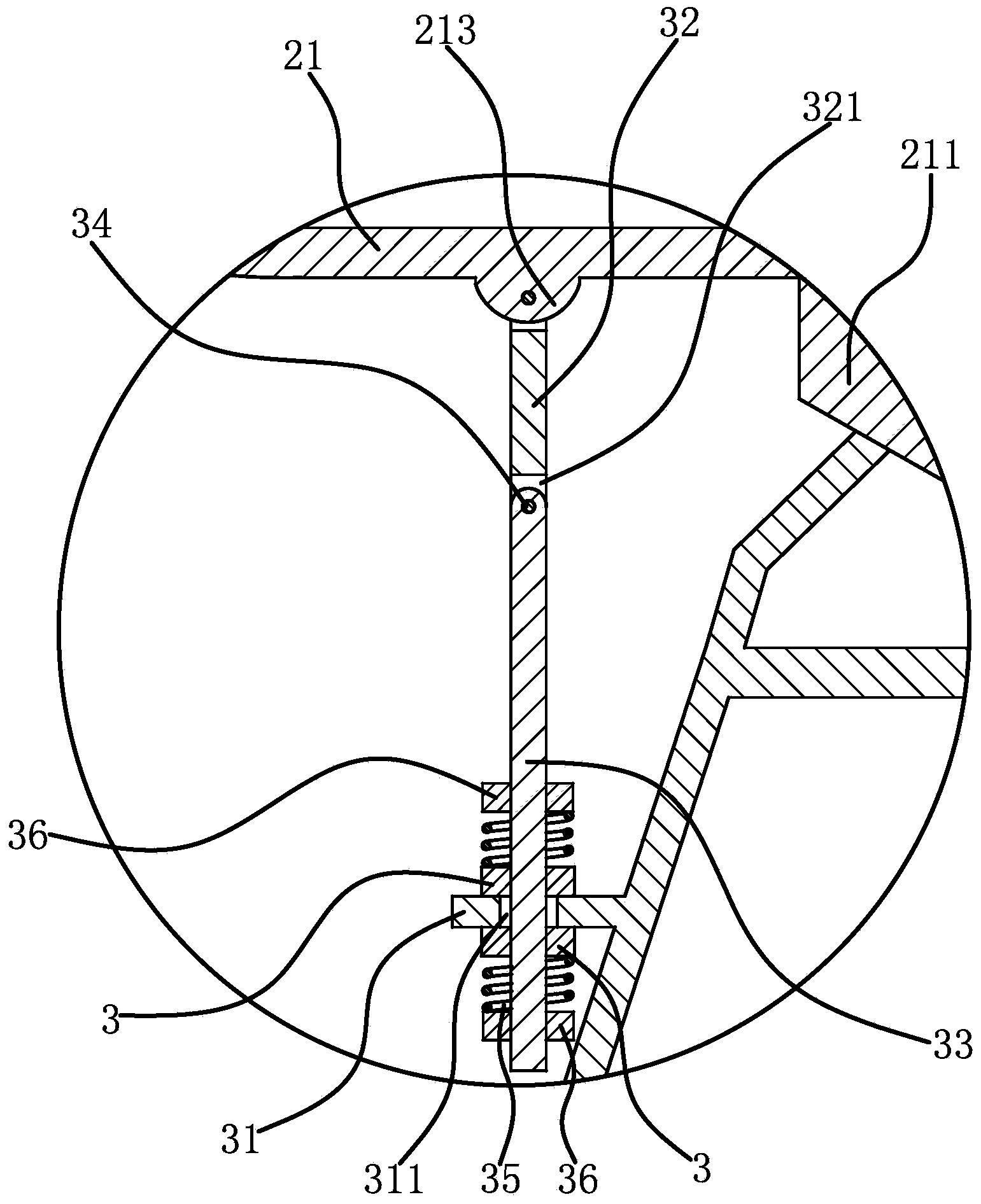

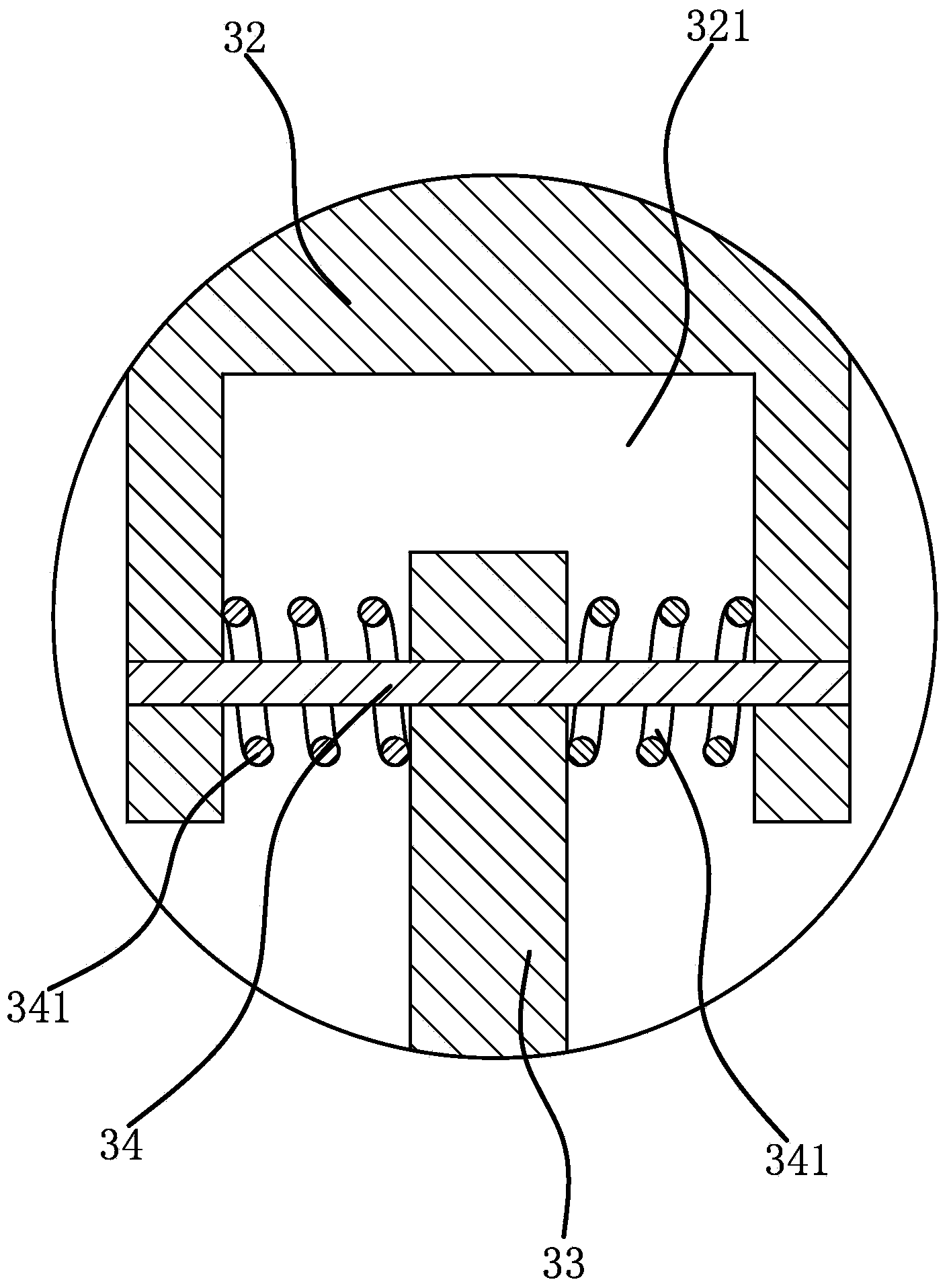

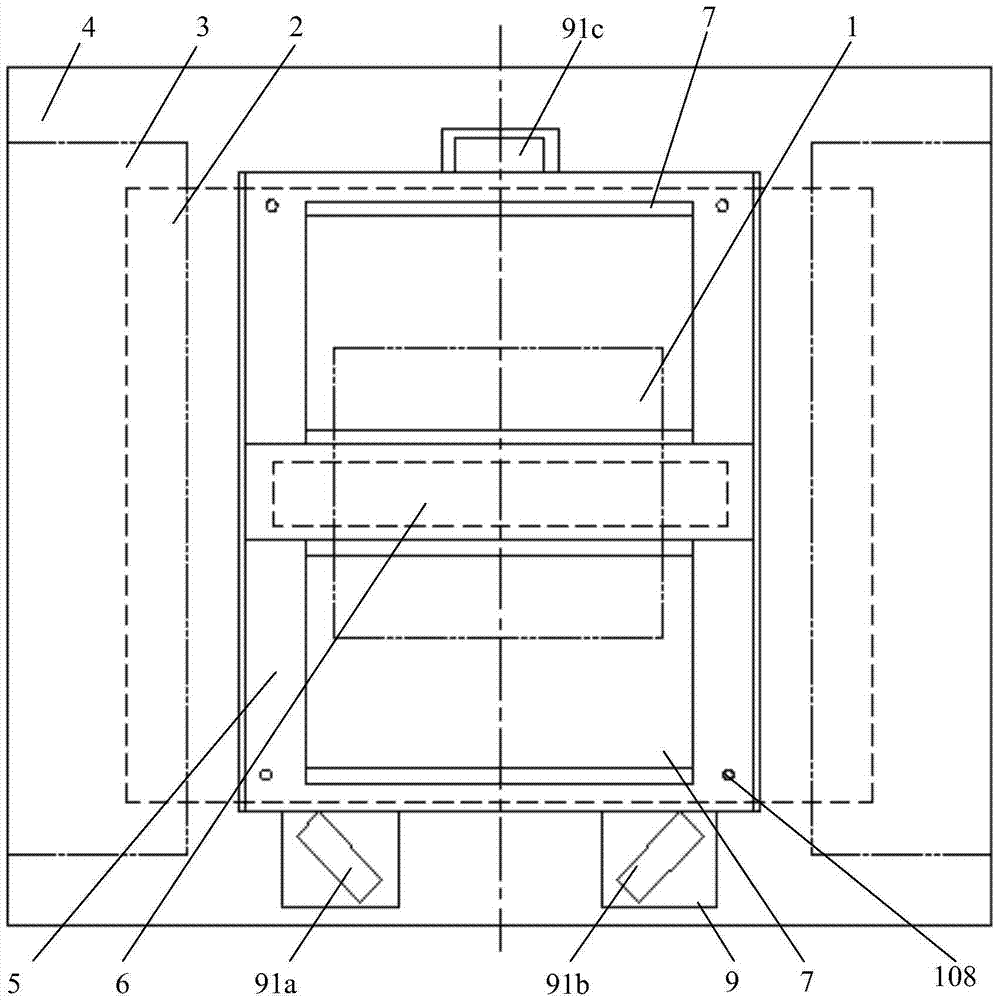

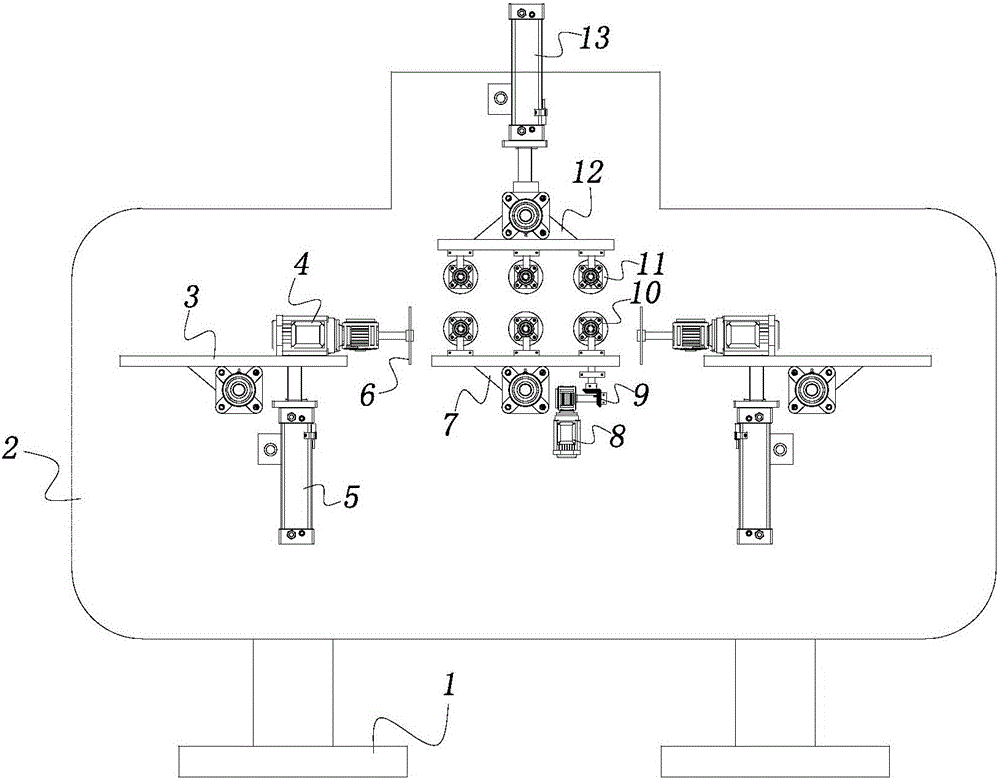

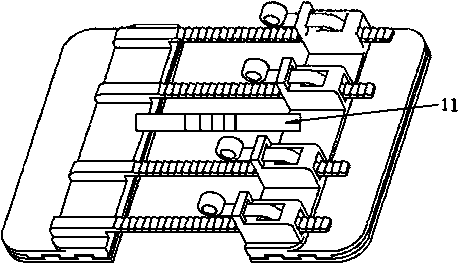

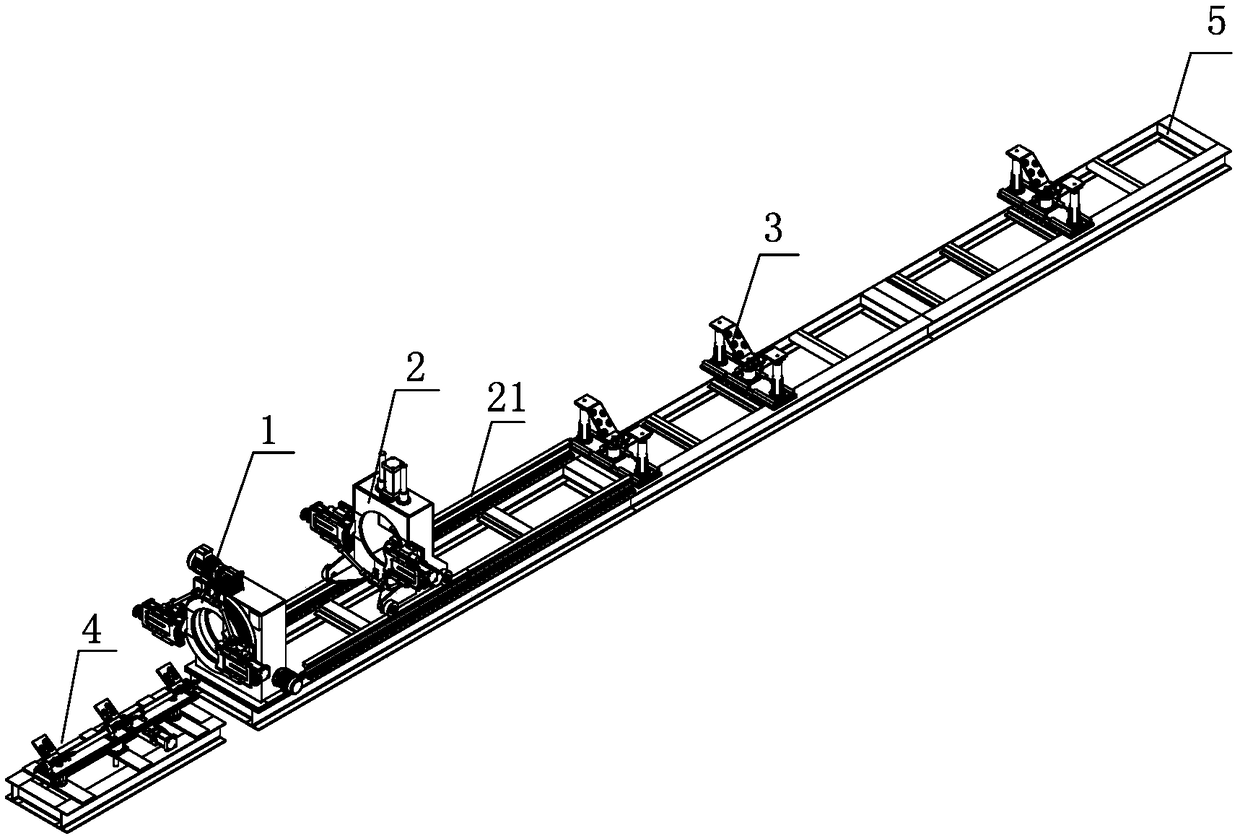

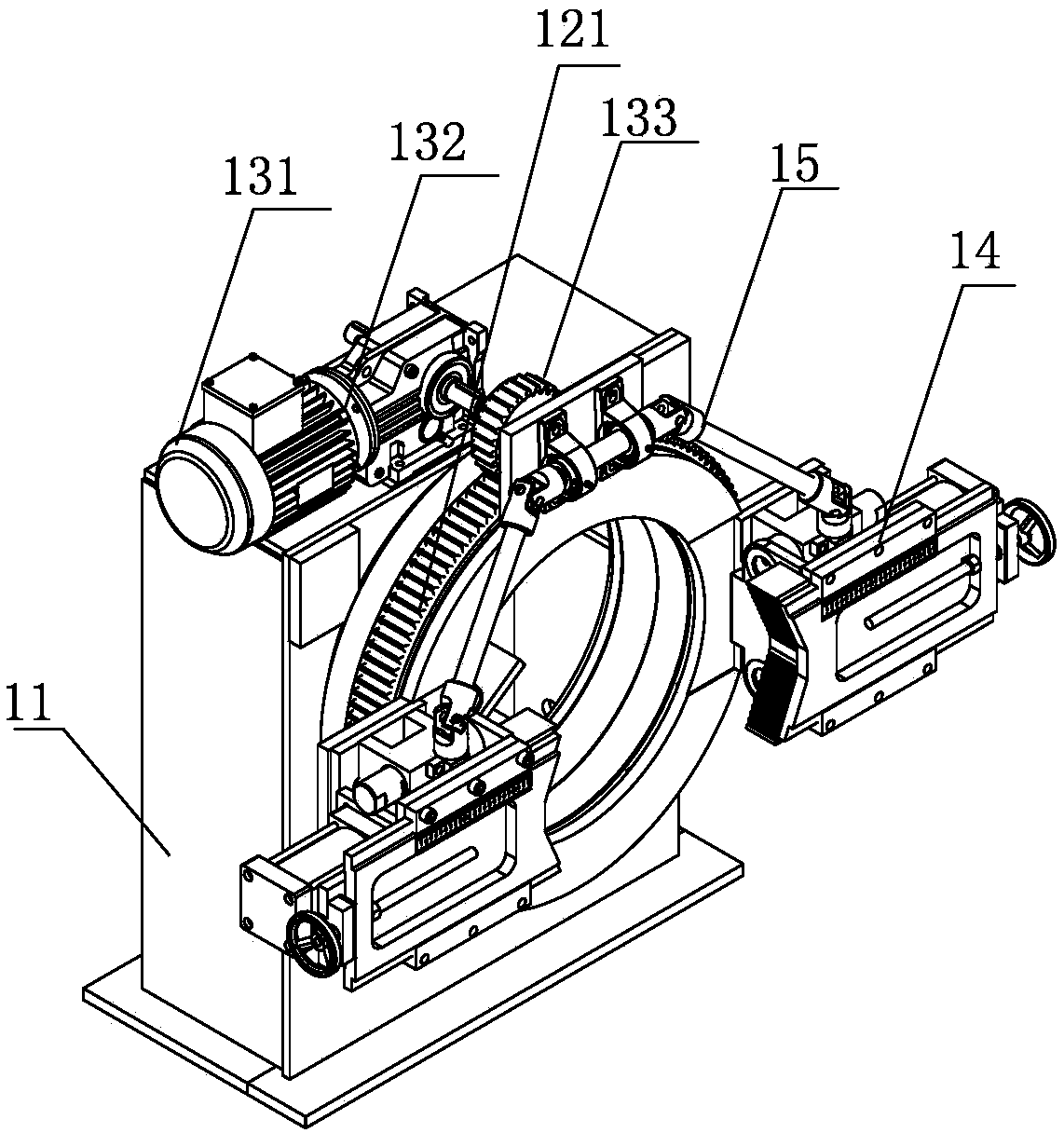

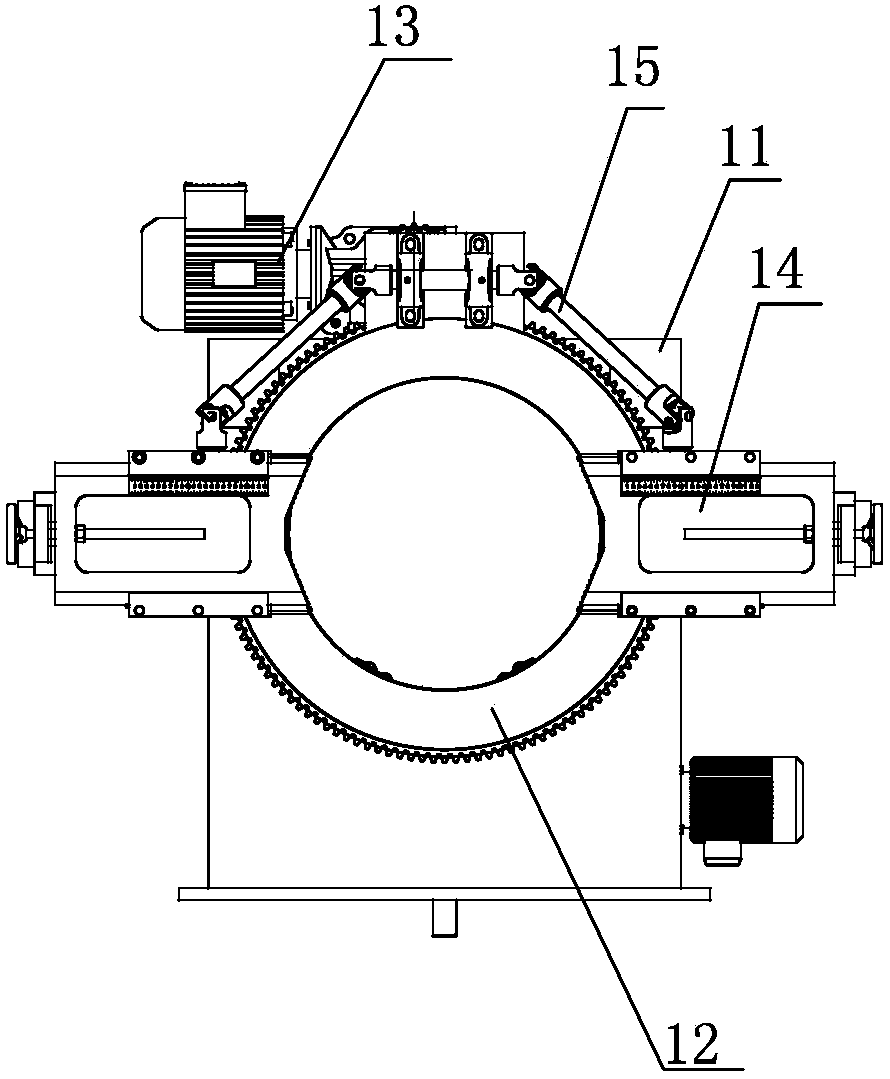

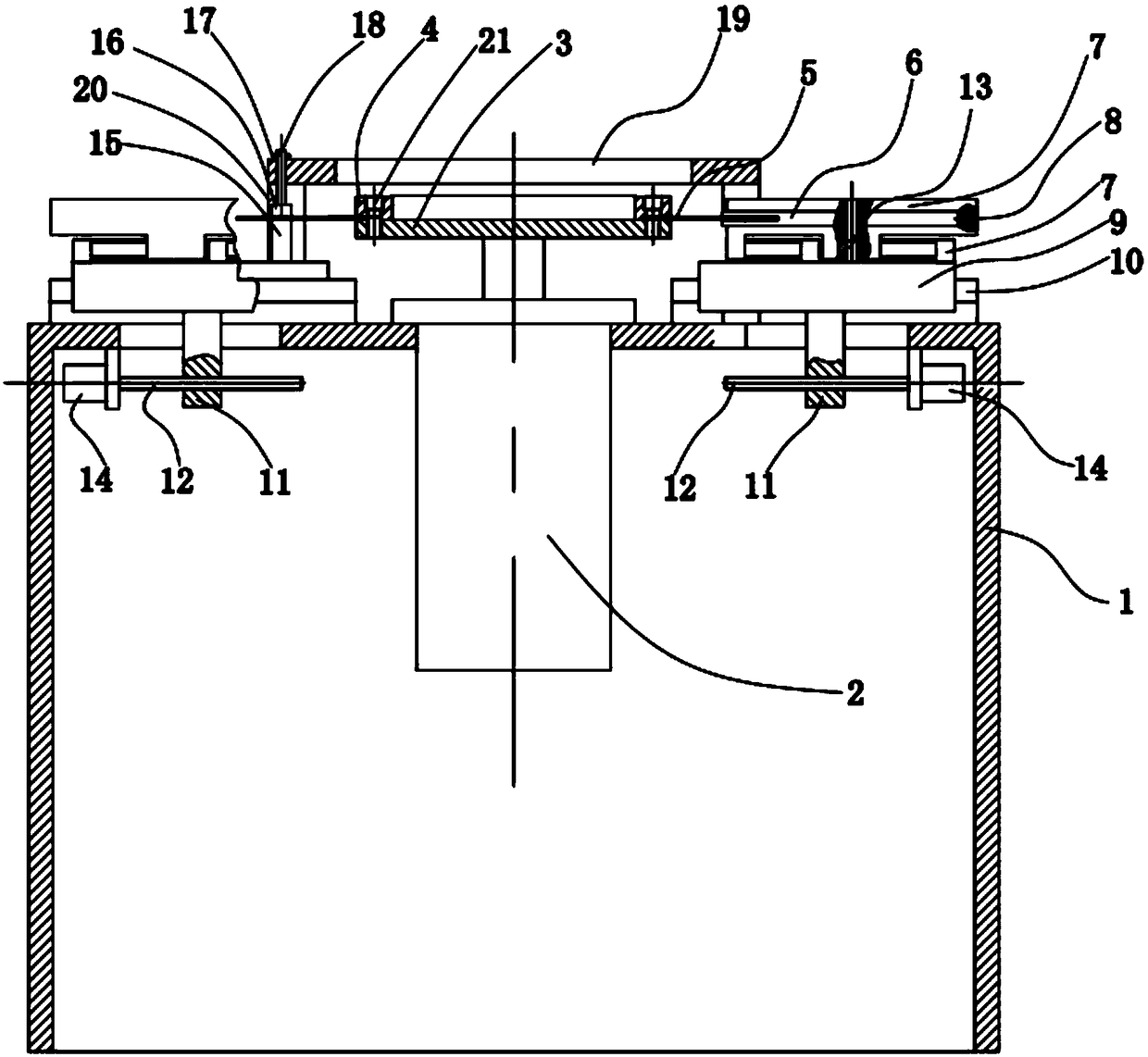

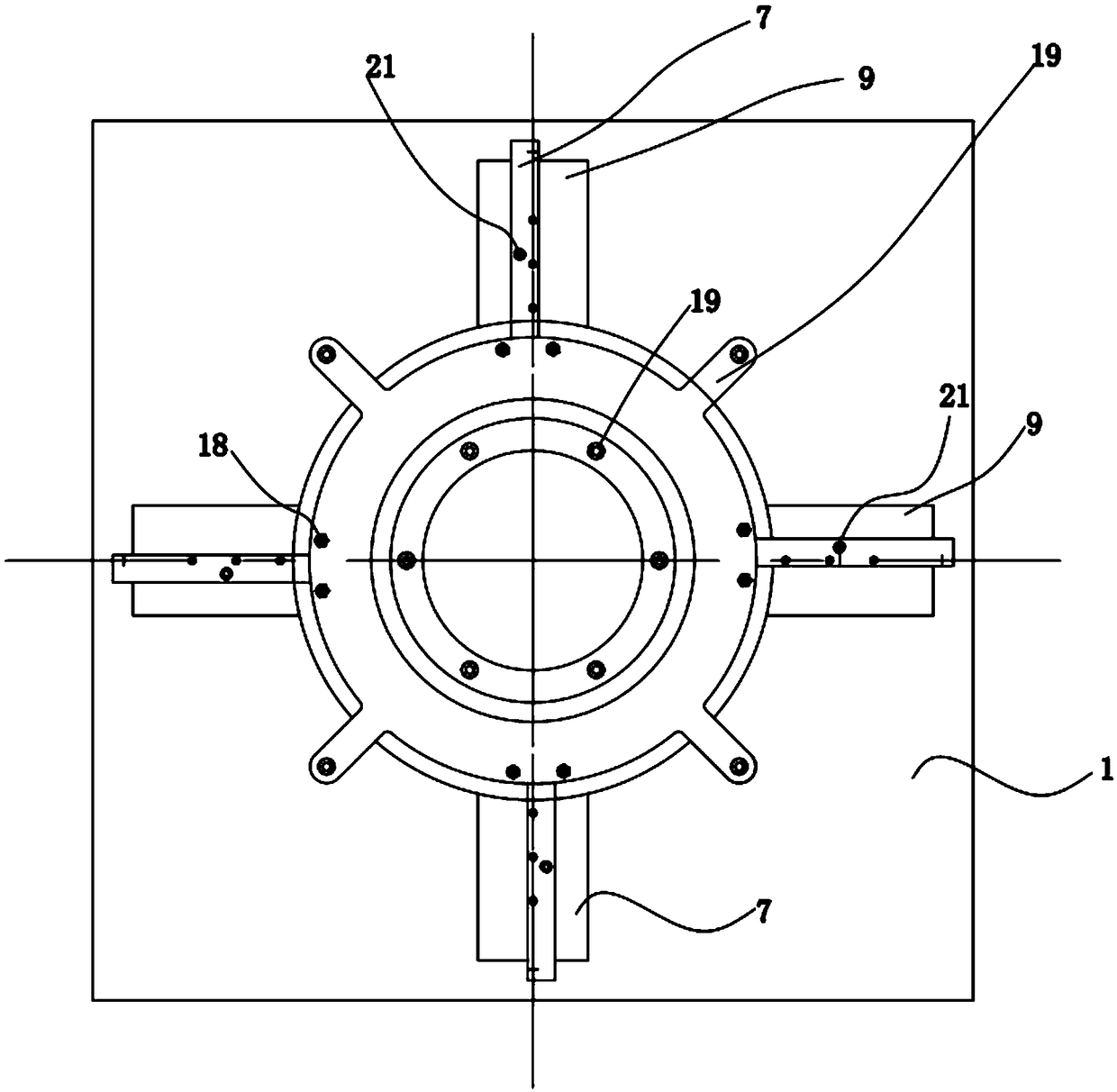

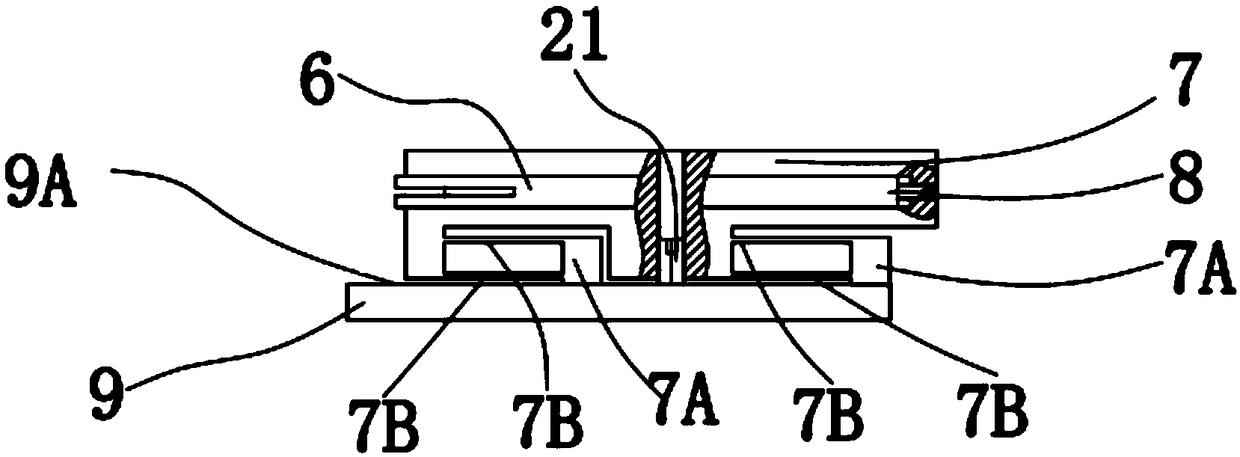

Two-way synchronous clamping plasma steel pipe cutting equipment

ActiveCN106216823AImprove the blessing effectReduce oppressionPlasma welding apparatusMetal working apparatusSizingEngineering

The invention provides two-way synchronous clamping plasma steel pipe cutting equipment, belongs to the technical field of steel pipe cutting devices, and aims to solve the technical problem of steel pipes incapable of rotating and transferring through a mechanical device when the steel pipes are cut by a plasma cutter. The equipment comprises a rotary clamping device, a clamping sizing transfer device, a bracket device and a turnover discharge device; the rotary clamping device includes a clamping mounting frame, a turntable mechanism, a clamping mechanism, a two-way synchronous clamping drive connecting mechanism, a turntable driving mechanism and a lifting mechanism; and the clamping sizing transfer device includes a sizing transfer guide rail, a sizing clamping mounting frame, the clamping mechanism, the two-way synchronous clamping drive connecting mechanism, the lifting mechanism and a clamping moving disc mechanism. The equipment can realize clamping and rotation of the steel pipes in the steel pipe cutting process, and performs fixed-distance transfer for the steel pipes.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

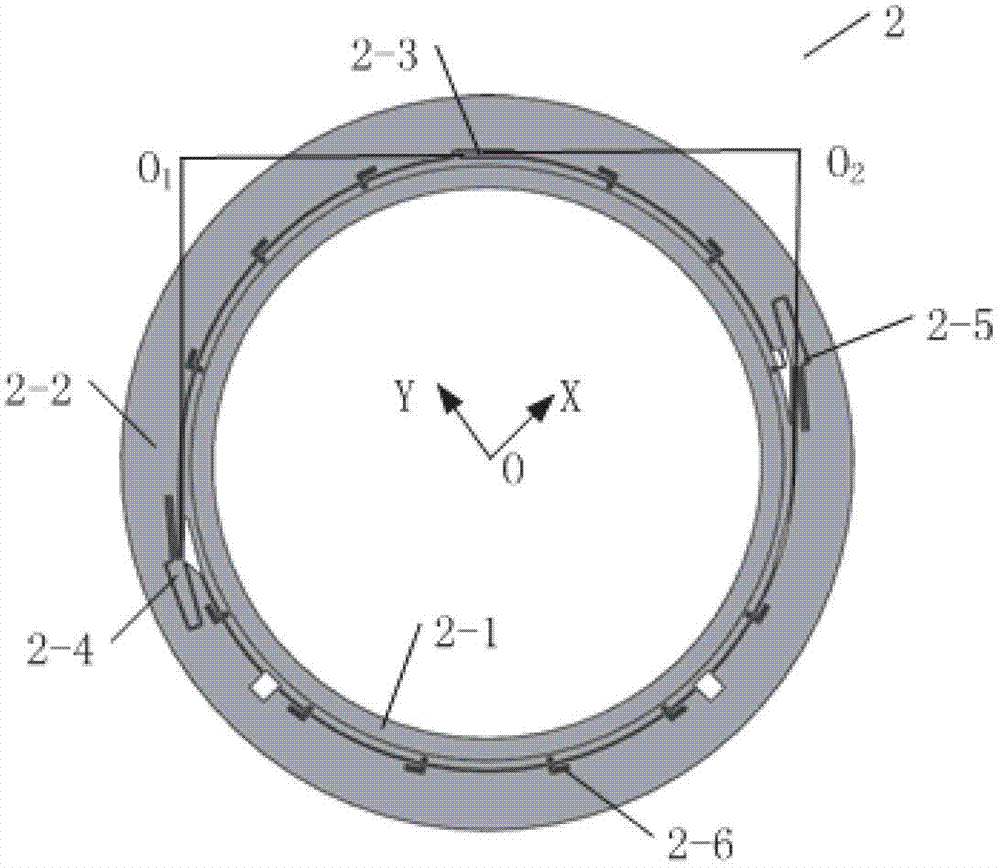

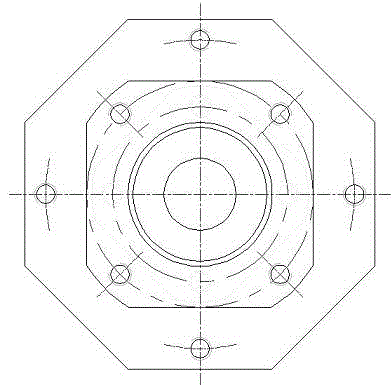

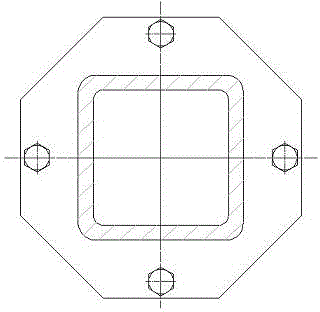

X-Y micro-adjustment apparatus for optical element in lithographic projection objective

InactiveCN102854758ARealize X-Y fine adjustmentRealize micro-adjustmentPhotomechanical exposure apparatusMicrolithography exposure apparatusPhotolithographyEngineering

An X-Y micro-adjustment apparatus for an optical element in a lithographic projection objective belongs to the deep-ultraviolet projection lithography objective structure design and aberration compensation fields. To solve the X-Y high-precision adjustment problem of the optical element in the lithographic projection objective, the apparatus comprises an objective frame, two drivers and two capacitance sensors, wherein the two drivers and the two capacitance sensors are respectively fixed on the objective frame; the drivers are arranged outside the outer ring of the objective frame; the input displacements of the drivers act on a first folding shrapnel and a second folding shrapnel; the input displacement directions are vertical to the outside shrapnel of the first folding shrapnel and the outside shrapnel of the second folding shrapnel respectively; each of the two capacitance sensors is a single-electrode capacitance sensor and is fixed at the inner side of the outer ring of the objective frame; and the circumferential interval between the two capacitance sensors is 90DEG, so the X-Y micro-adjustment of the optical element is realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

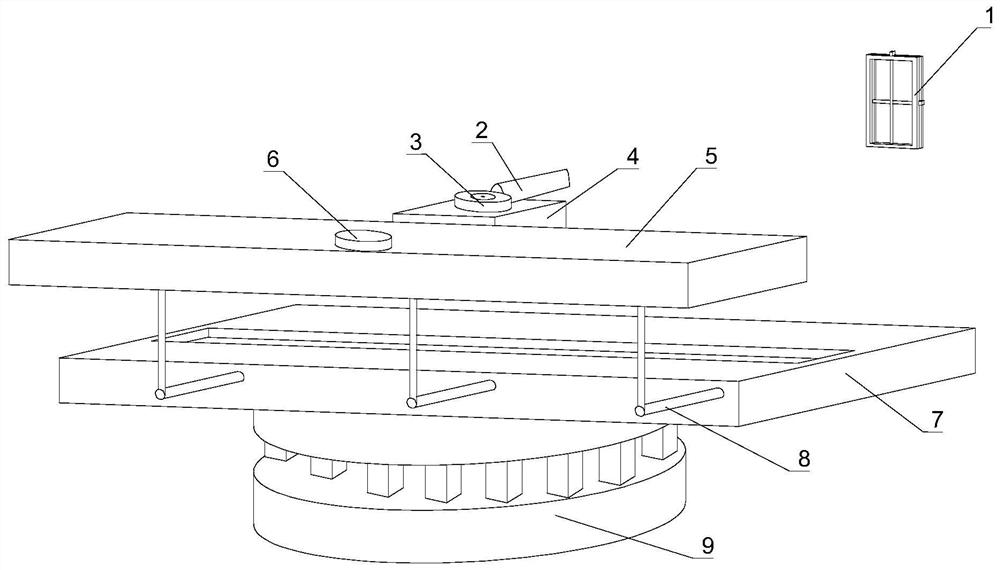

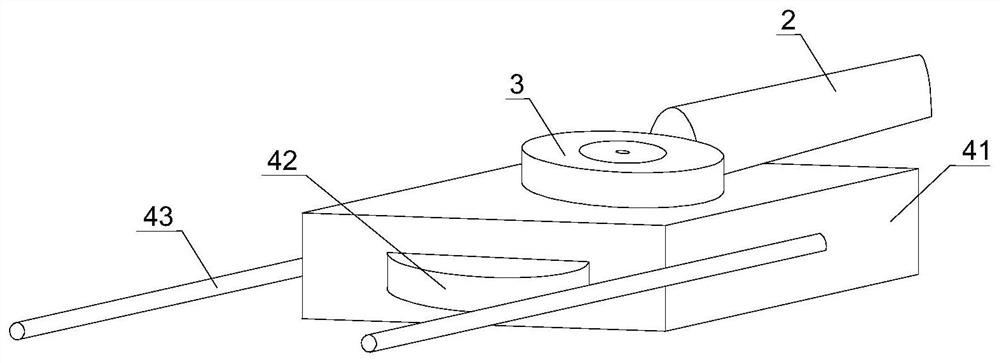

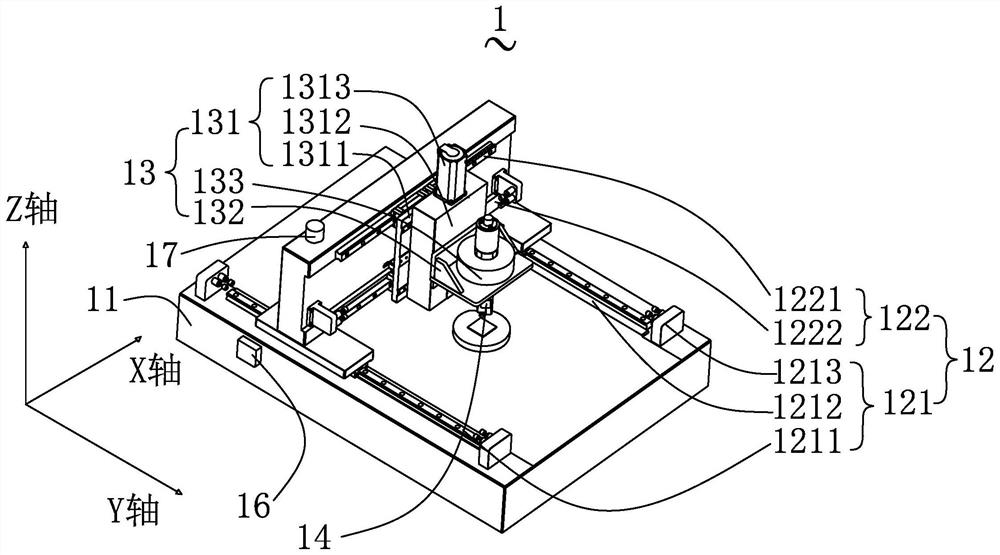

Running fix platform for macro/micro dual driven miniature type robot

InactiveCN1562729ASimple structureReduce volumeSemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityDrive wheel

A moving location platform for the microdriver / macrodriven miniature robot features that the first drive wheel is fixed to output shaft of the first motor, the first driven wheel is fixed to external moving location platform, the second drive wheel is fixed to the output shaft of the second motor, the second drive wheel is fixed to the external moving location platform, an internal microlocation platform is arranged in the center on the surface of external moving location platform, and three bipolar piezoelectric ceramics are respectively connected to said external moving location platform.

Owner:HARBIN INST OF TECH

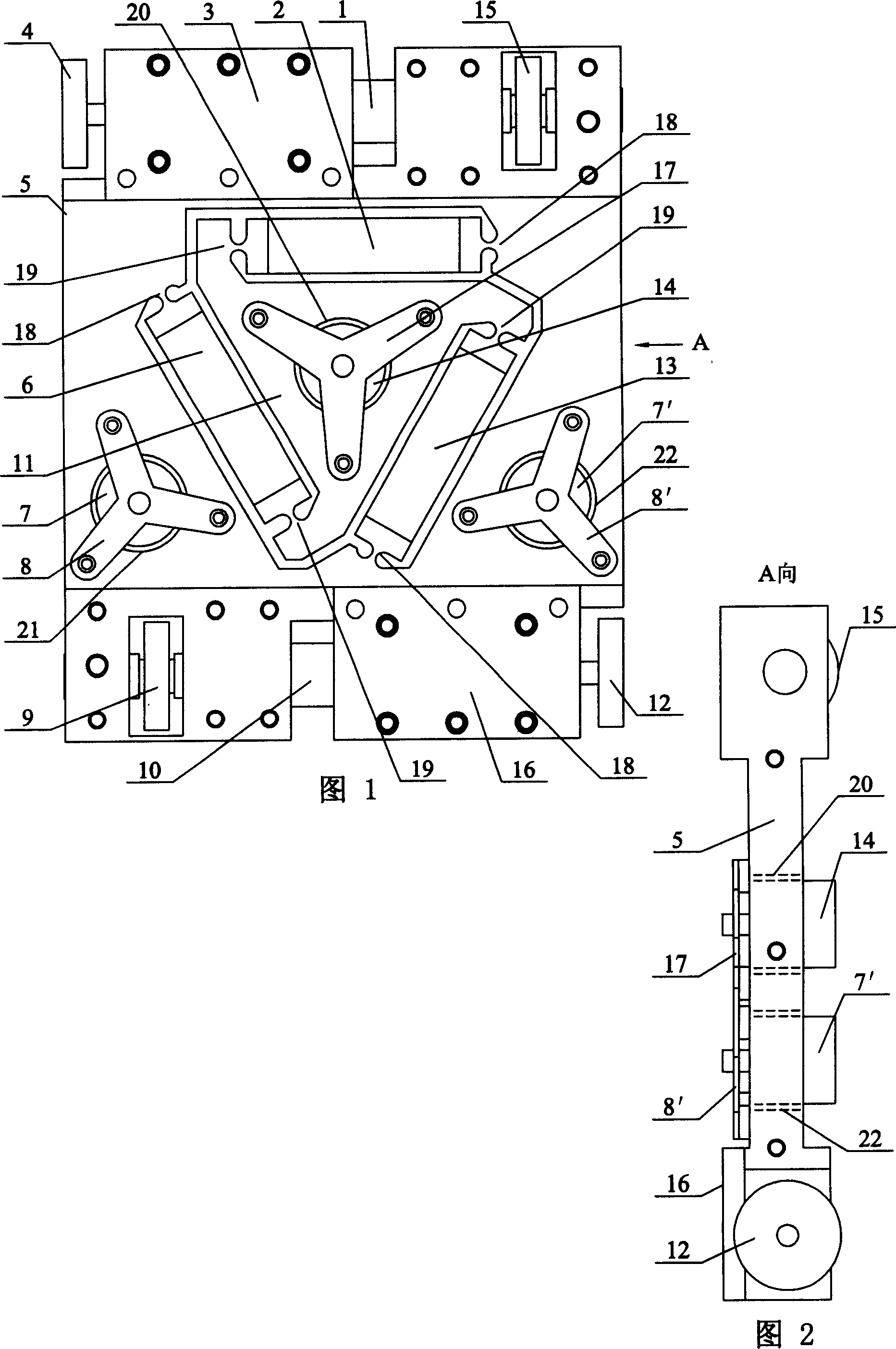

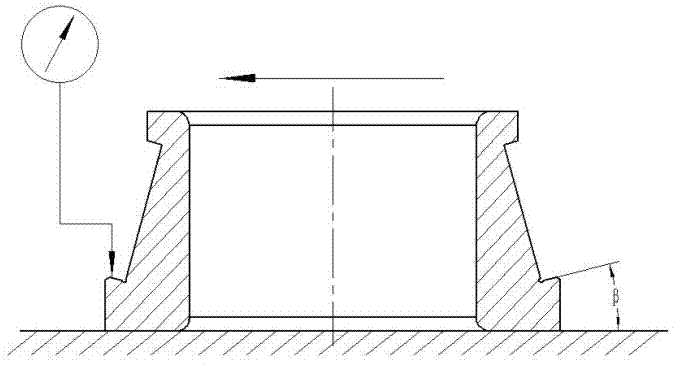

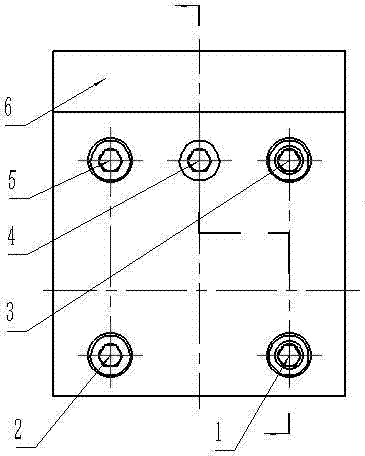

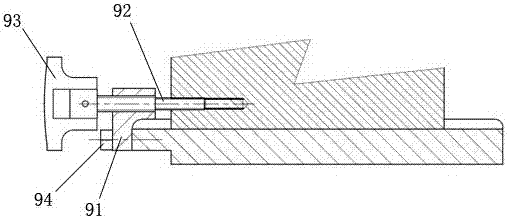

Detection and judgment method for included angle between inner ring conical rolling path and large flange

InactiveCN103206909AImprove detection accuracyReliable detection and judgmentAngles/taper measurementsEngineeringGauge block

Owner:LUOYANG BEARING RES INST CO LTD

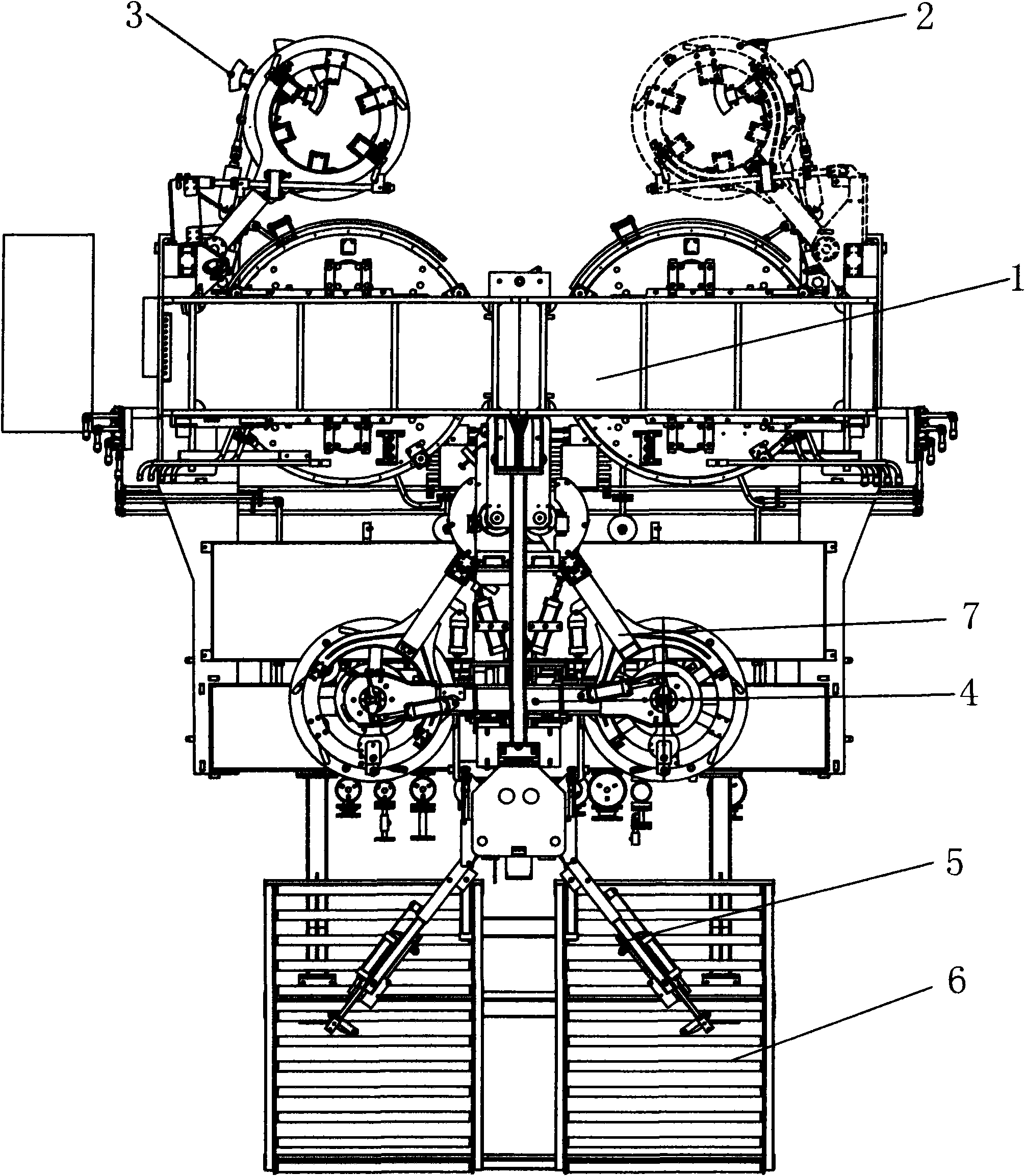

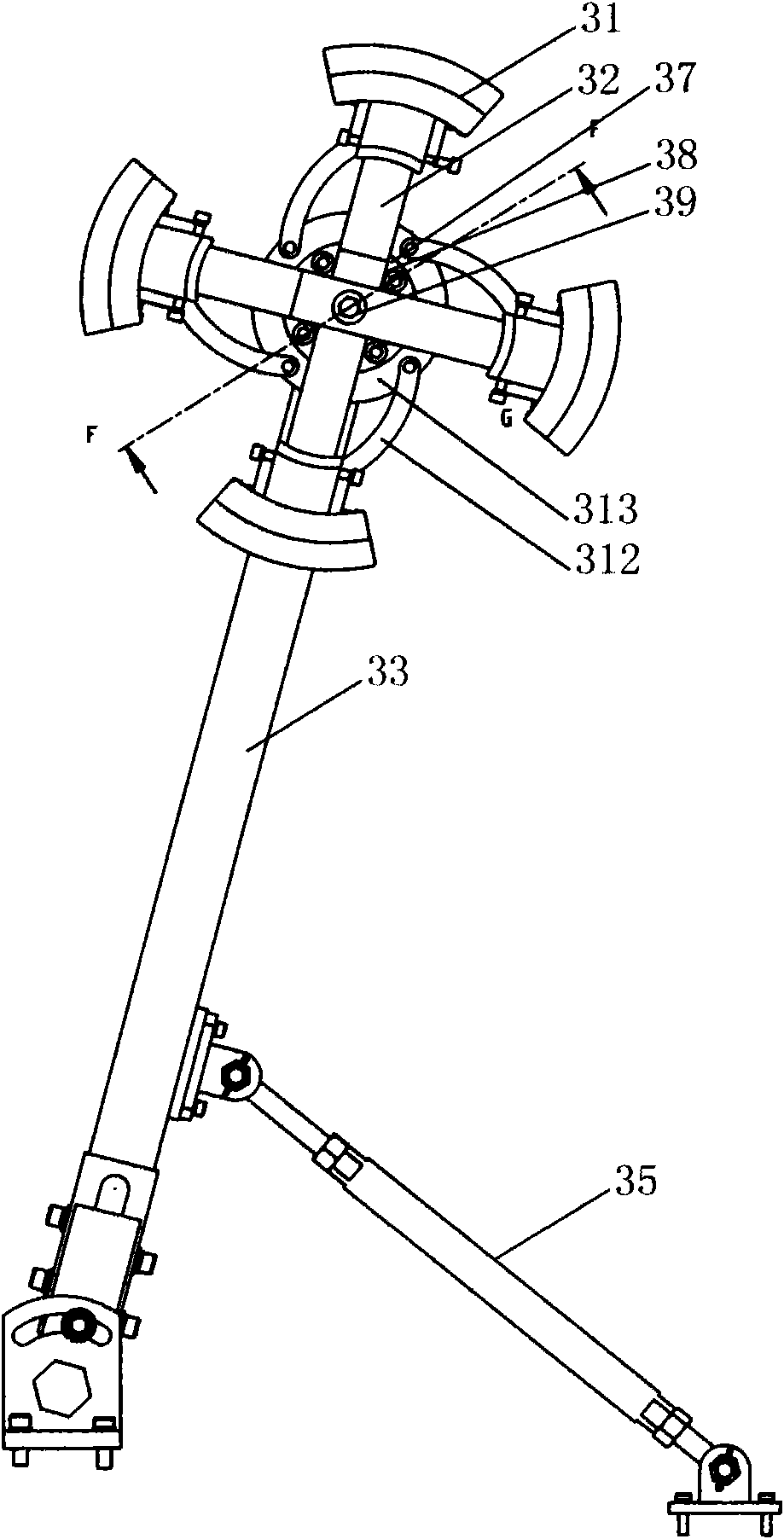

High-performance radial tire intelligent vulcanizing machine

ActiveCN102490296AImprove vulcanization efficiencyImprove vulcanization qualityAutomotive engineeringManipulator

The invention relates to a high-performance radial tire intelligent vulcanizing machine. The machine comprises a frame, a tire assembly mechanical arm, a pressurization mechanism, a vulcanizing chamber and a mould opening and closing mechanism, a central mechanism, a segmented mold drive device, an intermediate mechanical arm, a two-station four-point type rear inflation device, a tire detachment mechanical arm and a connecting roller way, wherein the frame is of a frame type integrated structure; and a lifting mechanism of the mould opening and closing mechanism adopts roller locking guidance, and a tire storage mechanism is arranged at the front end of the frame. The high-performance radial tire intelligent vulcanizing machine is of the frame type integrated structure, and a cylindrical insulator can be used for realizing pressure transfer, hydraulic and pneumatic pressure transmission and electrical signal control, so that the high automatic dual-mould vulcanizing machine integrated with machine, electricity, hydraulic pressure and pneumatic pressure can be realized. Steam and nitrogen are adopted as vulcanizing media, so that the vulcanizing efficiency and vulcanizing quality of a tire are greatly improved.

Owner:双星东风轮胎有限公司

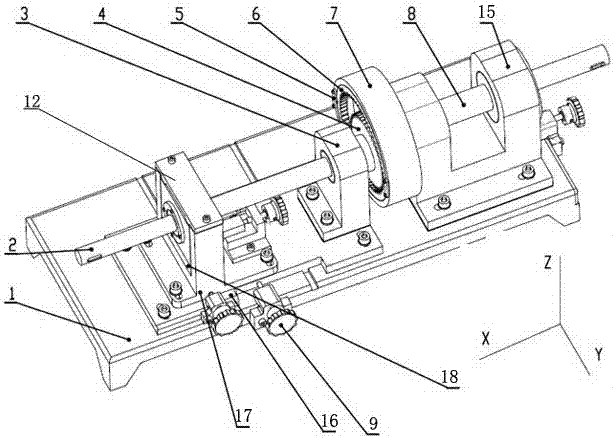

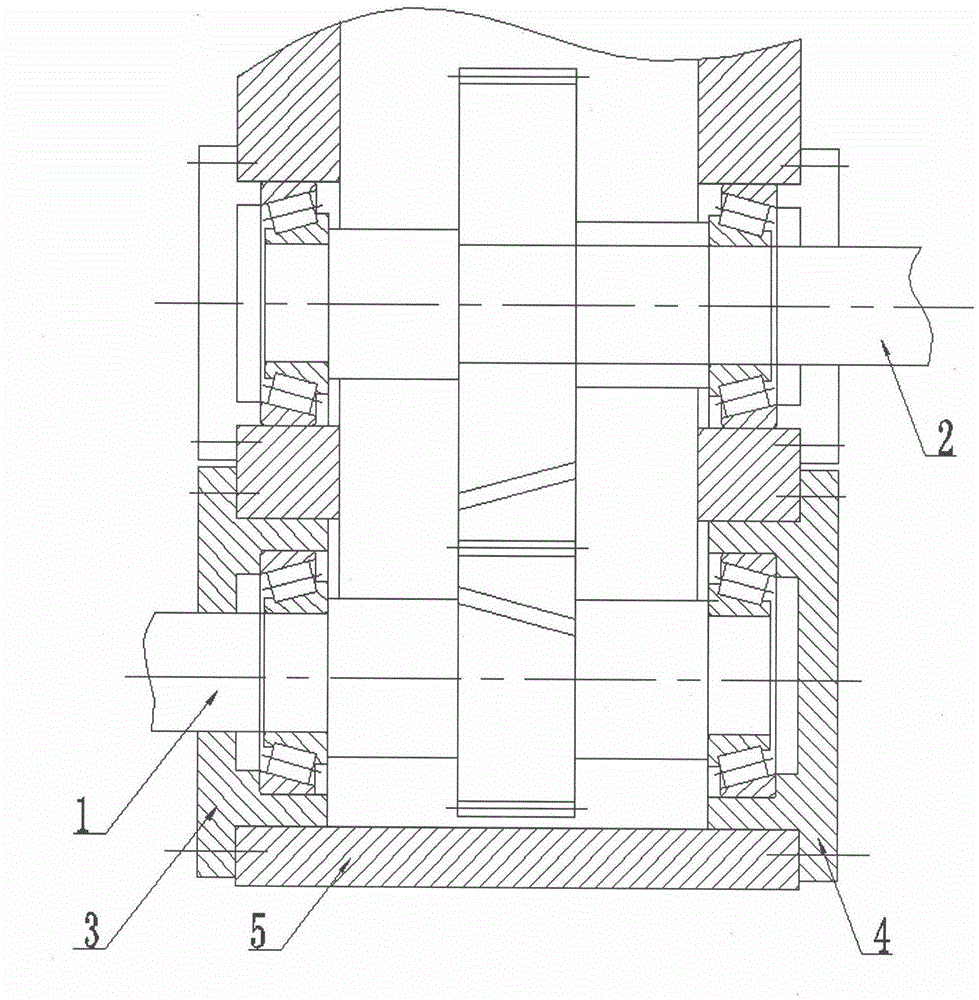

Internally meshed variable-tooth-thickness gear test bench

InactiveCN106932199AAdjust the center distanceRealize micro-adjustmentMachine gearing/transmission testingMobile endEngineering

The invention discloses an internally meshed variable-tooth-thickness gear test bench, which comprises a base. The front and back of the base are respectively provided with a transverse adjusting plate and an output shaft bearing seat. The output shaft bearing seat is provided with a front bearing fixed position and a rear bearing fixed position and is used for the installation of an output shaft. The front end of the output shaft is fixedly provided with a variable-tooth-thickness inner gear fixing disk. The upper surface of the transverse adjusting plate is provided with an input shaft fixed end bearing seat and an input shaft mobile end bearing seat and is used for the installation of an input shaft. The upper part of the input shaft mobile end bearing seat is provided with a square opening. An adjustment inclined block is arranged inside the square opening. The output shaft bearing seat, the transverse adjusting plate, the input shaft mobile end bearing seat and the adjustment inclined block are respectively connected with a corresponding handle adjusting mechanism. According to the technical scheme of the invention, the included angle, the central distance and the gear axial position of a variable-tooth-thickness gear shaft can be finely adjusted. Therefore, the test bench can be used for the research on the parallelism error, the shaft spacing deviation, the influences of different axial distances on the performances and the transmission precisions of internally meshed variable-tooth-thickness gear pairs and the like.

Owner:CHONGQING UNIV

Polishing machine

The invention provides a polishing machine, and belongs to the technical field of machining. The polishing machine solves the problem that the angle adjusting precision of a workbench of an existing polishing machine is low. The polishing machine comprises a machine frame and a workbench, wherein the lower portion of the workbench is rotationally connected to the upper portion of the machine frame through a connection shaft, a driving wheel and a driven wheel are rotationally connected with the workbench, and the driving wheel and the driven wheel are sleeved with a polishing abrasive belt; the lower end of the machine frame is further connected with the lower end of the workbench through a connection assembly provided with a screw, the lower end of the screw is connected to the machine frame in a sliding mode, and the screw is sleeved with a positioning nut capable of axially positioning the screw. According to the polishing machine, the angle of the workbench can be adjusted, the adjustment precision is high, and the workbench is fixed more firmly after adjustment is completed.

Owner:陈美青

Height adjusting device

The invention discloses a height adjusting device which comprises a beam, an adjusting wedge, a fixing heel, an adjusting screw, a nut, a turbine and worm combination and a threaded hole. The adjusting wedge is disposed between the beam and the fixing heel. The threaded hole is reserved in the adjusting wedge. One side of the adjusting wedge is provided with the nut. One end of the adjusting screw penetrates to be disposed on the nut and the threaded hole. The other end of the adjusting screw is fixedly connected with the turbine and worm combination. The height adjusting device is high in rigidity, precise and quick fine adjustment is achieved, and operation is stable and reliable.

Owner:太仓奥科机械设备有限公司

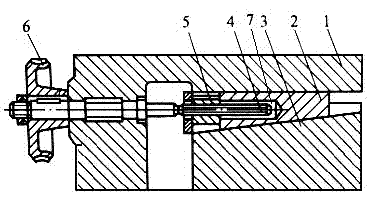

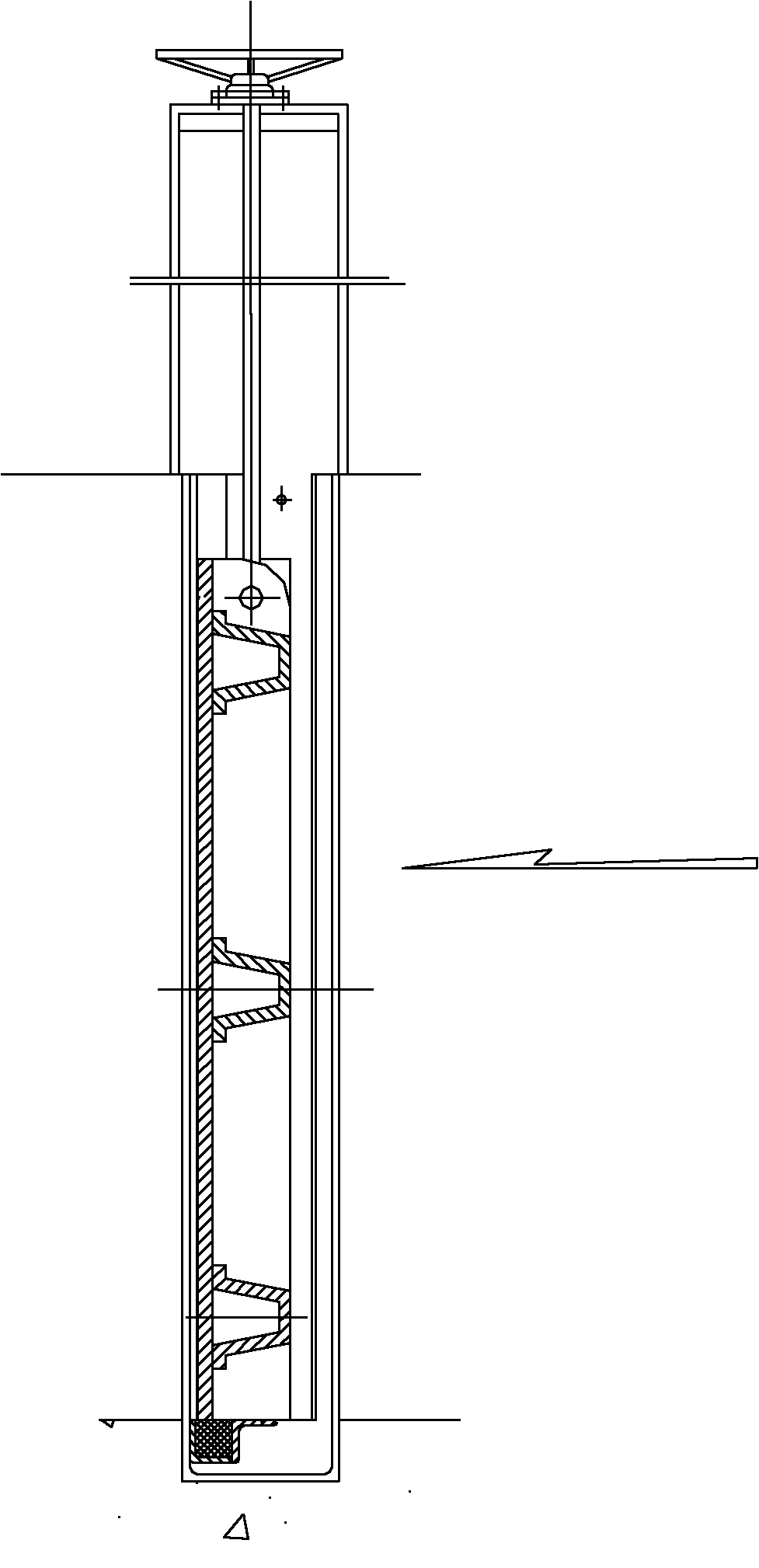

Sleeve valve with adjustable longitudinal flow

InactiveCN102031767AMeet the adjustment speed needsRealize micro-adjustmentBarrages/weirsArtificial water canalsRubber ringSleeve valve

The invention discloses a sleeve valve with an adjustable longitudinal flow, which comprises a valve bush, wherein a piston cylinder is arranged in the valve bush, sliding matching is formed between the piston cylinder and the valve bush, and guide holes are arranged on the piston cylinder. The sleeve valve is arranged between an upper pool and a lower pool, in particular, a hole is drilled on a platform between the upper pool and the lower pool, the valve bush is fixed on the hole in a manner of an expansion bolt or embedded steel plate, the upper end face of the valve bush is embedded with a flat rubber ring to be used as an end face seal, and the piston cylinder is arranged on the valve bush, therefore, because the valve body is structurally characterized by being closed and opened by a sleeve vertical motion, when the piston cylinder moves upwards, the guide holes of the piston cylinder play a role of guiding, with the increase of the lifting amount, the total guide area is continuously increased until the piston cylinder passes through the complete stroke, and the valve is equally completely opened. When the piston cylinder moves downwards, the quantity of the guide holes on the side surface is continuously reduced until the flat rubber end face is in complete contact with a fixed cylinder to play a role of sealing, and the valve is completely closed.

Owner:LANSHEN GRP CORP LTD

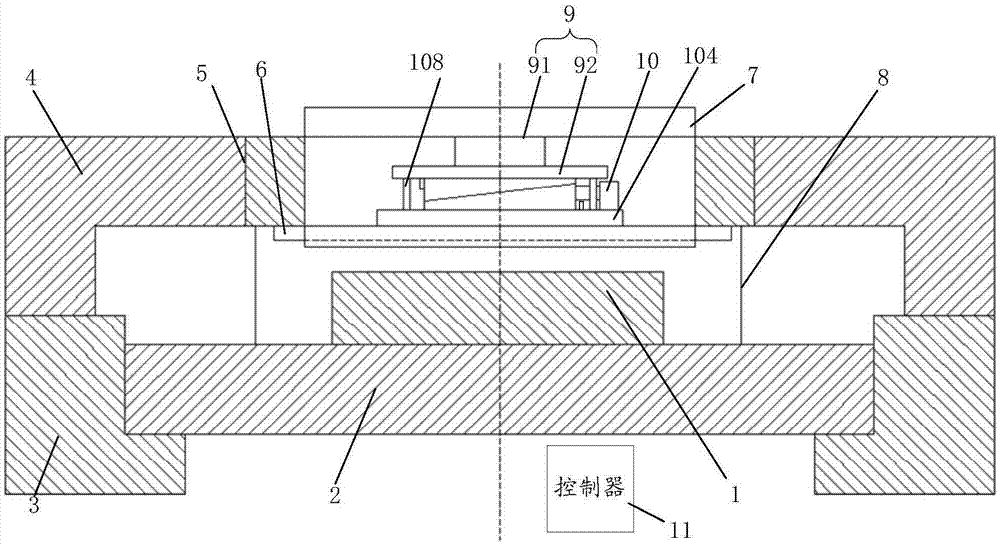

Leveling device and leveling method of photoetching machine projection objective

ActiveCN107290933ASuppression of low frequency vibrationImprove exposure image qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusImaging qualityEngineering

The invention discloses a leveling device and leveling method of a photoetching machine projection objective. The leveling device comprises a workbench, a hanging frame, a hanging frame support, an installation base plate, an objective frame, a photoelectric measurement system, a projection objective, a sensor measurement system, an active damper, a vertical adjustment mechanism and a controller, wherein the hanging frame is used for supporting the workbench, the hanging frame support is used for supporting the hanging frame, the installation base plate is arranged above the hanging frame support, the objective frame is arranged on the installation base plate, the photoelectric measurement system and the projection objective are arranged on the objective frame, the sensor measurement system is connected with a surface of the objective frame, the active damper is arranged on the installation base plate and is connected with the objective frame, the vertical adjustment mechanism is arranged below the active damper, and the controller is electrically connected with the sensor measurement system, the active damper and the vertical adjustment mechanism. By the leveling device, the purpose that the projection objective and the photoelectric measurement system are free from influence of external vibration and impact is achieved, meanwhile, the projection objective and the photoelectric measurement system are maintained in a static state relative to the position of the hanging frame of a support workpiece table all the way, the exposure imaging quality of the projection objective and the detection performance of the photoelectric measurement system are improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

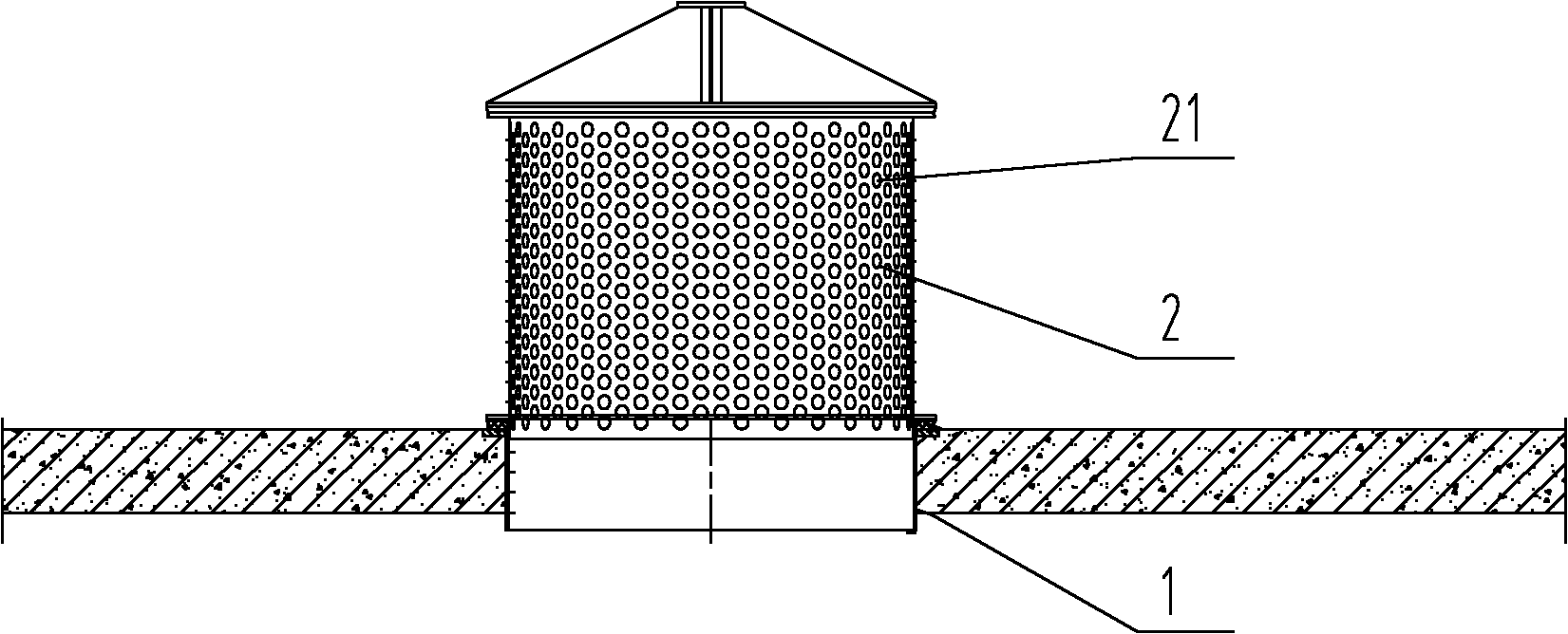

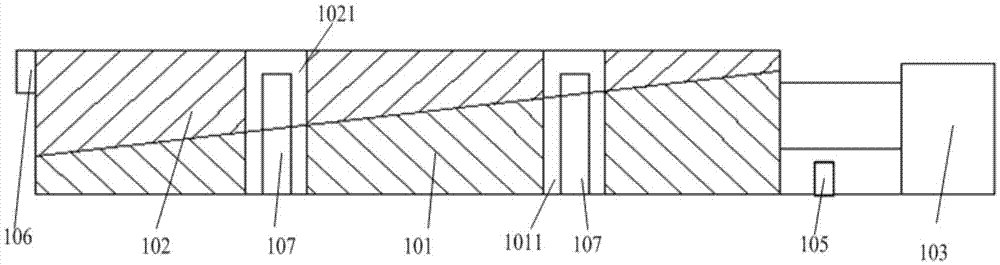

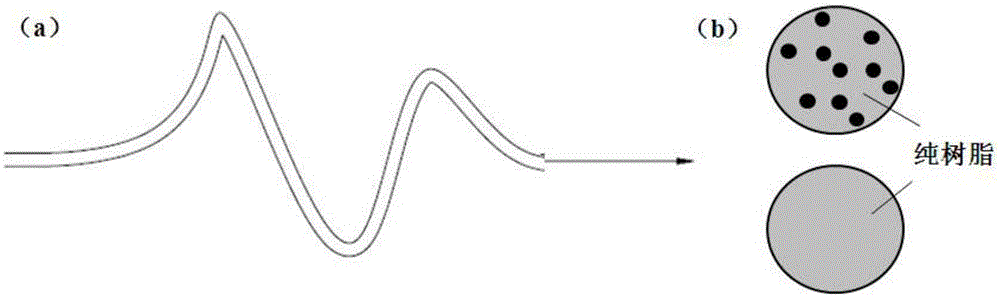

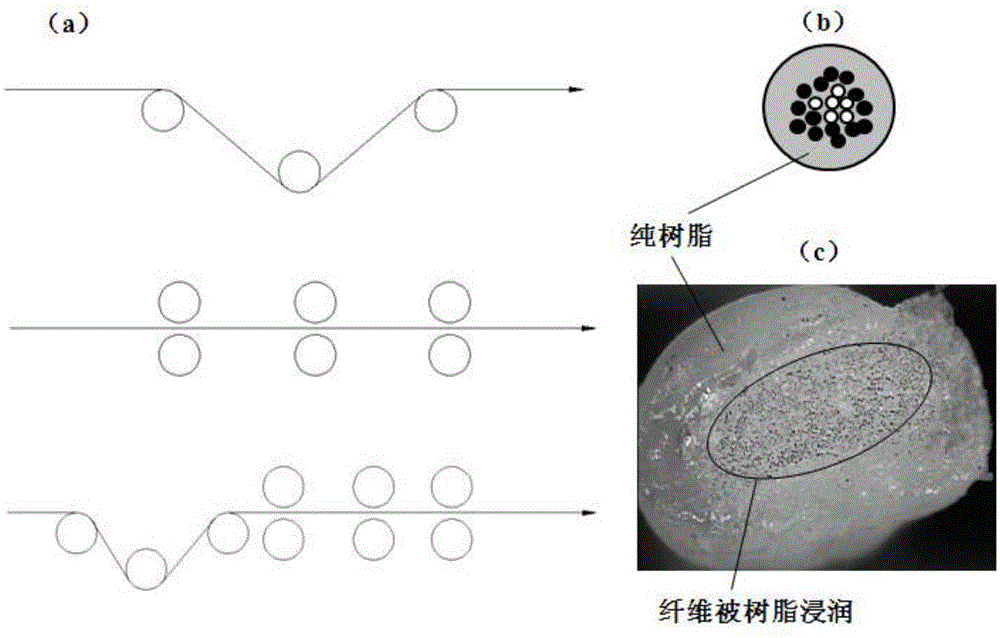

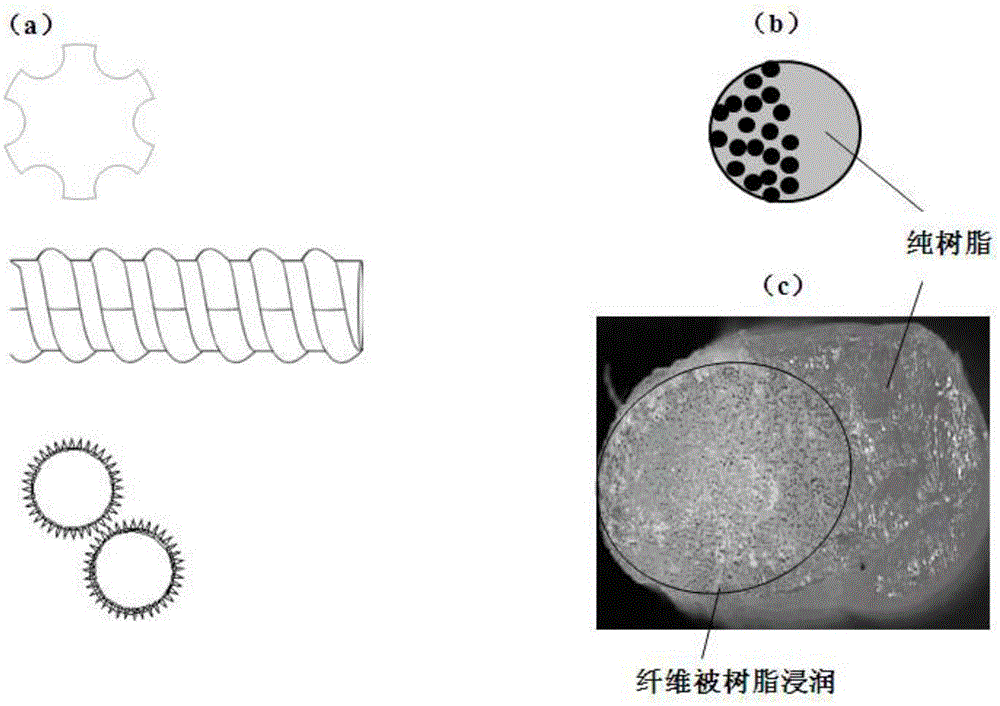

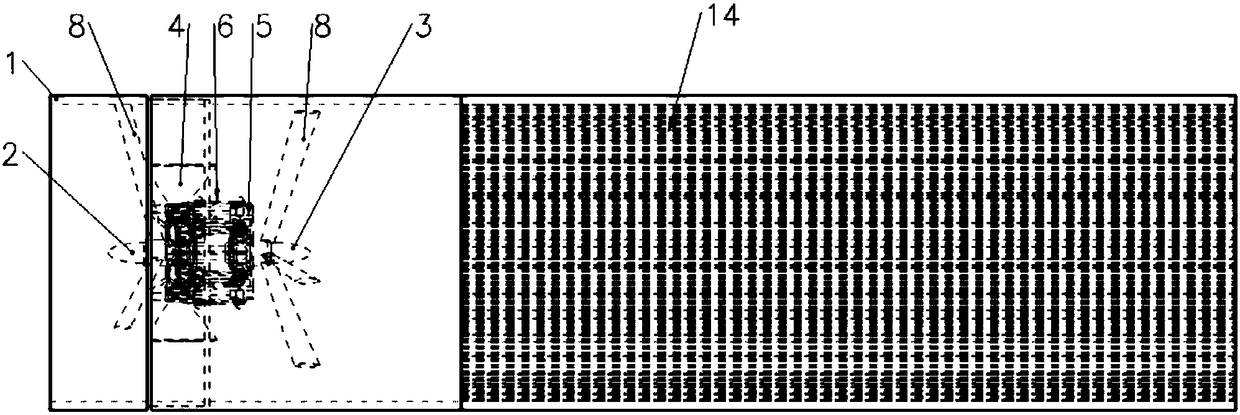

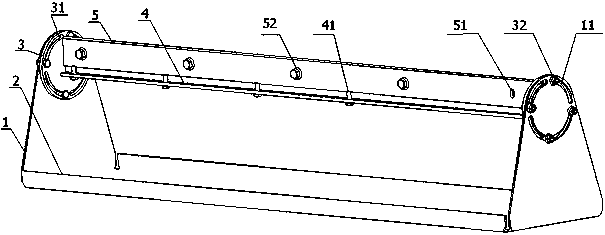

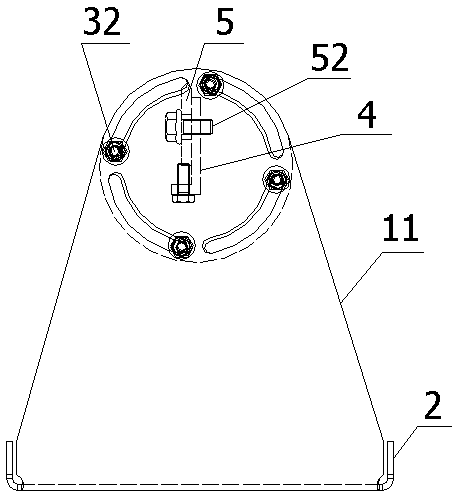

Long fiber bundle melt impregnation system

ActiveCN105538538ALess fiber breakageFully infiltratedCoatingsLong-fiber-reinforced thermoplasticResultant force

The invention provides a long fiber bundle melt impregnation system. The impregnation system includes a driving unit and at least one group of matched and paired driving covered rolls, the driving unit provides power for the driving covered rolls, the driving covered rolls are composed of a first driving roll and a second driving roll, a slit for a long fiber bundle to go through is left between the first driving roll and the second driving roll, the first driving roll and the second driving roll respectively contact with the long fiber bundle in the slit between the rolls when the first driving roll and the second driving roll rotate, and resultant force generated by mutual chimerism of the first driving roll and the second driving roll promotes the long fiber bundle in the slit between the rolls to move. The long fiber bundle melt impregnation system realizes the purposes of reduction of the thickness of the long fiber bundle in the impregnation process and increase of the filament dispersion uniformity of the long fiber bundle, and reaches less fiber breaking loss, full infiltration, uniform dispersion and high-speed stable production in order to obtain a long fiber reinforced thermoplastic plastic with excellent performances.

Owner:BENSONG ENG PLASTICS HANGZHOU

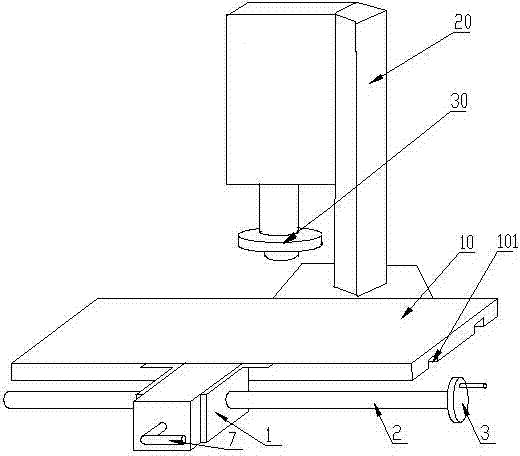

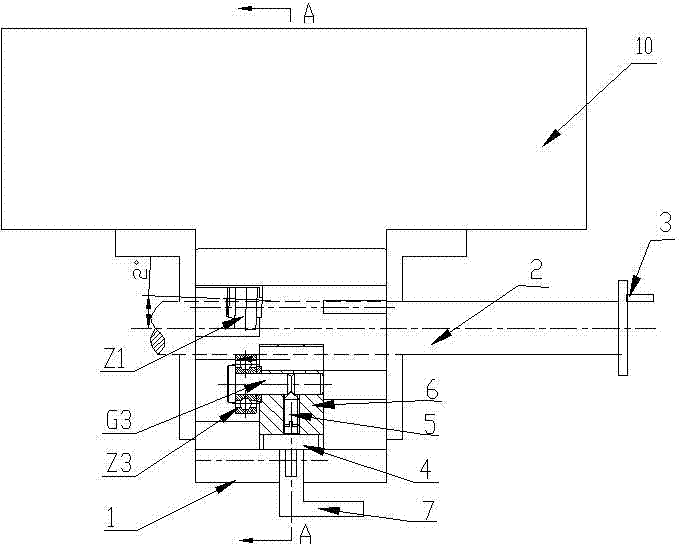

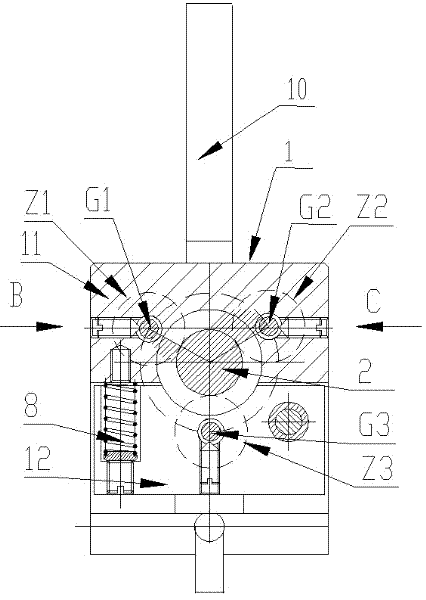

Imager mobile device

InactiveCN102645238AMove quicklyReduce exerciseMeasurement apparatus componentsEngineeringMobile device

The invention discloses an imager mobile device which is used for adjusting the movement of a bearing platform arranged below a lens. The imager mobile device comprises a mobile device connected with the bearing platform; a locking handle is arranged on the mobile device; when the locking handle is positioned at a first position, the mobile device drives the bearing platform to move at a first speed; when the locking handle is positioned at a second position, the mobile device drives the bearing platform to move at a second speed; and the first speed is smaller than the second speed. The imager mobile device has the beneficial effects that the switching between quick movement adjustment and accurate movement adjustment can be conveniently carried out, the effects of positioning the accurate movement adjustment and saving the adjustment time are achieved, and the operation is simple and convenient.

Owner:SUZHOU EASSON OPTOELECTRONICS

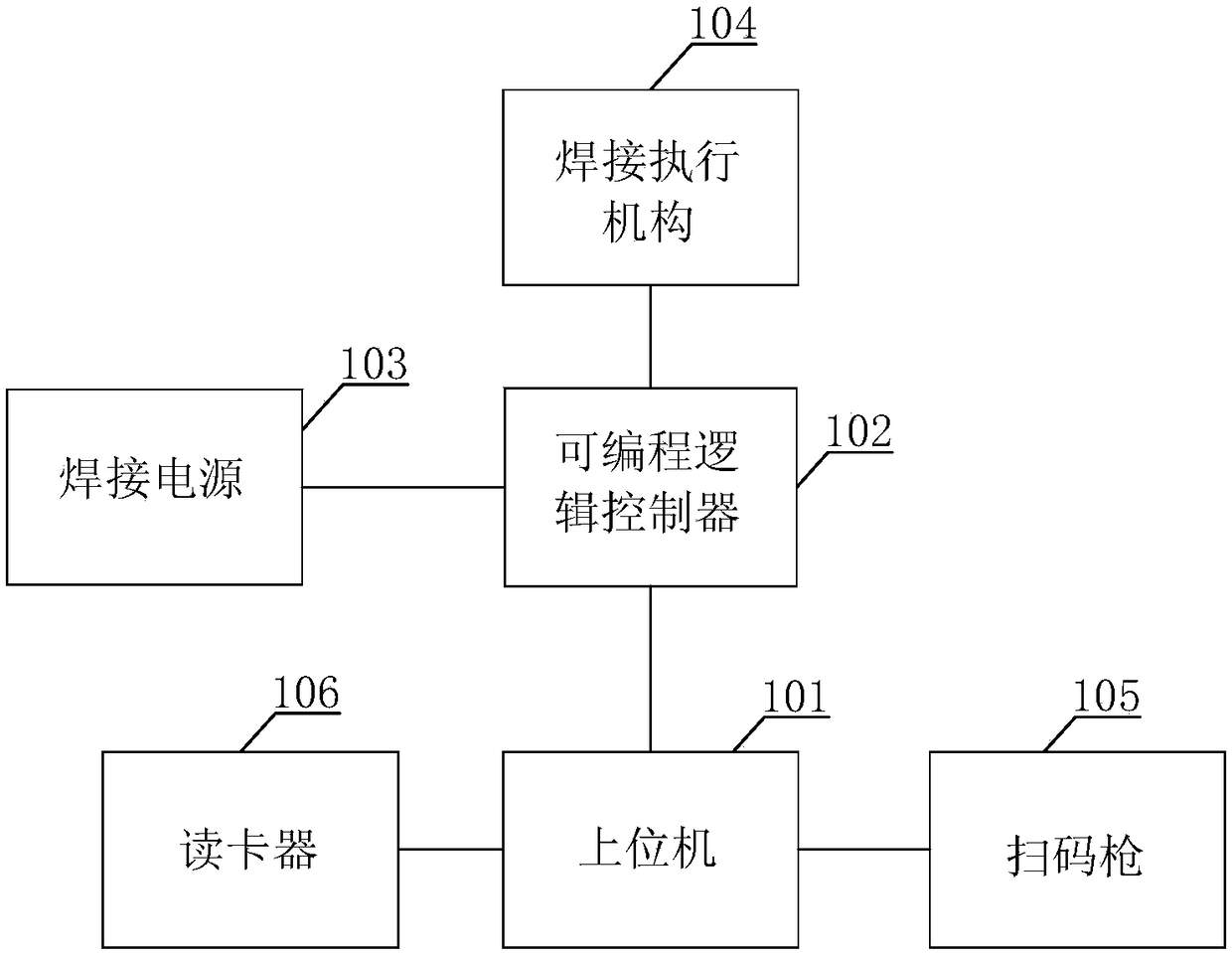

Multi-arc and multi-wire submerged arc welding intelligent control system

InactiveCN109093233AEasy to operateRealize micro-adjustmentArc welding apparatusProgrammable logic controllerSimulation

The invention discloses a multi-arc and multi-wire submerged arc welding intelligent control system. The multi-arc and multi-wire submerged arc welding intelligent control system comprises an upper computer and a programmable logic controller. The upper computer is connected with the programmable logic controller in a communicating mode. The programmable logic controller is connected to welding power source and welding executing agencies of a plurality of welding machines. According to the multi-arc and multi-wire submerged arc welding intelligent control system, an industrial tablet with a touch function is adopted to replace a traditional submerged arc welding controller, matching issue, type-in and adjustment of technological parameters are realized by a virtual keyboard on a screen, the human-computer interaction effect is good, and the idealized tool usage requirements of what you see is what you get are realized; and a DeviceNet means of communication is applied to concentrate control of a plurality of electric arcs on an interface, users are facilitated to operate to realize micro adjustment of multiple electric arc linkage, automatic matching issue of the parameters, real-time comparative analysis, process automatic recording and generation and export of a diagram are realized, and the reliability and traceability of control of the welding process are improved.

Owner:WUXI SANHONG MACHINERY EQUIP

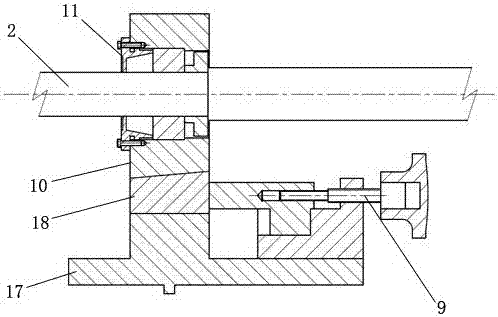

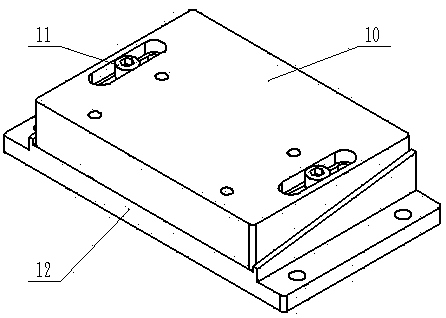

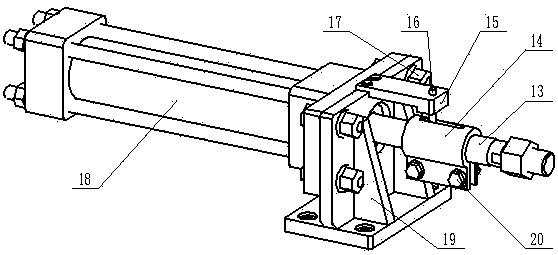

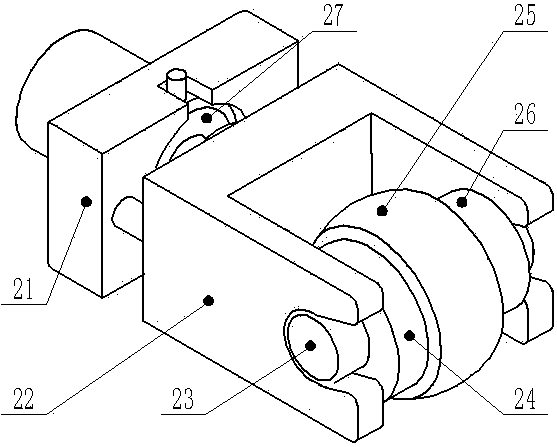

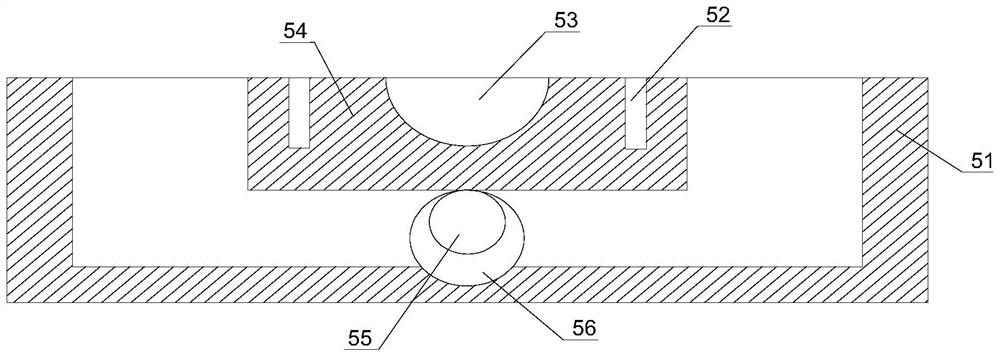

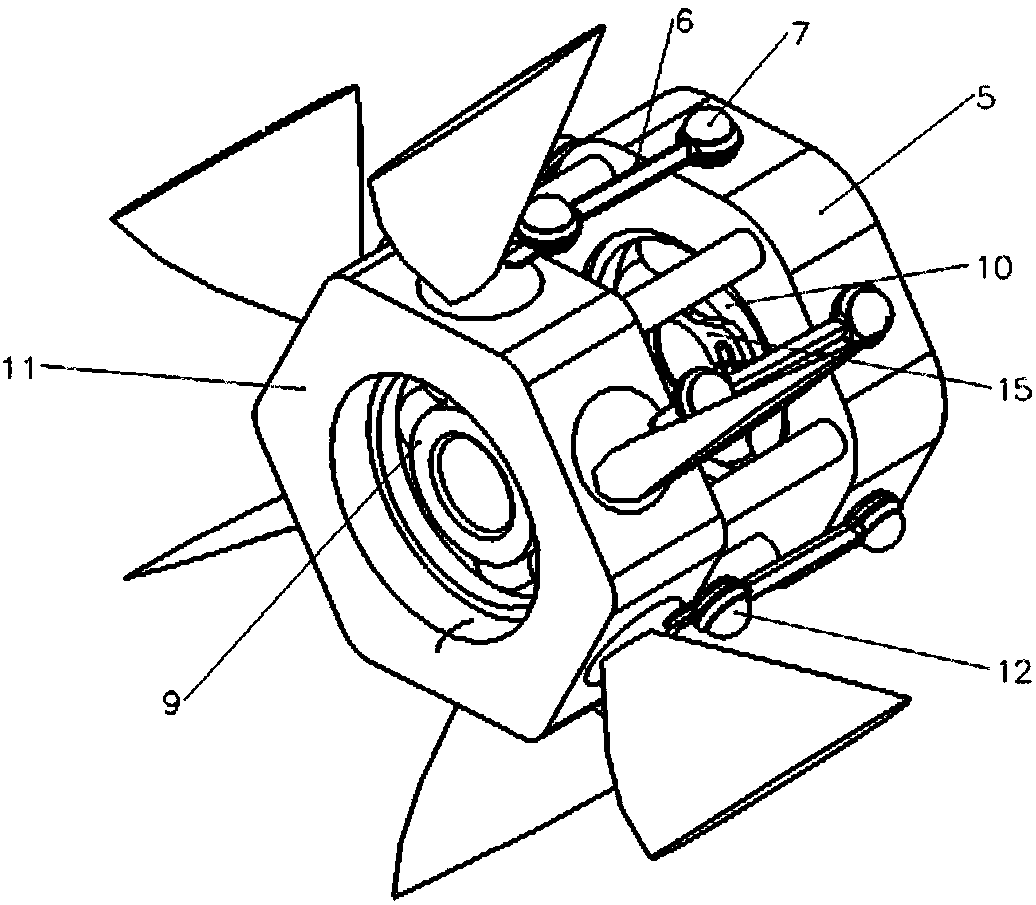

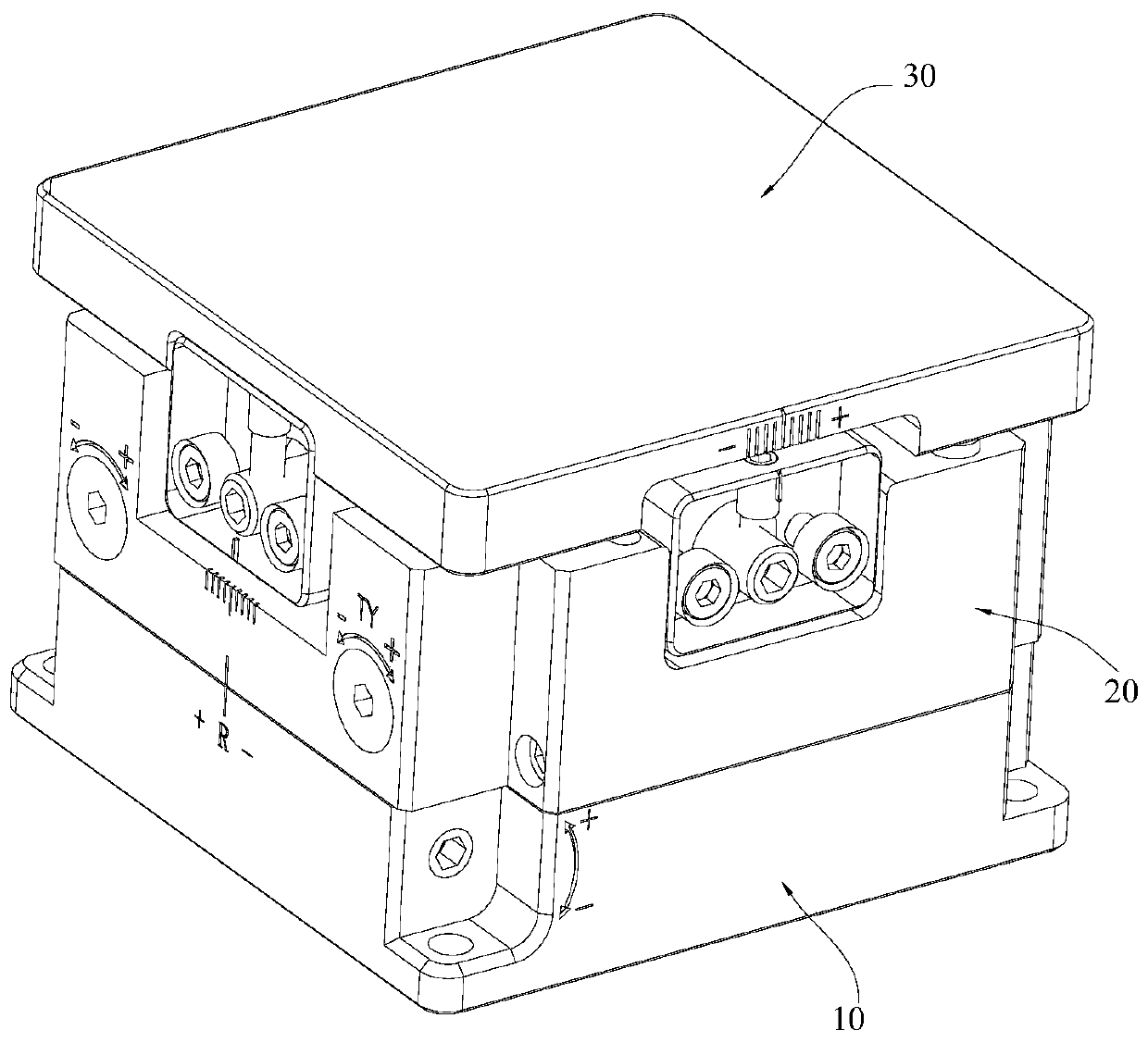

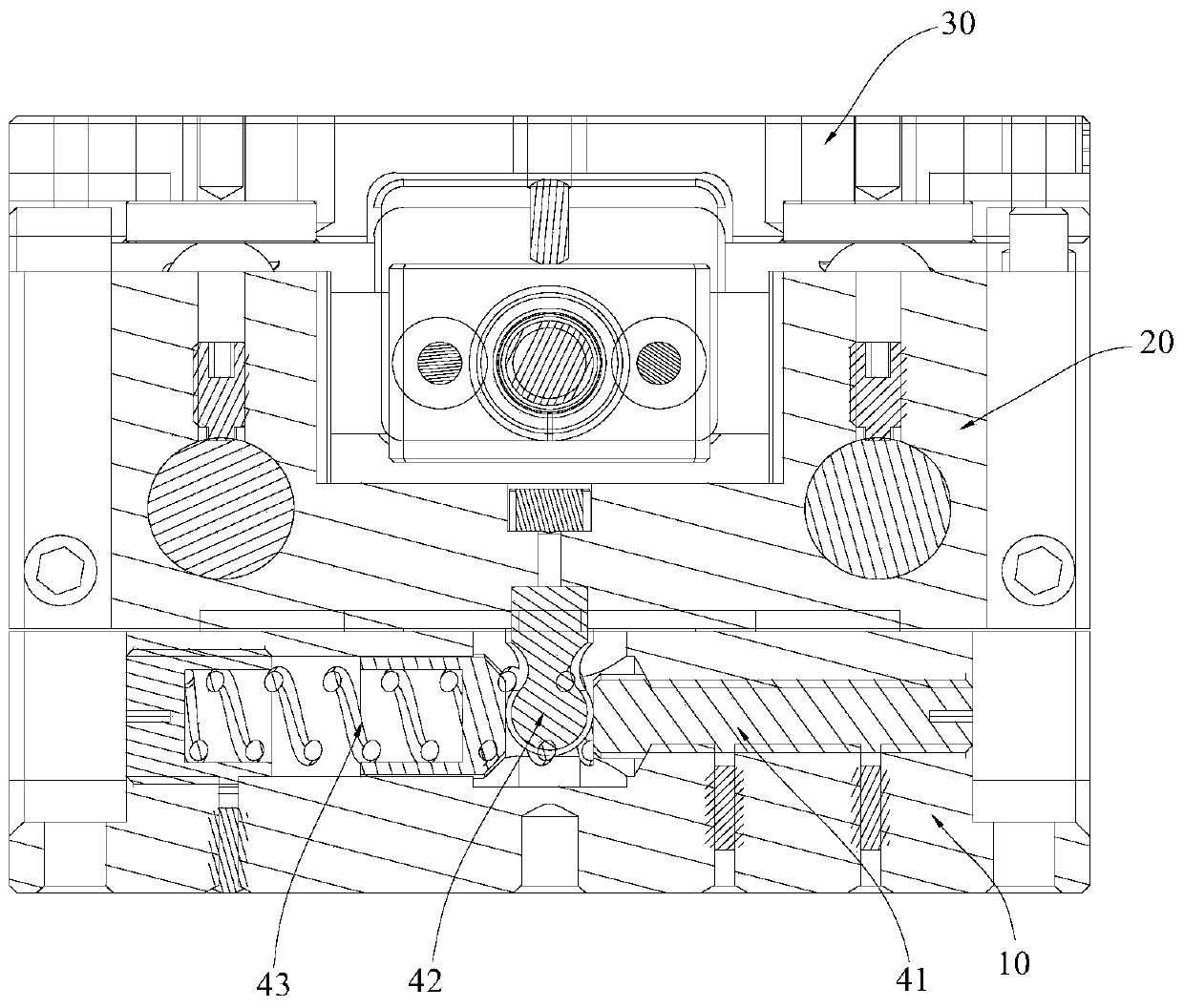

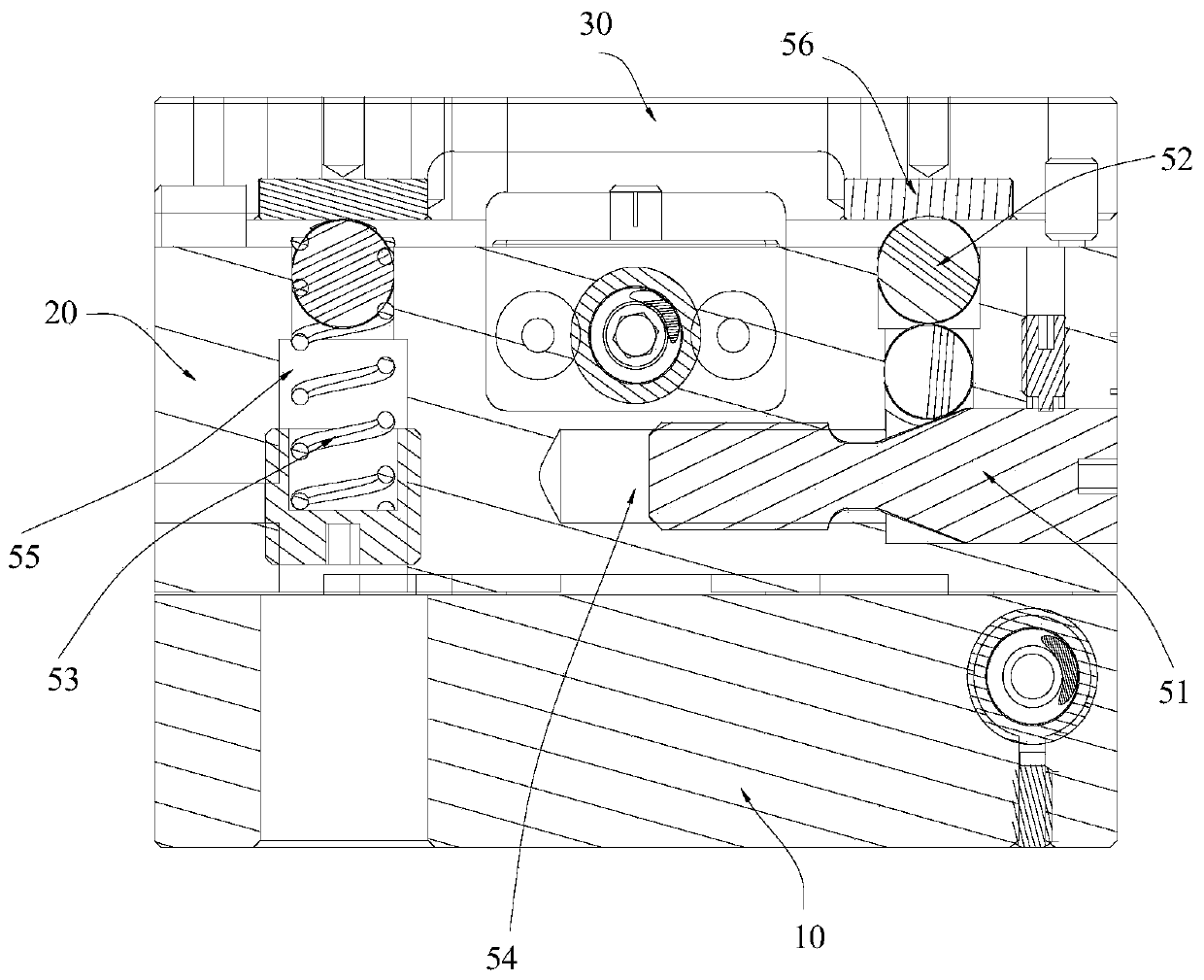

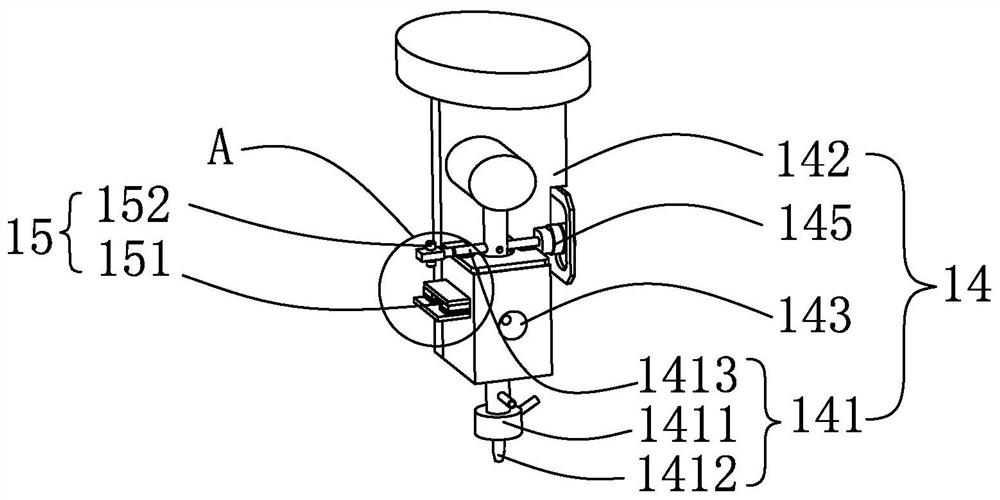

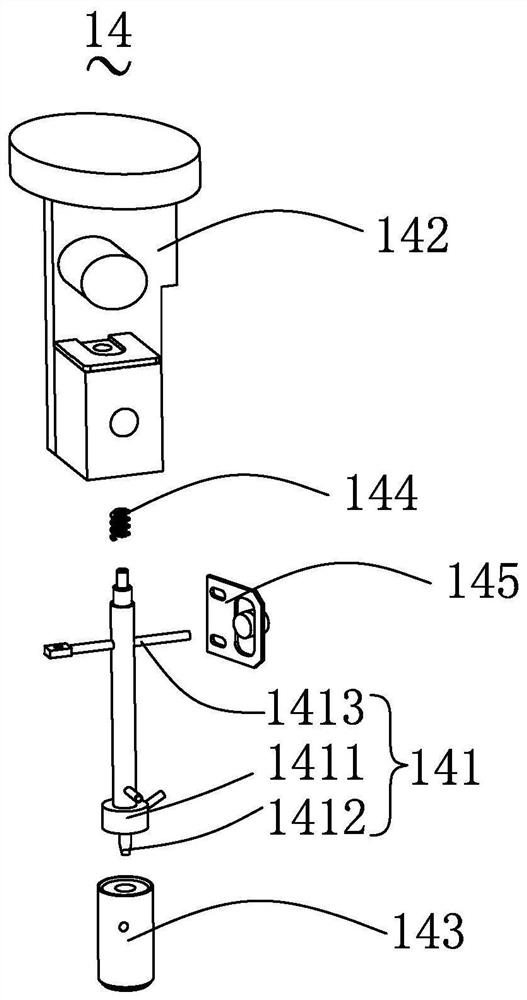

Shaft type part surface rolling and pressing reinforcing device based on piezoelectric type force sensors

InactiveCN107838630ARealize micro-adjustmentEasy to controlFurnace typesHeat treatment furnacesEngineeringMachine tool

The invention relates to a shaft type part surface rolling and pressing reinforcing device based on piezoelectric type force sensors. The shaft type part surface rolling and pressing reinforcing device based on the piezoelectric type force sensors comprises a base, inclined block lifting mechanisms, telescopic mechanisms, guiding mechanisms, rolling and pressing head mechanisms and the piezoelectric type force sensors; the base is installed on a large supporting plate of a turning lathe; the two sides on the base are each provided with the corresponding inclined block lifting mechanism; each inclined block lifting mechanism is provided with the corresponding telescopic mechanism; each telescopic mechanism is provided with the corresponding guiding mechanism and the corresponding rolling and pressing head mechanism; each rolling and pressing head mechanism is provided with the corresponding piezoelectric type force sensor; and the rolling and pressing head mechanisms on the two sides are oppositely arranged. According to the device, micro adjustment of the rolling and pressing head mechanisms in the z axis direction of a machine tool is achieved through the inclined block lifting mechanisms; the rolling and pressing head mechanisms are made to always act on the surface of a workpiece through the telescopic mechanisms; when rolling and pressing machine is performed through the guiding mechanisms, rolling and pressing heads perform normal rolling and pressing machining on the surface of the workpiece; and the piezoelectric type force sensors are used for achieving real-time feedback and control on the rolling and pressing force.

Owner:UNIV OF JINAN

Application method of control system for precisely measuring abbe errors

ActiveCN112066881AAdjust the horizontal positionHigh precisionUsing optical meansLaser transmitterControl system

The invention discloses an application method of a control system for precisely measuring abbe errors, which comprises a cross positioner and a laser emitter, wherein the cross positioner is providedwith a cross positioning point, the cross positioning point corresponds to an emitting port of the laser emitter in position, a fixed seat is fixed below the laser emitter, a fine adjustment plate isarranged on the side, away from an emission port of the laser emitter, of the fixed seat, a rotary knob is arranged on the upper surface of the fine adjustment plate, the fixed seat is fixed to the fine adjustment plate, the transverse position of the fixed seat can be adjusted through the rotary knob, a supporting base is arranged below the fixed seat, a gap is reserved between the supporting base and the fixed seat, a connecting rod is arranged between the supporting base and the fine adjustment plate, and a horizontal adjustment seat capable of adjusting the levelness of the fixed seat is fixed below the supporting base. By monitoring, regulating and controlling the abbe error influencing measurement, the influence of the axle distance is controlled within the reasonable range of the error by adopting auxiliary equipment, and the precision during precision measurement is improved.

Owner:常州巨特智能机械有限公司

Filling valve for weighing filling machine

The invention discloses a filling valve for a weighing filling machine. The filling valve comprises a valve body; a flow port sleeve communicates with the valve body; a valve core capable of moving upand down is arranged in the valve body and the flow port sleeve; a flow guide cone is arranged at the lower end of the valve core; and the upper end of the valve core is connected with a double-stroke cylinder. The valve core of the double-stroke cylinder is controlled to drive the flow guide cone to move up and down, so that valve opening and valve closing of the filling valve, slow filling, andfine adjustment of the opening size of the valve can be realized. According to the invention, slow filling of the filling valve and micro adjustment of the opening size of the valve can be realized;adjustment is sensitive and convenient; high-precision control of the flow rate and the flow rate of the filling valve can be realized; control precision reaches milligrams; uniformity of capacity offilling products is improved; product quality is improved; and meanwhile, the raw material budget and the filling amount are conveniently calculated. The sealing property of the valve can be improved;pollution risk of filling liquid can be avoided; and the service life of equipment can be prolonged. Splashing can be prevented; pollution on equipment and products can be avoided, and product quality can be ensured.

Owner:青州市鹏程包装机械有限公司

Adjustable universal stand bar for heavy equipment

InactiveCN104455955APrecise positioningAdjust the positioning accuratelyMachine framesBall bearingHeavy equipment

An adjustable universal stand bar for heavy equipment is characterized by comprising a lower installation plate, a universal ball bearing, a lower adjusting screw, an intermediate plate, an upper adjusting screw and an equipment stand bar plate, the universal ball bearing is used for achieving supporting, the upper adjusting screw is used for adjusting height, the lower adjusting screw is used for adjusting the lower installation plate to serve as a final support, the universal ball bearing can move forwards, backwards, leftwards and rightwards, and due to the adoption of rolling friction, resistance is small, and micro-adjustment can be achieved; the upper adjusting screw enables rising and falling of the heavy equipment to be achieved directly, the lower adjusting screw can be adjusted to enable the lower installation plate to make contact with the ground, final positioning after adjustment is finished can be achieved, the universal ball bearing can be taken out after positioning, and cost is reduced. By the adoption of the adjustable universal stand bar for the heavy equipment, accurate adjustment and positioning of the heavy equipment during manufacturing and installation can be achieved.

Owner:GANZHOU NONFERROUS METALLURGICAL MACHINERY

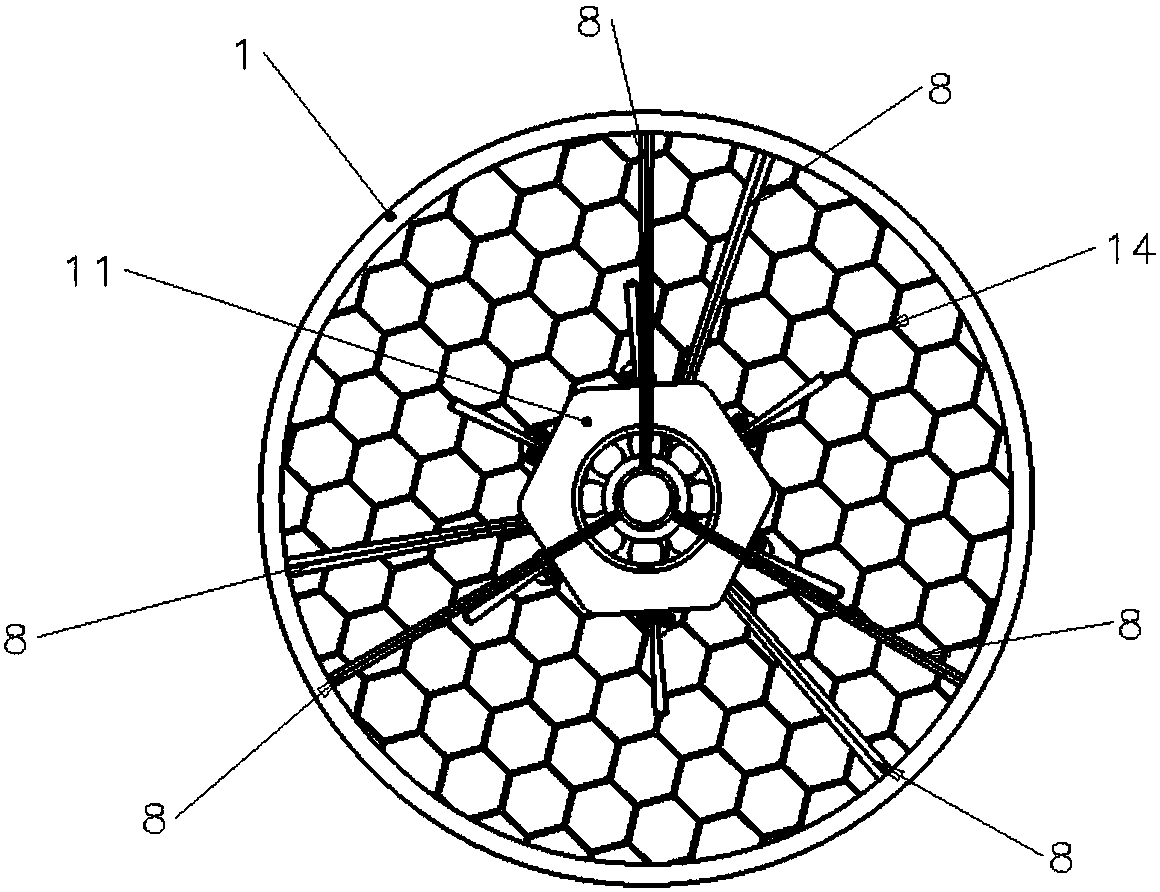

Device for improving stability of liquid flow

ActiveCN108533872AAccelerated dissipationIncrease thickness ratioPipe elementsHydro energy generationImpellerHoneycomb Pattern

The invention provides a device for improving the stability of a liquid flow. The device for improving the stability of the liquid flow comprises a shell, a flow stabilizing assembly, a flow fine adjustment assembly and a honeycomb-shaped channel. The shell comprises a shell front section and a shell rear section sliding relatively; the honeycomb-shaped channel is arranged on the cross section ofthe shell rear section; the flow stabilizing assembly comprises a main shaft, a front bearing and a rear bearing; the main shaft comprises a main shaft front section and a main shaft rear section inserting mutually and sliding relatively; the main shaft front section and the main shaft rear section are connected with the shell; the flow fine adjustment assembly comprises a fine adjustment impellerand an impeller shaft; the fine adjustment impeller is arranged on an outer ring of the front bearing in a sleeving mode; six cylindrical open holes are formed in one side of the impeller shaft; sixcylinders are arranged on the inner side of a connecting ring; an inner ring of the connecting ring is arranged on the rear bearing in a sleeving mode; and six circular slots are equidistantly formedin an outer ring of the connecting ring. The device for improving the stability of the liquid flow provided by the invention has the beneficial effects of elaborate design, lower manufacturing cost, and capabilities of reducing a turbulence effect and effectively improving the stability of the liquid flow, and has a flow fine adjustment function with higher accuracy.

Owner:SOUTHWEST JIAOTONG UNIV

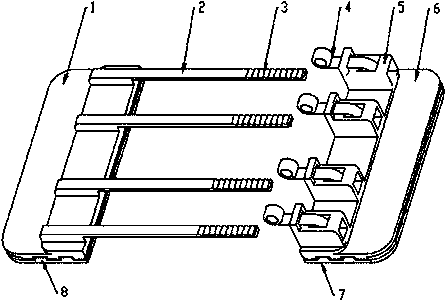

Five-axis micro sliding table

PendingCN111515710AReduced structure space sizeIncrease freedomLarge fixed membersSmall rangeMechanical engineering

The invention discloses a five-axis micro sliding table. The five-axis micro sliding table comprises a base, an adjustment block, a mounting plate, a first adjustment component, a second adjustment component and a third adjustment component; the adjustment block is pivoted on the base and can rotate around a Z axis; the mounting plate is mounted at the top of the adjustment block; the mounting plate is used for rotating around an X axis and rotating around a Y axis; the mounting plate is used for sliding in the X-axial direction and sliding in the Y-axial direction; the first adjustment component is used for driving the adjustment block to rotate around the Z axis; the second adjustment component is used for driving the mounting plate to rotate around the X axis, and is used for driving the mounting plate to rotate around the Y axis; the third adjustment component is used for driving the mounting plate to move in the X-axial direction and driving the mounting plate to move in the Y-axial direction. The five-axis micro sliding table disclosed by the invention can realize five-axis movement within a relatively small range.

Owner:ZHUHAI BOJAY ELECTRONICS

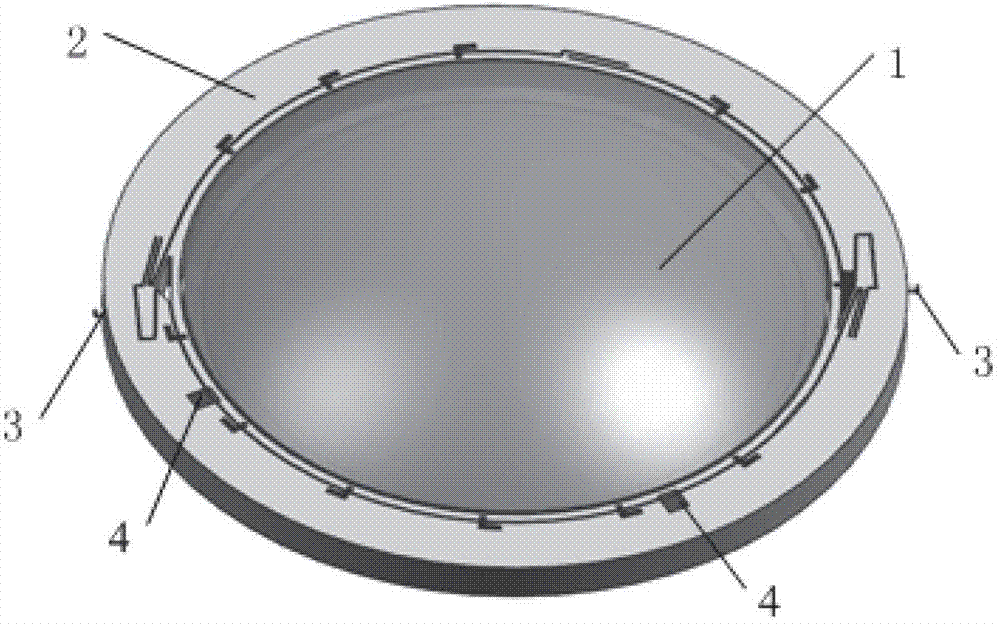

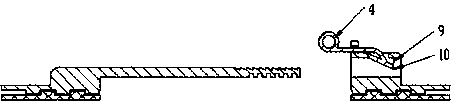

Fixed-length cutting machine for tiles of glass fiber reinforced plastics workshop

ActiveCN106272619ARealize up and down clamping and fixingRealize micro-adjustmentMetal working apparatusGlass fiberEngineering

The invention relates to a fixed-length cutting machine for tiles of a glass fiber reinforced plastics workshop. The fixed-length cutting machine comprises a side plate supported by upright columns, a supporting platform is fixedly mounted in the middle of the side plate, a plurality of supporting wheels are mounted on the supporting platform through bearing blocks, and a distance adjusting motor which is used for driving one of the supporting wheels is further arranged on the supporting platform; a vertical pressing cylinder is further fixedly mounted on the top of the side plate, a base is fixedly mounted at the lower end of a piston rod of the pressing cylinder, a plurality of pressing wheels are mounted on the lower surface of the base through bearing blocks, and the pressing wheels are aligned with the supporting wheels vertically; and lifting cutting devices are respectively arranged on the left side and the right side of the supporting platform, each lifting cutting device comprises a vertical lifting cylinder, a lifting platform is fixedly mounted at the upper end of a piston rod of each lifting cylinder, a cutting motor is fixedly mounted on the inner side of each lifting platform, and a cutting saw blade is mounted on a motor shaft of each cutting motor.

Owner:EULIKIND TIANJIN TECH

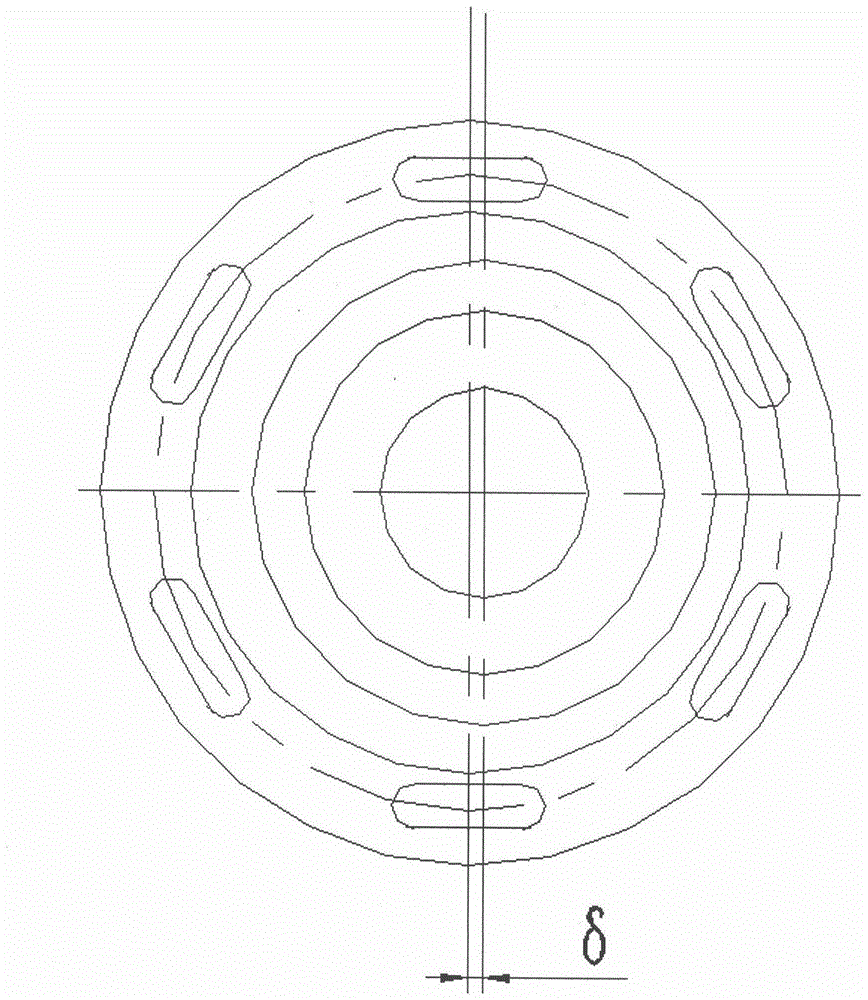

Online automatic cleaning device of belt conveyor idler

The invention relates to an online automatic cleaning device of a belt conveyor idler. The online automatic cleaning device comprises a scraping knife, a scraping knife adjusting bracket, scraping knife bases and fixed brackets, wherein the scraping knife bases are arranged on both sides of the scraping knife adjusting bracket, the fixed brackets are correspondingly arranged and are used for installing the scraping knife bases, and the scraping knife adjusting bracket is fixed to the scraping knife bases; a plurality of arc-shaped holes are circumferentially formed in the scraping knife bases,fastening holes are formed in positions, which correspond to the arc-shaped holes, of the fixed brackets in a matching mode, and connecting bolts pass through the corresponding arc-shaped holes and the fastening hole, so that the scraping knife bases are fastened to the fixed brackets, and the scraping knife bases can be circumferentially adjusted. According to the online automatic cleaning device of the belt conveyor idler, the arc-shaped holes are formed in the scraping knife bases and the fixed brackets, so that the scraping knife bases are rotatably adjusted, the scraping knife adjustingbracket and the scraping knife are driven to rotate, the angle of the scraping knife is adjusted, and the effects of automatically cleaning the belt conveyor idler on line and in real time and deeplycleaning the belt conveyor idler are realized.

Owner:CHINA TOBACCO HENAN IND

Reusable medical skin stapler with adjustable force

The invention discloses a reusable and intensity-adjustable medical skin stitcher. The reusable and intensity-adjustable medical skin stitcher comprises double sticky tapes, a first base, a second base, a rack, a locking fastener, a tensioner and a fine adjustment nut, wherein the locking fastener has a locked state and an unlocked state, when the locking fastener is in the locked state, the firstbase and the base can be close to each other, and when the locking fastener is in the unlocked state, the first base and the second base can be conveniently disconnected. The reusable and intensity-adjustable medical skin stitcher achieves unlocked separation of the first base and the second base as well as fine adjustment of the fine adjustment nut by changing the double sticky tapes to furtherachieve reusability and force adjustability and controllability, thereby solving the problem that medical skin stitchers in the prior art cannot be disconnected and are non-reusable after being closedonce.

Owner:SHANDONG PROVINCIAL HOSPITAL

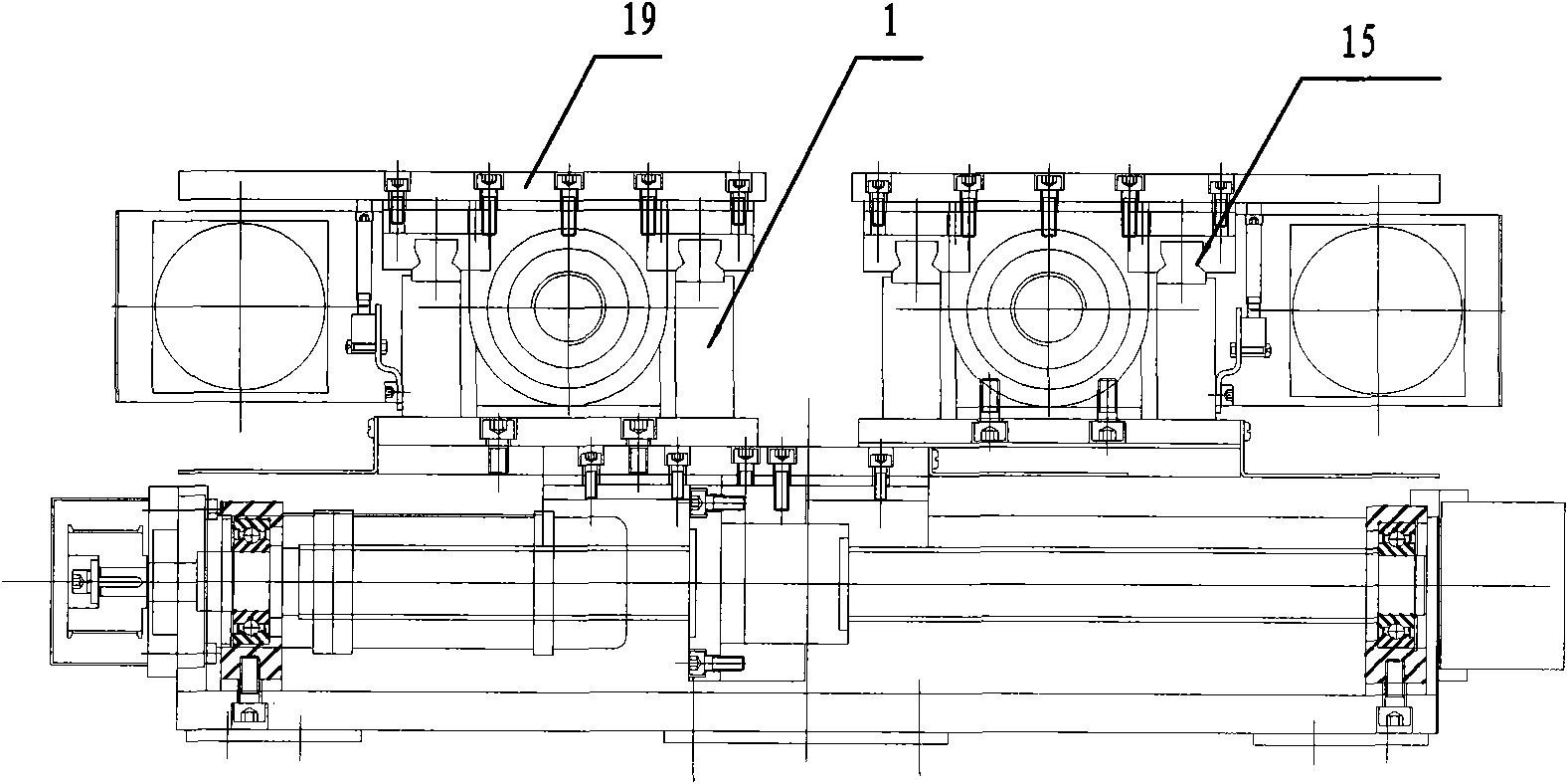

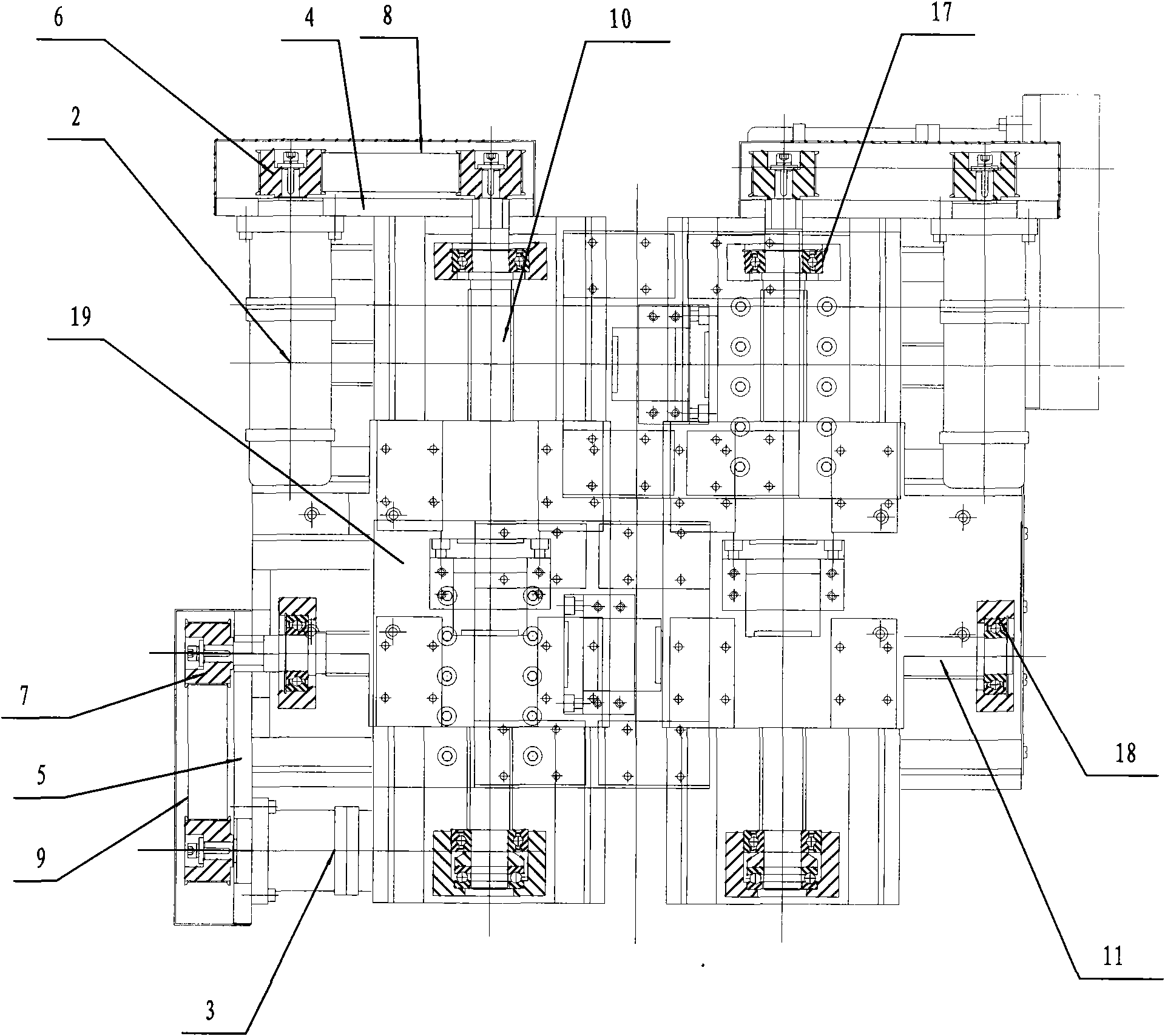

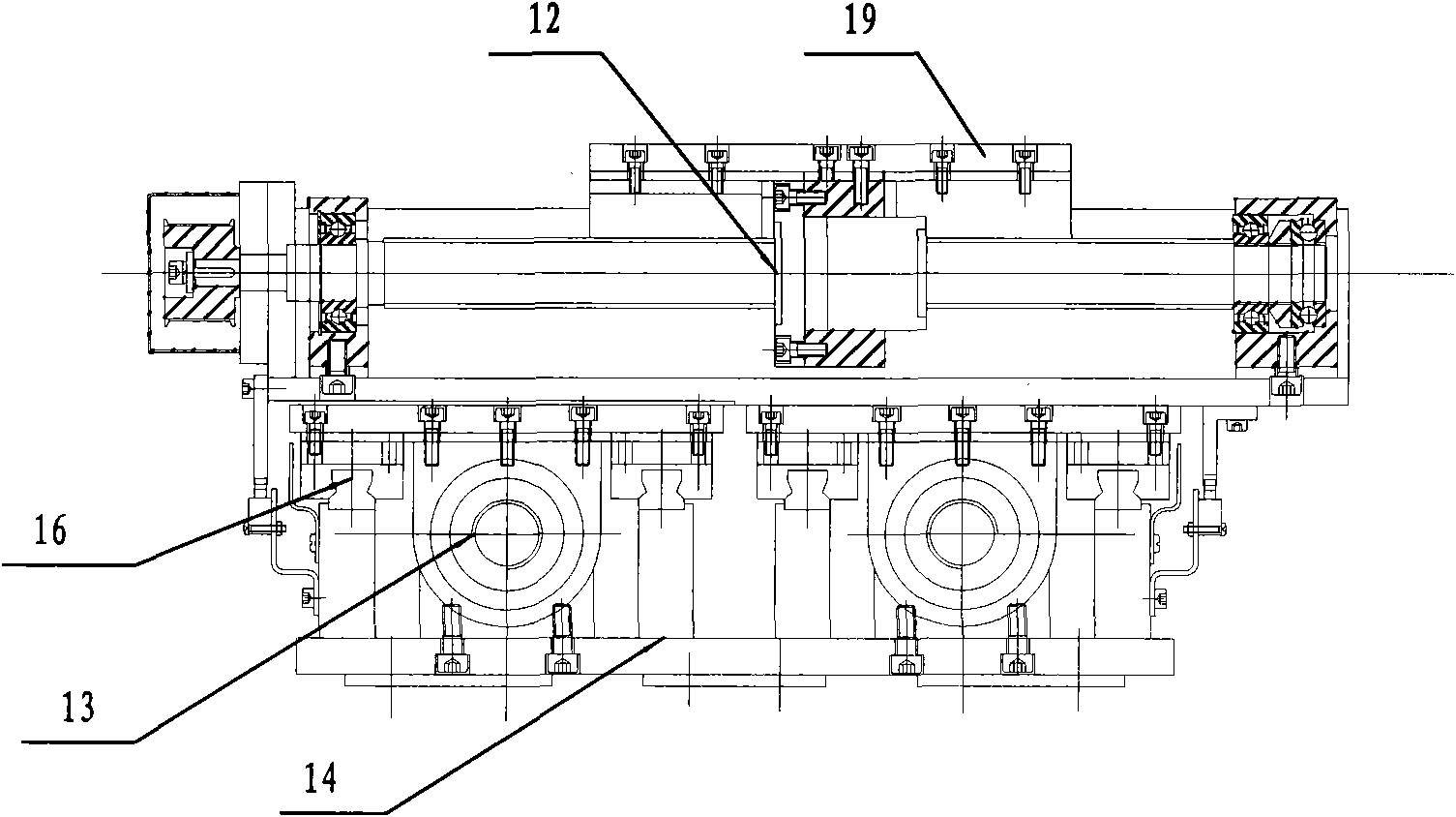

A two-way synchronous clamping plasma steel pipe cutting equipment

ActiveCN106216823BAchieve rotationRealize distance deliveryPlasma welding apparatusMetal working apparatusEngineeringSizing

The invention provides two-way synchronous clamping plasma steel pipe cutting equipment, belongs to the technical field of steel pipe cutting devices, and aims to solve the technical problem of steel pipes incapable of rotating and transferring through a mechanical device when the steel pipes are cut by a plasma cutter. The equipment comprises a rotary clamping device, a clamping sizing transfer device, a bracket device and a turnover discharge device; the rotary clamping device includes a clamping mounting frame, a turntable mechanism, a clamping mechanism, a two-way synchronous clamping drive connecting mechanism, a turntable driving mechanism and a lifting mechanism; and the clamping sizing transfer device includes a sizing transfer guide rail, a sizing clamping mounting frame, the clamping mechanism, the two-way synchronous clamping drive connecting mechanism, the lifting mechanism and a clamping moving disc mechanism. The equipment can realize clamping and rotation of the steel pipes in the steel pipe cutting process, and performs fixed-distance transfer for the steel pipes.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

Automatic chip mounter

ActiveCN112701065AAvoid damageImprove installation accuracySemiconductor/solid-state device manufacturingWaferingEngineering

The invention relates to the technical field of chip mounters, in particular to an automatic chip mounter. The automatic chip mounter comprises a driving assembly, a die bonding assembly and a sensing assembly which are connected in sequence. The die bonding assembly is used for sucking a wafer, the driving assembly drives the die bonding assembly to place the wafer on a substrate for bonding, and the sensing assembly detects the pressure between the wafer and the substrate when the wafer is bonded by the die bonding assembly. According to the design, the pressure when the wafer is attached to the substrate is detected, so that the phenomenon that the wafer and the substrate are not firmly attached or misplaced due to the fact that the attaching pressure between the wafer and the substrate is too small when an automatic chip mounter is used for die bonding can be avoided, meanwhile, the wafer can be prevented from being damaged due to the fact that the attaching pressure between the wafer and the substrate is too large, and by detecting the pressure when the wafer is attached to the substrate, the mounting precision between the wafer and the substrate during die bonding by the automatic chip mounter is further improved.

Owner:微见智能封装技术(深圳)有限公司

Ceramic grooving machining device

InactiveCN109080004ARealize micro-adjustmentImprove rigidityWorking accessoriesStone-like material working toolsEngineeringMachining

The invention discloses a ceramic grooving machining device comprising a tool body. A spindle is fixedly mounted on the upper portion in the middle of the tool body, a lower flange is mounted at the upper end of the spindle, a cutting blade is mounted on the upper surface of the lower flange concentrically, and an upper flange is mounted on the upper surface of the cutting blade to compress the cutting blade; a plurality of sliding table guide rails are mounted around the upper surface of the tool body, a sliding table is slidably connected to the upper portion of each sliding table guide rail, and sliding table tops are arranged on the upper surfaces of the sliding tables and provided with workpiece clamps; and bosses are arranged at the bottoms of the workpiece clamps, and the workpiececlamps are fixedly connected with the sliding table tops through the bosses. The ceramic grooving machining device can simultaneously cut a plurality of workpieces, the cutting blade is supported through an upper supporter and a lower supporter, thus the rigidity of the cutting blade is improved, and the cutting efficiency of the cutting blade is improved; and when the distance between the grooving position and the cutting blade has a deviation, micro-adjustment can be directly achieved only by rotating a third screw, and using is quite convenient.

Owner:嘉兴市耐思威精密机械有限公司

Inter-shaft central distance adjusting mechanism

InactiveCN104455339ARealize micro-adjustmentMachining accuracy adjustmentTransmission elementsGearing detailsDrive shaftEngineering

The invention discloses an inter-shaft central distance adjusting mechanism which comprises a driving shaft and a driven shaft. The two ends of the driving shaft are installed on two driving bearing pedestals respectively. The inner surfaces of the two driving bearing pedestals are non-concentric cylindrical surfaces. The eccentricity exists between the two driving bearing pedestals. By means of the inter-shaft central distance adjusting mechanism, the central distance can be slightly adjusted, the machining errors are reduced, and the assembling accuracy is adjusted.

Owner:杨桂珍

Tracking device for welding hull longitudinal

InactiveCN101596658ARealize micro-adjustmentAchieve automatic adjustment tracking weldingWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention relates to a tracking device for welding hull longitudinal, comprising a welding arm. The invention is characterized in that the welding arm is fixed on a welding arm seat, the welding arm seat is connected with an upper micro-adjustment mechanism and a lower micro-adjustment mechanism of the welding arm, and the upper micro-adjustment mechanism and the lower micro-adjustment mechanism of the welding arm are connected with a left micro-adjustment mechanism and a right micro-adjustment mechanism of the welding arm. The welding arm is connected with the upper micro-adjustment mechanism and the lower micro-adjustment mechanism of the welding arm and the left micro-adjustment mechanism and the right micro-adjustment mechanism of the welding arm, which can realize the micro-motion regulation of the welding arm in the upper, lower, left and right directions, so that the automatic regulation and the tracking welding of the welding seam of the hull longitudinal are achieved and the work efficiency is high.

Owner:WUXI HUALIAN PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com