Filling valve for weighing filling machine

A filling valve and filling machine technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of liquid splash, large valve opening flow, calculation of raw material budget and filling volume, etc., to achieve sensitive and convenient adjustment, The effect of improving product quality and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

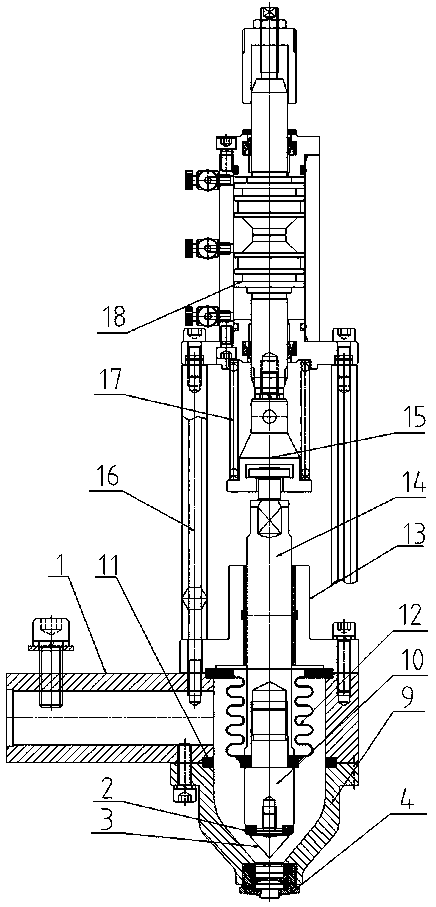

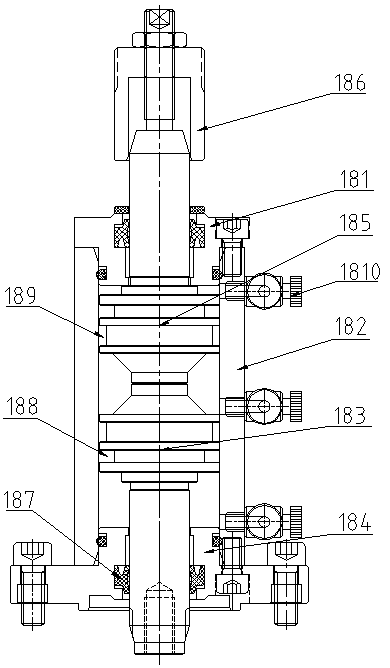

[0034] Embodiment 1 A kind of filling valve for weighing filling machine

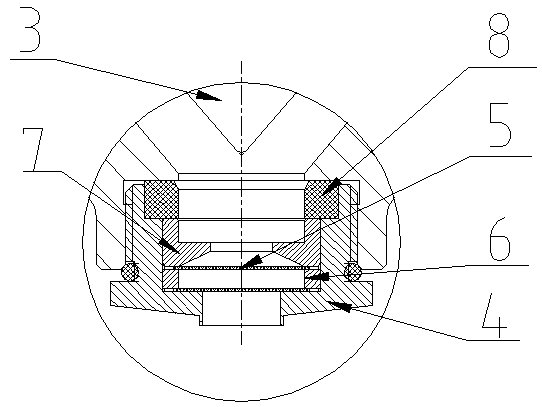

[0035] Such as Figure 1-4 Commonly shown, the present invention provides a filling valve for a weighing filling machine, including a valve body 1, a valve core, an orifice sleeve 9 and a double-action double-stroke cylinder 18, and the valve body 1 is used for conveying and filling The passage of the liquid; the valve body 1 is provided with a liquid inlet and a liquid outlet, and the central axes of the liquid inlet and the liquid outlet are arranged perpendicular to each other.

[0036] The outlet end of the valve body 1 is fixedly provided with an orifice sleeve 9, the orifice sleeve 9 is funnel-shaped, and the orifice sleeve 9 is used to store the filling liquid to be discharged; the orifice sleeve 9 It is fixedly connected with the valve body 1 by bolts; the orifice sleeve 9 and the valve body 1 are sealed by an orifice sealing ring 11; the channel outlet end of the orifice sleeve 9 is a conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com