Detection and judgment method for included angle between inner ring conical rolling path and large flange

A technology of conical raceway and large rib, applied in the direction of angle/taper measurement, etc., to achieve the effect of eliminating errors, reliable judgment and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

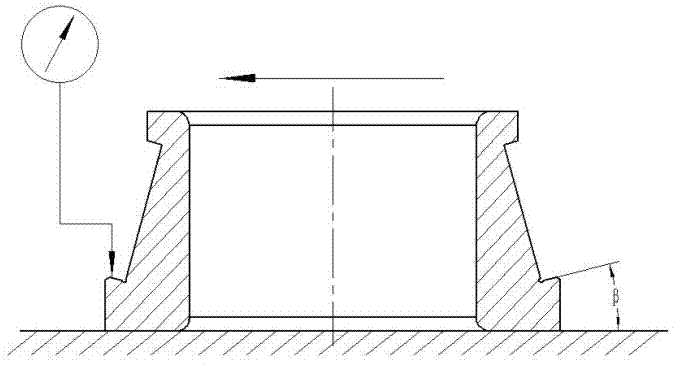

[0029] The invention is a method for detecting and judging the included angle between the conical raceway of the inner ring and the large rib. The detection and judgment method can timely determine whether the included angle between the conical raceway of the inner ring and the large rib conforms to the designed angle ω in the production process. , has the characteristics of high detection accuracy, small error and reliable judgment.

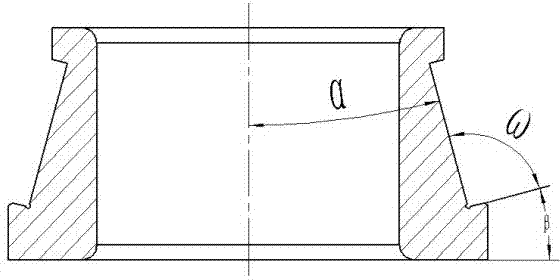

[0030] combine figure 1 , the inner ring has a conical raceway, and a small rib and a large rib are respectively arranged at both ends of the conical raceway. The small rib and the large rib have the same inclination relative to the conical raceway, and The end face of the inner ring adjacent to the small rib is called the small end face, and the end face of the inner ring adjacent to the large rib is called the large end face, and the side length of the small rib ≤ the side length of the big rib, so The design included angle between the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com