Fixed-length cutting machine for tiles of glass fiber reinforced plastics workshop

A fiberglass and cutting machine technology, applied in metal processing and other directions, can solve the problems of fixed-length cutting troubles, difficult cutting machine loading and fixing, etc., achieve good cutting effect, improve positioning accuracy and convenience, and simple and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

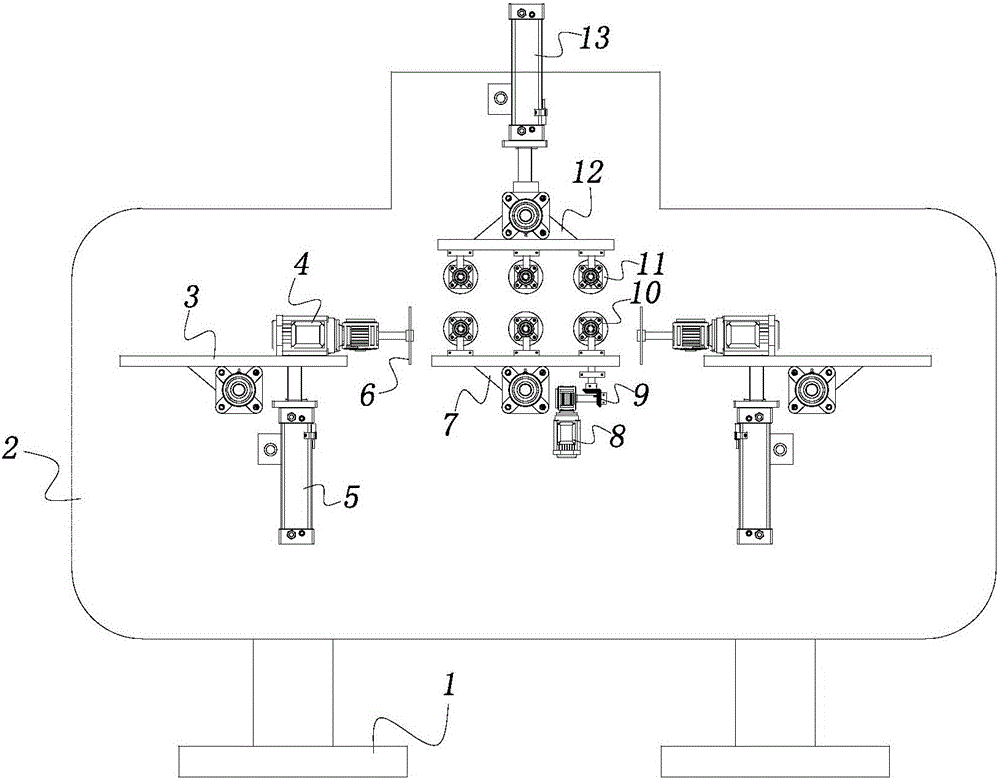

[0012] See figure 2 , the fixed-length cutting machine for FRP factory building tiles of the present invention includes a side plate 2 supported by a column 1, a support platform 7 is fixedly installed in the middle of the side plate 2, and a plurality of support wheels 10 are installed on the support platform 7 through a bearing seat , On the supporting platform 7, there is also a pitch-adjusting motor 8 that drives one of the supporting wheels 10 .

[0013] The top of side plate 2 is also fixedly installed with vertical compression cylinder 13, and base 12 is fixedly installed on the lower end of its piston rod, and a plurality of pressure rollers 11 are installed by bearing seat on the lower surface of base 12, each The pressure rollers 11 are aligned up and down with each support roller 10 .

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com