Polishing machine

A polishing machine and frame technology, which is applied in the polishing machine field, can solve the problems of unstable fixation, offset worktable, and low adjustment precision, and achieve the effects of wide adjustment range, precise precision and long force arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

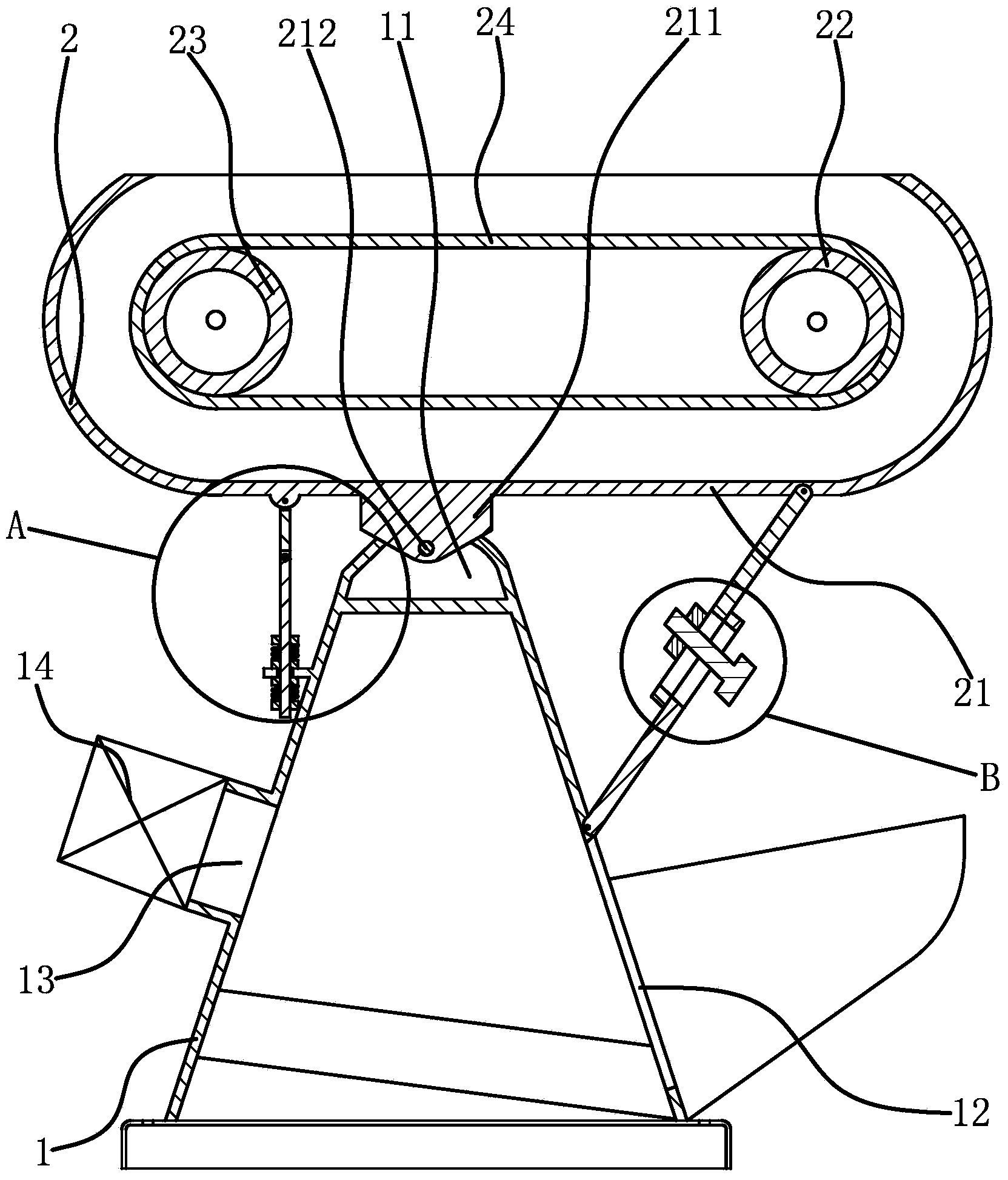

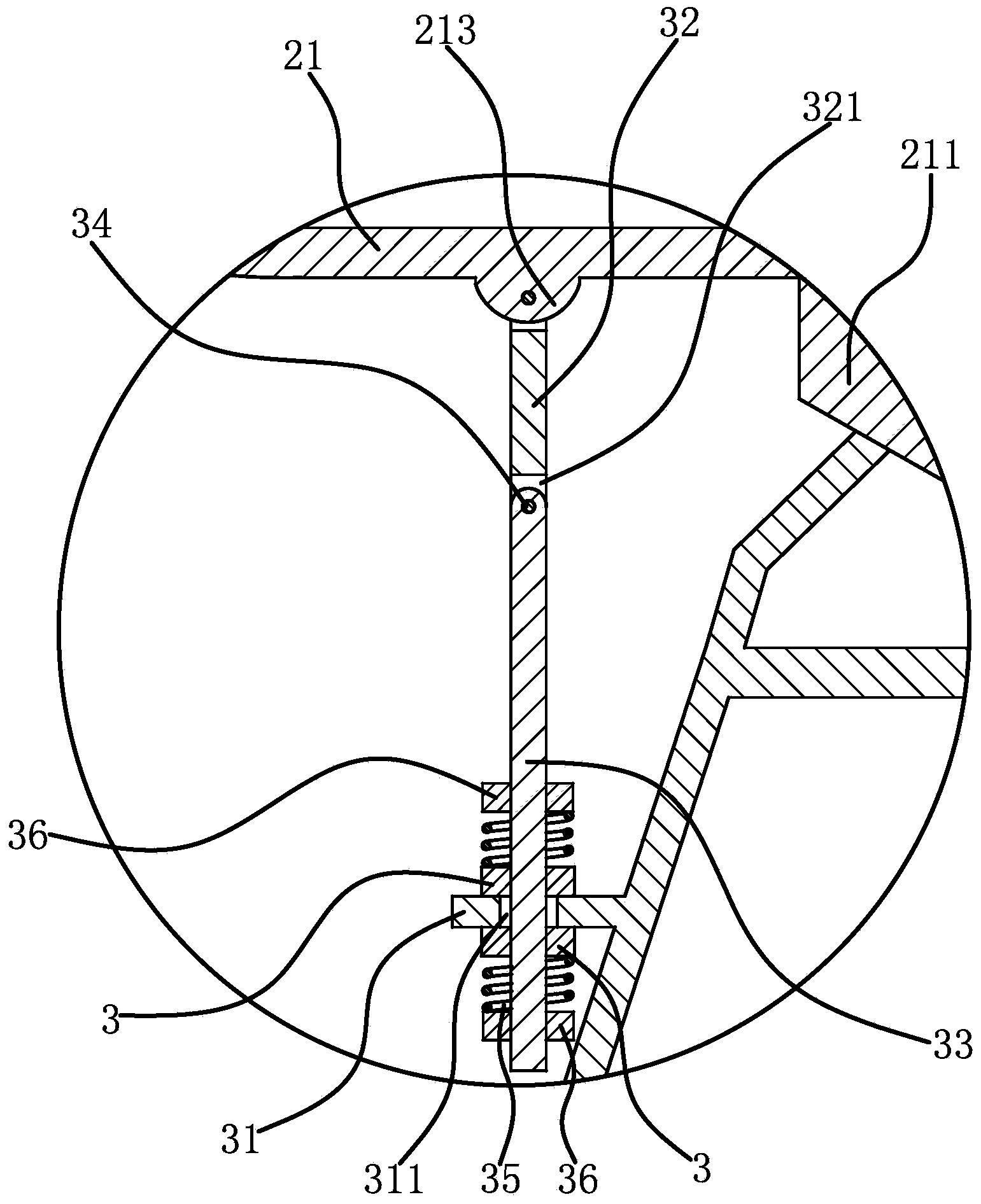

[0031] Such as figure 1 As shown, a polishing machine includes a frame 1 and a workbench 2. The workbench 2 is in the shape of a strip. The lower part of the workbench 2 is connected to the top of the frame 1 through a connecting shaft 212. There is a driving wheel 22 and a driven wheel 23, the driving wheel 22 and the driven wheel 23 are respectively rotatably connected to the two ends of the workbench 2, and the polishing belt 24 is set on the driving wheel 22 and the driven wheel 23, and the polishing belt 24 is set After driving wheel 22 and driven wheel 23, it can run along the length direction of workbench 2. The upper side and two arcuate surfaces of polishing abrasive belt 24 are polishing work points, and frame 1 and workbench 2 lower ends also pass through A connecting assembly with a screw 33 is connected, and the lower end of the screw 33 is slidingly connected to the frame 1 , and a positioning nut 3 is sleeved on the screw 33 , and the positioning nut 3 can axial...

Embodiment 2

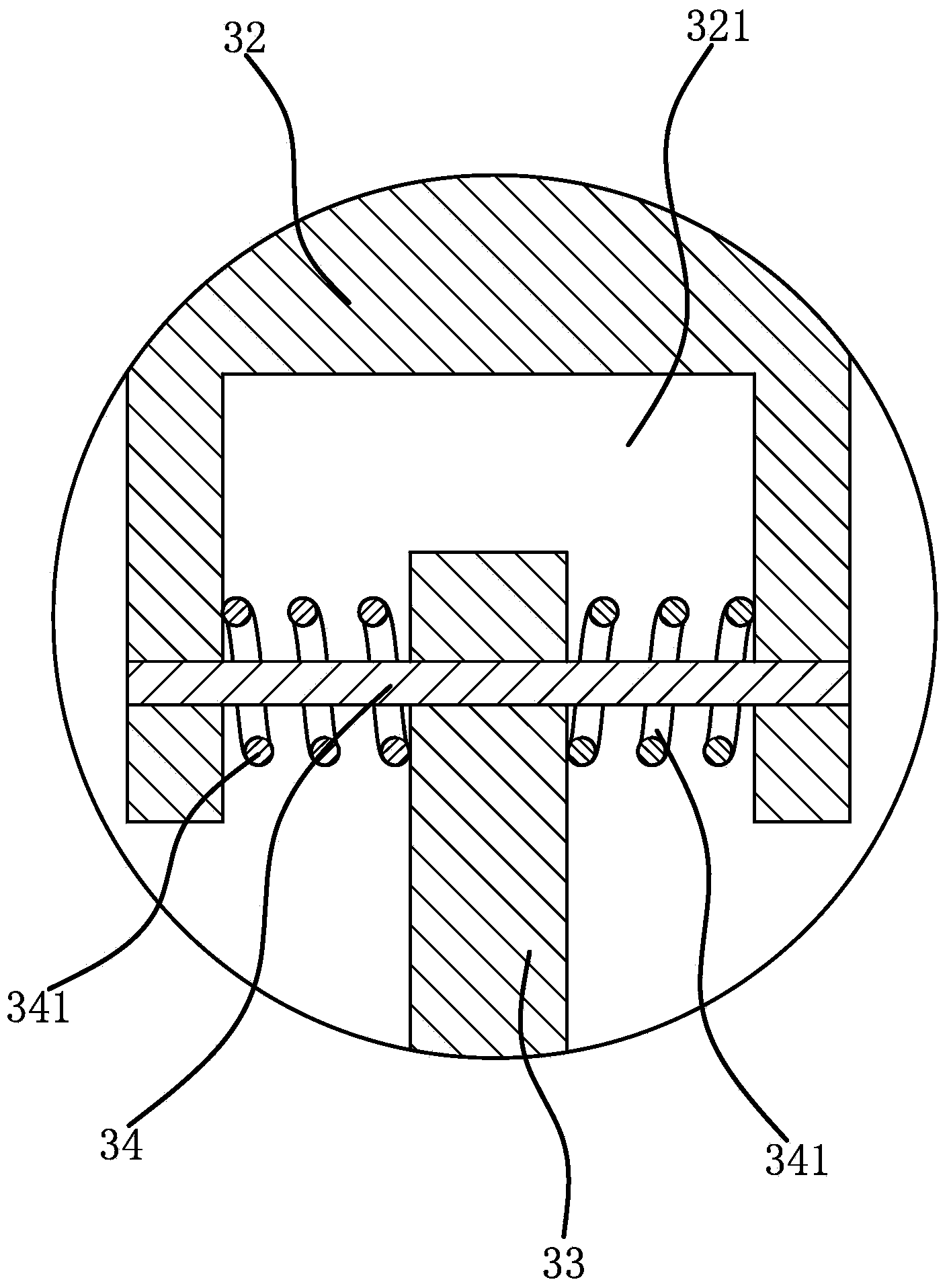

[0036] The structure of the polishing machine is basically the same as that of Embodiment 1, the difference is that Figure 5 , Figure 6 , Figure 7 As shown, a strip-shaped adjusting plate 4 is also provided between the two connecting plates 11, and an annular connecting groove 111 is provided on the opposite sides of the two connecting plates 11, and the connecting groove 111 is coaxially arranged with the connecting hole, and the adjusting plate 4 The two relatively long edges of the upper side are vertically fixed with a support plate 41, and a through hole 411 is opened on the support plate 41. The outer surface of the support plate 41 surrounds the through hole 411 and has an annular convex edge 412, which is slidably connected to the connection In the slot 111 , the connecting shaft 212 passes through the through hole 411 , and an adjustment mechanism 5 capable of adjusting the angle of the table surface of the workbench 2 is provided between the adjustment plate 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com