Computer hydraulic synchronous propelling method and apparatus thereof

A hydraulic synchronization and computer technology, applied in computer control, earthwork drilling, instruments, etc., can solve the problems of long construction period, high technical difficulty, large engineering quantity, etc., achieve shortened construction period, high technical content, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

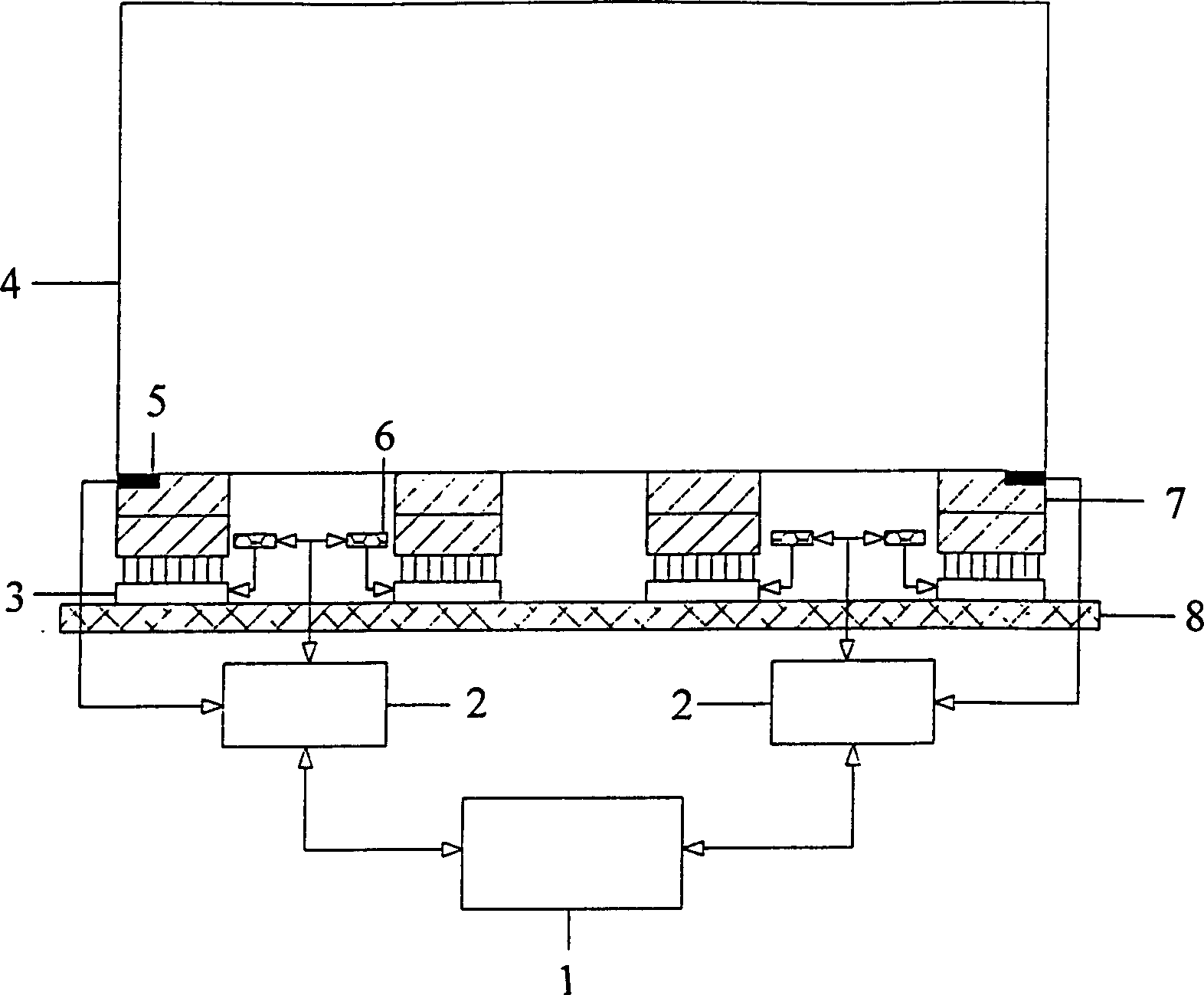

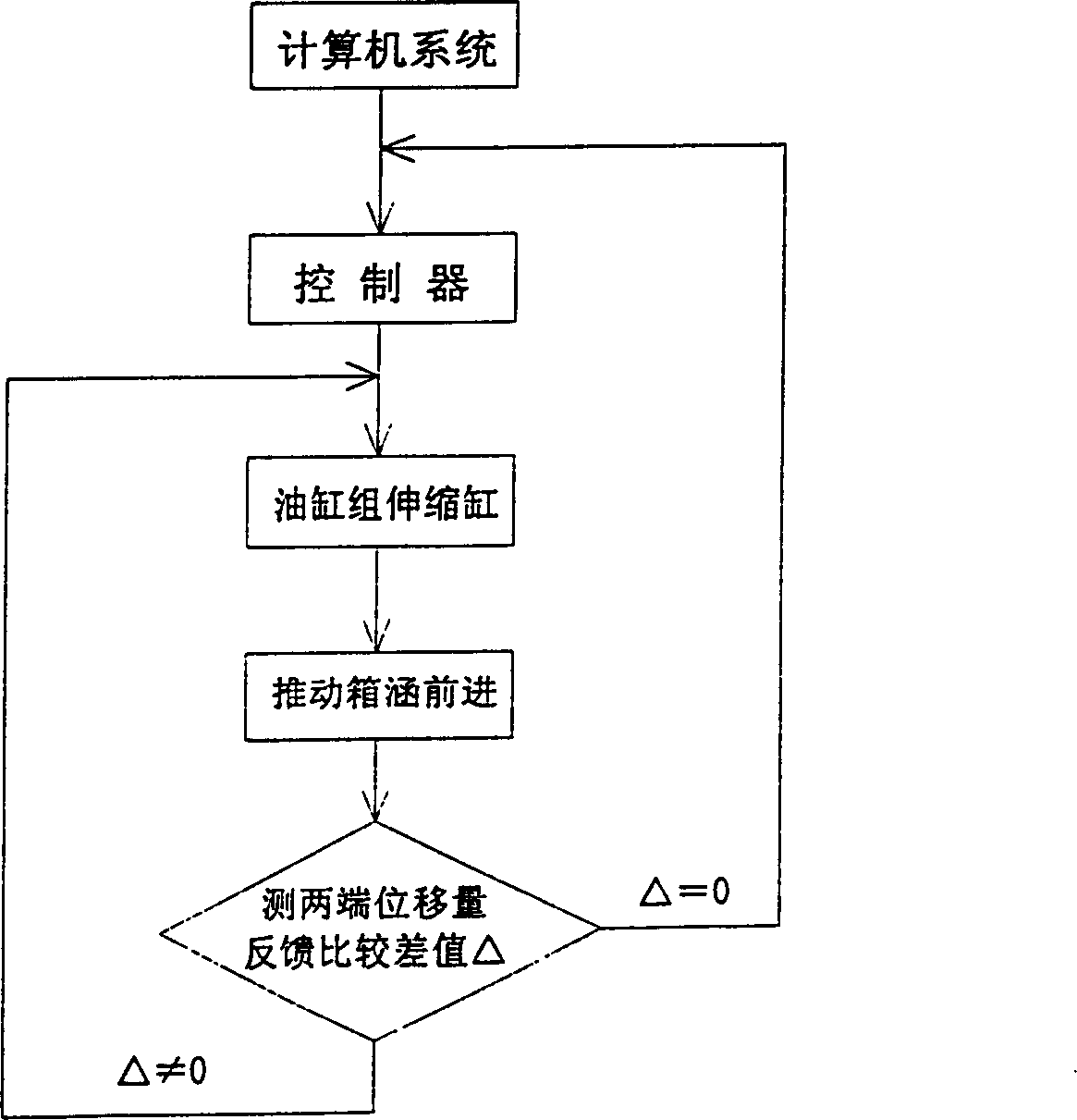

[0023] Specific embodiments: now in conjunction with the accompanying drawings the present invention is further described by computer control coordination, and completes the operation in the following order:

[0024] 1) start the computer control system 1, 2; and issue operation instructions in sequence;

[0025] 2) The thruster oil cylinder group 3 extends the cylinder to push the box culvert 4 forward;

[0026] 3) The displacement sensor group 5 feeds back the displacement signal;

[0027] 4) The oil pressure sensor 6 feeds back the oil pressure signal;

[0028] 5) Compare and control:

[0029] If the displacement is large, reduce the speed of the oil cylinder that produces this displacement;

[0030] If the displacement is small, increase the speed of the oil cylinder that produces this displacement;

[0031] 6) Continue to push the box culvert 4 to complete a cylinder stroke synchronously;

[0032] 7) The computer control system controls all the oil cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com