Patents

Literature

36results about How to "Adjust the positioning accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

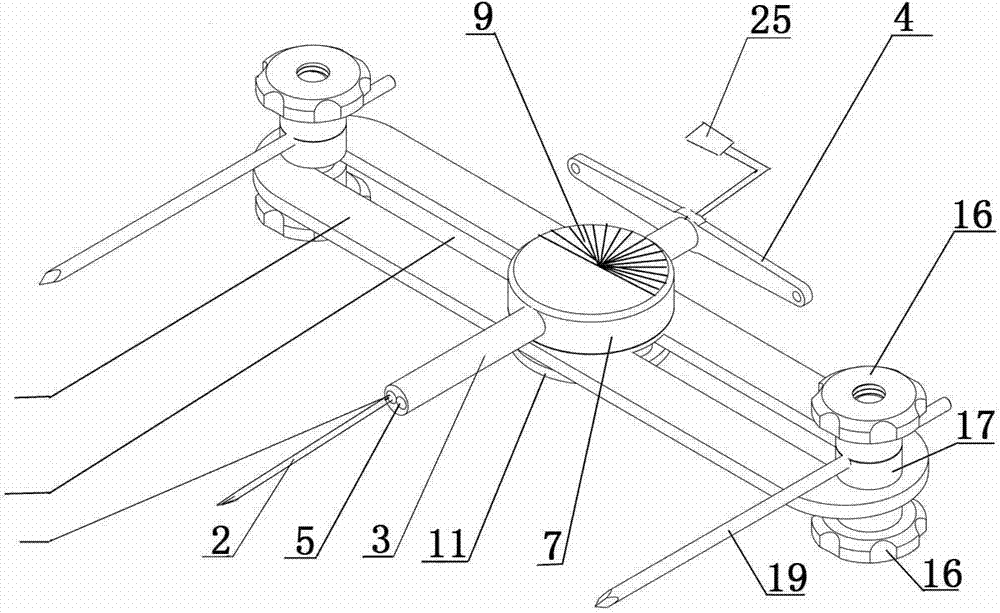

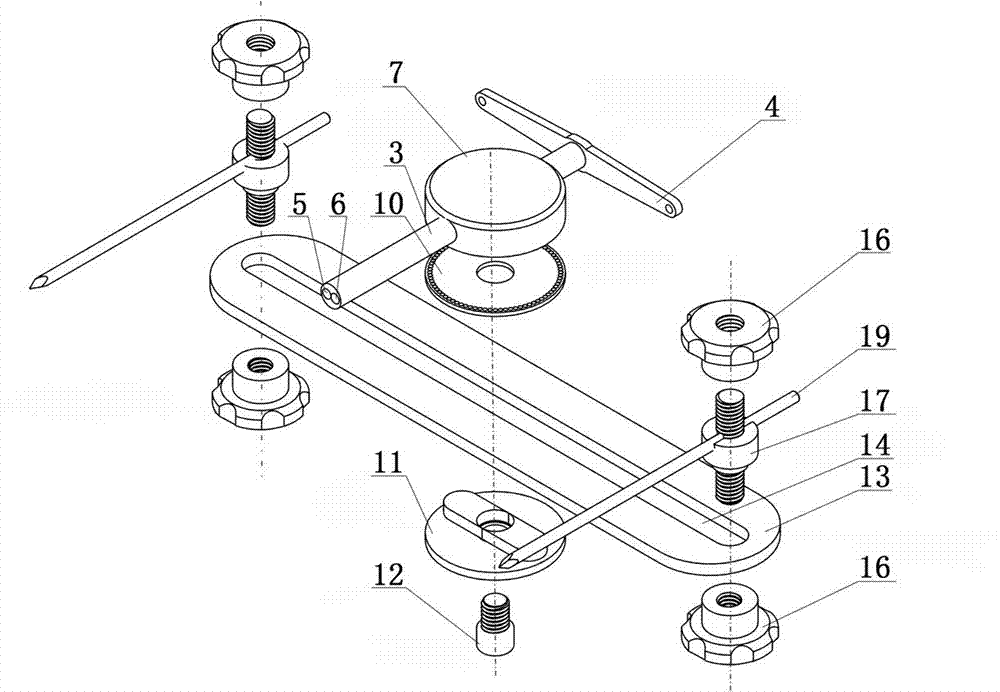

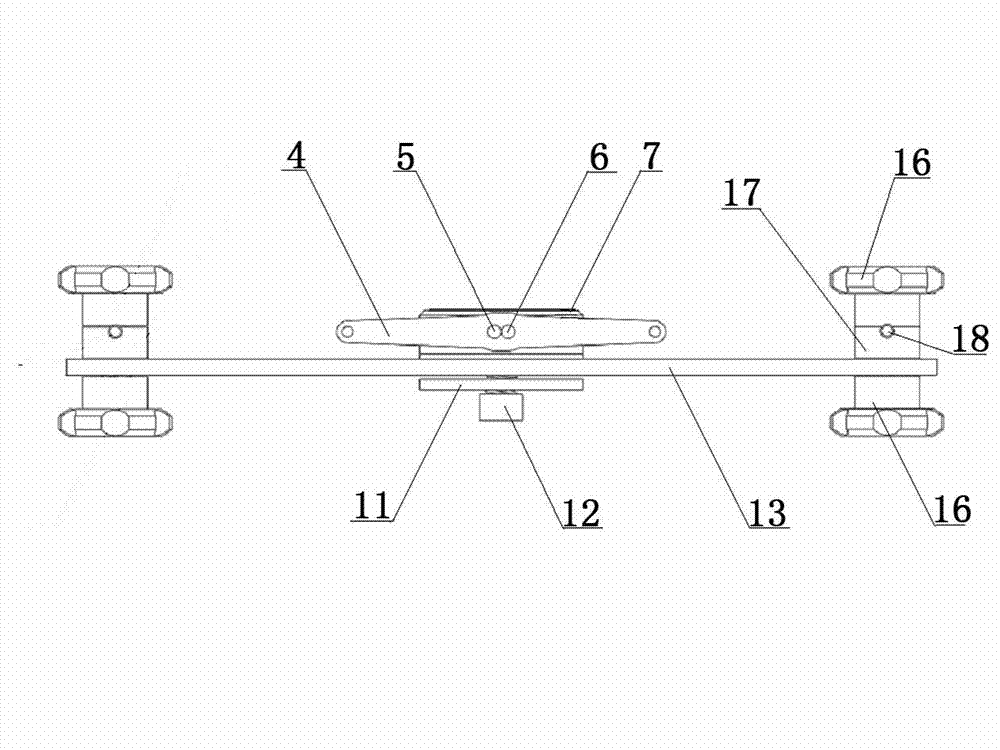

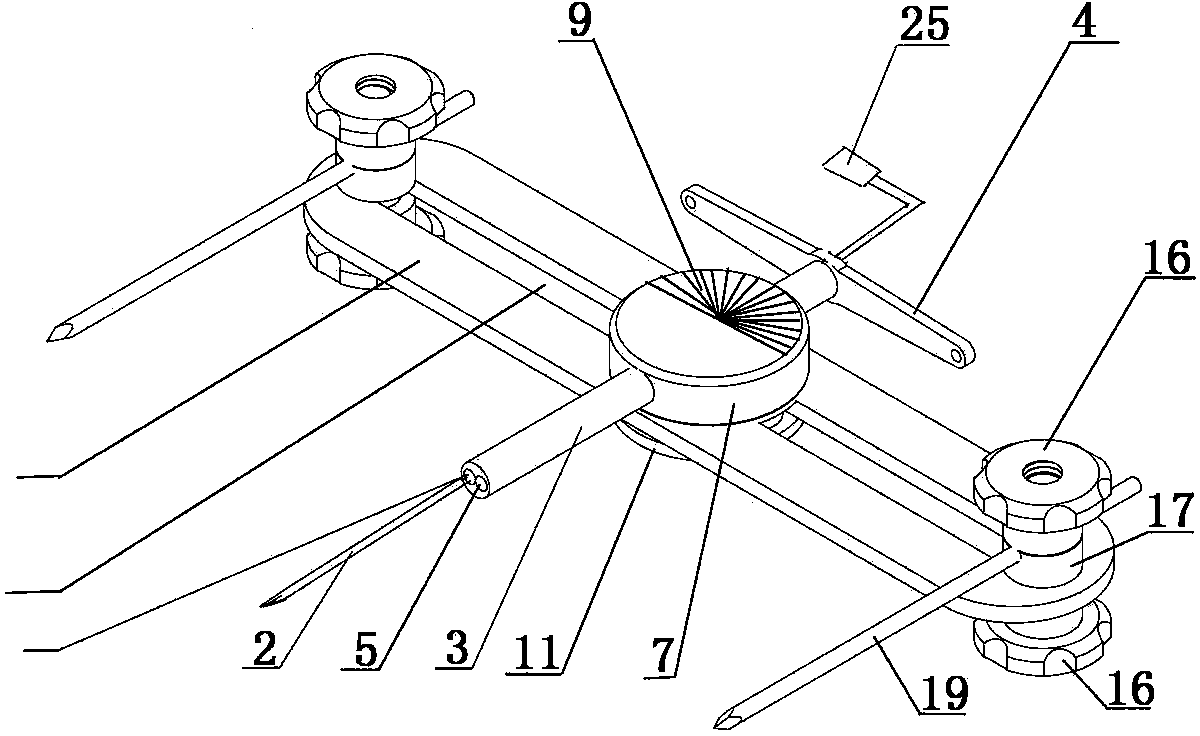

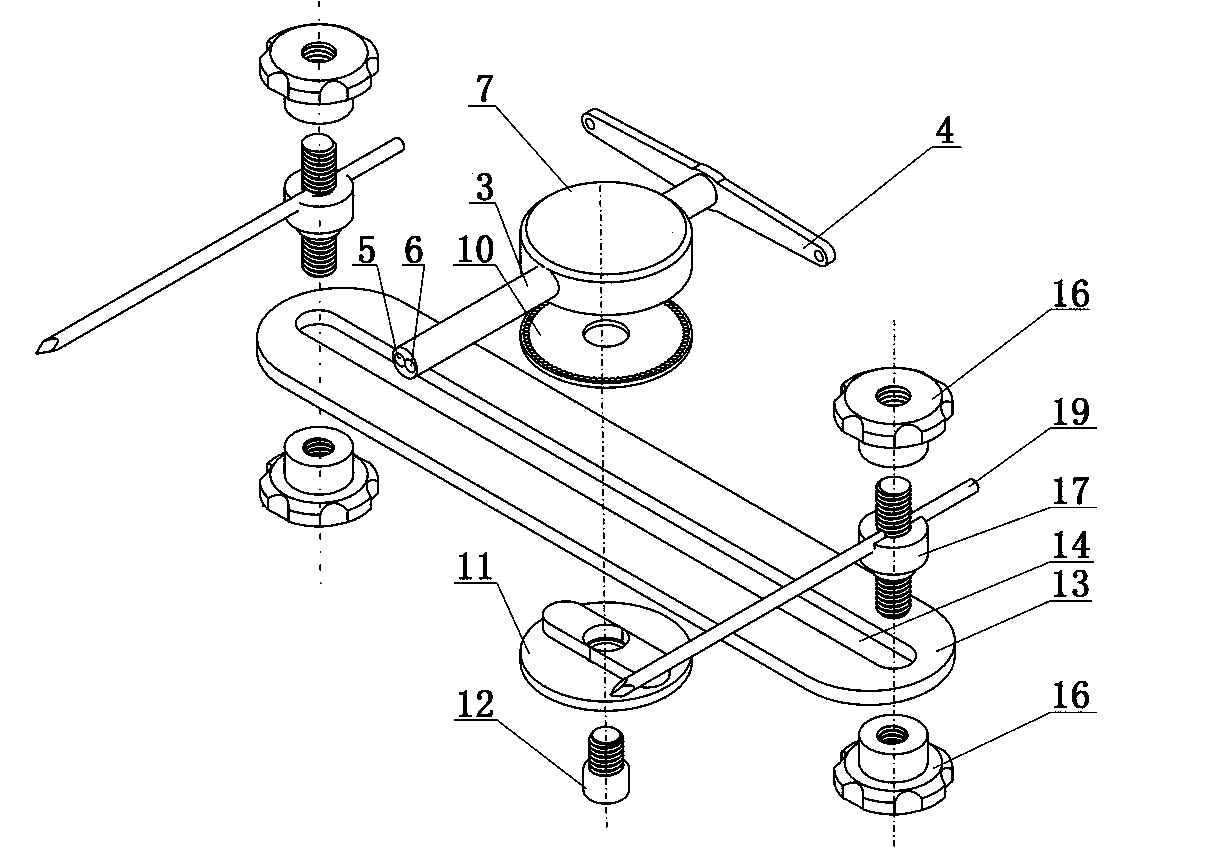

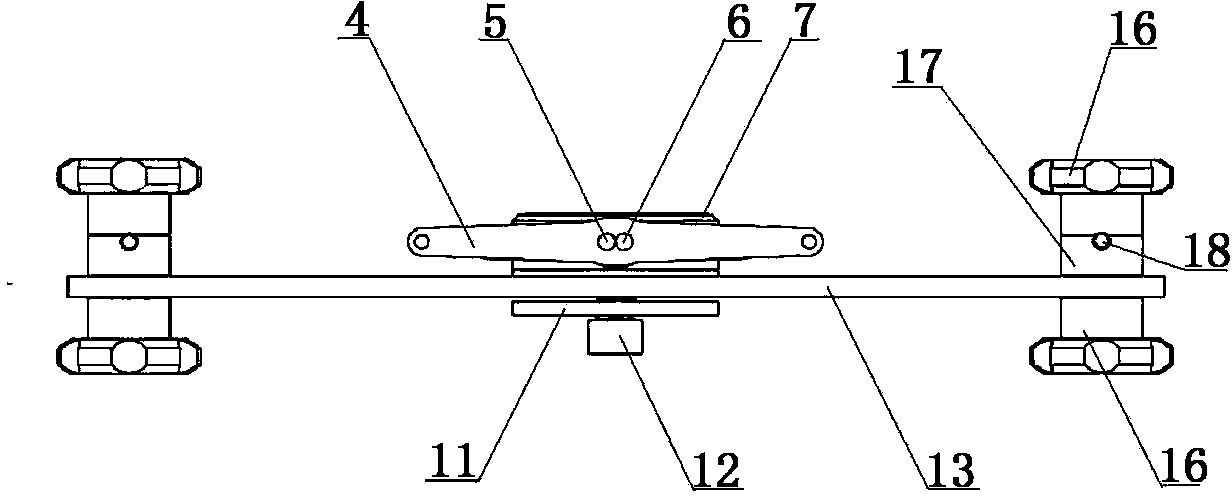

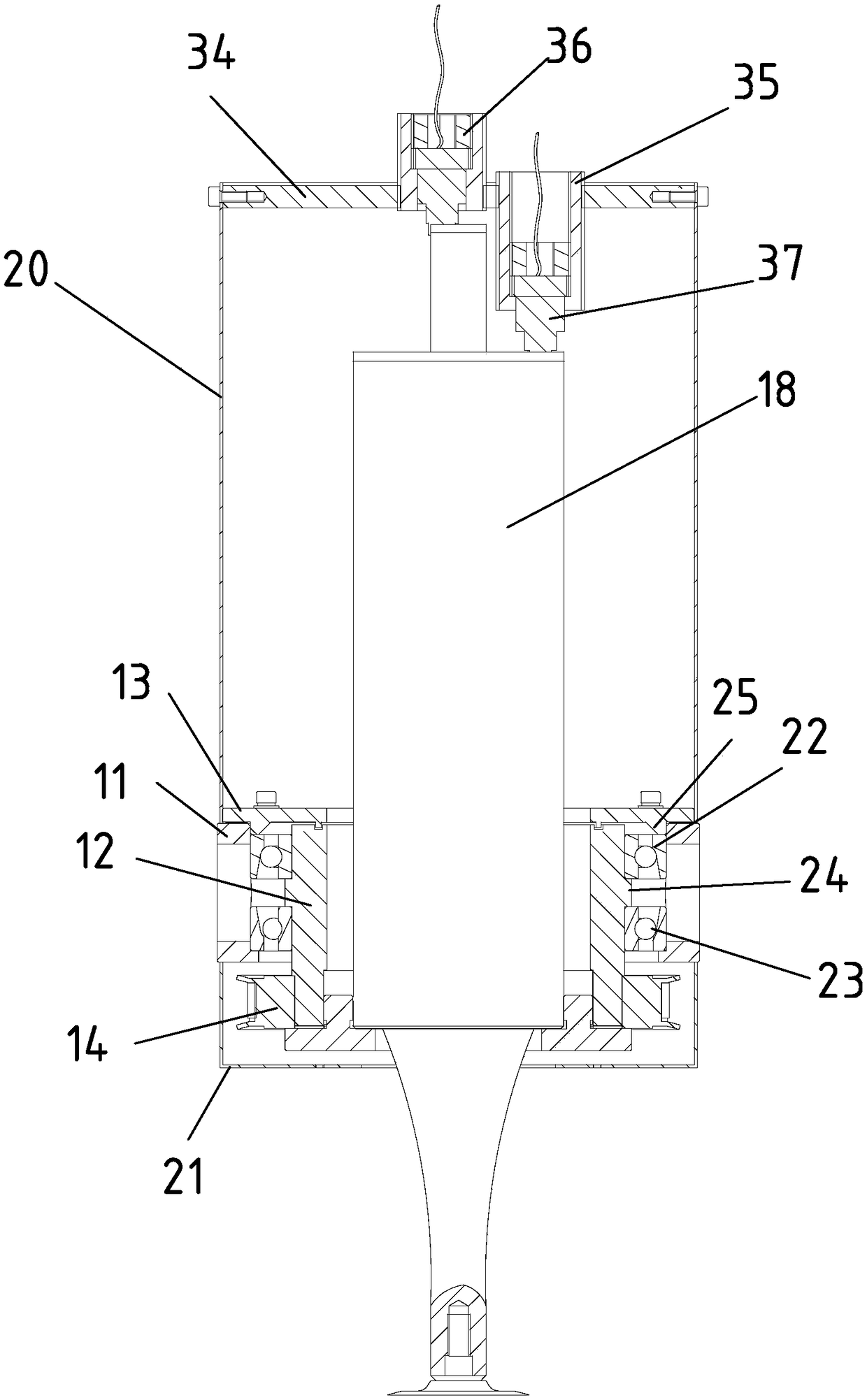

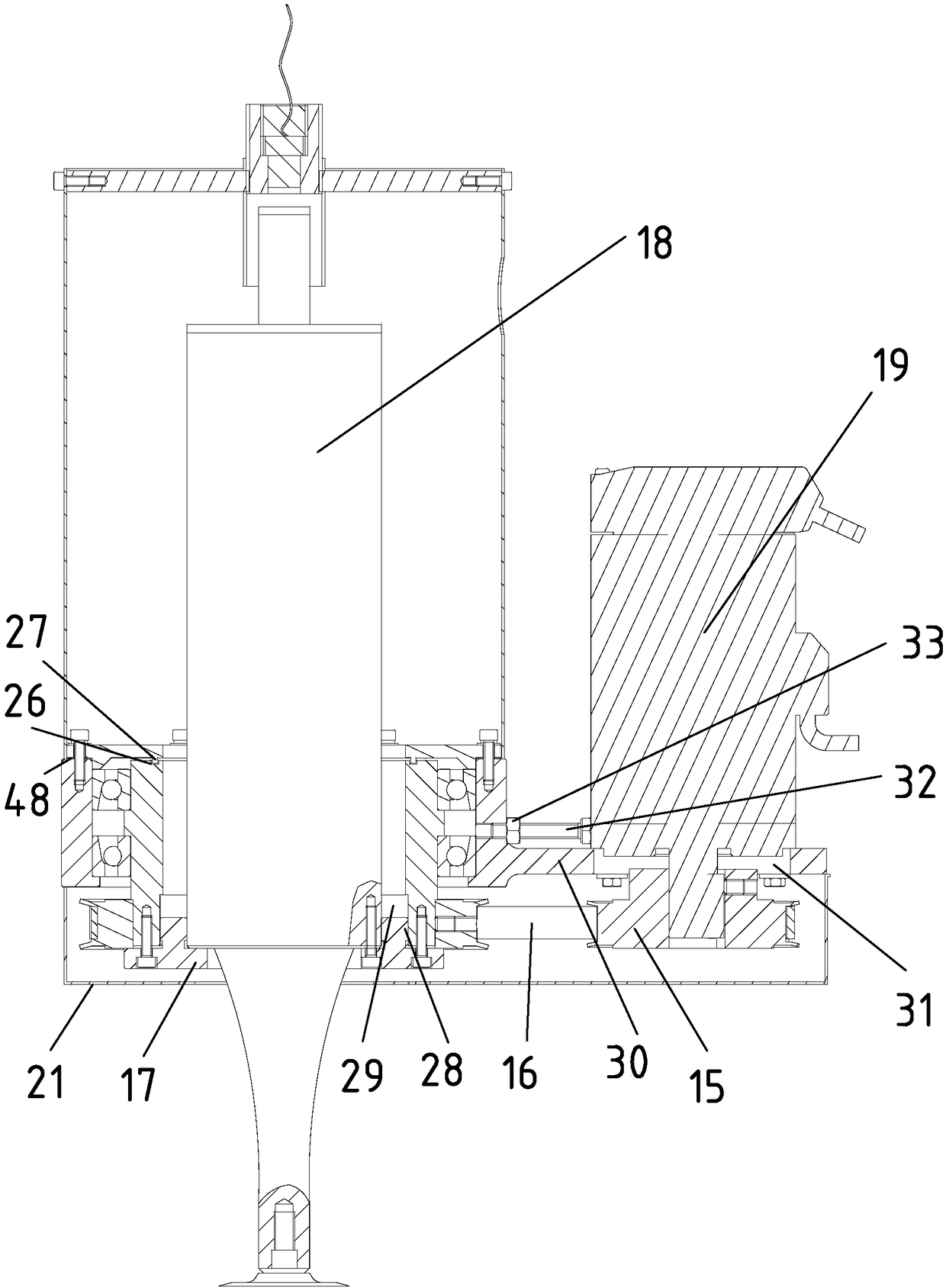

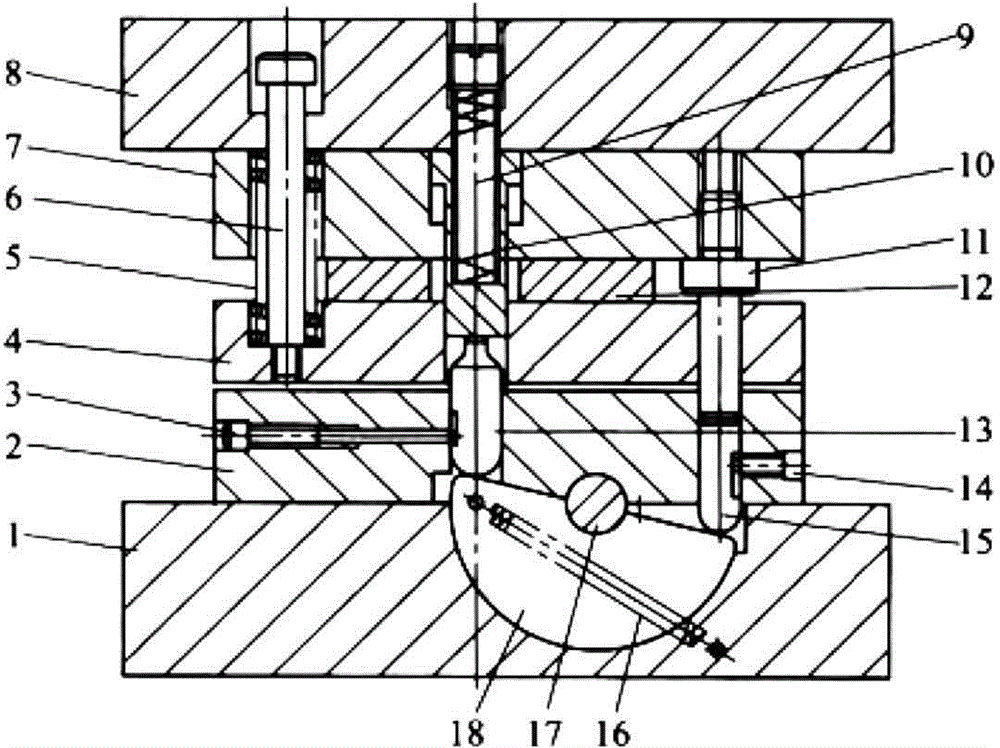

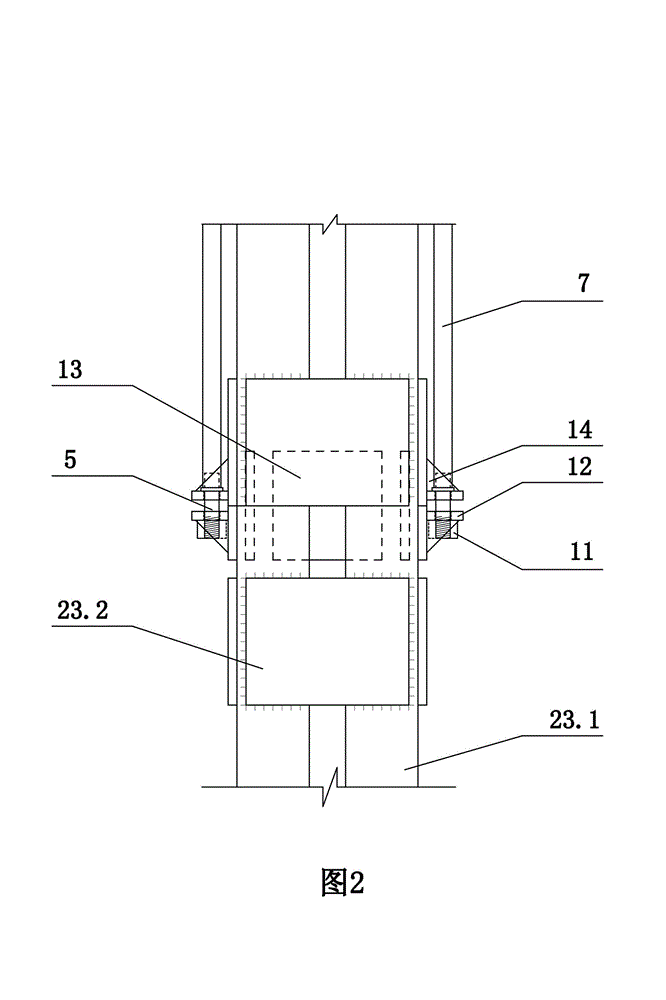

Longitudinal minimal-invasion bone cutter for tubular bones

InactiveCN102860860AFor lateral tractionFacilitates longitudinal osteotomySurgeryTraction TreatmentPeriosteum

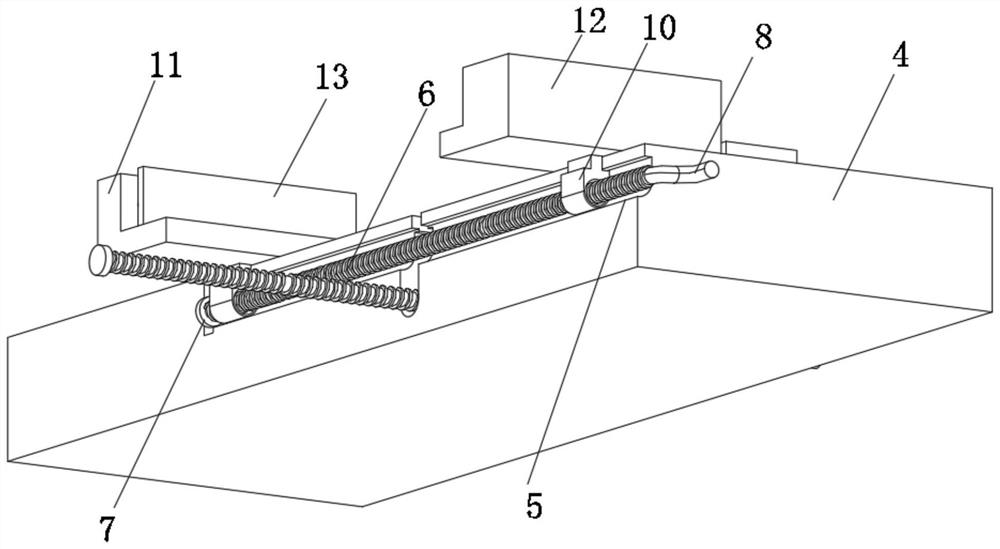

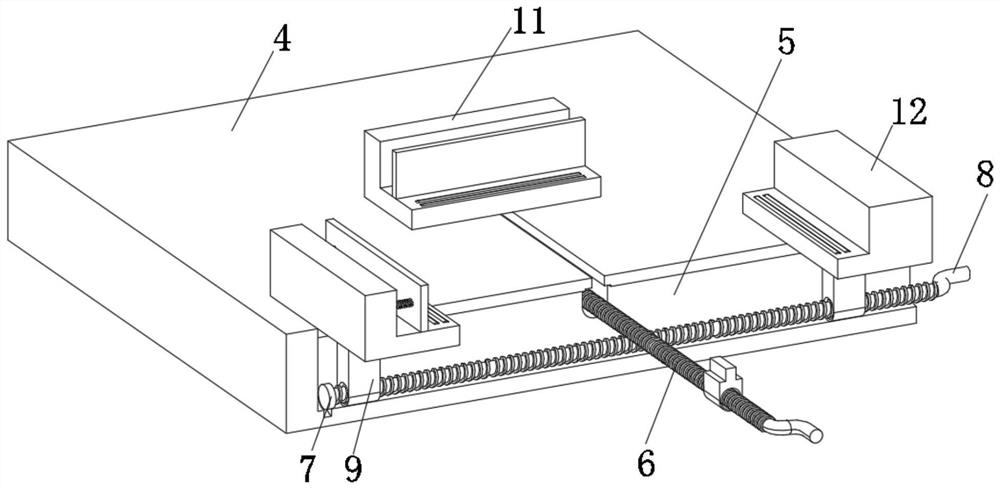

A longitudinal minimal-invasion bone cutter for tubular bones comprises a bone cutting end bone cutting device and far end positioning devices. The bone cutting end bone cutting device is slidingly sleeved on a positioning adjusting guide rail which is in a long-strip shape, a sliding groove is arranged in the middle of the positioning adjusting guide rail along the length direction, and scales of the positioning adjusting guide rail are arranged along the sliding groove. The far end positioning devices are symmetrically sleeved at two ends of the positioning adjusting guide rail slidingly. By means of the longitudinal minimal-invasion bone cutter, medical workers can perform longitudinal bone cutting operations on the tubular bones according to treatment needs, and the longitudinal minimal-invasion bone cutter is convenient to operate. When the operations are performed, the longitudinal minimal-invasion bone cutter provides convenience for transverse traction of bone blocks and meets needs of angiitis treatment. The bone cutting operations performed by the aid of the longitudinal minimal-invasion bone cutter belong to minimal-invasion operations, do not damage nerves, blood vessels, soft tissues and periostea, have small invasion, facilitate reconstruction and union of bones, and meet needs of longitudinal traction treatment of the tubular bones. By means of the longitudinal minimal-invasion bone cutter, safety and accuracy of the longitudinal bone cutting operations of the tubular bones are improved, medical workers can conveniently perform the operations, and the operation effect is guaranteed.

Owner:JIANGSU GUANGJI MEDICAL TECH

Longitudinal minimal-invasion bone cutter for tubular bones

InactiveCN102860860BFor lateral tractionFacilitates longitudinal osteotomySurgeryLess invasive surgeryEngineering

A longitudinal minimal-invasion bone cutter for tubular bones comprises a bone cutting end bone cutting device and far end positioning devices. The bone cutting end bone cutting device is slidingly sleeved on a positioning adjusting guide rail which is in a long-strip shape, a sliding groove is arranged in the middle of the positioning adjusting guide rail along the length direction, and scales of the positioning adjusting guide rail are arranged along the sliding groove. The far end positioning devices are symmetrically sleeved at two ends of the positioning adjusting guide rail slidingly. By means of the longitudinal minimal-invasion bone cutter, medical workers can perform longitudinal bone cutting operations on the tubular bones according to treatment needs, and the longitudinal minimal-invasion bone cutter is convenient to operate. When the operations are performed, the longitudinal minimal-invasion bone cutter provides convenience for transverse traction of bone blocks and meets needs of angiitis treatment. The bone cutting operations performed by the aid of the longitudinal minimal-invasion bone cutter belong to minimal-invasion operations, do not damage nerves, blood vessels, soft tissues and periostea, have small invasion, facilitate reconstruction and union of bones, and meet needs of longitudinal traction treatment of the tubular bones. By means of the longitudinal minimal-invasion bone cutter, safety and accuracy of the longitudinal bone cutting operations of the tubular bones are improved, medical workers can conveniently perform the operations, and the operation effect is guaranteed.

Owner:JIANGSU GUANGJI MEDICAL TECH

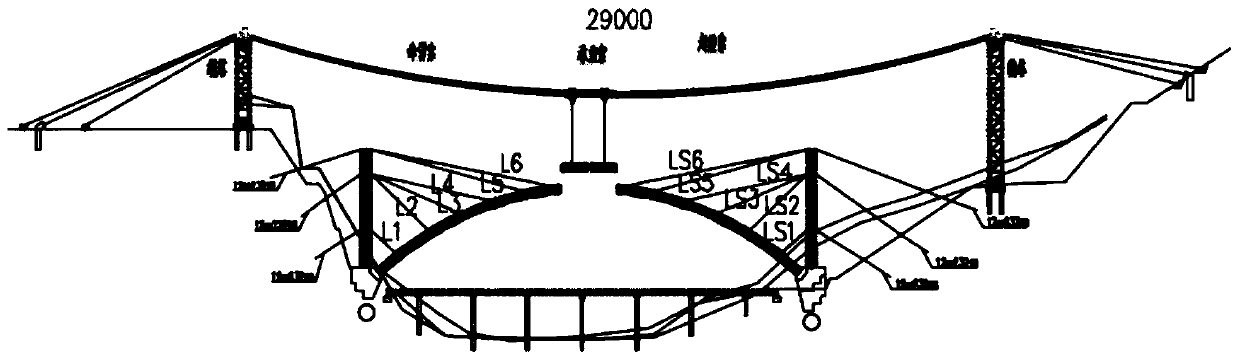

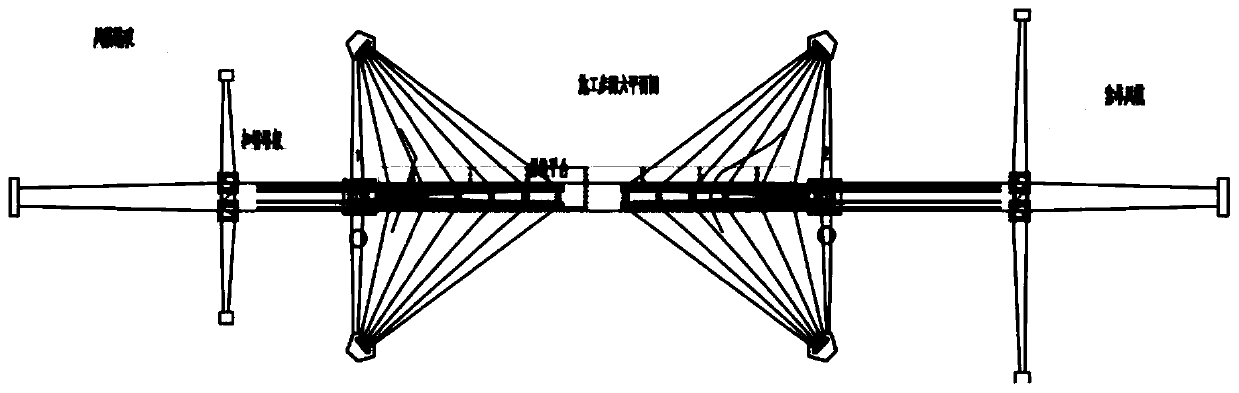

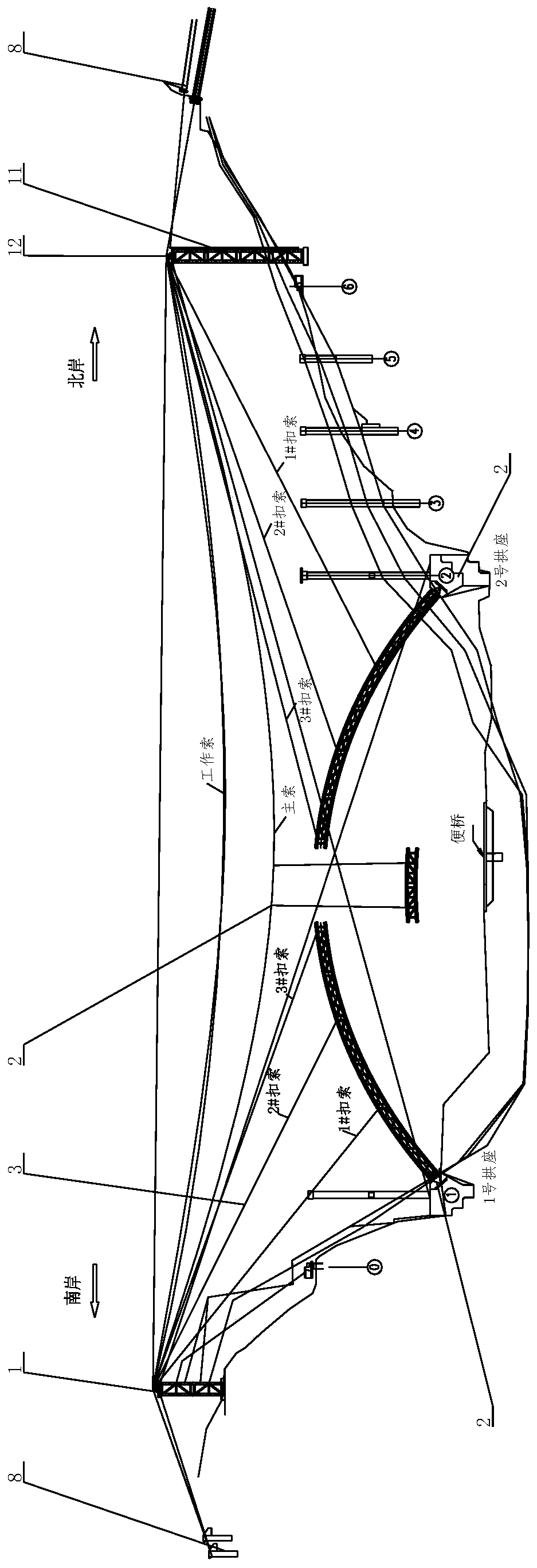

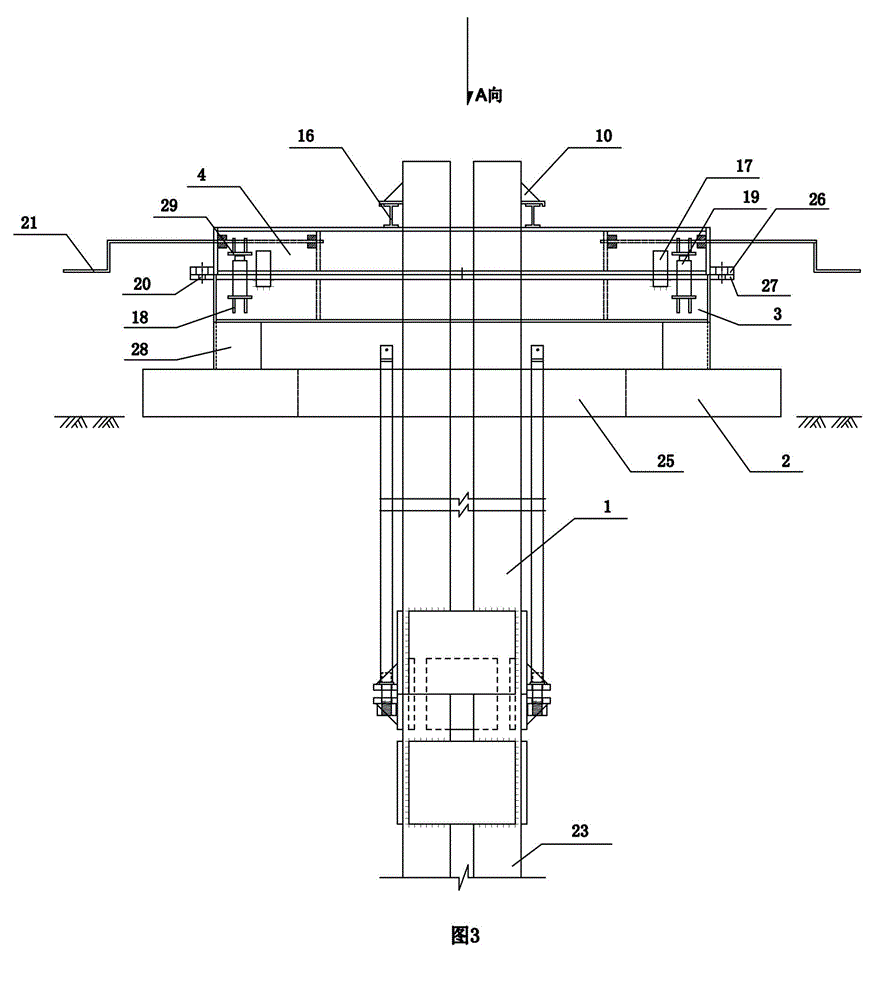

Hoisting and tower buckling integrated construction method for cable of arch bridge

InactiveCN109853394AEasy to adapt to constructionReduce layoutBridge erection/assemblyTowerArch bridge

The invention provides a hoisting and tower buckling integrated construction method for cable of arch bridge, and relates to the technical field of hoisting construction method of arch ribs of an archbridge. Two sets of tower frames of the same structure, that is, a main cable tower frame and a buckle cable tower frame, are integrated and systematically arranged, the arrangement of a buckle toweris reduced, so that the method is easier to adapt to; construction of arch bridges at places restricted by geographical conditions such as mountainous areas; the method reduces the input of cable system equipment and the engineering quantity of the cable arrangement, saves the engineering cost and shortens the construction period; the whole construction is monitoring the integrated tower frame, so that components can be more conveniently hoisted to the designated position, and then through cooperation of a buckle cable system, a guy cable system and the measurement, accurately adjusting and positioning the axis and the elevation are realized.

Owner:安徽省路港工程有限责任公司

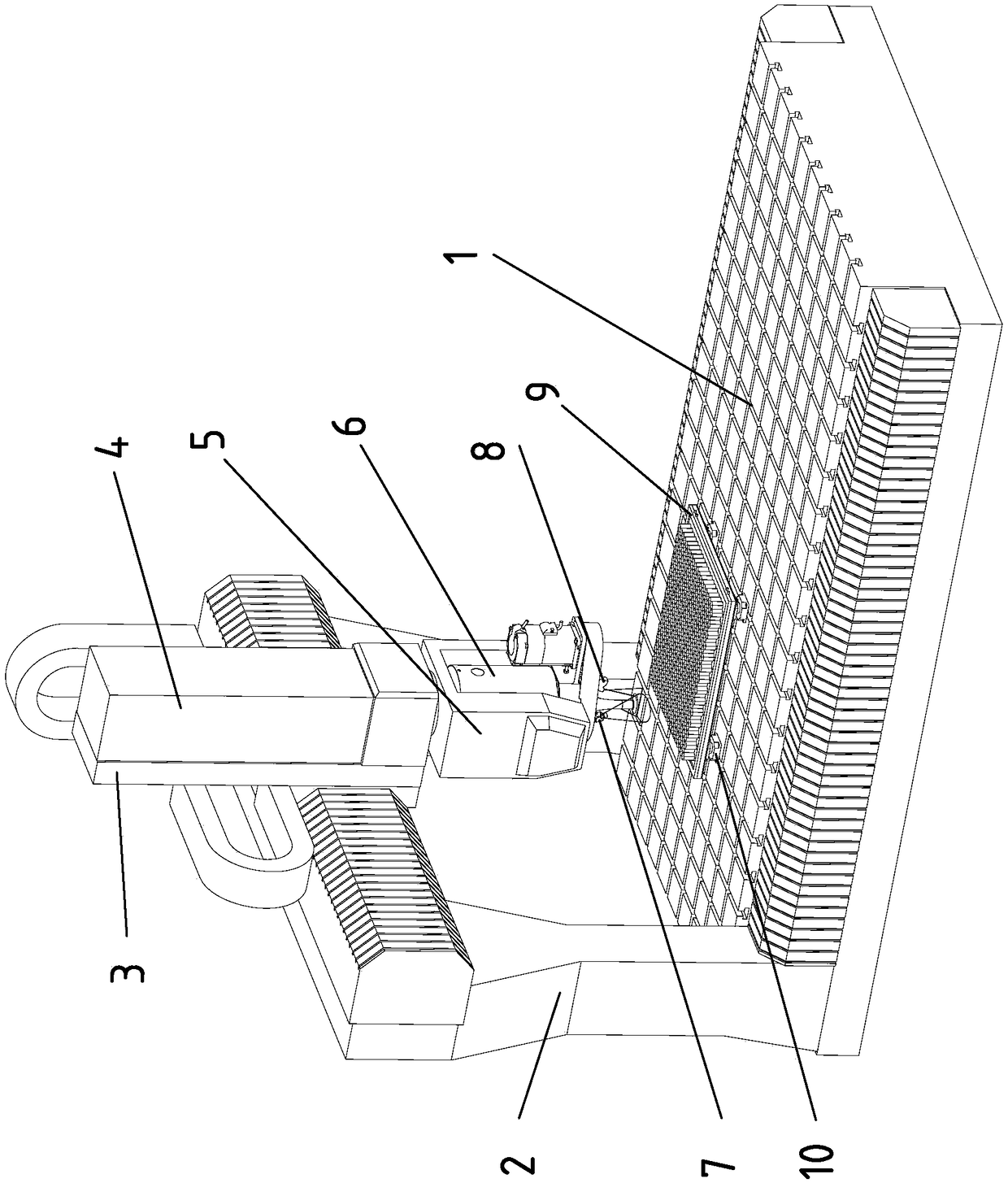

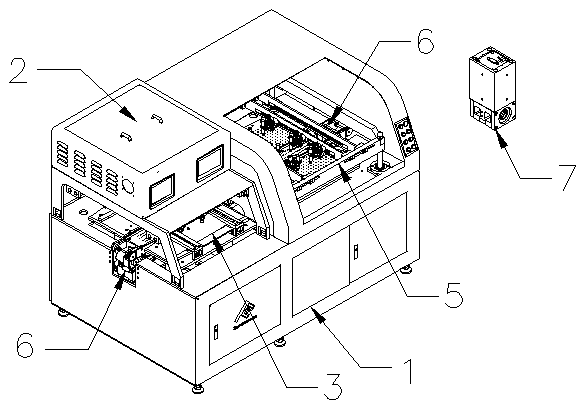

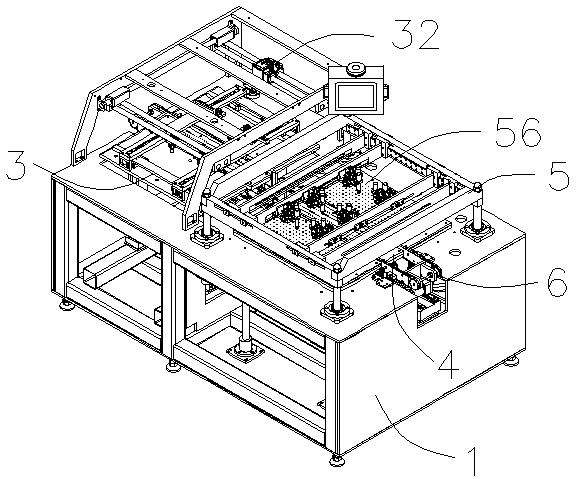

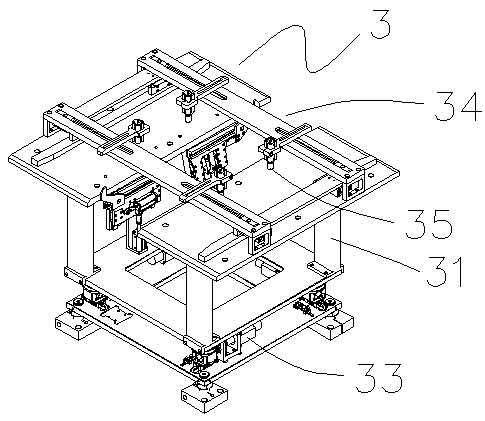

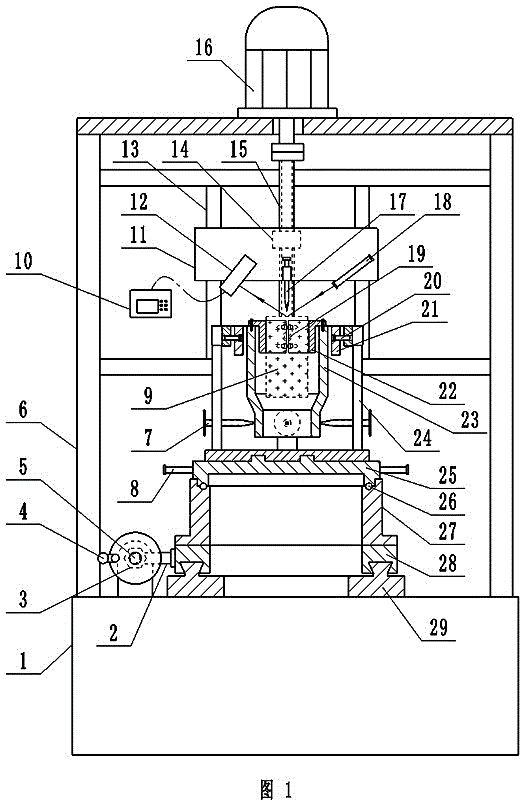

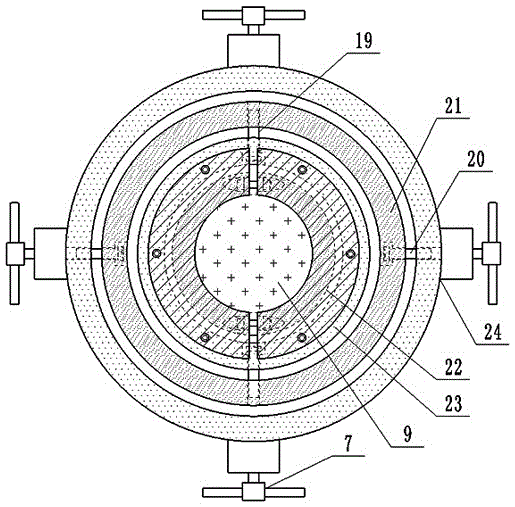

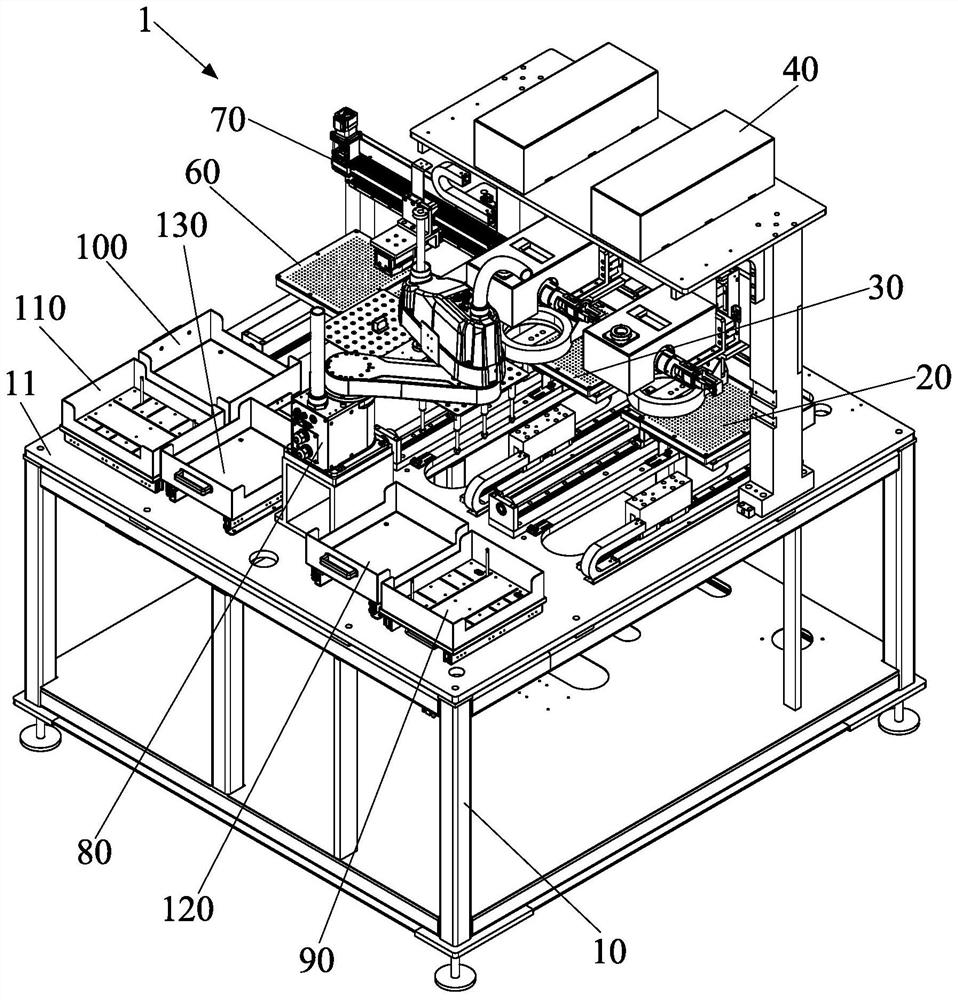

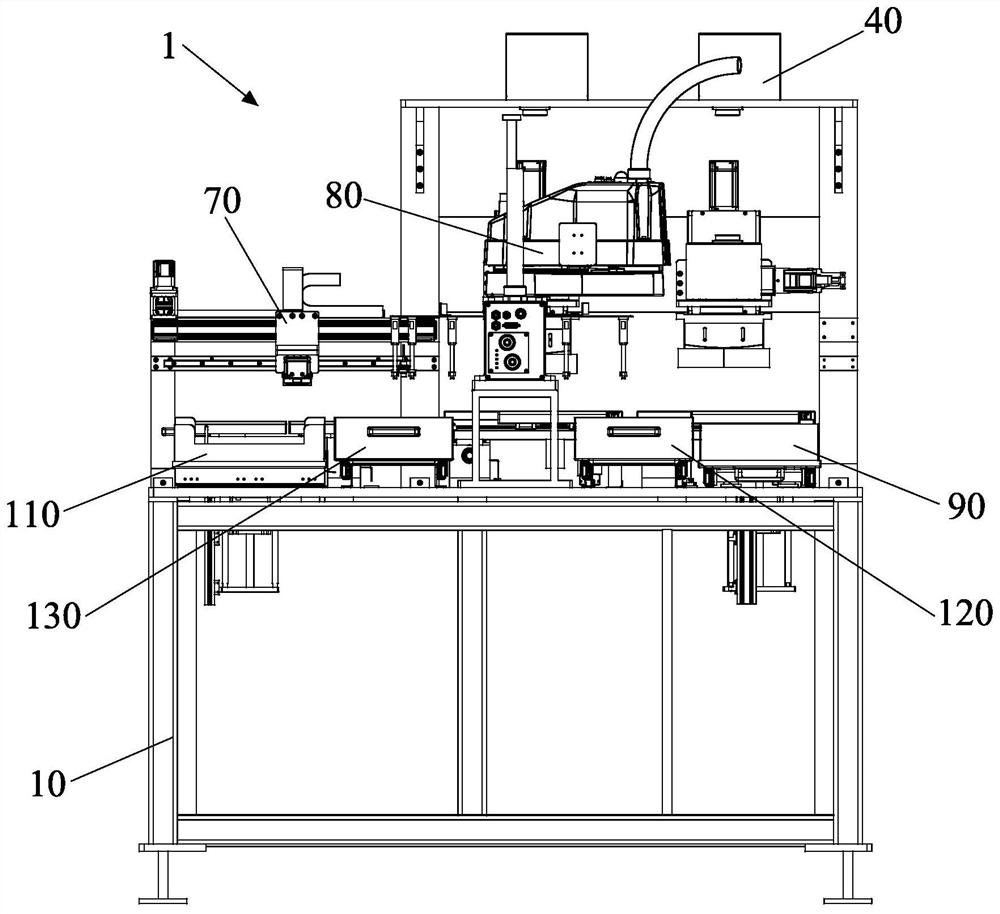

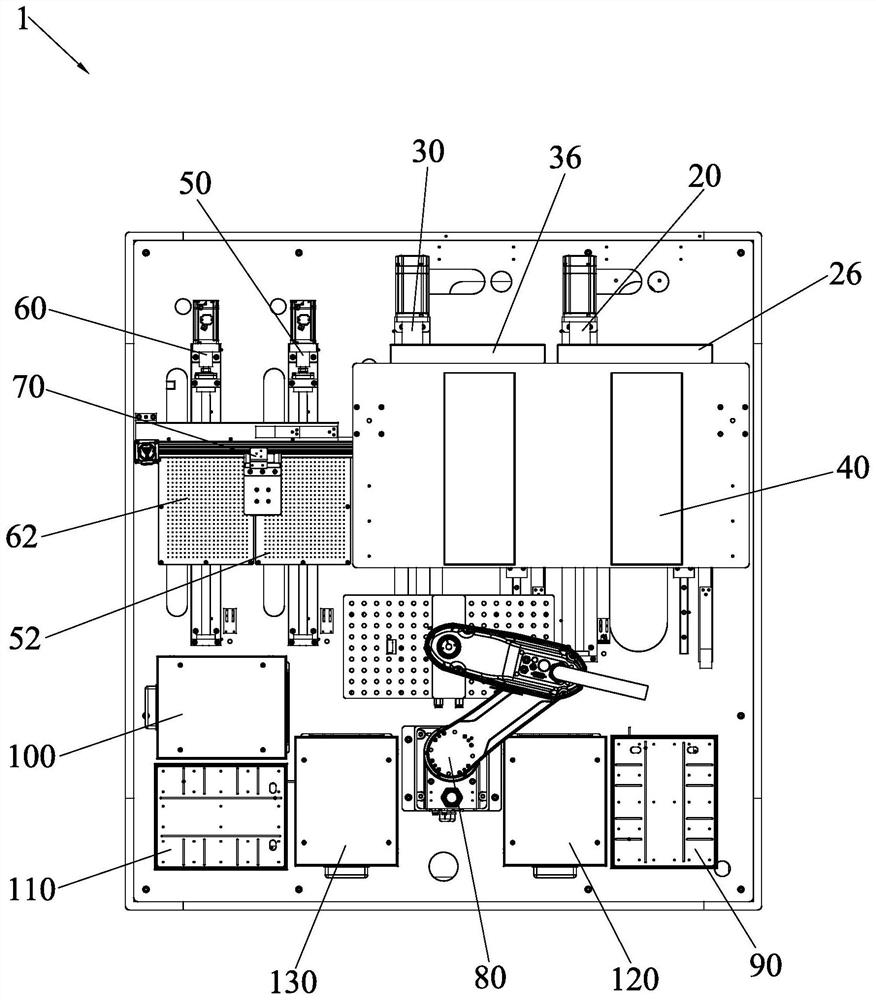

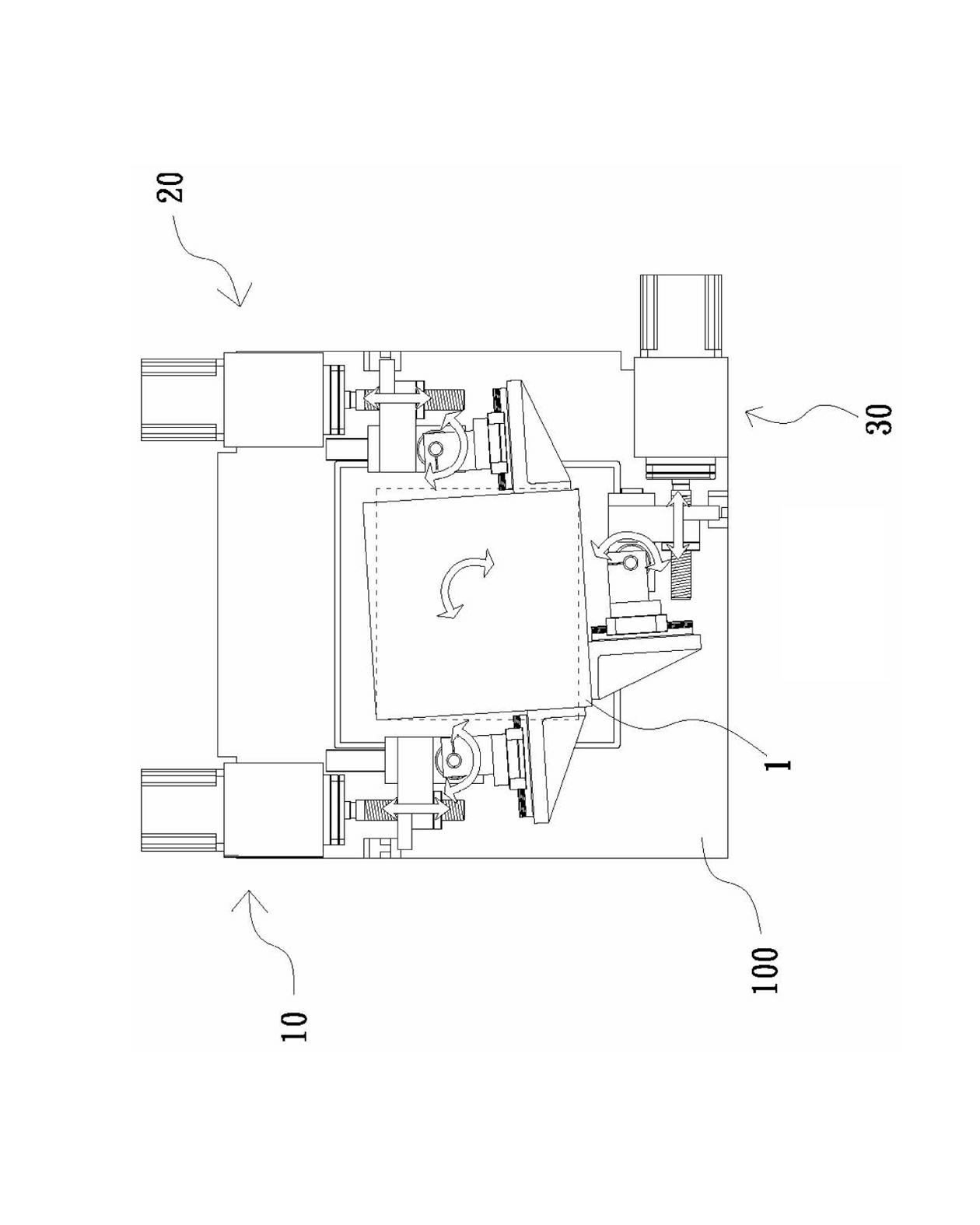

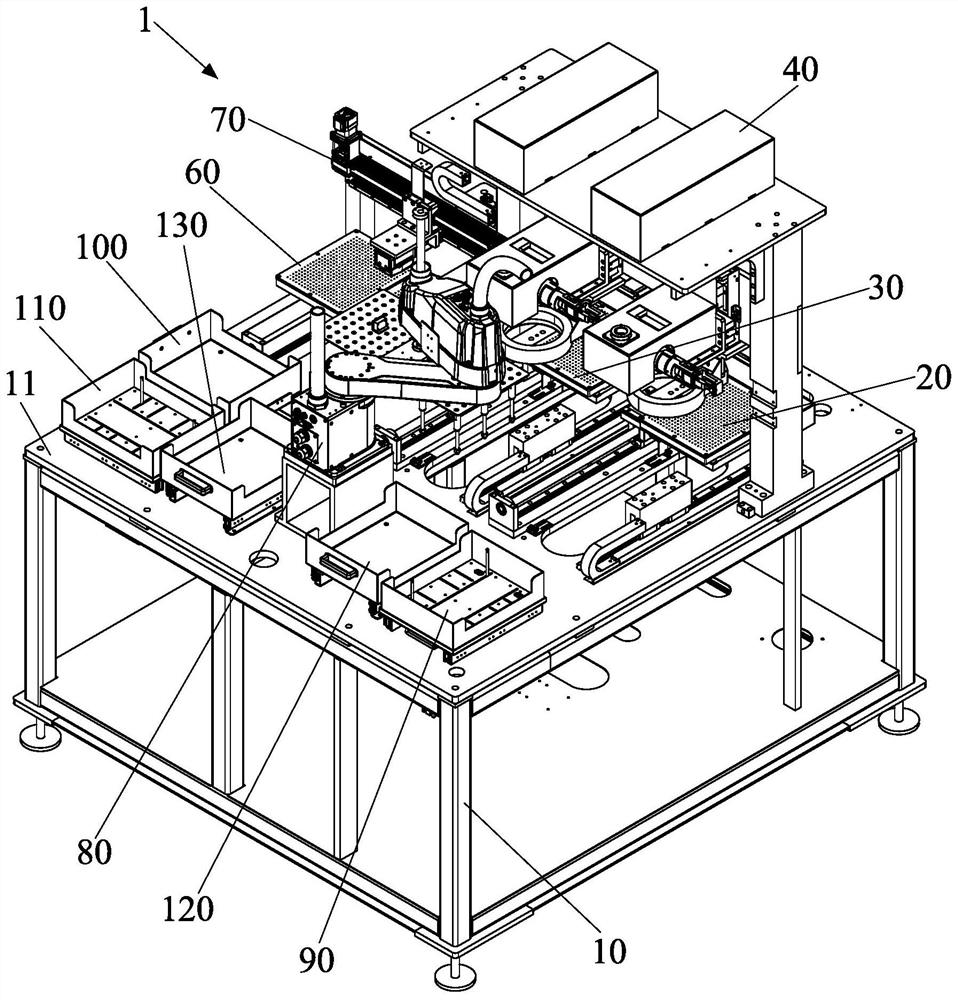

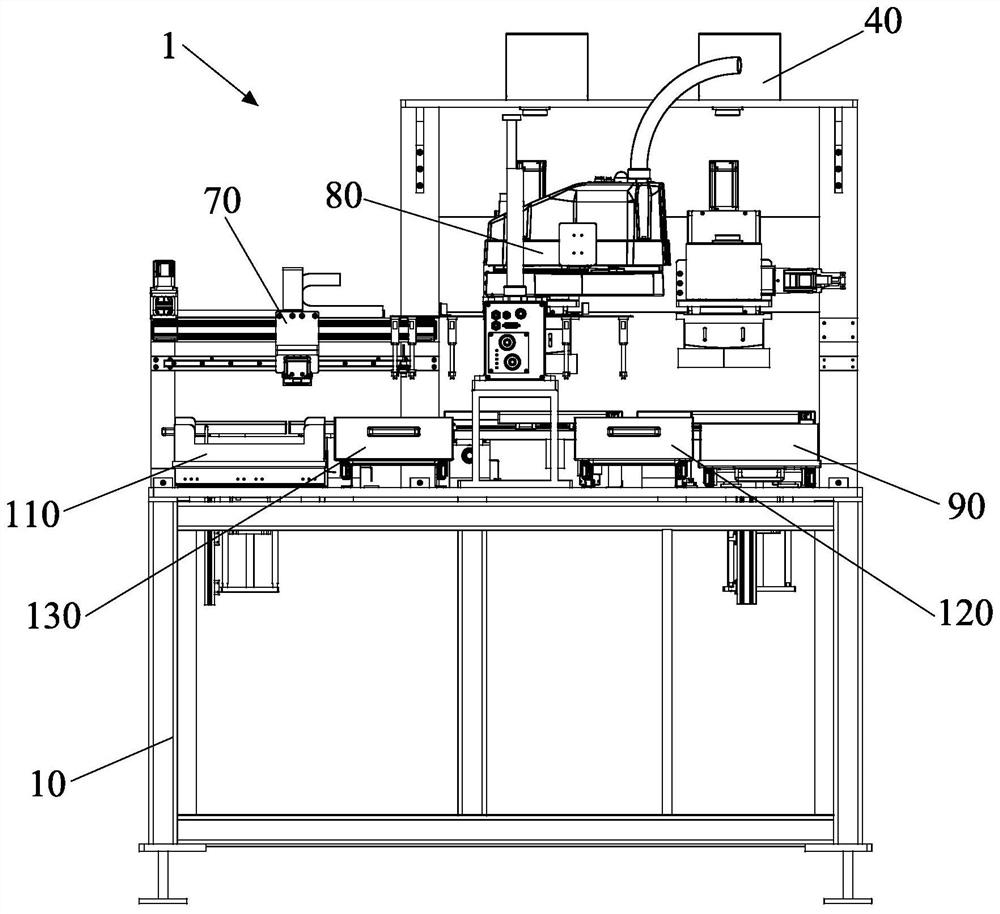

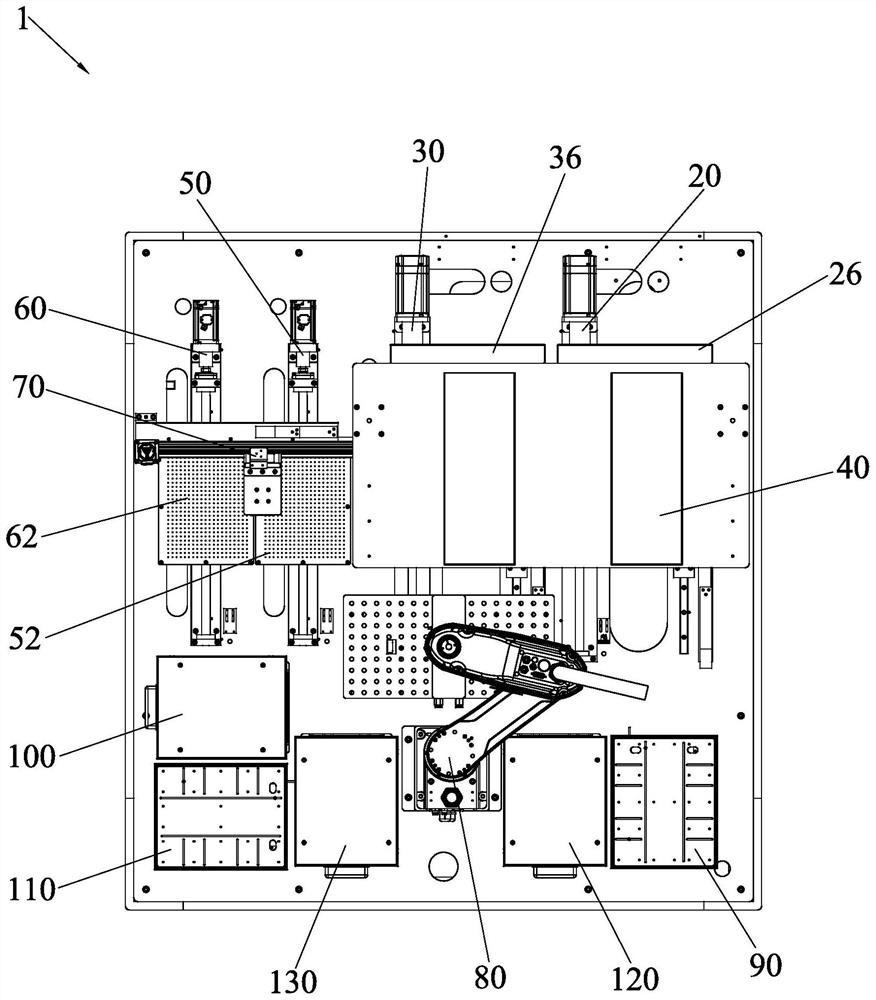

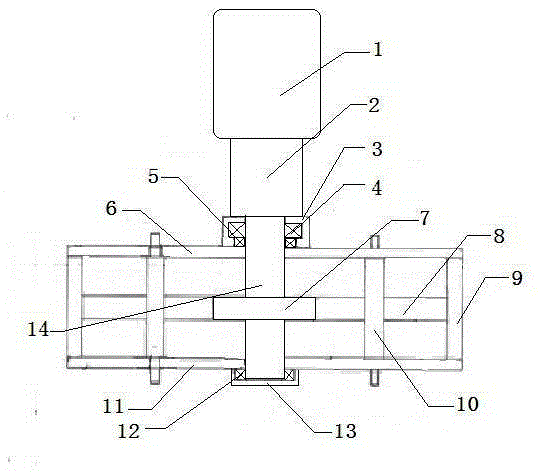

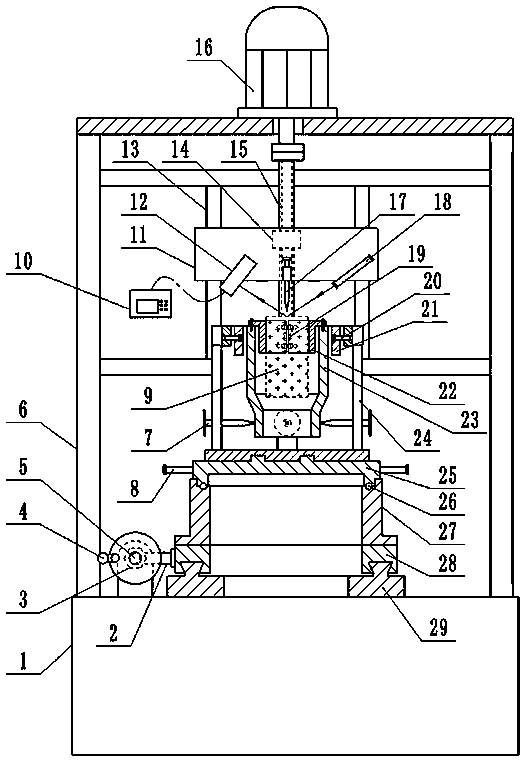

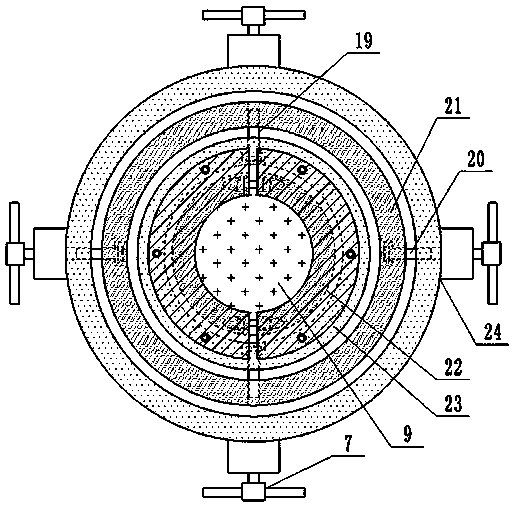

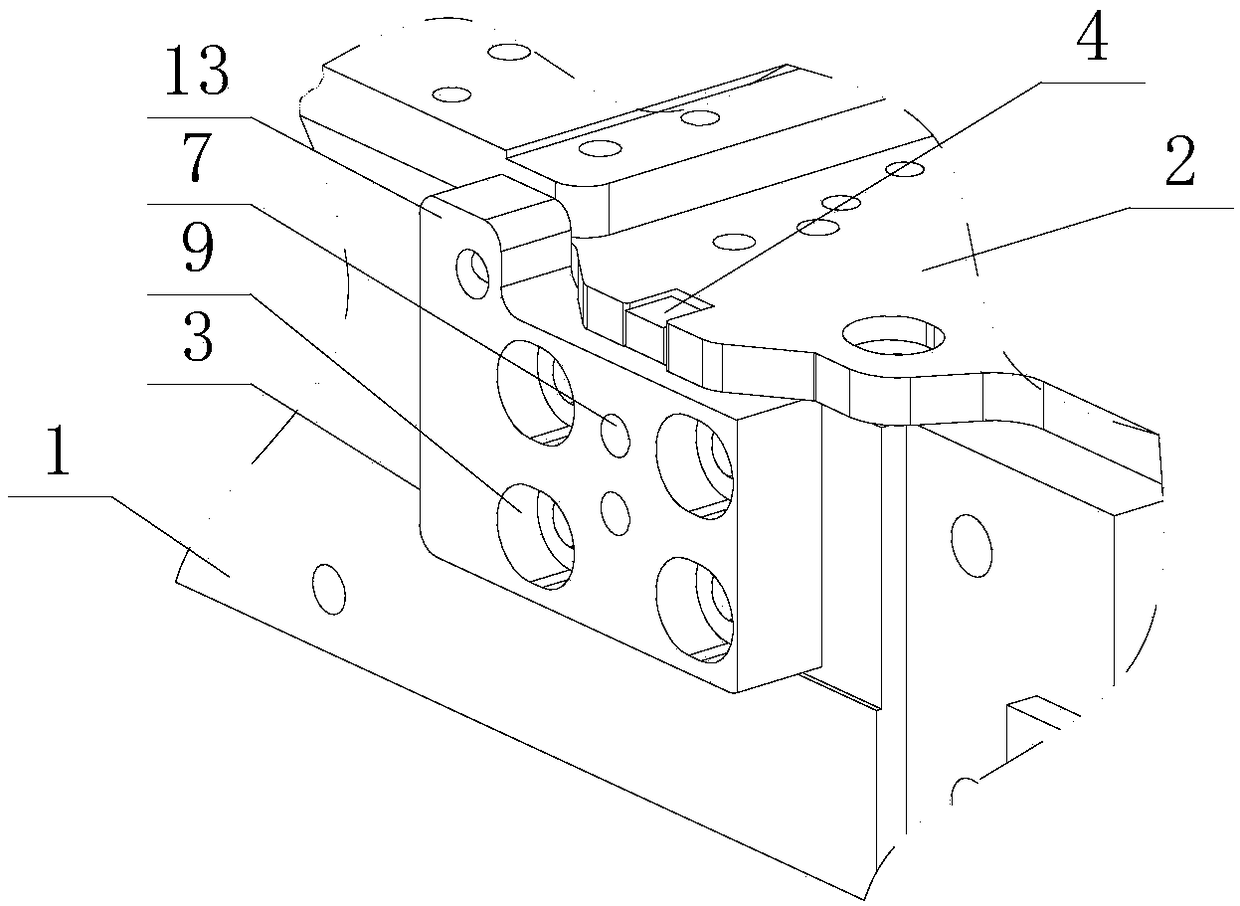

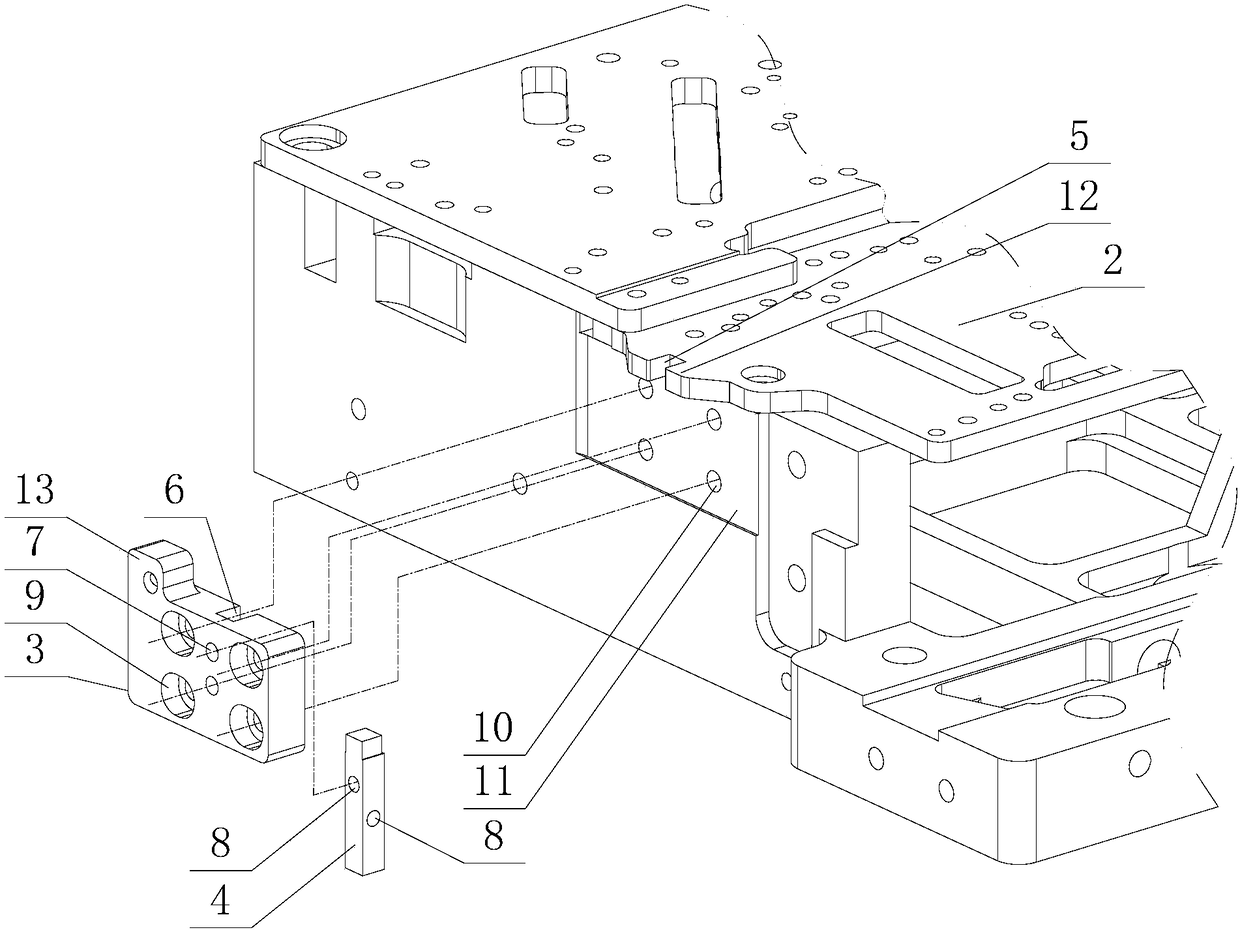

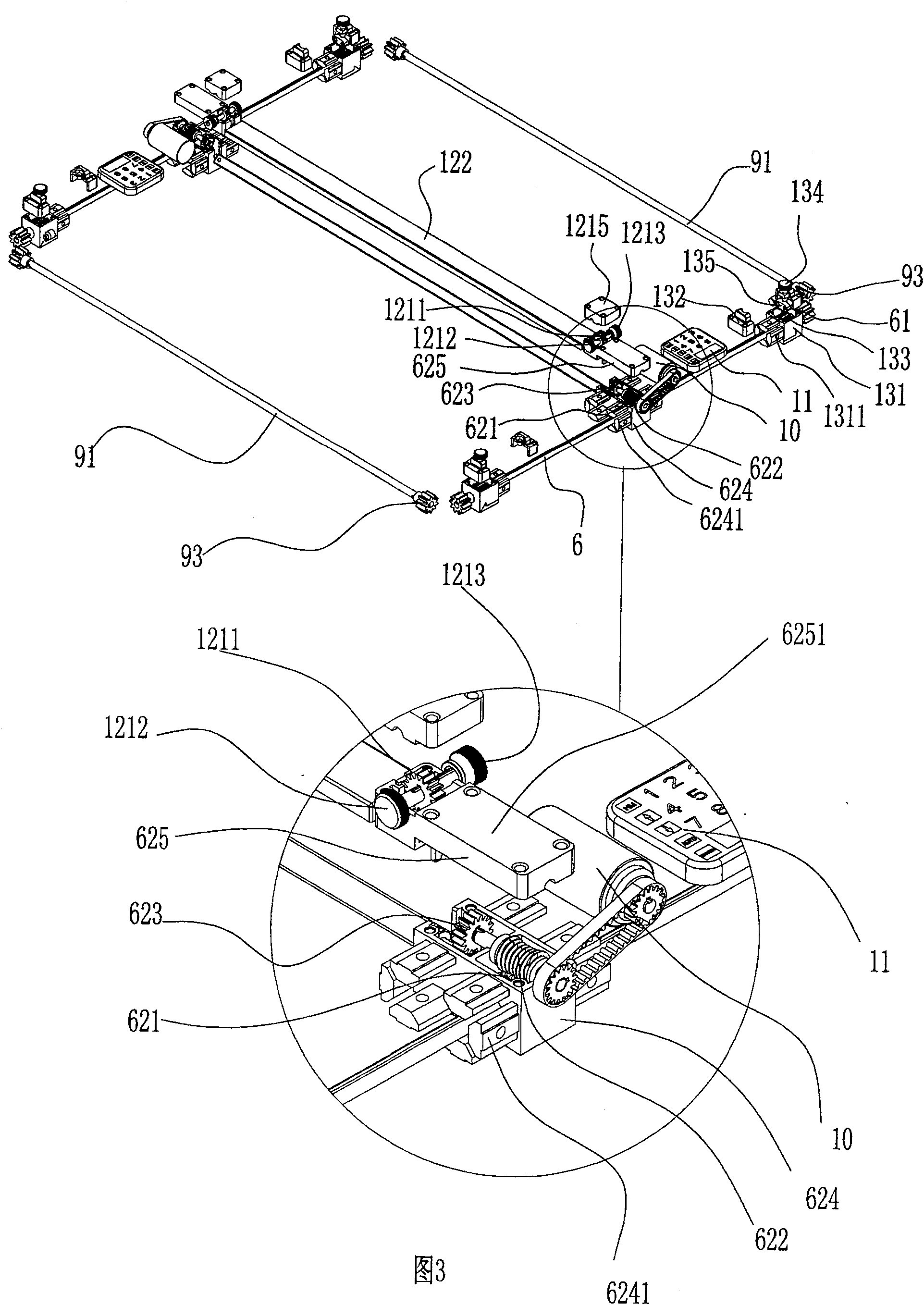

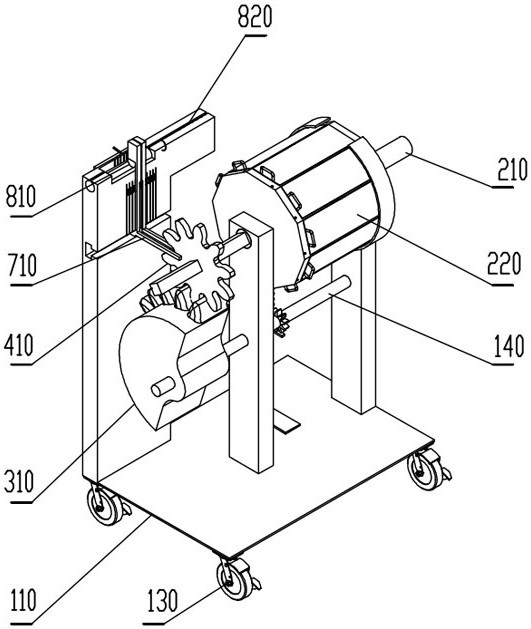

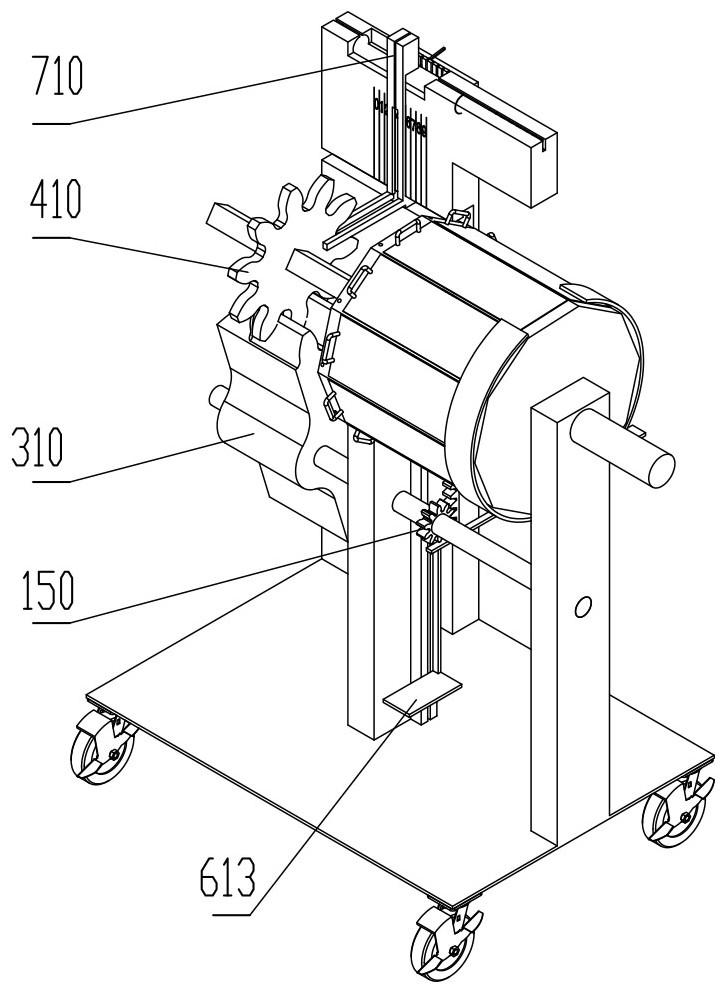

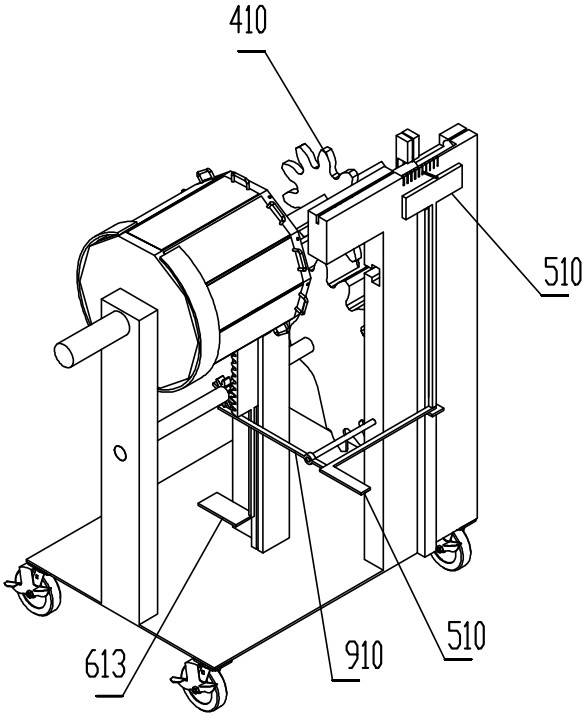

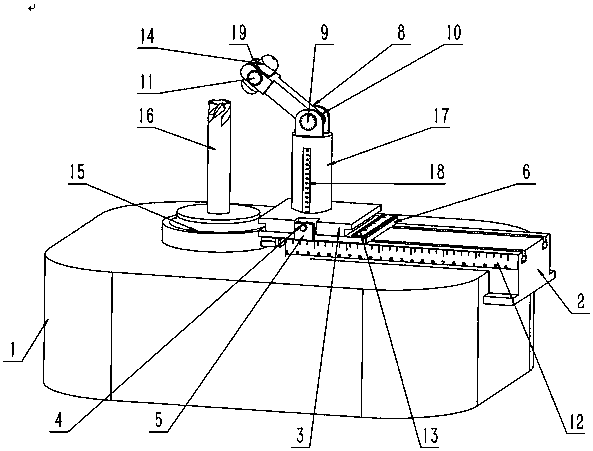

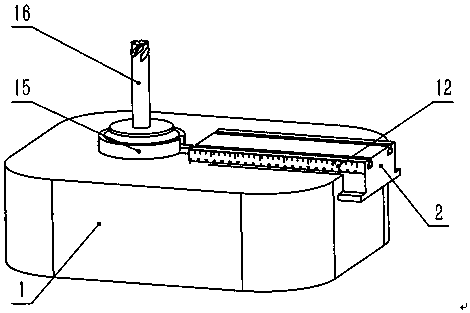

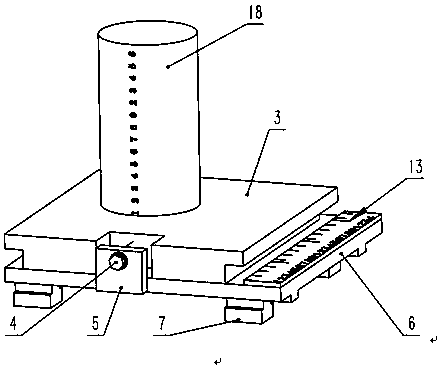

Ultrasonic cutting testing platform for honeycomb material

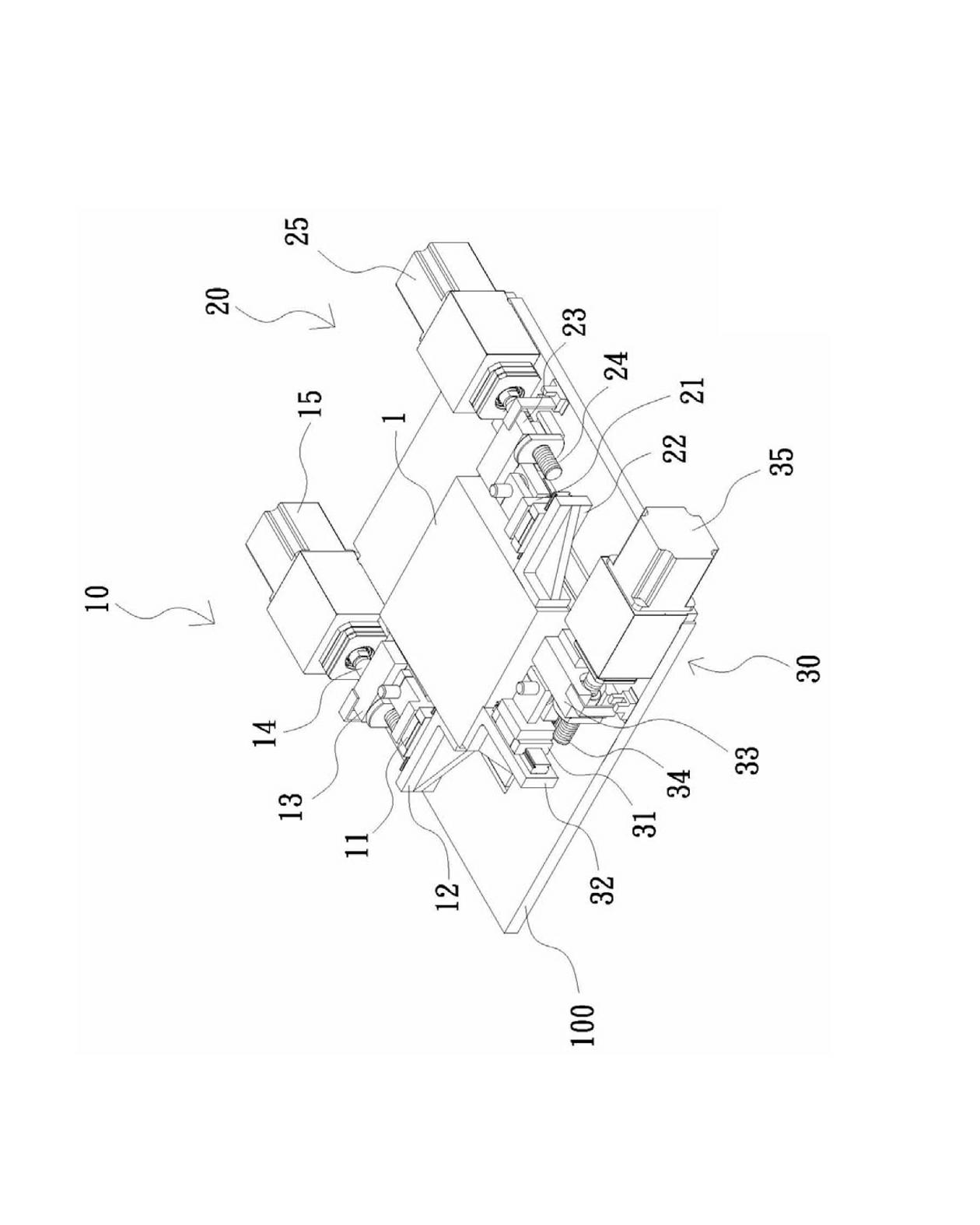

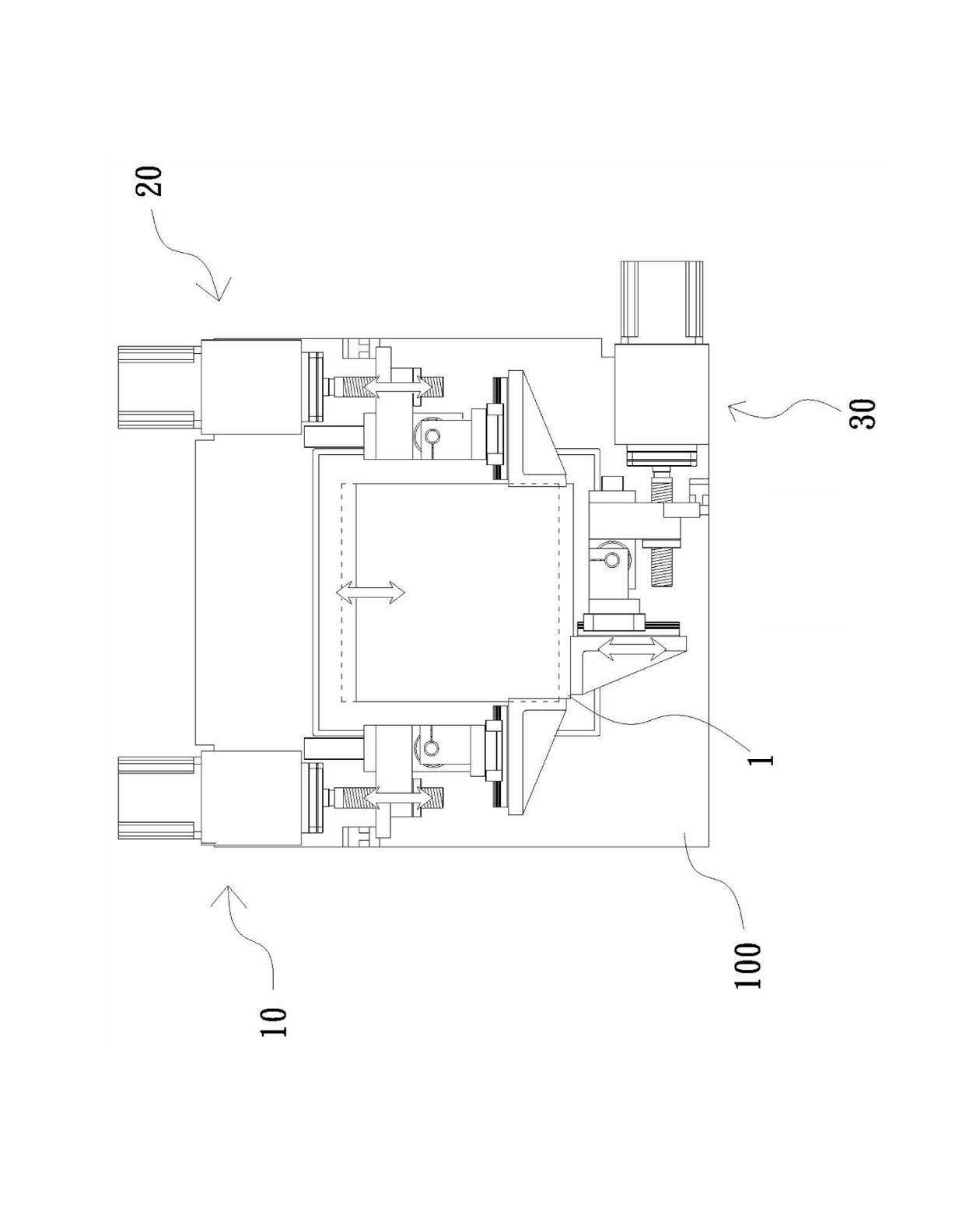

ActiveCN108436186AStable jobAdjust the positioning accuratelyMeasurement/indication equipmentsMetal working apparatusHoneycombEngineering

The invention discloses an ultrasonic cutting testing platform for a honeycomb material. The platform comprises a five-axis moving platform, a special mechanical main shaft device for ultrasonic cutting, a cutting temperature measuring device, an ultrasonic vibrating performance measuring device, a honeycomb material clamping device and a cutting force measuring device. The platform is characterized in that the special mechanical main shaft device for ultrasonic cutting is fixed to an A / C front sway of the five-axis moving platform; the cutting force measuring device is fixed to a worktable ofthe five-axis moving platform; the honeycomb material clamping device is fixed to the cutting force measuring device; and the cutting temperature measuring device and the ultrasonic vibrating performance measuring device are fixed to the special mechanical main shaft device for ultrasonic cutting. The ultrasonic cutting testing platform disclosed by the invention is suitable for different types of ultrasonic cutting tools, is suitable for honeycomb materials of different specifications and different dimensions, and is various in test types.

Owner:DALIAN UNIV OF TECH

Automatic multi-head precise drilling machine and drilling technique thereof

PendingCN107838458APrecise positioningAdjust the positioning accuratelyMeasurement/indication equipmentsPrinted circuit manufactureControl engineeringProcess engineering

The invention discloses an automatic multi-head precise drilling machine comprising a rack body. The rack body is internally provided with an alignment platform, a conveying sliding table, a multi-head drilling device and conveying belts. The two ends of the conveying sliding table extend into the alignment platform and the multi-head drilling device correspondingly; the conveying belts are arranged in the multi-head drilling device and located at the front end and the rear end of the conveying sliding table; and the automatic multi-head precise drilling machine further comprises a control boxfor controlling the alignment platform, the conveying sliding table, the multi-head drilling device and the discharging conveying belts to work normally, and a bidirectional observation instrument for observing position adjustment of the multi-head drilling device. The automatic multi-head precise drilling machine has the beneficial effects that firstly, a drill bit and a to-be-machined positioning hole are precisely adjusted and positioned through observation of the bidirectional observation instrument; and the drilling efficiency of the automatic multi-head precise drilling machine is fivetimes or above of that of existing drilling equipment, the automatic multi-head precise drilling machine can completely keep up with the advance speed of an automation line of a single-sided printed circuit board, and an original operation mode of the circuit board can be changed thoroughly.

Owner:DONGGUAN ZHUNRUI AUTOMATION EQUIP

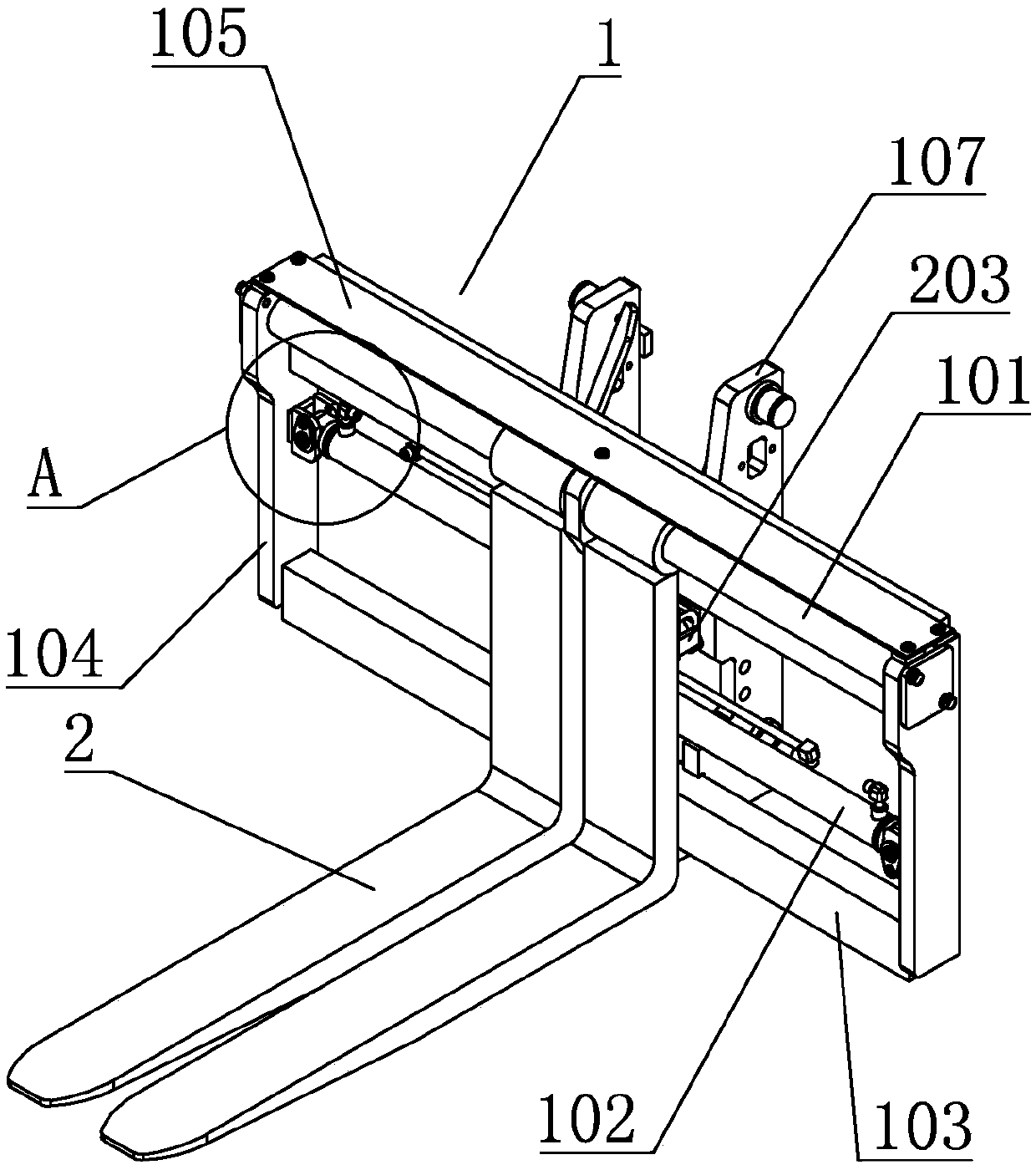

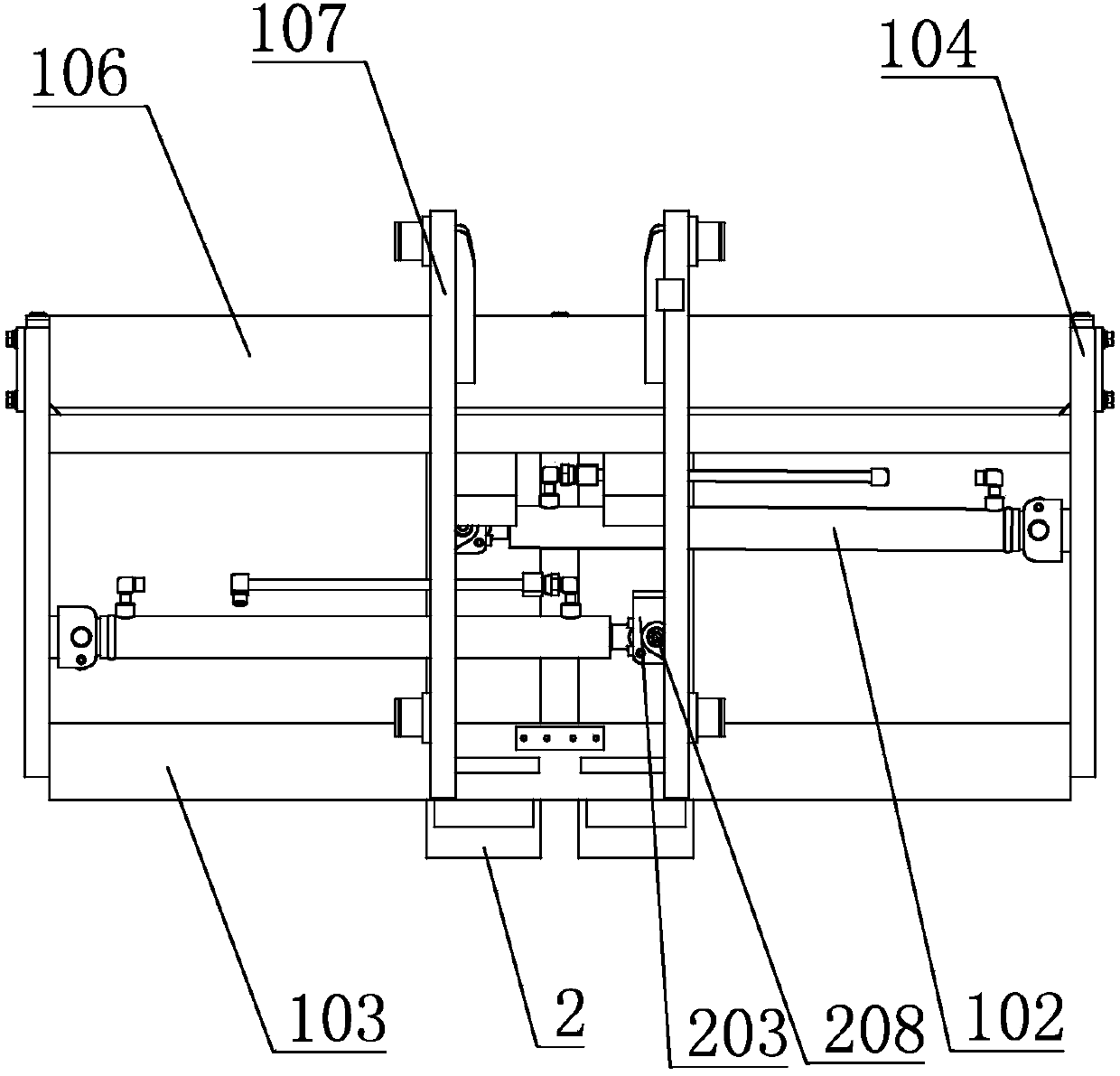

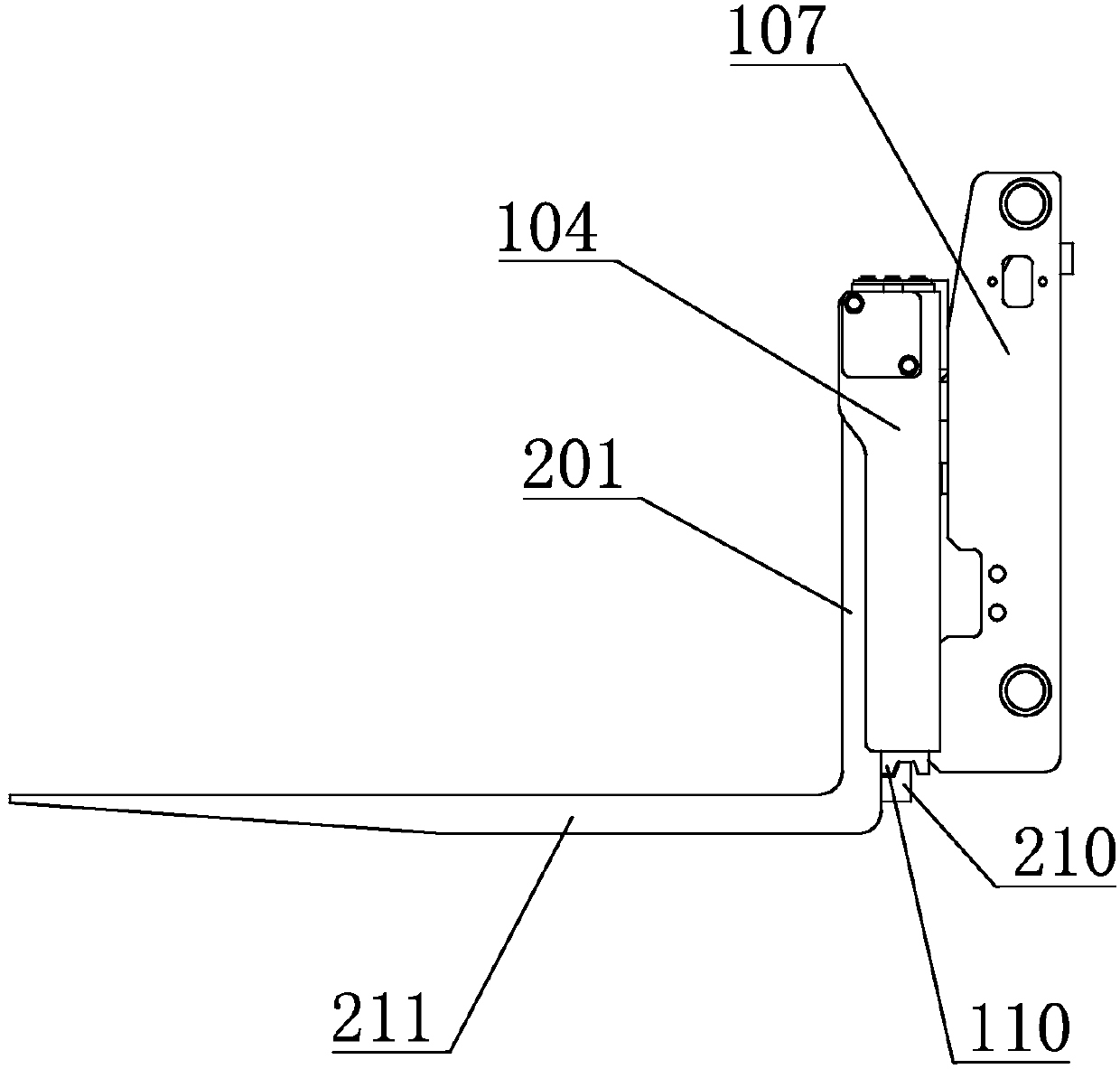

Hydraulic distance adjusting fork for forklift truck

The invention discloses a hydraulic distance adjusting fork for a forklift truck. The hydraulic distance adjusting fork comprises a distance adjusting frame arranged on a lifting frame on the front side of the forklift truck and two L-shaped forks which can adjusting the opening and closing distance on the distance adjusting frame. The distance adjusting frame is provided with a guide rod which ishorizontally arranged, and a cylindrical guide sleeve matched with the guide rod is fixed to the tops of perpendicular parts of the forks. Lubricating grease is smeared to the inner ring of the guidesleeve and the guide rod, and the upper portion and the lower portion of the rear side of the perpendicular parts are provided with upper hooks and lower clamping grooves correspondingly. Distance adjusting oil cylinders which are opposite horizontally are arranged on the two sides of the distance adjusting frame, and a sliding rod which is horizontally and transversely arranged is arranged on the lower side of the distance adjusting frame. The tail ends of output rods of the two distance adjusting oil cylinders are hinged to the two hooks, and the lower side of the sliding rod is clamped inthe lower clamping grooves. Due to the fact that the hydraulic distance adjusting oil cylinder is used for directly driving the series forks for stepless distance adjustment, the front suspension distance of the forklift truck is shortened, and the carrying capability is greatly improved; and the product structure is relatively simple, the friction resistance is small, losses can be reduced to themaximum degree, and therefore energy conversion is completed.

Owner:余伟宏

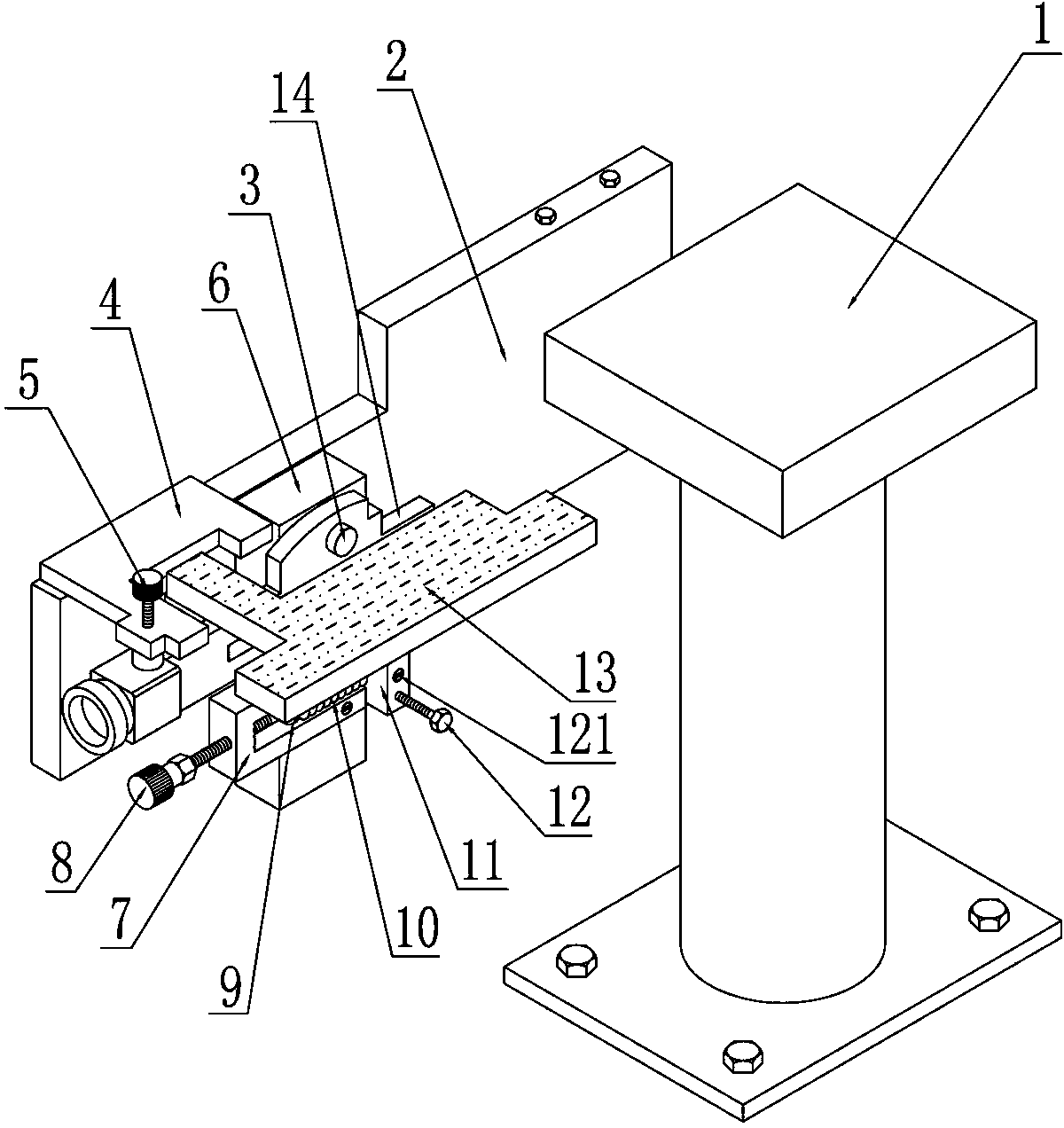

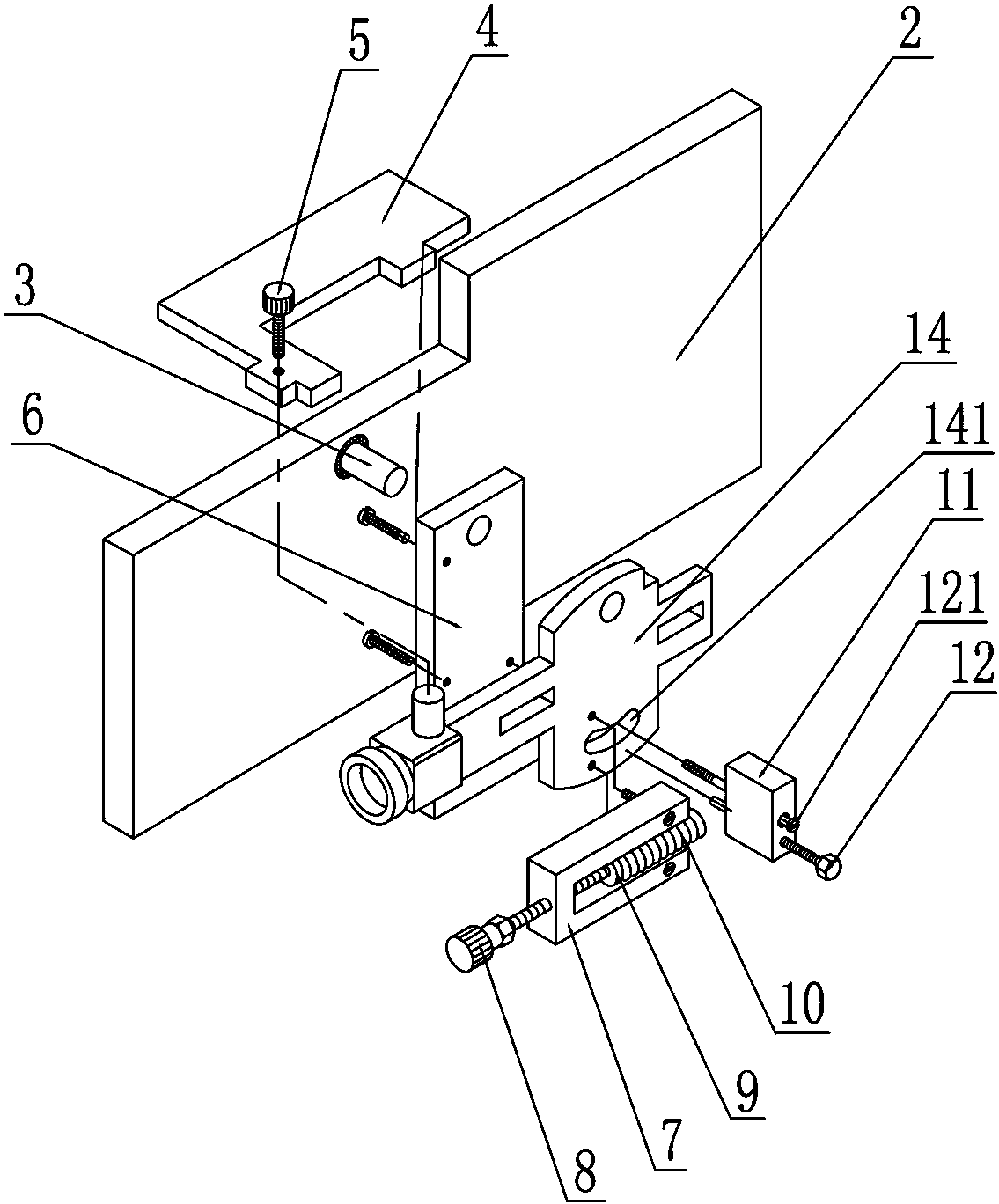

Sapphire crystal bar crystal axis detection and positioning device

ActiveCN106352816AControl angle of incidenceControl reflection angleUsing optical meansData displayRotary stage

The invention discloses a sapphire crystal bar crystal axis detection and positioning device. The sapphire crystal bar crystal axis detection and positioning device consisting of a crystal axis detection device, a crystal axis positioning device and a movable base. A bracket is arranged above a working table of the device; the crystal axis detection device is arranged on the bracket; the movable base is arranged on the working table; the crystal axis positioning device is arranged on the movable base; the movable base consists of a longitudinal movement guide rail, a longitudinal movement platform, a longitudinal screw rod, a supporting platform and a rotating platform; the crystal axis positioning device consists of a round bracket, a longitudinal oscillation sleeve, a transverse oscillation cylinder, an arc-shaped clamping block and an adjusting screw; and the crystal axis detection device consists of a lifting platform, an infrared transmitter, an infrared receiver and a data display device. In a detection adjustment process, an operator directly rotates the adjusting screw and the rotating platform, and performs observation and adjustment from different directions to quickly correct a crystal axis side of a crystal bar, the adjustment and positioning operation quick, easy and accurate, the detection device is arranged on the lifting platform, an incident angle and a reflection angle of detection light rays are controlled reasonably, and the detection effect is relatively good.

Owner:YUNNAN CRYSTALAND

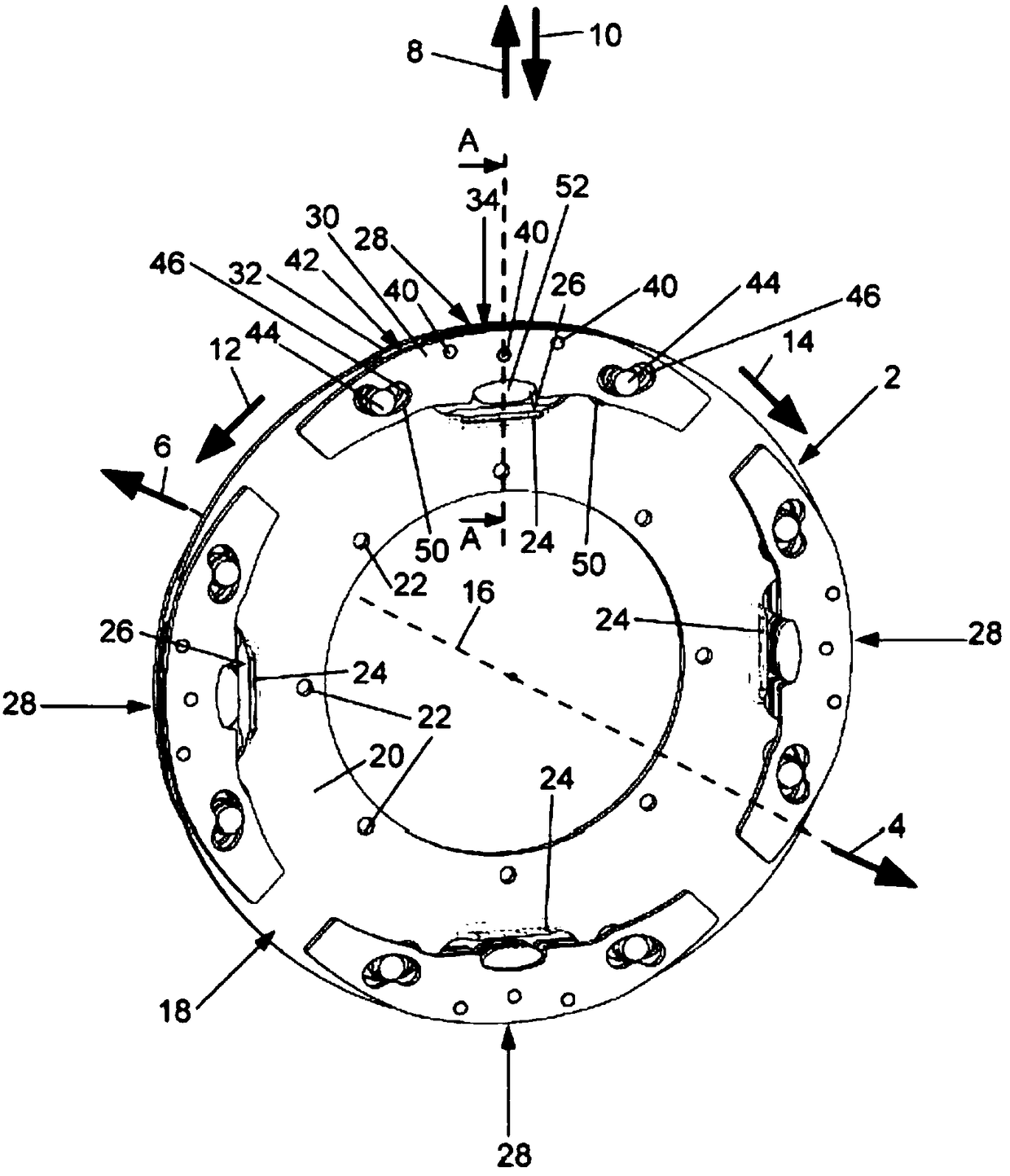

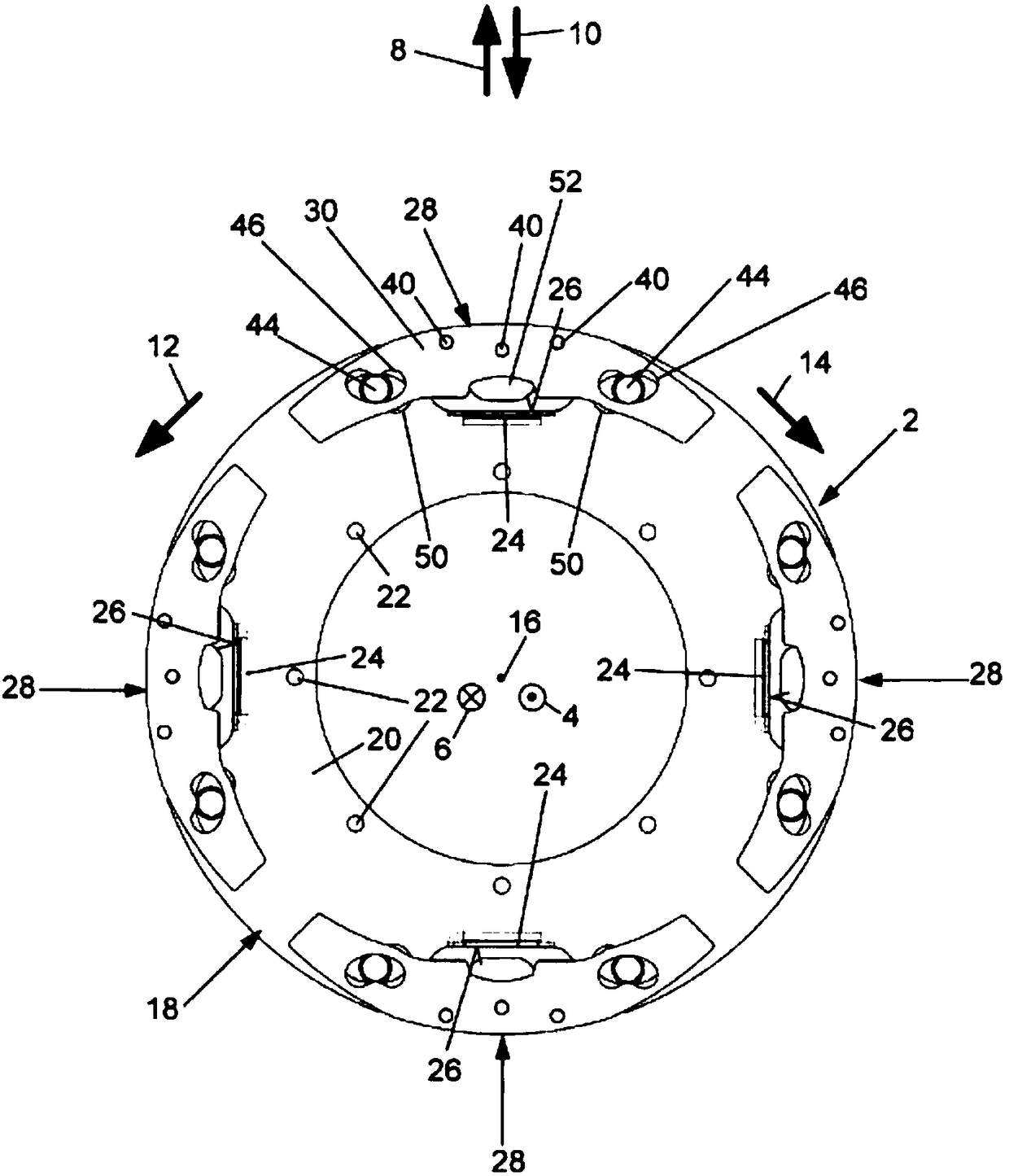

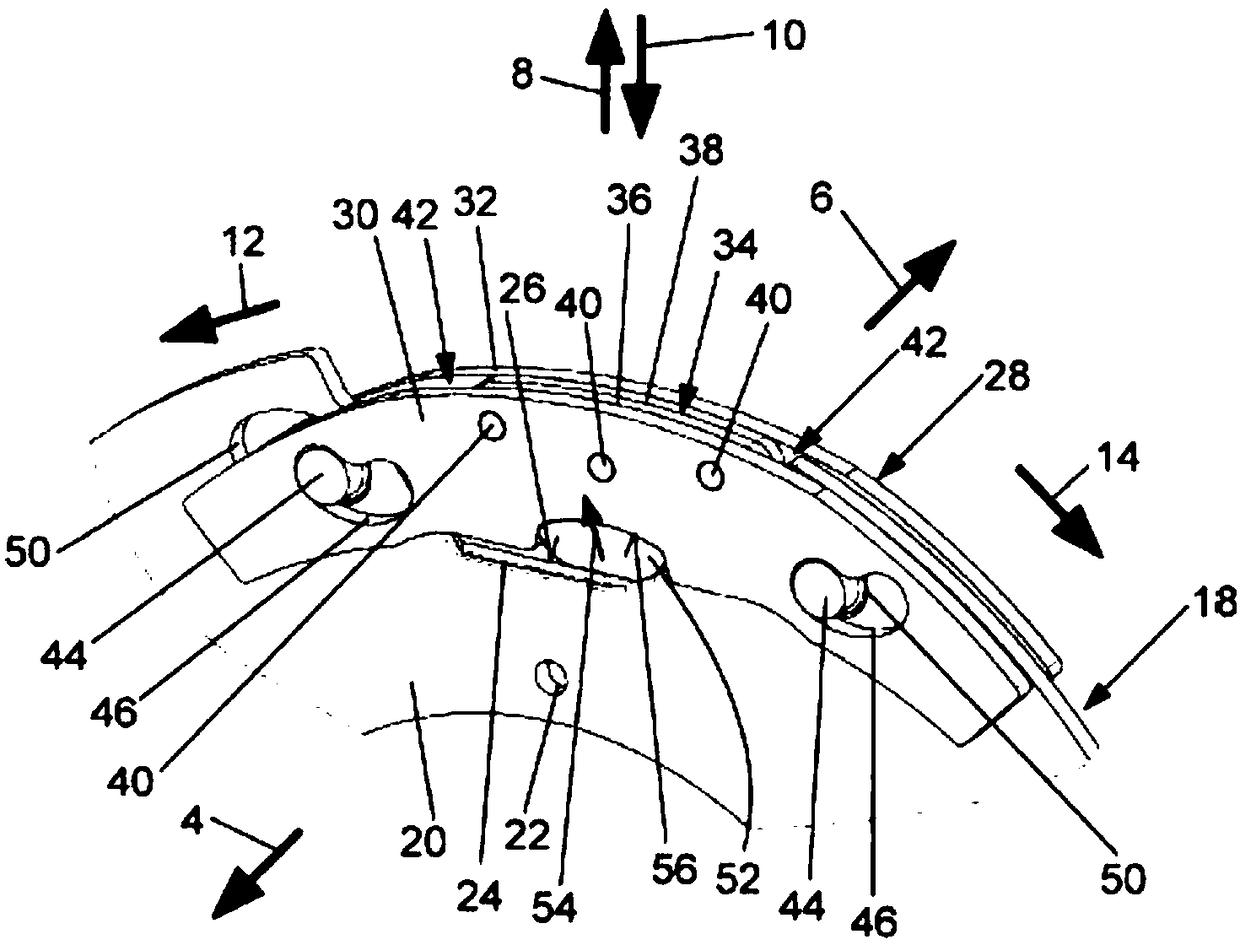

Centrifugal pendulum device and torsional vibration damper comprising such a centrifugal pendulum device

ActiveCN108691951AEasy to manufactureAdjust the positioning accuratelyRotating vibration suppressionEngineeringTorsional vibration

The present invention relates to a centrifugal pendulum device (2) comprising a rotatable pendulum mass carrier (18) and at least one pendulum mass (28), which is arranged thereon to be moveable between two end positions relative to the pendulum mass carrier (18) due to at least one guide element (44) which extends in guide means (46, 48, 50) in the pendulum mass carrier (18) and the pendulum mass(28), wherein a damping element (52) is arranged on the pendulum mass (28) via which the pendulum mass (28) is supported or supportable on the pendulum mass carrier (18) before reaching at least oneof the end positions, preferably both end positions. In addition, the present invention relates to a torsional vibration damper comprising such a centrifugal pendulum device (2).

Owner:BORGWARNER INC

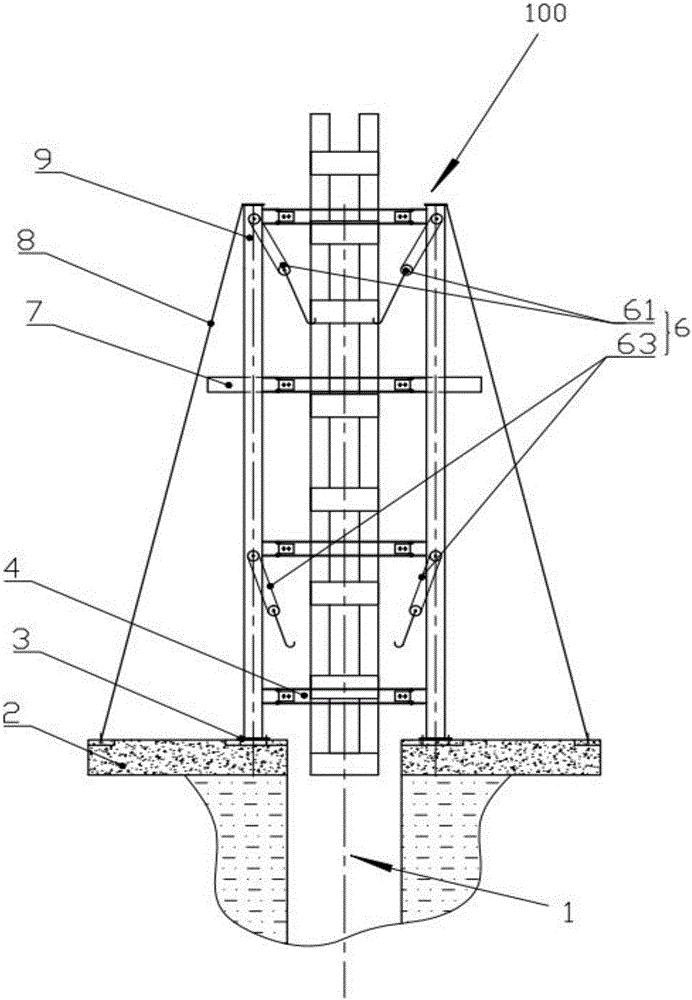

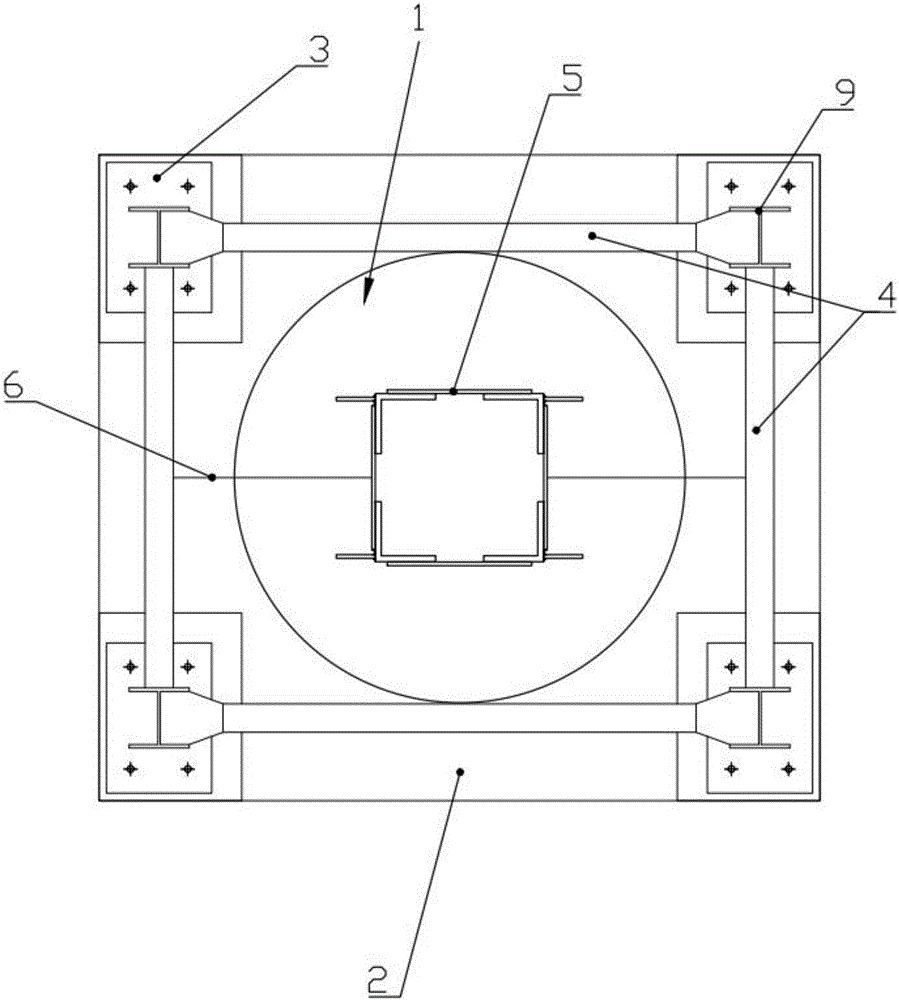

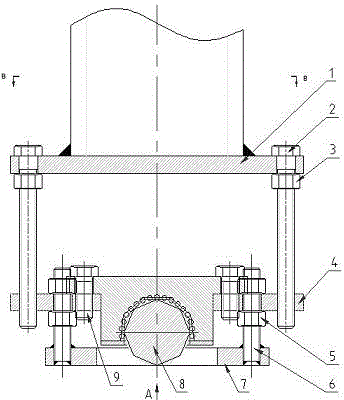

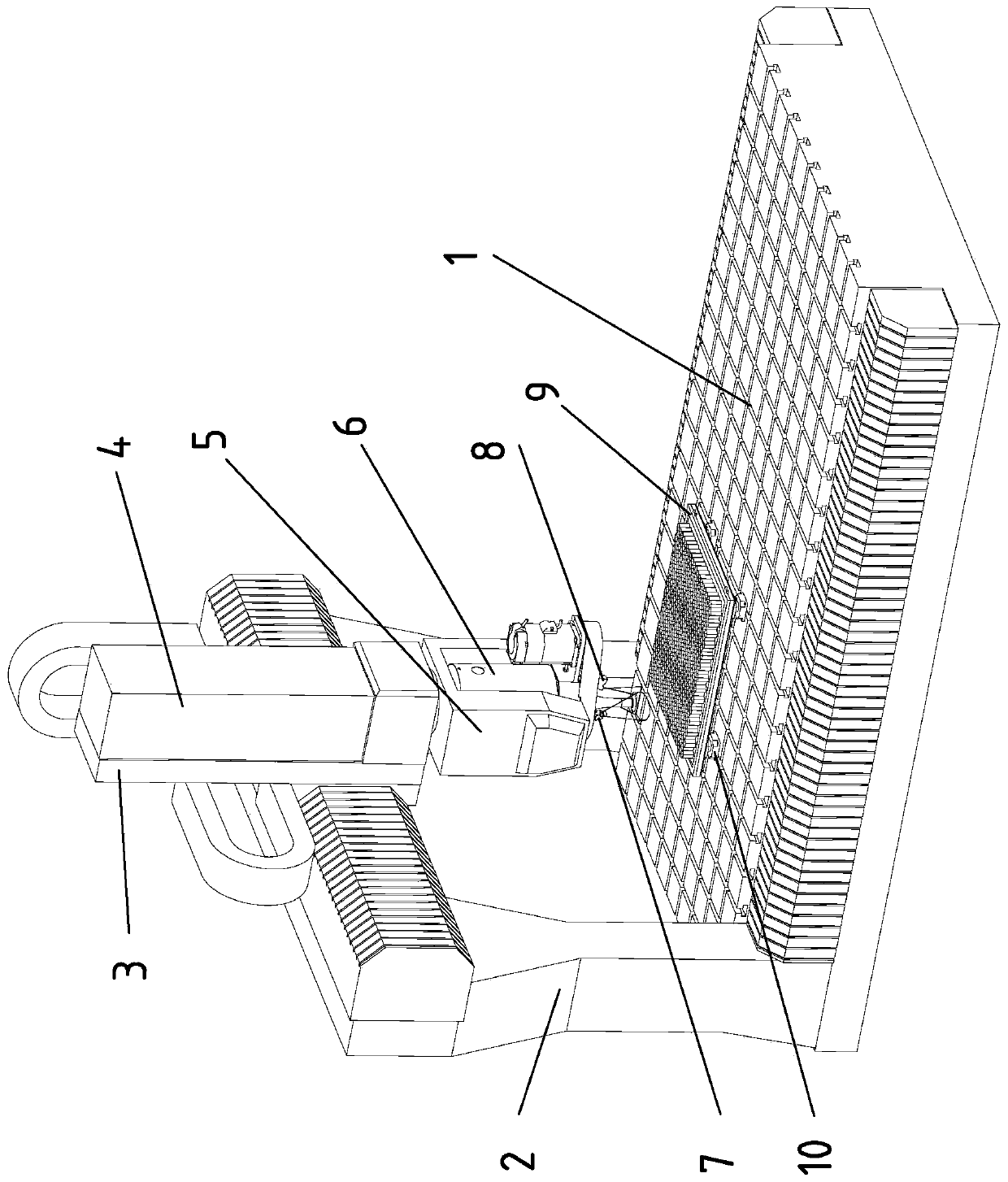

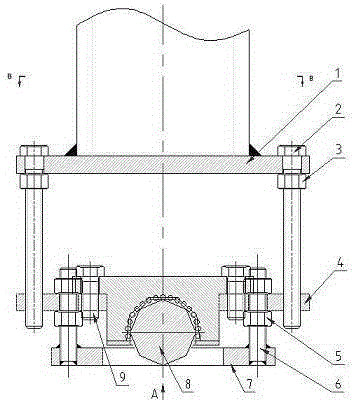

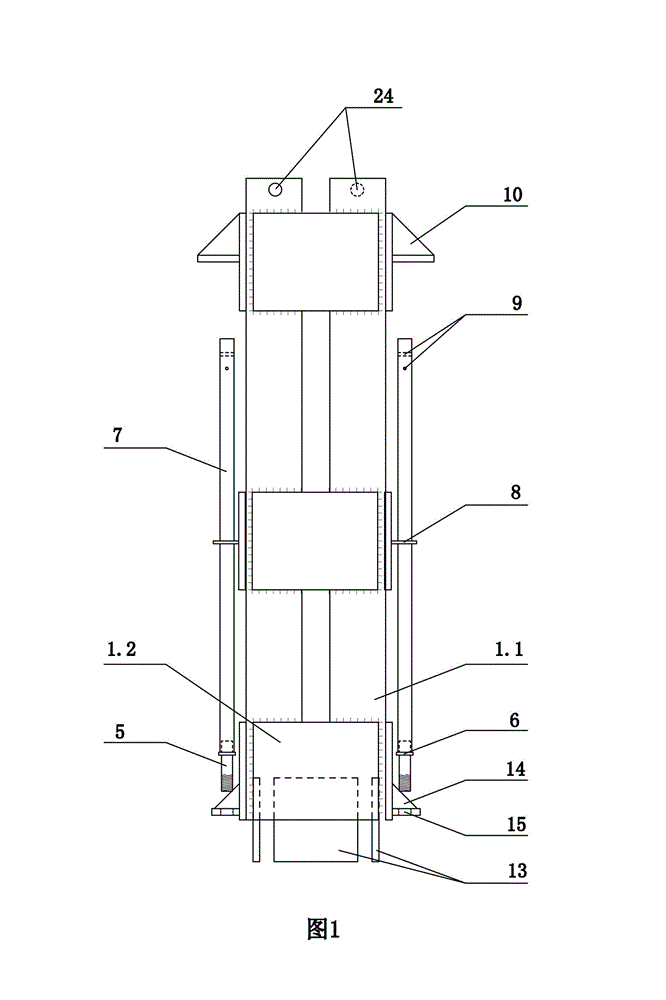

Latticed column welding device and method

InactiveCN106121040AGuaranteed installationAdjust the positioning accuratelyBuilding material handlingEngineeringTower crane

The invention discloses a welding lattice column device and a welding method, comprising a sleeve frame (100), the sleeve frame (100) including four upright columns (9) and a beam (4) detachably connecting the upright columns (9) ), the beam (4) is divided into several layers from top to bottom, the bottom of the column (9) is fixed on the concrete base (2) by the steel plate (3), the upper part of the sleeve frame (100) and A chain block (6) is provided on the corresponding crossbeam (4) at the bottom, and a shaft (1) is provided at the bottom of the casing (10), and the center of gravity line of the casing (100) is aligned with the center of the shaft (1). Lines overlap. It solves the problem of material waste caused by the direct lengthening of the lattice column in the traditional method and is not conducive to the quality control of the positioning construction of the steel lattice column. The invention adopts the method of supporting by the sleeve frame (100), controlling by the chain hoist (6) and segmentally welding at the wellhead, so that super-long and super-heavy lattice columns can be connected and installed in segments by means of a small tower crane on steep slopes.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

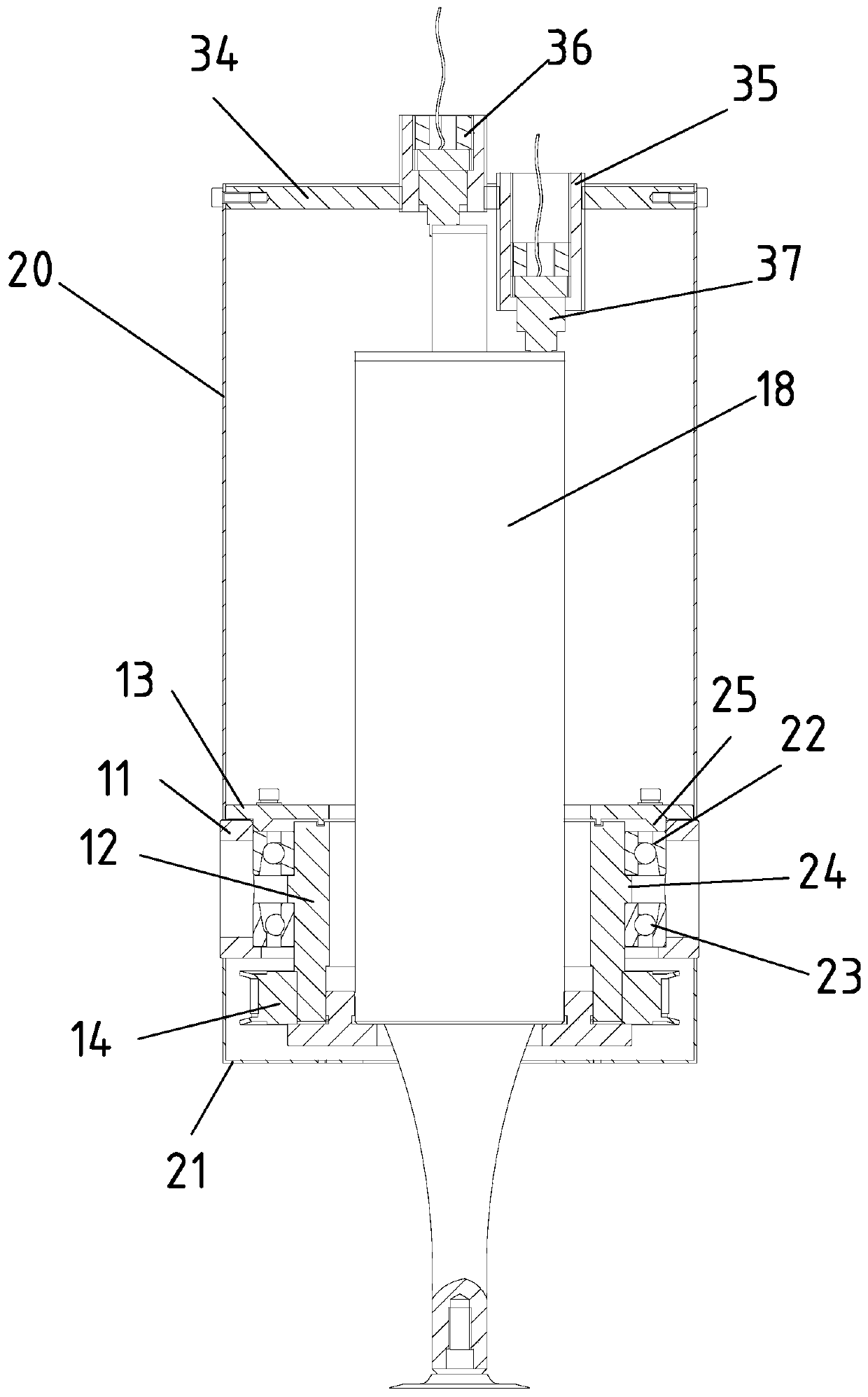

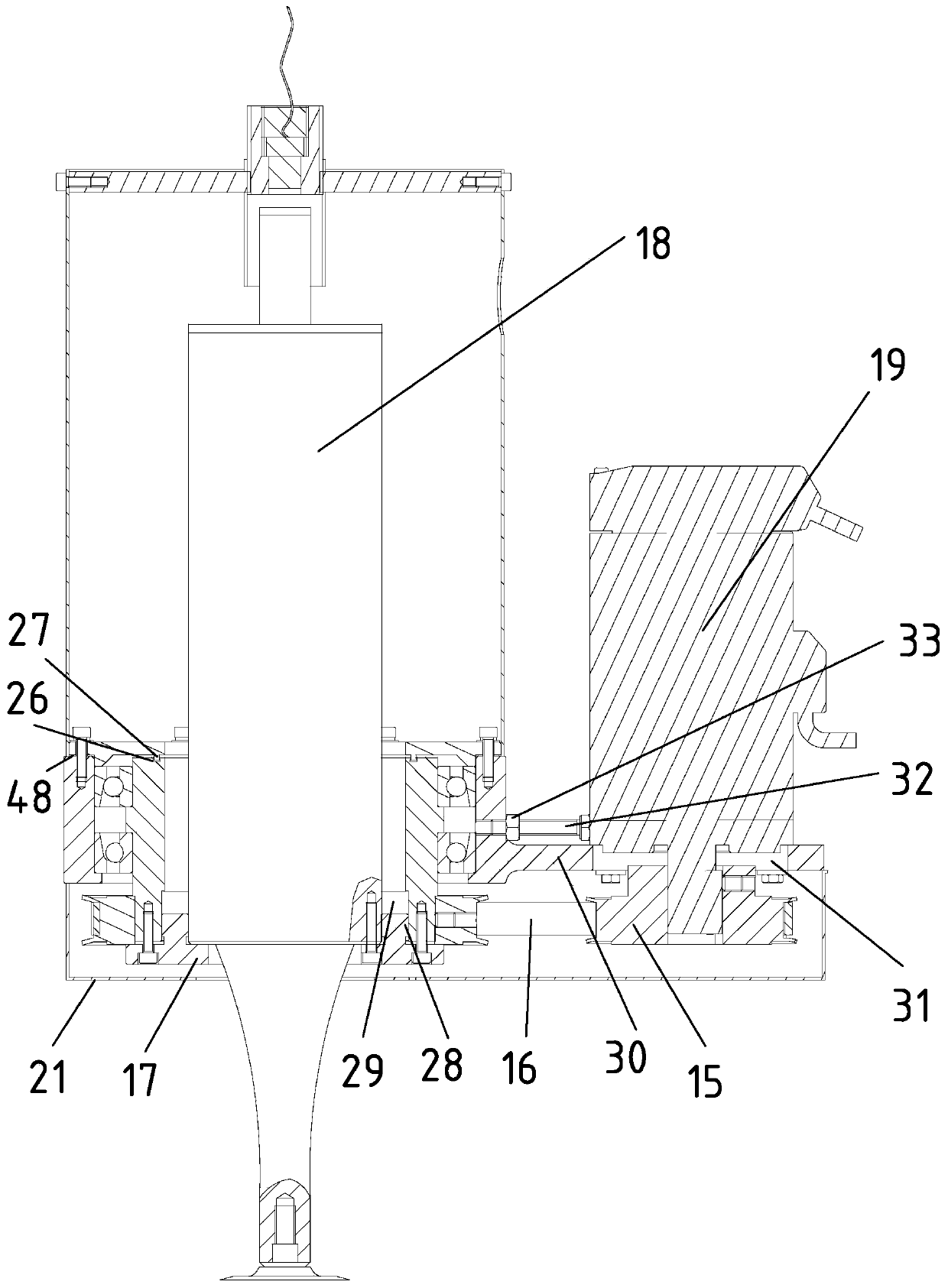

Adjustable universal stand bar for heavy equipment

InactiveCN104455955APrecise positioningAdjust the positioning accuratelyMachine framesBall bearingHeavy equipment

An adjustable universal stand bar for heavy equipment is characterized by comprising a lower installation plate, a universal ball bearing, a lower adjusting screw, an intermediate plate, an upper adjusting screw and an equipment stand bar plate, the universal ball bearing is used for achieving supporting, the upper adjusting screw is used for adjusting height, the lower adjusting screw is used for adjusting the lower installation plate to serve as a final support, the universal ball bearing can move forwards, backwards, leftwards and rightwards, and due to the adoption of rolling friction, resistance is small, and micro-adjustment can be achieved; the upper adjusting screw enables rising and falling of the heavy equipment to be achieved directly, the lower adjusting screw can be adjusted to enable the lower installation plate to make contact with the ground, final positioning after adjustment is finished can be achieved, the universal ball bearing can be taken out after positioning, and cost is reduced. By the adoption of the adjustable universal stand bar for the heavy equipment, accurate adjustment and positioning of the heavy equipment during manufacturing and installation can be achieved.

Owner:GANZHOU NONFERROUS METALLURGICAL MACHINERY

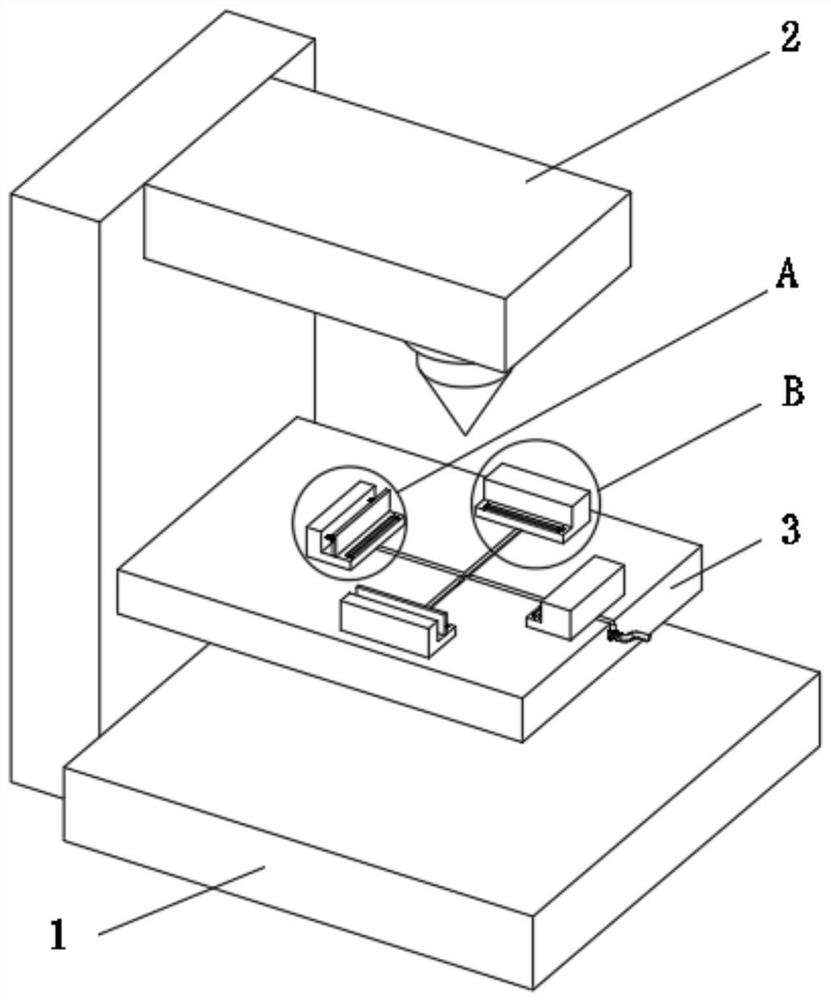

Laser code marking and scanning equipment

PendingCN112548350AReduce labor costsImprove processing efficiencyLaser beam welding apparatusComputer hardwareLaser

The invention discloses laser code marking and scanning equipment. The laser code marking and scanning equipment comprises a machine frame, a code marking platform mechanism, a laser code marking mechanism, a code scanning platform mechanism, a code scanning mechanism, a material moving mechanism, a product feeding mechanism and a product receiving frame. The code marking platform mechanism, the code scanning platform mechanism, the material moving mechanism, the product feeding mechanism and the product receiving frame are integrated on the same machine frame to form the laser code marking and scanning equipment, and the laser code marking and scanning equipment has the functions of automatic feeding, laser code marking, code scanning and automatic material receiving at the same time. Compared with single laser code marking equipment and single code scanning equipment, the laser code marking and scanning equipment has the advantages that one code scanning process, one set of code scanning equipment and operators are reduced, the equipment and labor cost can be greatly reduced, and the processing efficiency can be improved.

Owner:厦门柔性电子研究院有限公司

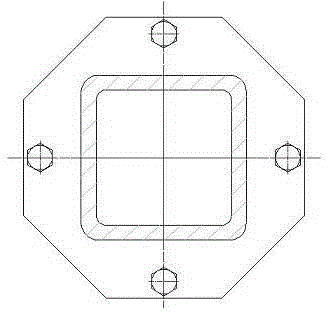

Mask frame

PendingCN112130427AAccurate locationAccurate adjustment and positioningPhotomechanical exposure apparatusMicrolithography exposure apparatusErbium lasersExposure

The invention discloses a mask frame, which comprises an exposure table and a laser assembly fixed above the exposure table; and the mask frame is characterized in that a fixed adjusting assembly capable of adjusting and fixing masks with different sizes is arranged between the exposure table and the laser assembly, and a threaded rod is driven to rotate by shaking a rotating handle; a first sliding block and a second sliding block in a same movable groove are accurately controlled to move in opposite directions, so that the fixing effect of adjusting masks of different sizes is achieved; thesituation that the masks are damaged due to too fast thread adjustment is avoided through a spring and a check block on the first sliding block, a second sliding block at the opposite position is notprovided with a spring and a check block, so that the position accuracy of the side of the masks is guaranteed. Elastic errors are not generated on the side, the mask is adjusted and located more accurately through cooperation with the extrusion fixing effect of the spring and the baffle on the first sliding block, the friction force between the sliding block and the bottom face of the mask in theadjusting process is reduced through rolling wheels, and abrasion to the mask in the adjusting process is reduced.

Owner:WUXI ZHONGWEI MASK ELECTRONICS

Electric adjusting positioning mechanism

InactiveCN102368387AAdjust the positioning accuratelyPrecise positioningInstrumental componentsWork benchesEngineeringPositioning system

Owner:NAT KAOHSIUNG UNIV OF SCI & TECH

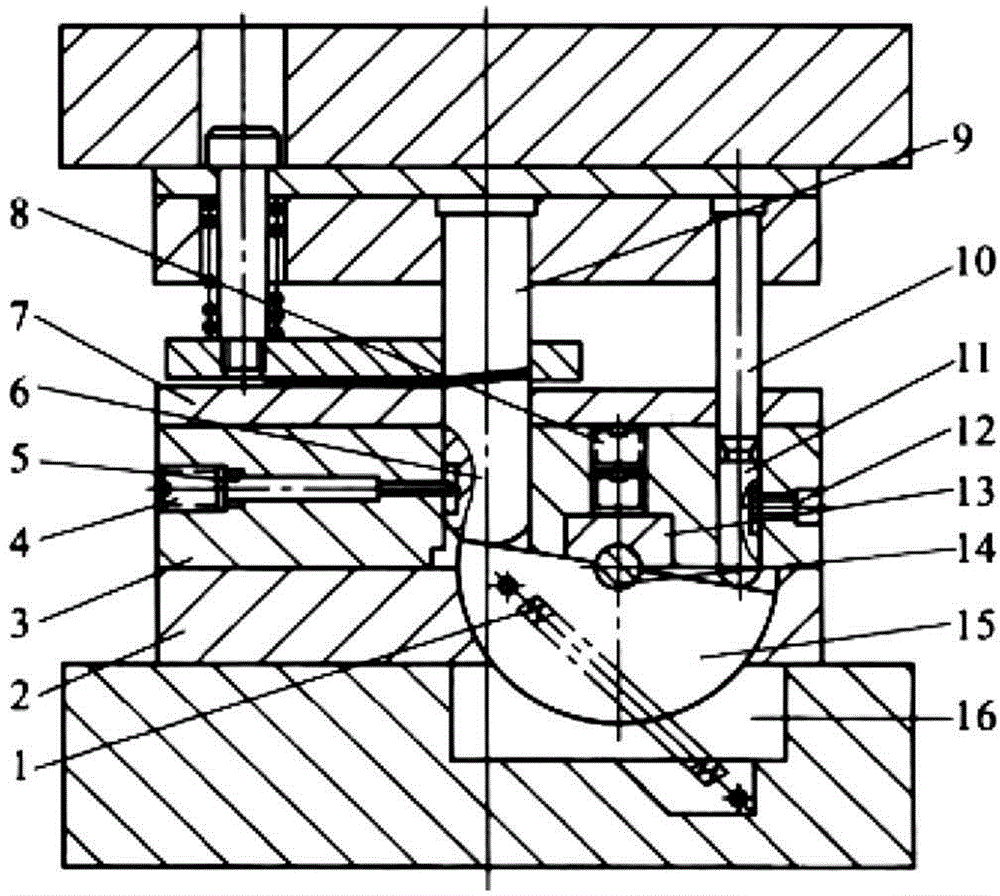

Unloading forming tool

InactiveCN104525779ALess prone to imbalanceSmooth rotationPerforating toolsStripping-off devicesEngineeringMechanical engineering

The invention relates to a stamping mould, in particular to a reverse stamping type unloading forming tool. The unloading forming tool comprises an unloading plate arranged on an upper mould and serving as the first unloading plate, an unloading plate arranged on a lower mould and serving as the second unloading plate, an ejection rod, a rotary semicircle and a punch, wherein the ejection rod, the rotary semicircle and the punch are sequentially connected, the upper end of the ejection rod is fixed to the upper mould, the other end of the ejection rod penetrates to the lower portion of the lower mould, the rotary semicircle is installed on a lower mould frame, one end of the upper surface of the rotary semicircle abuts against the lower end of the ejection rod, the other end of the upper surface of the rotary semicircle abuts against the lower end of the punch, the punch penetrates through the lower mould, the first unloading plate and the second unloading plate, the upper end of the punch corresponds to a groove hole in the upper mould in shape and position, and the rotary semicircle is hinged to the lower mould frame and semispherical. The unloading forming tool overcomes the defects that adjustment and positioning of a lever in the prior art are not accurate, and is accurate in positioning when fast operating.

Owner:CHONGQING YUANCHUANG AUTOMATION EQUIP

Double-station laser coding equipment and operation method thereof

PendingCN112548353AImprove coding efficiencyImprove scanning efficiencyLaser beam welding apparatusGalvanometerErbium lasers

The invention discloses double-station laser coding equipment and an operation method thereof. The equipment comprises a rack, a first coding platform mechanism, a second coding platform mechanism, alaser coding mechanism, a first code scanning platform mechanism, a second code scanning platform mechanism, a code scanning mechanism, a material moving mechanism, a product feeding mechanism and a product receiving frame. Two sets of coding platform mechanisms are adopted, and two sets of lasers and CCD galvanometer coaxial assemblies are matched, so that double-station laser coding is formed, independent control is achieved, mutual influence is avoided, two sets of single-station laser coding equipment are equivalently integrated, and the coding efficiency is greatly improved; the two setsof code scanning platform mechanisms are adopted to form double-station code scanning, one set of scanning mechanism is shared, and double stations alternately operate to scan codes, so that the working time of the scanning mechanisms is fully utilized, and the code scanning efficiency is greatly improved; The double-station laser coding equipment has the coding and scanning functions at the sametime, coding and code scanning are integrated on one piece of equipment, one code scanning procedure and one set of code scanning equipment and manpower are reduced, the production efficiency is improved, and the cost is reduced.

Owner:厦门柔性电子研究院有限公司

A honeycomb material ultrasonic cutting test platform

ActiveCN108436186BStable jobAdjust the positioning accuratelyMeasurement/indication equipmentsMetal working apparatusHoneycombEngineering

The invention discloses an ultrasonic cutting testing platform for a honeycomb material. The platform comprises a five-axis moving platform, a special mechanical main shaft device for ultrasonic cutting, a cutting temperature measuring device, an ultrasonic vibrating performance measuring device, a honeycomb material clamping device and a cutting force measuring device. The platform is characterized in that the special mechanical main shaft device for ultrasonic cutting is fixed to an A / C front sway of the five-axis moving platform; the cutting force measuring device is fixed to a worktable ofthe five-axis moving platform; the honeycomb material clamping device is fixed to the cutting force measuring device; and the cutting temperature measuring device and the ultrasonic vibrating performance measuring device are fixed to the special mechanical main shaft device for ultrasonic cutting. The ultrasonic cutting testing platform disclosed by the invention is suitable for different types of ultrasonic cutting tools, is suitable for honeycomb materials of different specifications and different dimensions, and is various in test types.

Owner:DALIAN UNIV OF TECH

Fine-adjustment coining mechanism

The invention relates to a stamping mold, in particular to an inverse-stamping type fine-adjustment coining mechanism. The fine-adjustment coining mechanism comprises an upper mold frame, an upper mold body, a lower mold frame, a lower mold body and a discharging plate arranged on the molded surface of the upper mold body, and further comprises a jacking and pressing rod, a rotating semicircular part and a flanging male mold, wherein the jacking and pressing rod, the rotating semicircular part and the flanging male mold are sequentially connected. The upper end of the jacking and pressing rod is fixed into the upper mold body, the other end of the jacking and pressing rod extends to the portion below the lower mold body, the rotating semicircular part is installed on the lower mold frame, one end of the upper surface of the rotating semicircular part abuts against the lower end of the jacking and pressing rod, the other end of the upper surface of the rotating semicircular part abuts against the lower end of the flanging male mold, the upper end of the flanging male mold is in a frustum shape, a polyester elastomer is arranged between the upper mold body and the discharging plate, and the rotating semicircular part is hinged to the lower mold frame and is hemispherical. By means of the fine-adjustment coining mechanism, the defect that in the prior art, lever adjustment positioning is inaccurate is overcome, and the fine-adjustment coining mechanism is accurate in positioning when running at a high speed.

Owner:CHONGQING YUANCHUANG AUTOMATION EQUIP

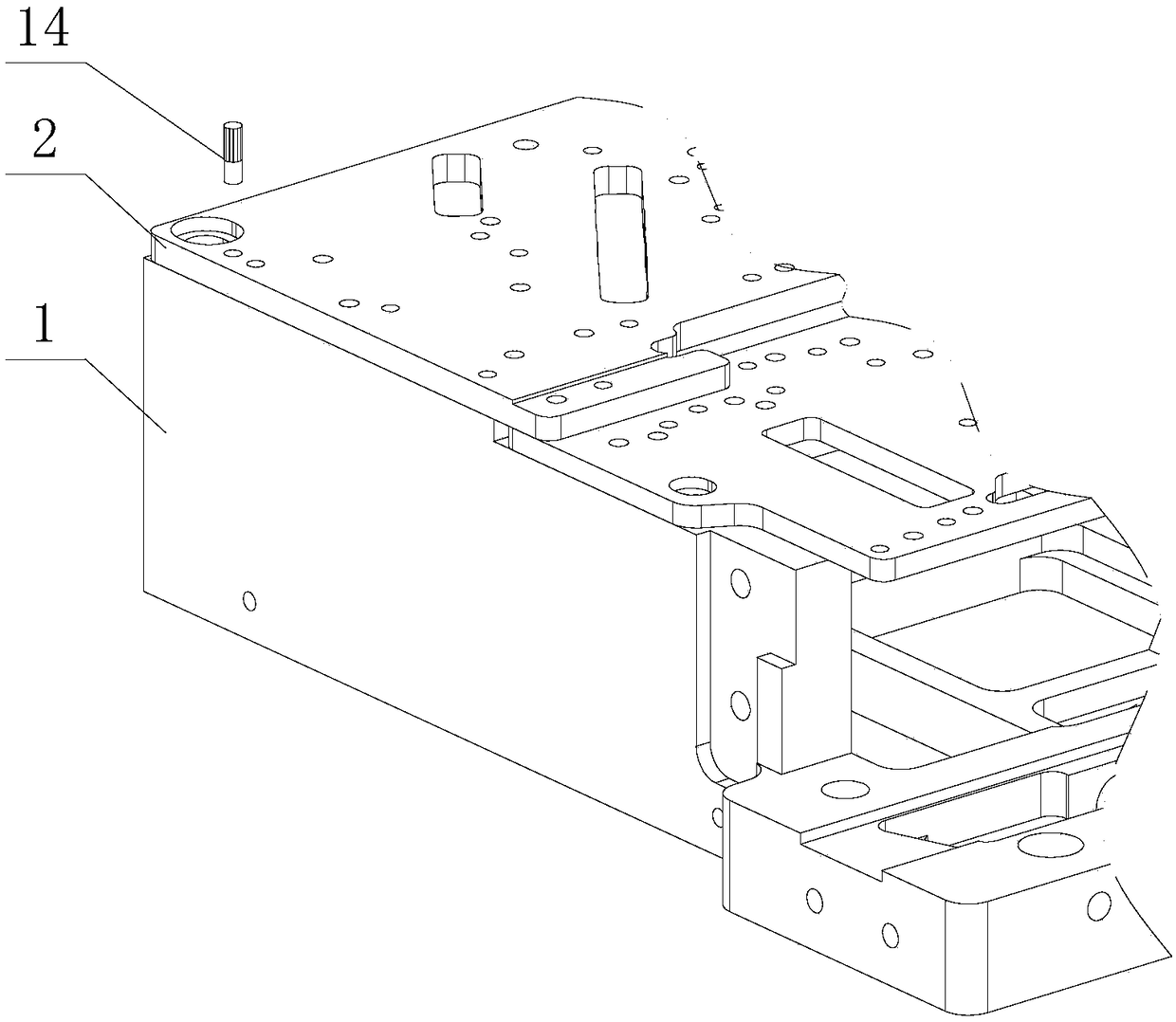

Gear type transmission adjusting and positioning mechanism

InactiveCN106801727APrecise positioningFlexible positioningGearing detailsFriction gearingsBall bearingReduction drive

A gear type transmission adjusting and positioning mechanism is characterized by a motor, a decelerator, an upper bearing sleeve, a first bearing set, a second bearing set, an upper base plate, a gear, a rack, side plates, supporting columns, a lower base plate, a third bearing set, a lower bearing sleeve and a rotary main shaft, wherein a power output shaft of the motor is connected with the rotary main shaft; the decelerator is mounted on a connection part between the power output shaft and the rotary main shaft; the first and second bearing sets are further arranged on the connection part and fixed via the upper bearing sleeve; the gear is mounted in the middle of the rotary main shaft; the gear is engaged with the rack on the lower side in an external tangent way; the other end of the rotary main shaft is provided with the third bearing set and the third bearing set is fixed by the lower bearing sleeve; the supporting columns on two sides of the rack are fixed on the upper and lower base plates; protective side plates are arranged on two ends of the rack; rubber sealing rings are arranged between the first and second bearing sets and the upper bearing sleeve; a rubber sealing ring is arranged between the third bearing set and the lower bearing sleeve; the first and third bearing sets are both deep groove ball bearing sets; and the second bearing set is a thrust ball bearing set. The gear type transmission adjusting and positioning mechanism is advantaged by simple structure, low manufacturing cost, stable work and operation, accurate positioning, flexible adjustment and high processing precision; and work piece defective percentage can be reduced and high-demand for modernization production can be met.

Owner:董博良

Sapphire crystal rod crystal axis detection and positioning device

ActiveCN106352816BQuality assuranceFast adjustment and positioningUsing optical meansData displayEngineering

The invention discloses a sapphire crystal bar crystal axis detection and positioning device. The sapphire crystal bar crystal axis detection and positioning device consisting of a crystal axis detection device, a crystal axis positioning device and a movable base. A bracket is arranged above a working table of the device; the crystal axis detection device is arranged on the bracket; the movable base is arranged on the working table; the crystal axis positioning device is arranged on the movable base; the movable base consists of a longitudinal movement guide rail, a longitudinal movement platform, a longitudinal screw rod, a supporting platform and a rotating platform; the crystal axis positioning device consists of a round bracket, a longitudinal oscillation sleeve, a transverse oscillation cylinder, an arc-shaped clamping block and an adjusting screw; and the crystal axis detection device consists of a lifting platform, an infrared transmitter, an infrared receiver and a data display device. In a detection adjustment process, an operator directly rotates the adjusting screw and the rotating platform, and performs observation and adjustment from different directions to quickly correct a crystal axis side of a crystal bar, the adjustment and positioning operation quick, easy and accurate, the detection device is arranged on the lifting platform, an incident angle and a reflection angle of detection light rays are controlled reasonably, and the detection effect is relatively good.

Owner:YUNNAN CRYSTALAND

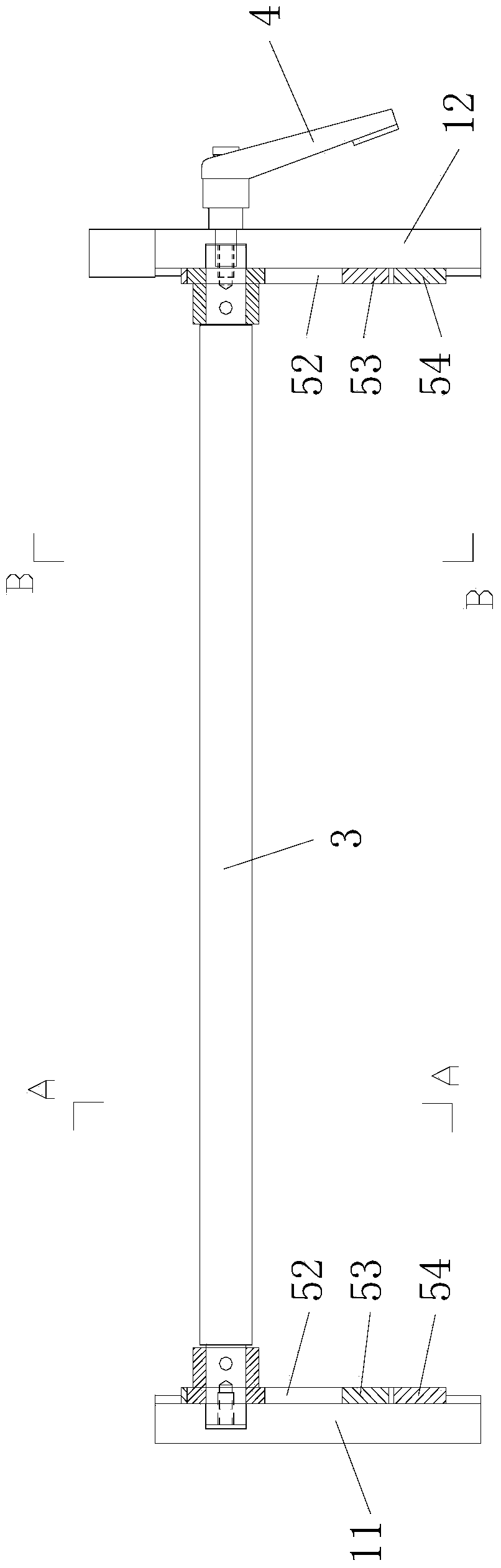

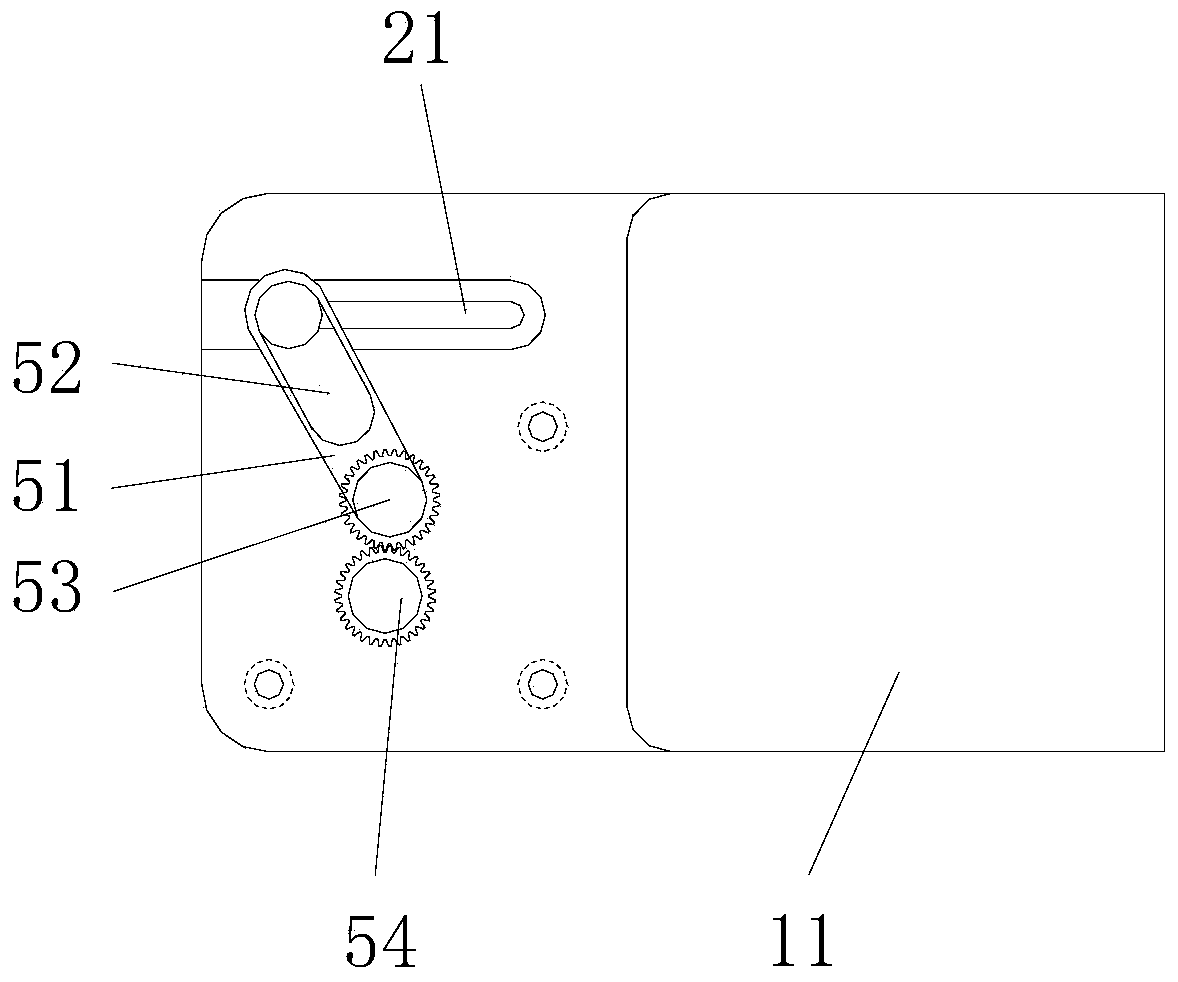

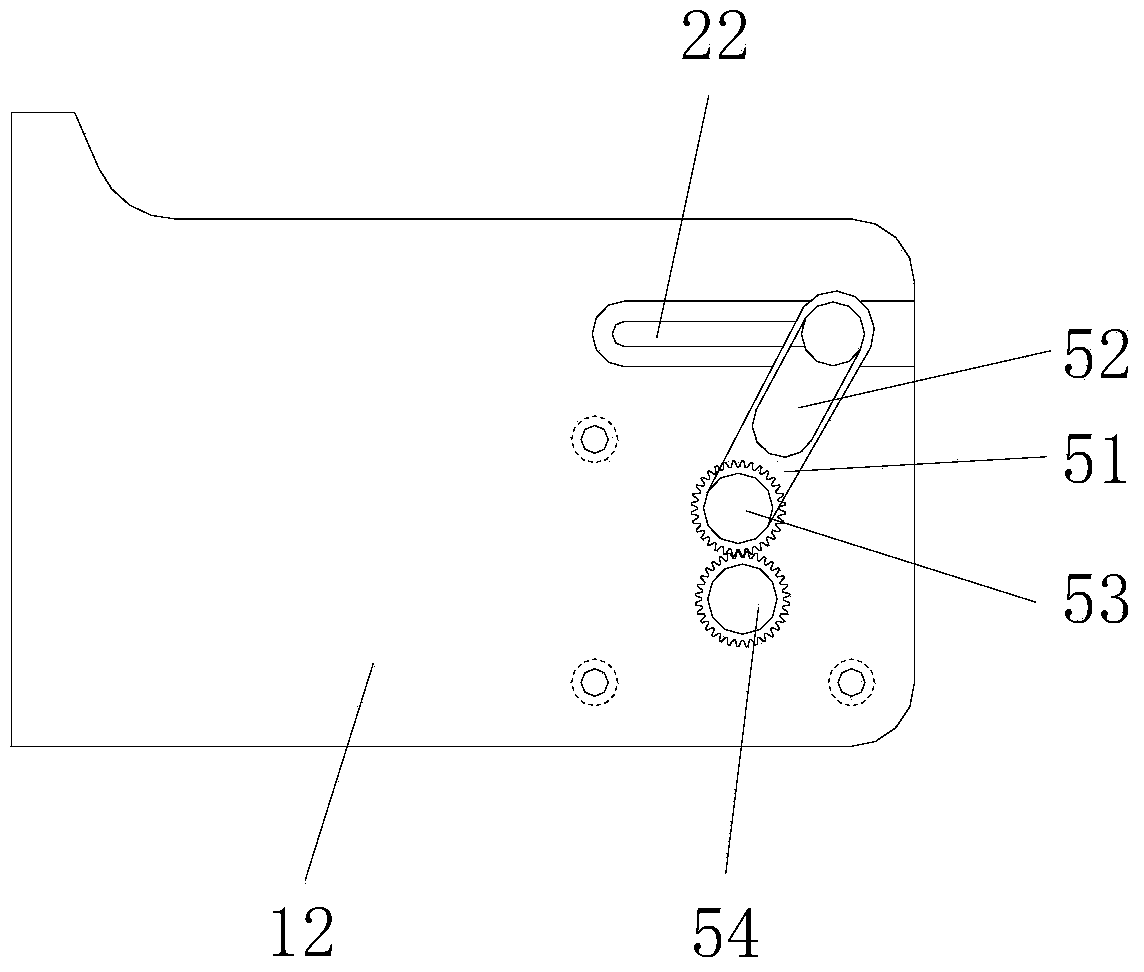

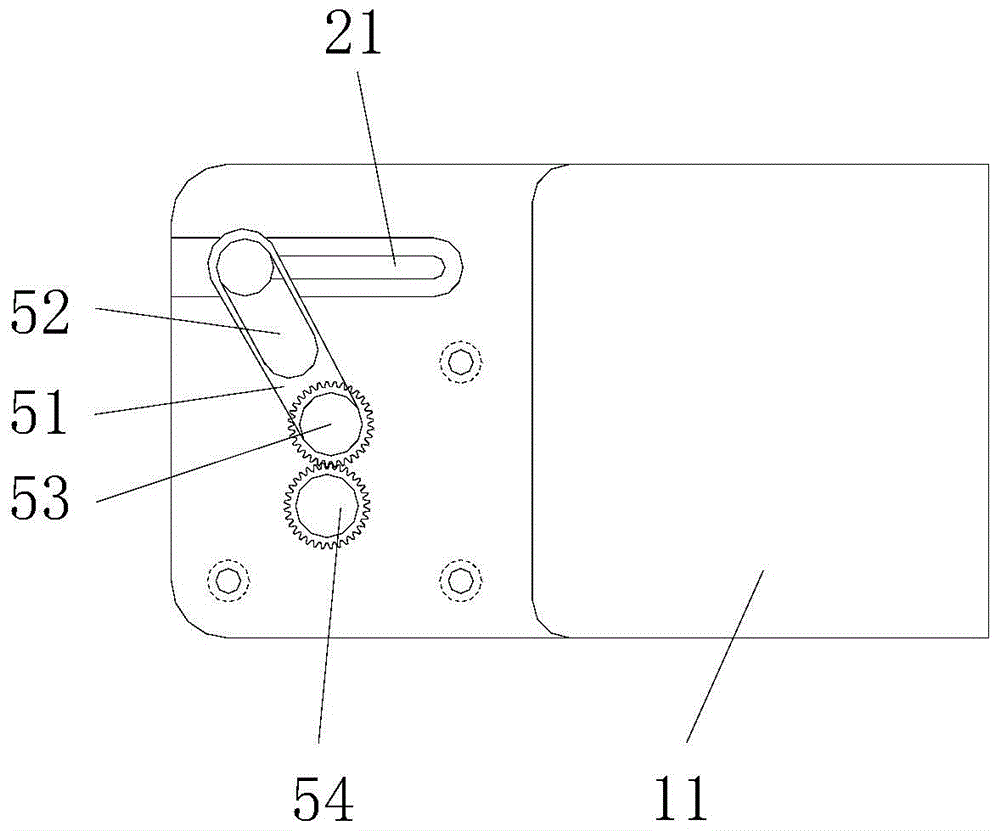

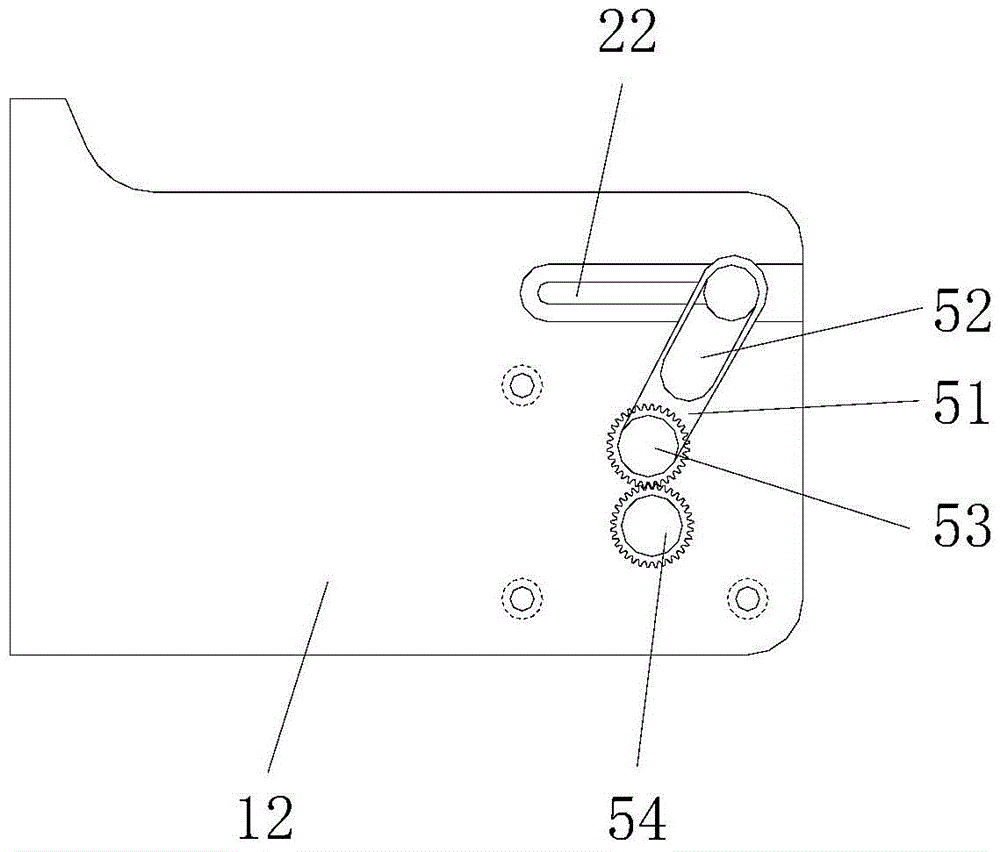

Rolling shaft adjusting device and application method thereof

ActiveCN104389972AGuaranteed parallelismAdjust the positioning accuratelyGearingGear driveEngineering

The invention discloses a rolling shaft adjusting device and an application method thereof. The rolling shaft adjusting device comprises two support plates, a rolling shaft, two adjusting devices and a handle, wherein strip-shaped openings are respectively formed in opposite end surfaces of the two support plates; the two ends of the rolling shaft are respectively positioned in the openings of the support plates in a sliding manner; the two adjusting devices are respectively connected with the two ends of the rolling shaft; and the handle is connected with the end of the rolling shaft. When the handle is released, a main gear rotates and drives a secondary gear to rotate; the secondary gear drives a swinging rod to swing surrounding a fixed end, so that the swinging rod drives the rolling shaft to slide along the openings; and when the rolling shaft arrives at a proper position, the handle is tightened to lock the rolling shaft. As the swinging of the swinging rod is driven through the transmission of the gear, and the movement of the rolling shaft is driven by the swinging rod, the movement parallelism of the rolling shaft is guaranteed through the transmission precision of the gear, and the adjusting positioning accuracy of the rolling shaft is achieved.

Owner:SHANGHAI LONGTENG TECH

Plate locating structure for flat knitting machine

ActiveCN108301111ASmall sizePrecise positioningWeft knittingTextile/flexible product manufactureNeedle positionEngineering

The invention discloses a plate locating structure for a flat knitting machine. The plate locating structure comprises an aluminum box and a plate body. The plate body is fixed to the aluminum box, the plate locating structure further comprises a mounting base and a square cotter, the square cotter is fixed to the mounting base, the mounting base is fixed to the side wall of the aluminum box, anda pin hole matched with the square cotter is formed in the plate body. The plate locating structure for the flat knitting machine has the advantages that the mode that the square cotter is fixed to the mounting base, the mounting base is fixed to the aluminum box, and then the square cotter is inserted into the plate body is adopted, the size of the square cotter can be effectively increased, thehardness of the parts is improved, and the parts are not easily worn; moreover, precise locating of a reference surface is achieved, adjustment and location of different overturning needle positions can be achieved by overturning the square cotter, the accuracy of locating a plate is greatly improved, and the adjustment of the overturning needle positions is more convenient and quick. At the sametime, the contact area between the square cotter and the plate and the contact area between the square cotter and the aluminum box are greatly increased, so that location of the plate is more stable and reliable.

Owner:ZHEJIANG FENGFAN NC MACHINERY

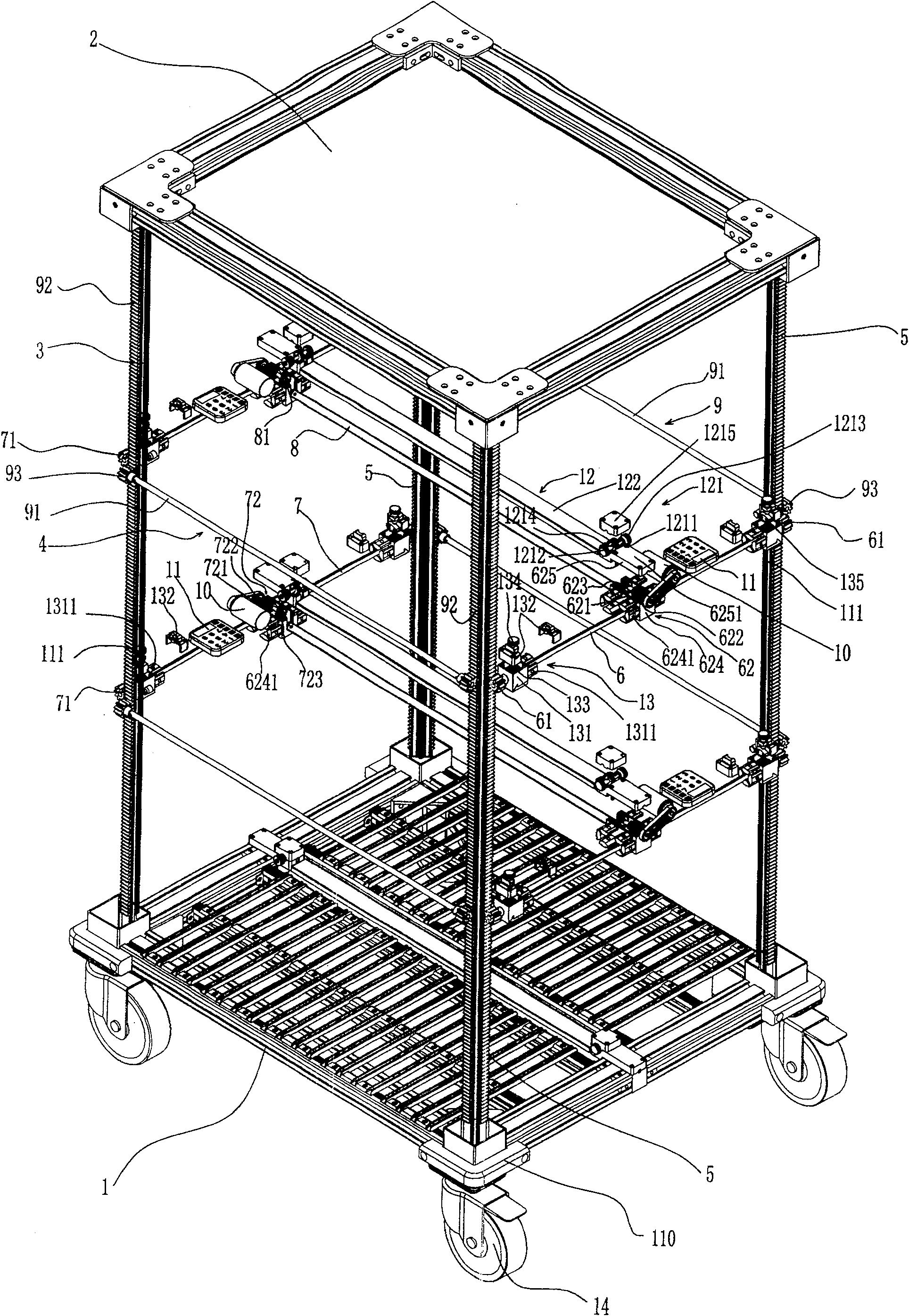

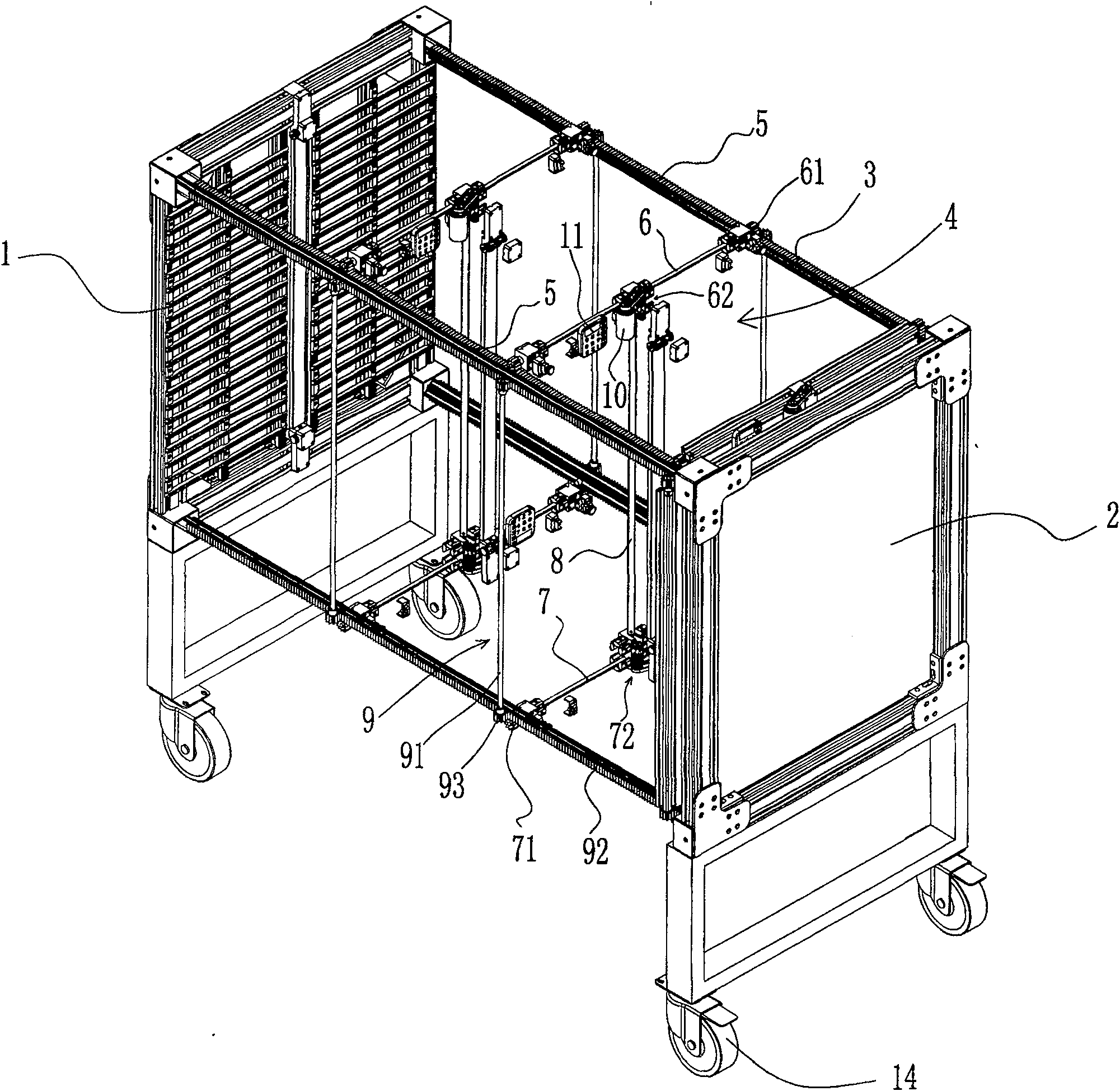

Turning holder with a convenient easy-adjustable movable loading plate

InactiveCN100515846CImprove regulation efficiencyParallel no longer worryHand carts with multiple axesVehicle frameDrive shaft

A turnover frame for a convenient and easy-to-adjust movable bearing plate, comprising a vehicle frame and at least one movable bearing plate, the movable bearing plate includes a driving part of the movable bearing plate and a bearing plate part, and the structure of the driving part is: Each connecting piece is provided with a tooth rack, and the tooth direction of the tooth racks on the connecting piece on the same side is the same; a transmission shaft is respectively provided between the two tooth racks on the same side, and the two ends of the transmission shaft are respectively Each is provided with a gear, and the gears are meshed with their corresponding racks; a worm gear mechanism is provided on the transmission shaft, and the worm gear in the worm gear mechanism is fixedly connected to the transmission shaft coaxially; the movable bearing The disc portion is arranged on at least the driving drive shaft and the driven drive shaft. The invention has the advantages of high adjustment efficiency, accurate adjustment and positioning and wide power sources.

Owner:张彦勤

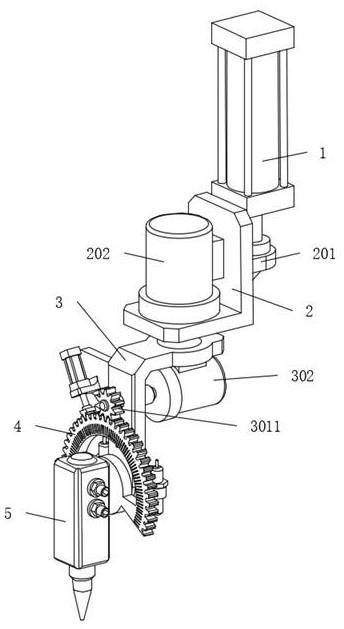

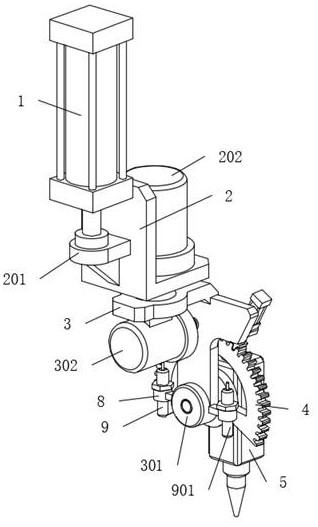

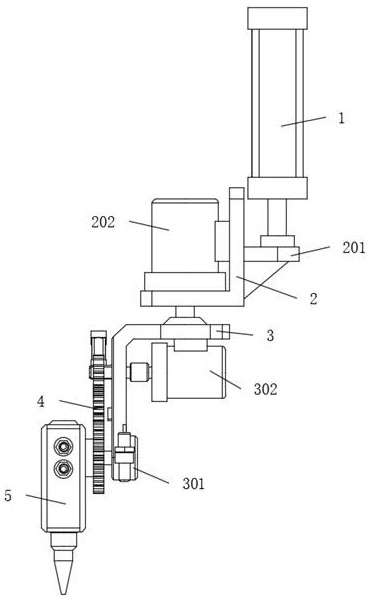

Cutting angle control system of flame cutting gun head

PendingCN114309875AIncrease diversityMeet cutting needsGas flame welding apparatusControl systemEngineering

The invention discloses a cutting angle control system of a flame cutting gun head, and relates to the field of flame cutting equipment, the cutting angle control system comprises a hydraulic lifting drive, a steering system assembly and a deflection system assembly, and the cutting angle control system has the beneficial effects that lifting of the steering system assembly and the deflection system assembly is controlled through the hydraulic lifting drive; the steering system assembly controls rotation of the deflection system assembly, the deflection system assembly controls the cutting deflection angle of the flame cutting gun head, the diversity of the cutting angle of the flame cutting gun head is greatly improved, and the cutting requirements of more machined parts are met. After the cutting angle of the flame cutting gun head is adjusted, the telescopic rod of the electromagnetic limiting telescopic rod is controlled to extend until the limiting top head arranged at the end of the telescopic rod of the electromagnetic limiting telescopic rod is matched and inserted with the outer gear teeth of the gear ring seat, so that the gear ring seat is limited, and the situation that the cutting precision is reduced due to the fact that the gear ring seat is loosened is prevented.

Owner:陈家坤

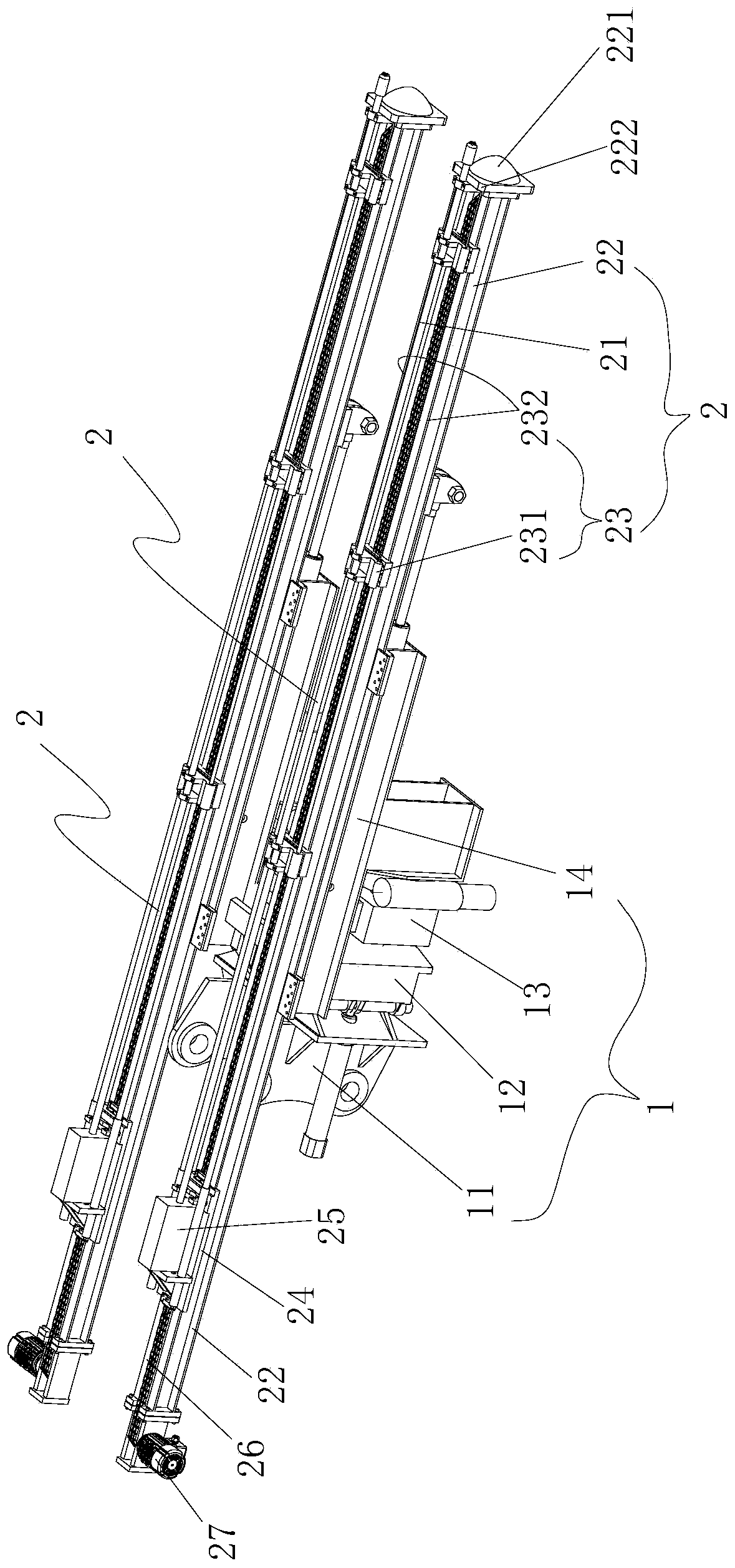

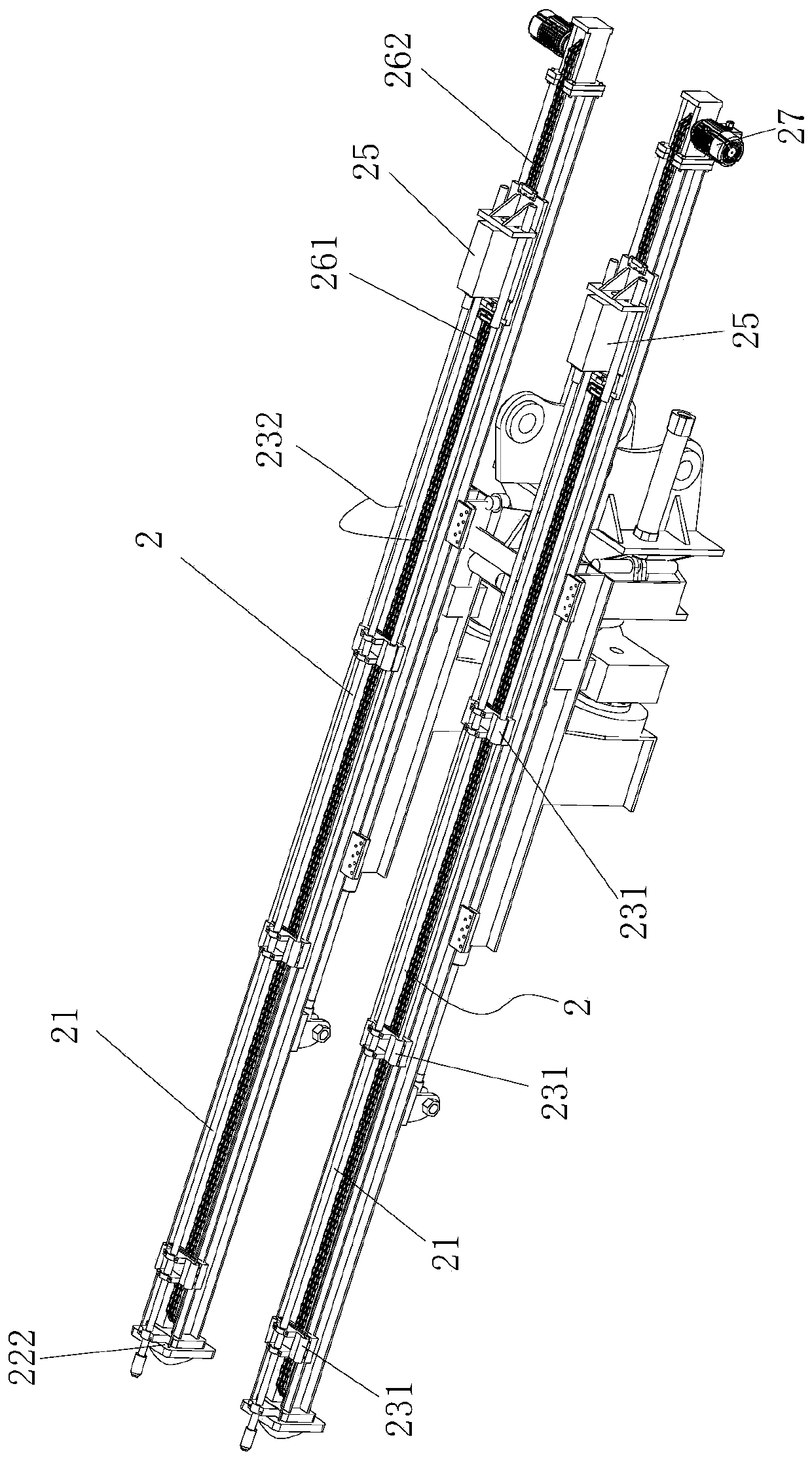

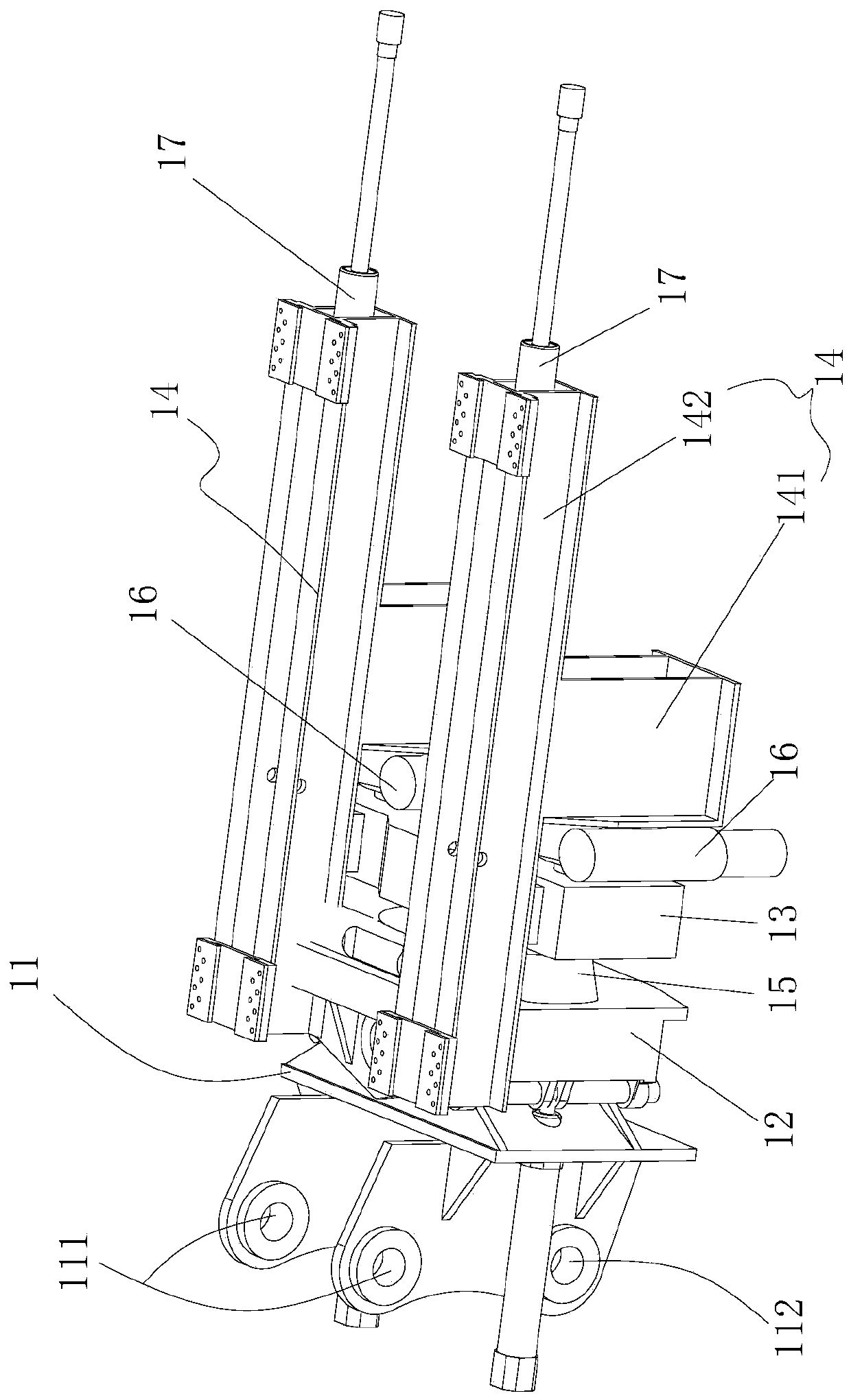

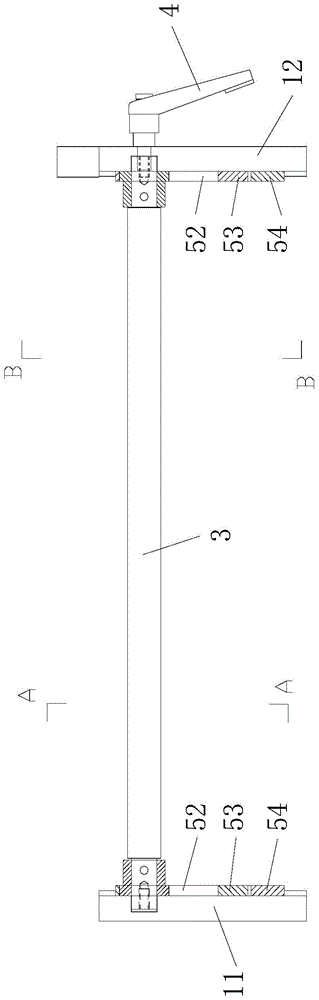

Double-pole multi-degree-of-freedom drilling rig

PendingCN109826563AAdjust the positioning accuratelyImprove drilling efficiencyDerricks/mastsDirectional drillingMulti degree of freedomDegrees of freedom

The invention discloses a double-pole multi-degree-of-freedom drilling rig. The rig comprises a seat assembly and a drilling assembly, the seat assembly is provided with the drilling assembly, and theseat assembly has more than two degree-of-freedom adjustment; the drilling assembly is composed of two sets of drills, the two sets of drills are installed side by side on the seat assembly to form adouble-pole structure, each set of drills include drilling rods, slide tables and deviation prevention assemblies, the deviation prevention assemblies include deviation prevention support seats and telescopic rods, the telescopic rods are symmetrically disposed on the two sides of the drilling rods to form combined bodies with the deviation prevention support seats, the tail ends and the front ends of the two telescopic rods are respectively fixedly arranged to prevent deviation when the drilling rods conduct drilling, and the telescopic rods are synchronously driven to gradually contract from back to front when the drilling rods move forward with the deviation prevention support seats as nodes; the degree-of-freedom adjustment of the seat assembly is used for controlling the two sets ofdrills to work together.

Owner:厦门森那美信昌机器工程有限公司

A roller adjusting device and method of using the same

ActiveCN104389972BGuaranteed parallelismAdjust the positioning accuratelyGearingGear driveEngineering

Owner:SHANGHAI LONGTENG TECH

Heavy duty adjustable swivel feet

InactiveCN104455955BPrecise positioningAdjust the positioning accuratelyMachine framesRolling resistanceBall bearing

An adjustable universal stand bar for heavy equipment is characterized by comprising a lower installation plate, a universal ball bearing, a lower adjusting screw, an intermediate plate, an upper adjusting screw and an equipment stand bar plate, the universal ball bearing is used for achieving supporting, the upper adjusting screw is used for adjusting height, the lower adjusting screw is used for adjusting the lower installation plate to serve as a final support, the universal ball bearing can move forwards, backwards, leftwards and rightwards, and due to the adoption of rolling friction, resistance is small, and micro-adjustment can be achieved; the upper adjusting screw enables rising and falling of the heavy equipment to be achieved directly, the lower adjusting screw can be adjusted to enable the lower installation plate to make contact with the ground, final positioning after adjustment is finished can be achieved, the universal ball bearing can be taken out after positioning, and cost is reduced. By the adoption of the adjustable universal stand bar for the heavy equipment, accurate adjustment and positioning of the heavy equipment during manufacturing and installation can be achieved.

Owner:GANZHOU NONFERROUS METALLURGICAL MACHINERY

A kind of medicine dispensing device and operation method

A medicine dispensing device and operation method, comprising a frame, a universal wheel, a central shaft, a No. 2 gear, a No. 2 spring, a medicine box, a cover, a magnet, a hinge, a half gear, a No. 1 gear, a gear lever, and a rack , Adjustment block, adjustment shaft, No. 1 spring, lever, the front part of the frame has 2 left and right columns, the middle of the 2 columns has 2 coaxial holes, and the upper part of the central hole has 2 coaxial holes The shaft hole of the medicine box on the right side has a locking ring coaxial with the shaft hole of the medicine box, the inner side of the left column has a rack chute, the rear side of the rack has a vertical plate, and the upper part of the vertical plate has an adjustment ring. Block chute, there are eleven scale lines on the front side of the rack, a label in the middle of the adjacent scale lines, an adjustment shaft hole on the upper part of the rack, a notch in the middle of the adjustment shaft hole, and 10 adjustment slots on the back side of the notch , and each adjustment slot corresponds to 1 label.

Owner:JIAMUSI UNIVERSITY

Solid carbide tool wear state detection fixture

ActiveCN105021525BEasy to operateAdjust the positioning accuratelyMaterial analysis by optical meansCarbideAlloy

A fixture for detecting the wear state of an integral hard alloy tool, including a tool fixing base, a mobile platform and a micro-adjustment device; On the rail, the micro-adjustment device is set on the mobile platform. Place the handle of the solid carbide tool in the positioning groove of the tool fixing base; adjust the horizontal position of the microscope by adjusting the vertical slide and horizontal slide of the mobile platform; move the micro adjustment device on the inner column of the mobile platform Adjust the height position of the microscope; adjust the angle of the microscope on the micro adjustment device. The fixture can comprehensively detect the wear state of the tool, and the operation is simple and fast, and the positioning can be adjusted accurately to find the most suitable detection position, achieve the best shooting effect, and improve the detection efficiency.

Owner:CHENGDU JIAODA PUER IND CO LTD

Adjusting and positioning device for front and rear inclination angle of scissors fixture in scissors grinding machine

ActiveCN102837233BImprove work efficiencyAdjust the positioning accuratelyOther manufacturing equipments/toolsCantilevered beamEngineering

The invention discloses a front-back inclined angle adjusting and positioning device of a scissor clamp in a scissor grinding machine, comprising a main rack and the scissor clamp, wherein a front-back inclined angle fine tuning mechanism capable of adjusting a front-back inclined angle of the scissor clamp is arranged between the main rack and the scissor clamp. The front-back inclined angle adjusting and positioning device is structurally characterized in that a cantilever beam is fixedly arranged at one side of the main rack; the other end of a connecting shaft fixedly arranged on the cantilever beam passes through a connecting plate to be arranged at the upper part of a cross-shaped connecting block; a spring bracket is fixedly arranged at the outer side of the lower part of the cross-shaped connecting block; the spring bracket is internally provided with a compressed spring; one end of the compressed spring is connected with the spring bracket and the other end of the compressed spring is connected with the positioning block; the positioning block is fixedly connected with the connecting plate; the positioning block and the connecting plate are fixed and the connecting plate and the cantilever beam are fixed; the cantilever beam is provided with a supporting plate; and an inclined angle fine tuning screw passes through the supporting plate to tightly press the top surface at the left end of the cross-shaped connecting block. The front-back inclined angle adjusting and positioning device disclosed by the invention has the advantages that the working efficiency is improved, and the front-back inclined angle of the scissor clamp can be accurately adjusted and positioned.

Owner:ZHANG JIA GANG CITY JIN CHENG SCISSORS FACTORY

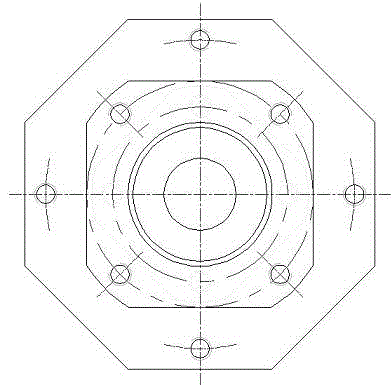

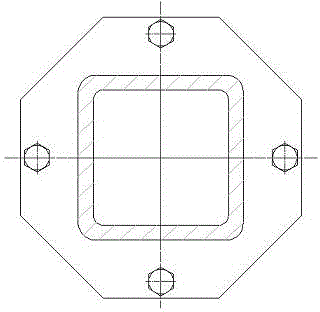

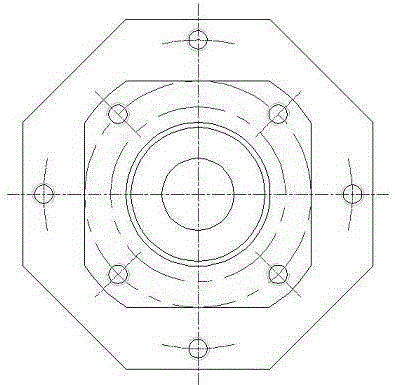

Abutting joint device of steel lattice column, and construction method of same

ActiveCN102493554BAdjust the positioning accuratelyMeet the design requirementsBuilding constructionsExcavationsSteel columnsSymmetric structure

The invention discloses an abutting joint device of a steel lattice column, which comprises the steel lattice column, wherein the steel lattice column is composed of four angle steel arm members and batten plates which are surrounded and welded around the four angle steel arm members at intervals; the upper end of the steel lattice column is connected with a movable joint; the upper end of the movable joint is connected with a locator; the movable joint is connected as a rigid main body by four section steel columns and steel surrounding members which are welded around the four section steel columns at intervals; the left side surface and the right side surface of the rigid main body are symmetrical structures; the movable joint is connected with the steel lattice column through an abutting joint screw rod; the locator is composed of a base plate, an adjusting frame support and an adjusting frame; the base plate is a cast-in-place reinforced concrete plate with middle holes; the adjusting frame support is a square-shaped hollow frame with four support legs; the hollow frame is internally filled with concretes; the adjusting frame is a square-shaped hollow frame obtained by welding steel plates and is arranged on the adjusting frame support; and the size of the adjusting frame is the same as that of the adjusting frame support. The abutting joint device of the steel lattice column, and the construction method of the same disclosed by the invention solve the problems in material waste and control of location and construction qualities if the steel lattice column is lengthened directly.

Owner:北京城建中南土木工程集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com