Turning holder with a convenient easy-adjustable movable loading plate

A technology of bearing plate and turnover frame, which is applied in the field of turnover frame, can solve the problems of inability to realize automatic control adjustment, low adjustment accuracy, low adjustment efficiency, etc., and achieve the effect of compact structure, wide power source and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

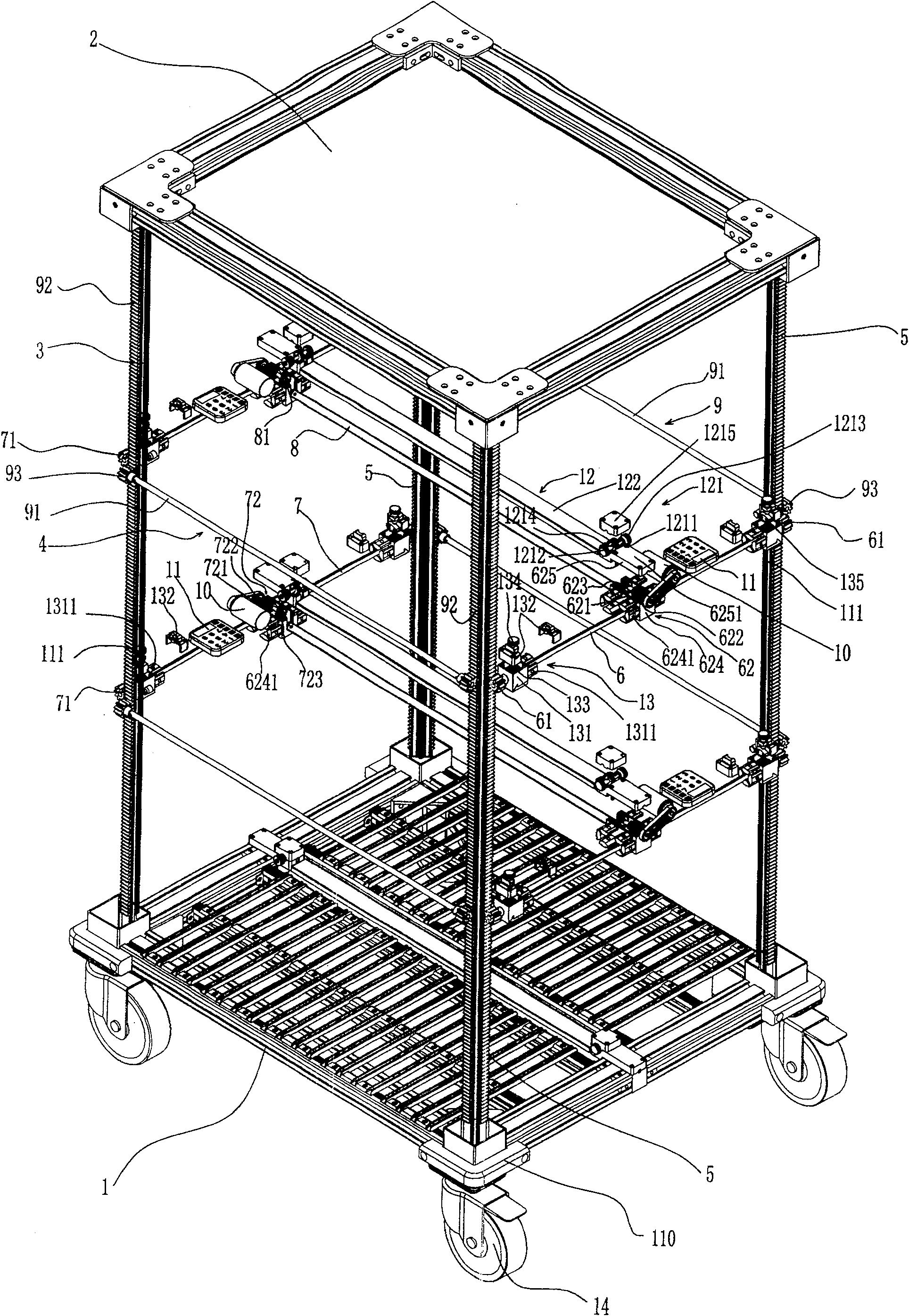

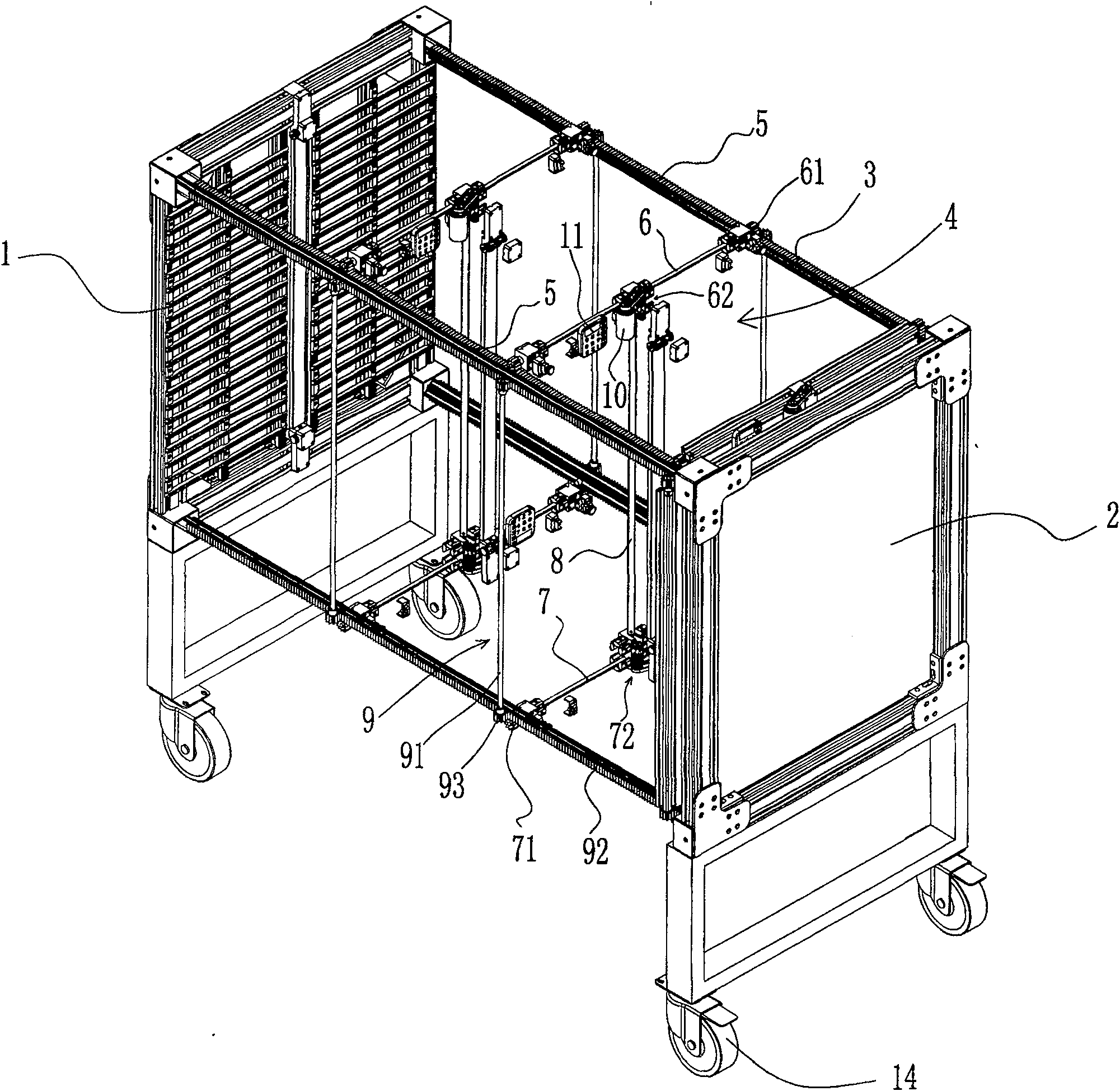

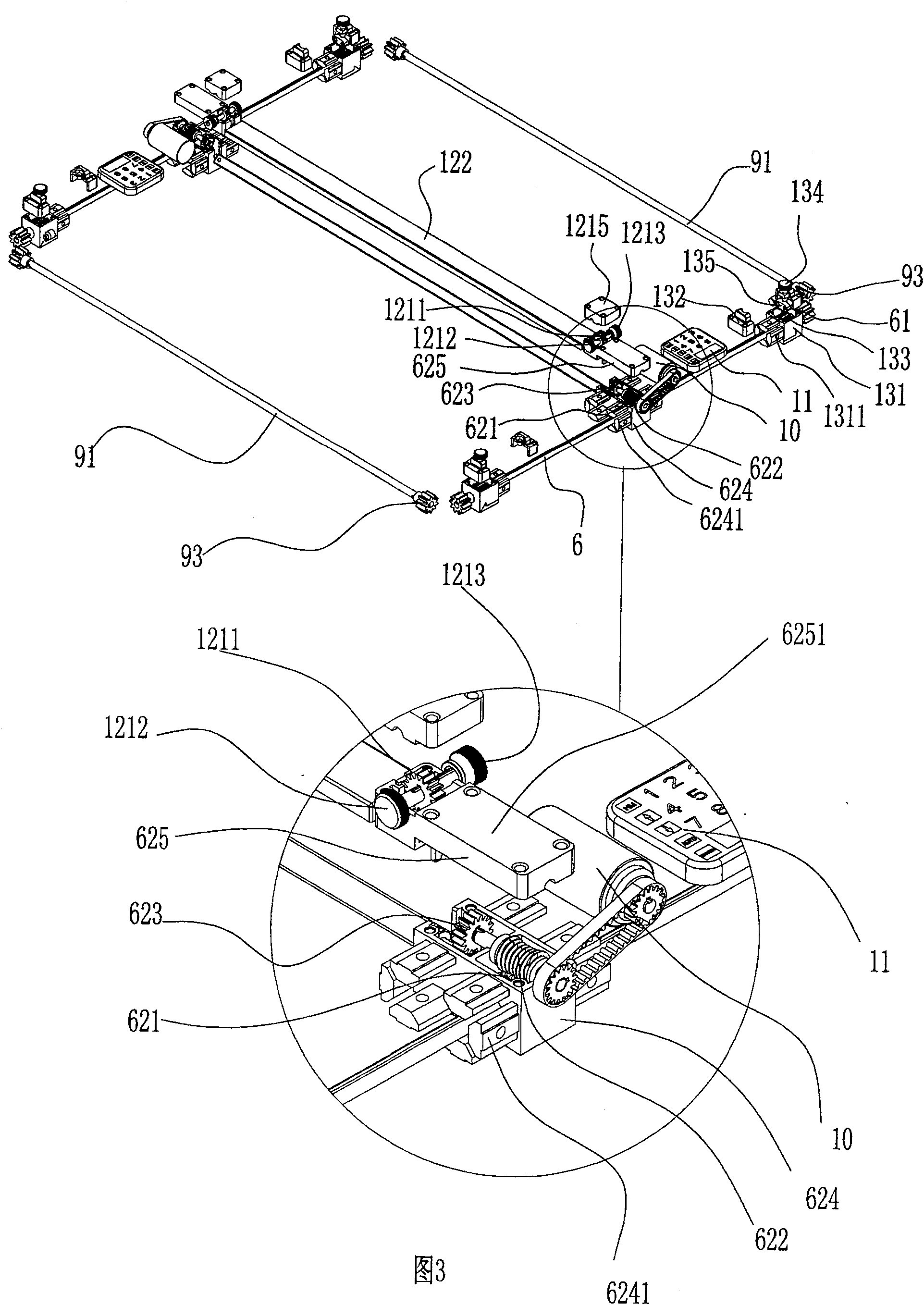

[0046] The present invention will be further described below in conjunction with accompanying drawing:

illustration:

[0047] 1. Lower panel;

[0048]11. Automatic control device; 111. Position sensor; 112. Scale; 113. Position indicating arrow;

[0049] 12, stop rod mechanism; 121, stop rod lifting mechanism; 1211, gear; 1212, knurled screw rod; 1213, positioning knurled nut 1214, movable rack; 1215, lifting mechanism cover; 122, stop rod;

[0050] 13. Safety lock mechanism; 131. Safety lock gear box; 1311. Plug; 1312. End face of safety lock gear box; 1313. Safety lock gear box hole; 132. Safety lock gear box cover; 133. Safety lock gear; 134. Safety Knurled screw rod; 135, tooth fork; 136, nut cover; 137, nut;

[0051] 14. Casters;

[0052] 2. Upper panel;

[0053] 3. Connecting piece; 30. Hand wheel;

[0054] 4. Movable bearing plate; 41. Laminate beam; 411. Hole; 412. End face; 413. Notch;

[0055] 42. Flat deck beams; 43. Corner connectors;

[0056] 5. Rack;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com