Unloading forming tool

A technology of tooling and unloading plate, which is applied in the field of stamping processing molds, can solve the problems of inaccurate adjustment and positioning of levers, tremors at the end of stamping speed levers, etc., and achieve the effect of stable rotation and not easy to lose balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

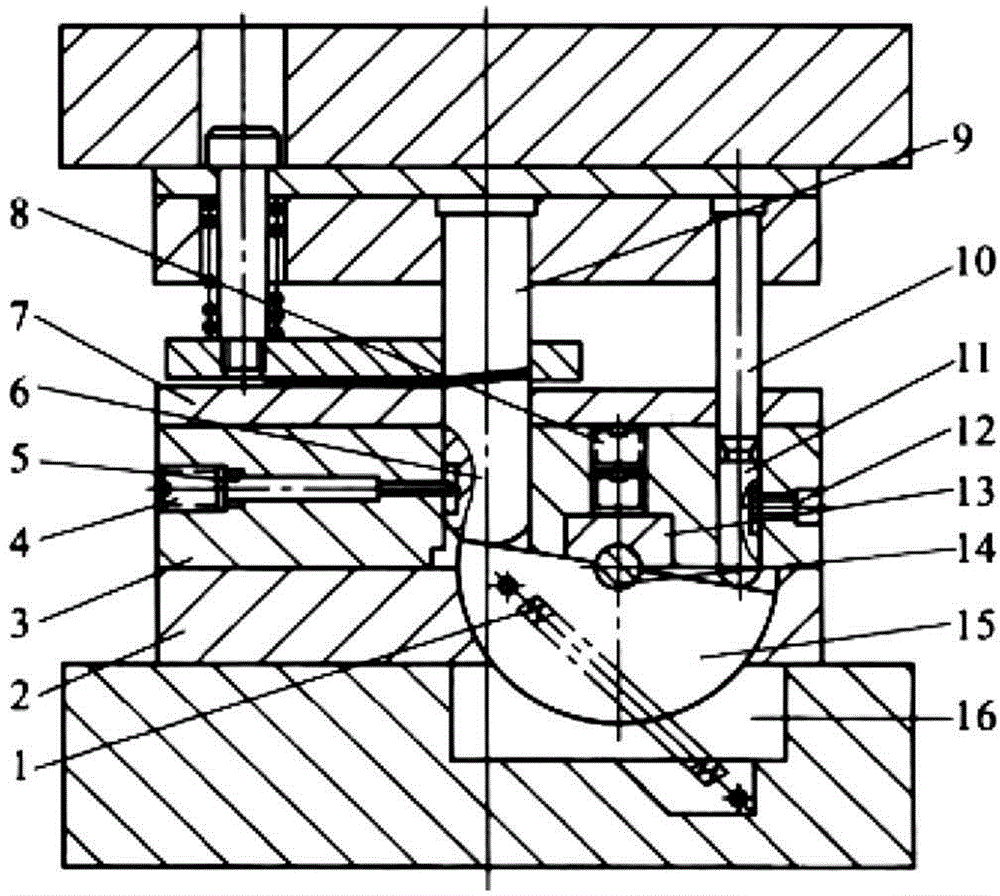

[0018] The reference signs in the drawings of the description include: punch 9, push rod 10, lower die 3, jacking screw 12, locking bolt 5, plug 4, second unloading plate 7, cushion block 8, cushion groove 13, Backing plate 2, extension spring 1, support seat 16, rotating semicircle 15, punch lower end 6, top pressure rod lower end 11, mandrel 14.

[0019] Such as figure 1 As shown, the unloading forming tooling of the present invention comprises an upper mold frame, an upper mold, a lower mold frame, a lower mold and a stripping plate that is respectively arranged on the upper and lower model surfaces, wherein the stripping plate that is located on the upper mold is The first stripping plate, the stripping plate arranged on the lower mold is the second stripping plate. A spring element is arranged between the first unloading plate and the upper mold frame, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com