Hoisting tower crane with double hoisting ends

A lifting tower and load-bearing block technology is applied in the directions of cranes, load hanging components, transportation and packaging, etc., which can solve the problem of difficult removal of black scale and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

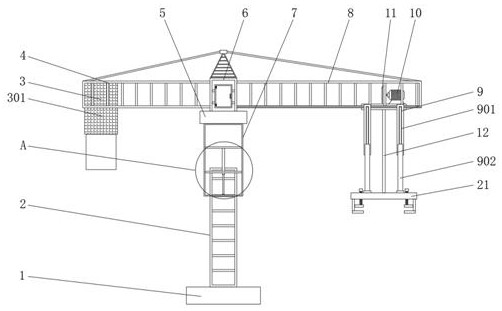

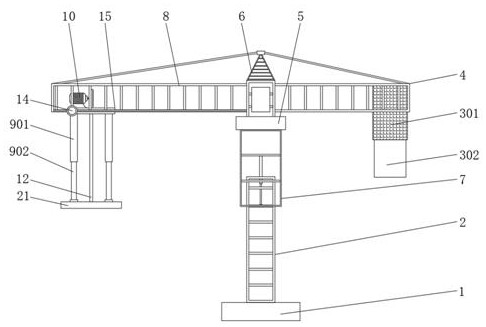

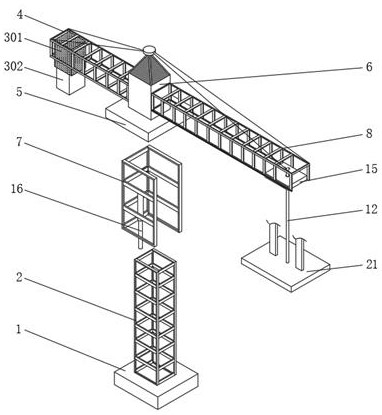

like Figure 1-8 As shown, the embodiment of the present invention provides a double-end lifting tower crane, including a base 1, a first frame body 2 is fixedly connected to the upper surface of the base 1, and a top sleeve 7 is provided on the upper surface of the first frame body 2, and the top sleeve 7 A hydraulic cylinder 16 is fixedly connected to the inside of the hydraulic cylinder 16, and the output end of the hydraulic cylinder 16 is fixedly connected to the first frame body 2, and the top sleeve 7 can be pushed up and down by the expansion and contraction of the hydraulic cylinder 16, so that the second frame body 4 and the third frame body 4 can be moved up and down. The height of the frame body 8 is adjusted, and the upper surface of the top sleeve 7 is fixedly connected with the turning plate 5, and the fixed frame 6 can drive the second frame body 4 and the third frame body 8 to rotate by controlling the turning plate 5 from the outside. A fixing frame 6 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com