Centrifugal pendulum device and torsional vibration damper comprising such a centrifugal pendulum device

A technology of centrifugal pendulum and support device, applied in spring/shock absorber, rotational vibration suppression, vibration suppression adjustment, etc., can solve the problems of reducing the weight of rotation or torsional vibration, weight of pendulum weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

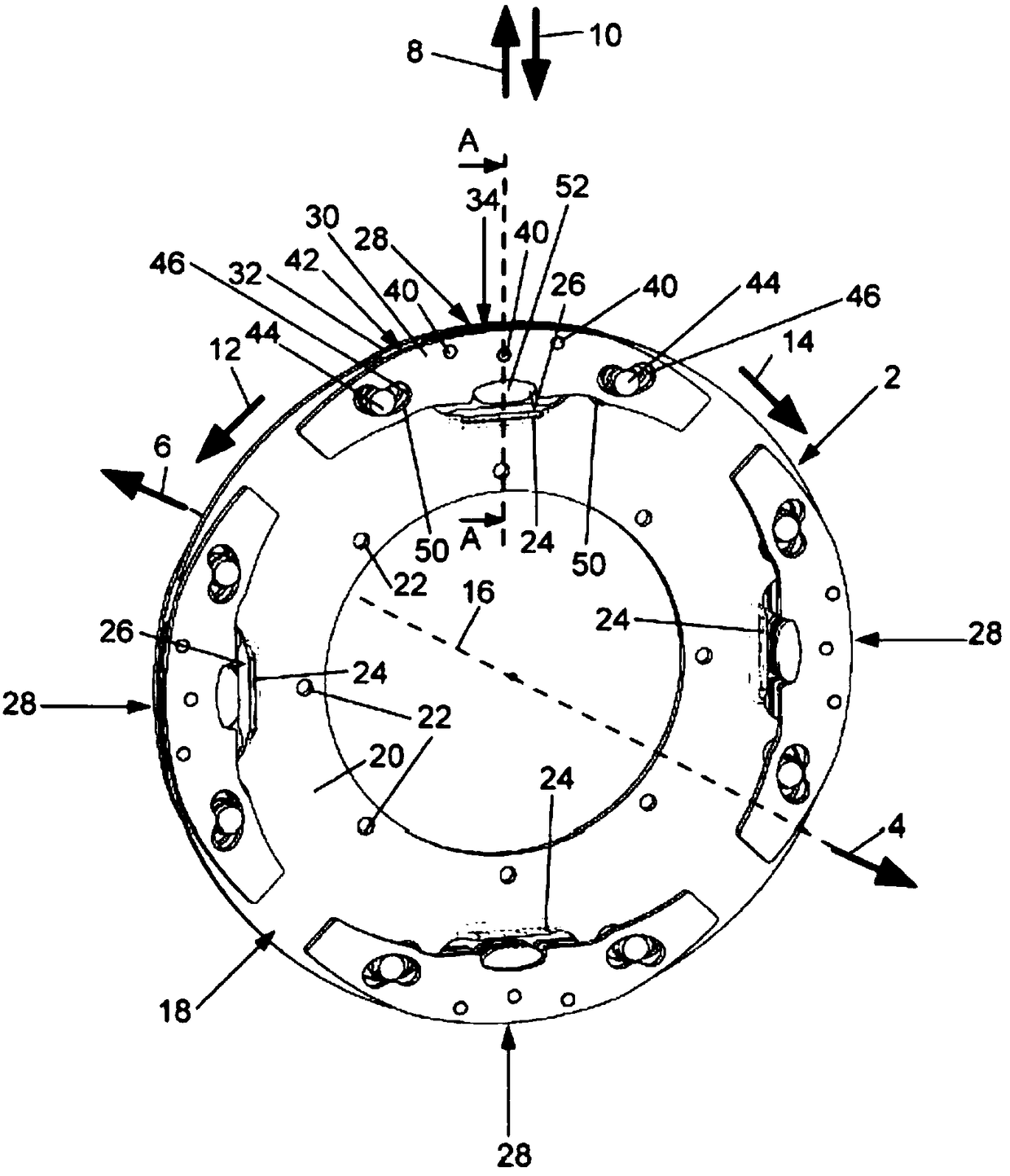

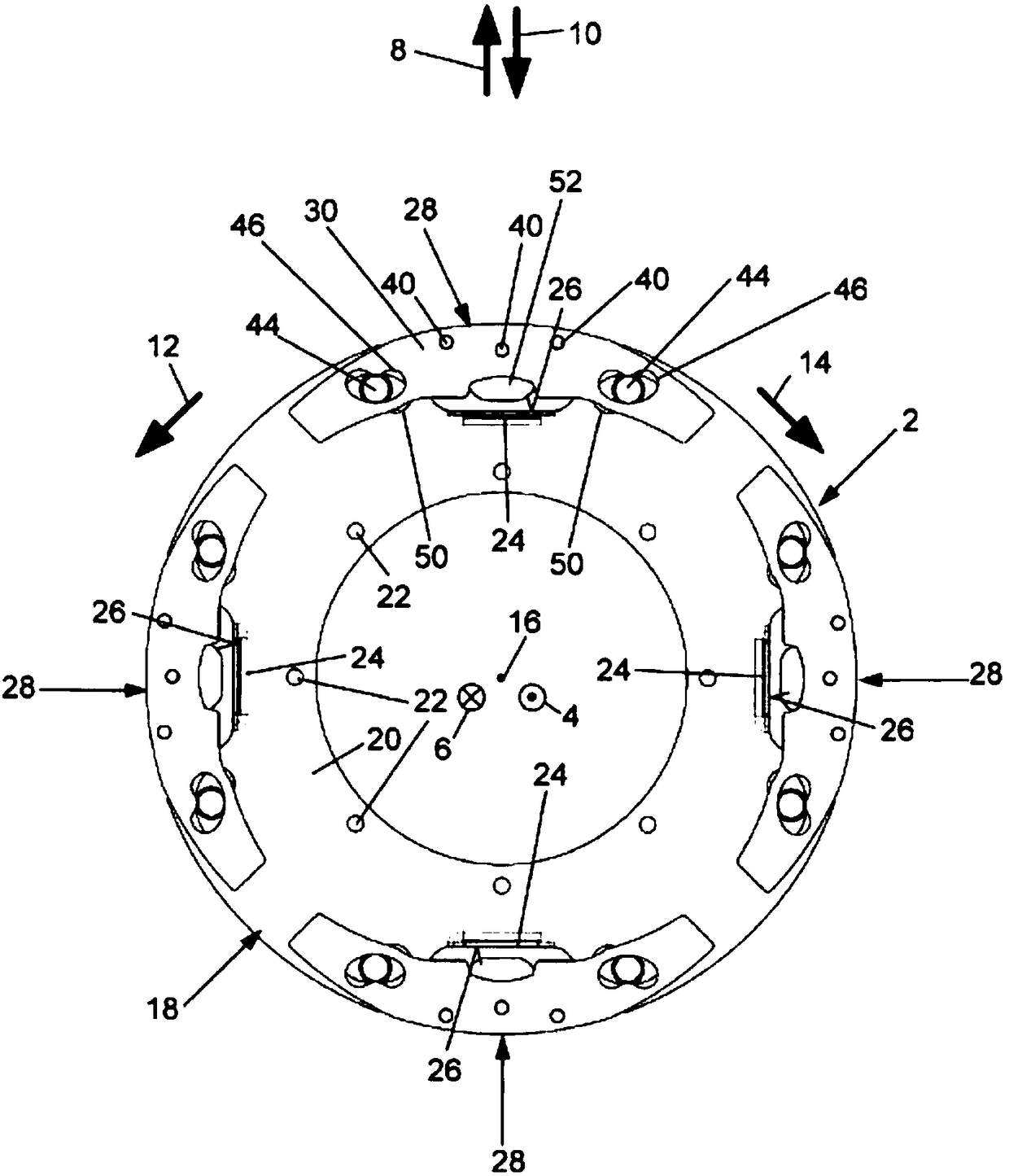

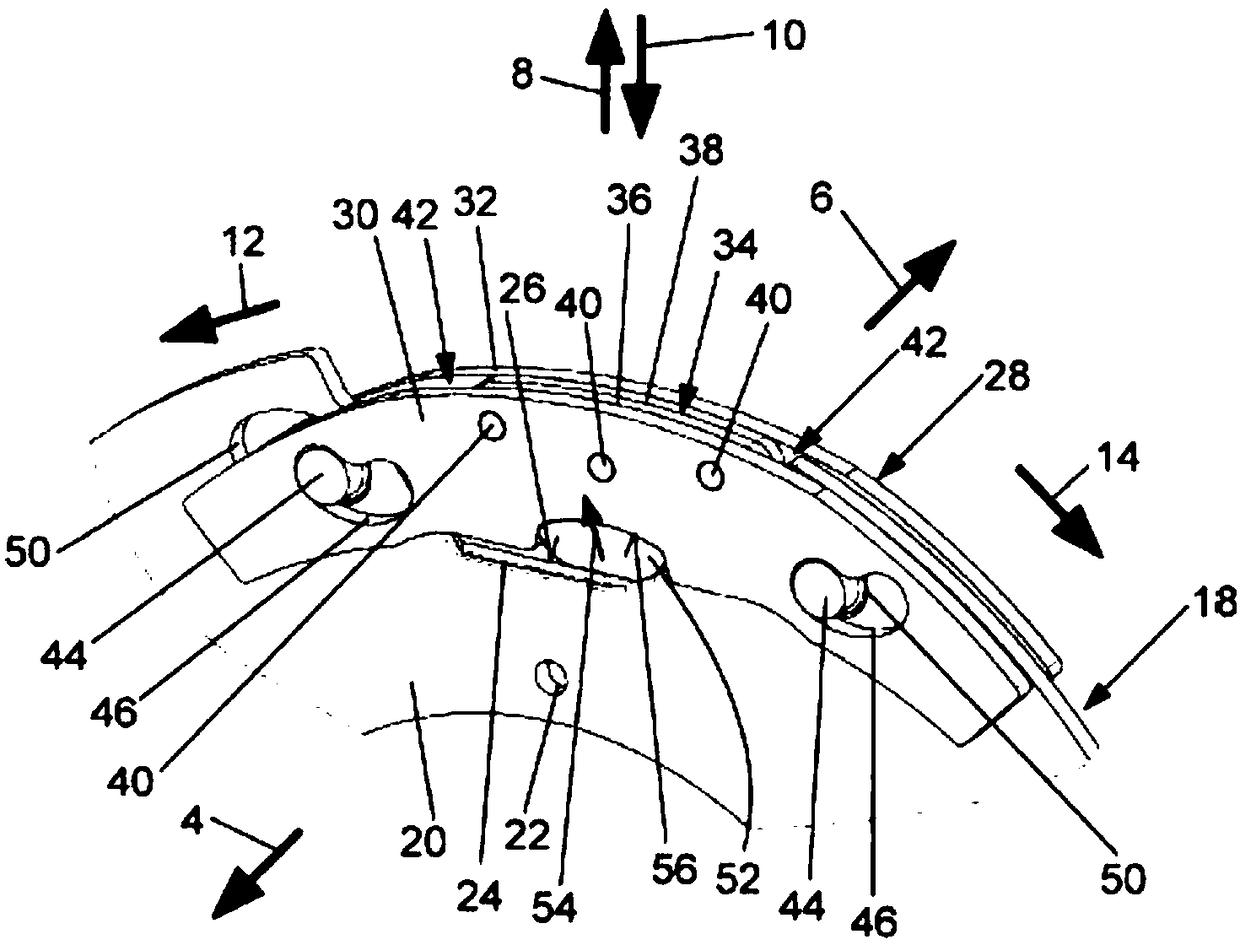

[0037] figure 1 and 2 A centrifugal pendulum device 2 for a drive train of a motor vehicle is shown. In the drawings, the mutually opposite axial directions 4, 6 of the centrifugal pendulum device 2, the mutually opposite radial directions 8, 10 and the mutually opposite circumferential directions 12, 14 of the centrifugal pendulum device 2 are shown according to corresponding arrows, for which the centrifugal pendulum device 2 Alternatively, the pendulum carriage, which will be described in detail below, rotates about a rotational axis 16 extending in the axial direction 4 , 6 .

[0038] The centrifugal pendulum device 2 has a pendulum carriage 18 rotatable about an axis of rotation 16 . The pendulum carriage 1 extends around its periphery in the circumferential direction 12, 14 and is plate-like or disk-shaped, more precisely ring-shaped. Inner extension. The pendulum bracket 18 essentially consists of a load-bearing section 20, on which there are fixed openings 22 distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com