Solid carbide tool wear state detection fixture

A technology of solid carbide and tool wear, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of low efficiency, cumbersome operation, large errors in measuring shooting angles and distances, etc., and achieves overcoming cumbersome operations and simple and fast operations , the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

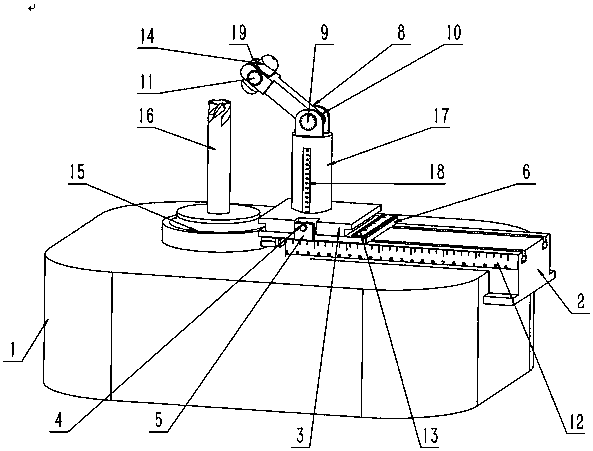

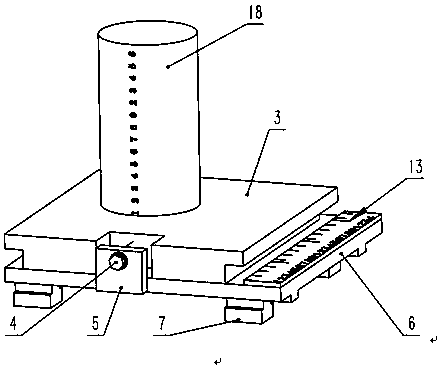

[0023] Such as figure 1 As shown, the jig for detecting the wear state of a solid carbide tool of the present invention includes a tool fixing base 1, a moving platform and a micro-adjustment device.

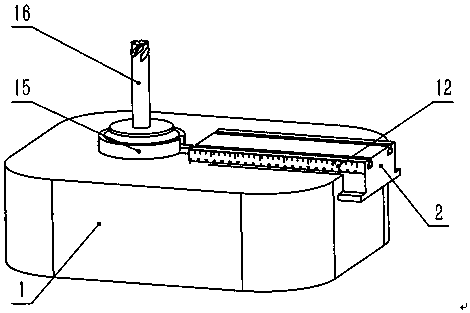

[0024] The structure of cutter fixed base 1 is referring to figure 2 , which is provided with a cutter positioning groove 15 and a slide rail fixing groove. The positioning groove 15 can play the role of fixing the solid carbide tool 16. When it is necessary to detect the wear state of the tool in the process of numerical control machining, the solid carbide tool 16 is removed together with the handle, and the handle is directly placed in the positioning position. In the groove 15, the cutter is positioned and placed by the fixed boss thereon. A horizontal slide rail 2 is installed in the slide rail fixing groove, and a horizontal scale 12 is arranged on the horizontal slide rail 2 . Mobile platform is installed on the horizontal slide rail 2. The horizontal ruler 12 can re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com