Hydraulic distance adjusting fork for forklift truck

A technology of distance adjustment and forklift, which is applied to the field of forklift distance adjustment forks, can solve the problems of poor distance adjustment accuracy of external chain plate type transmission, reduced fork service life, large wear of connecting parts, etc., so as to increase the load capacity and enhance the stability. , the effect of low friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

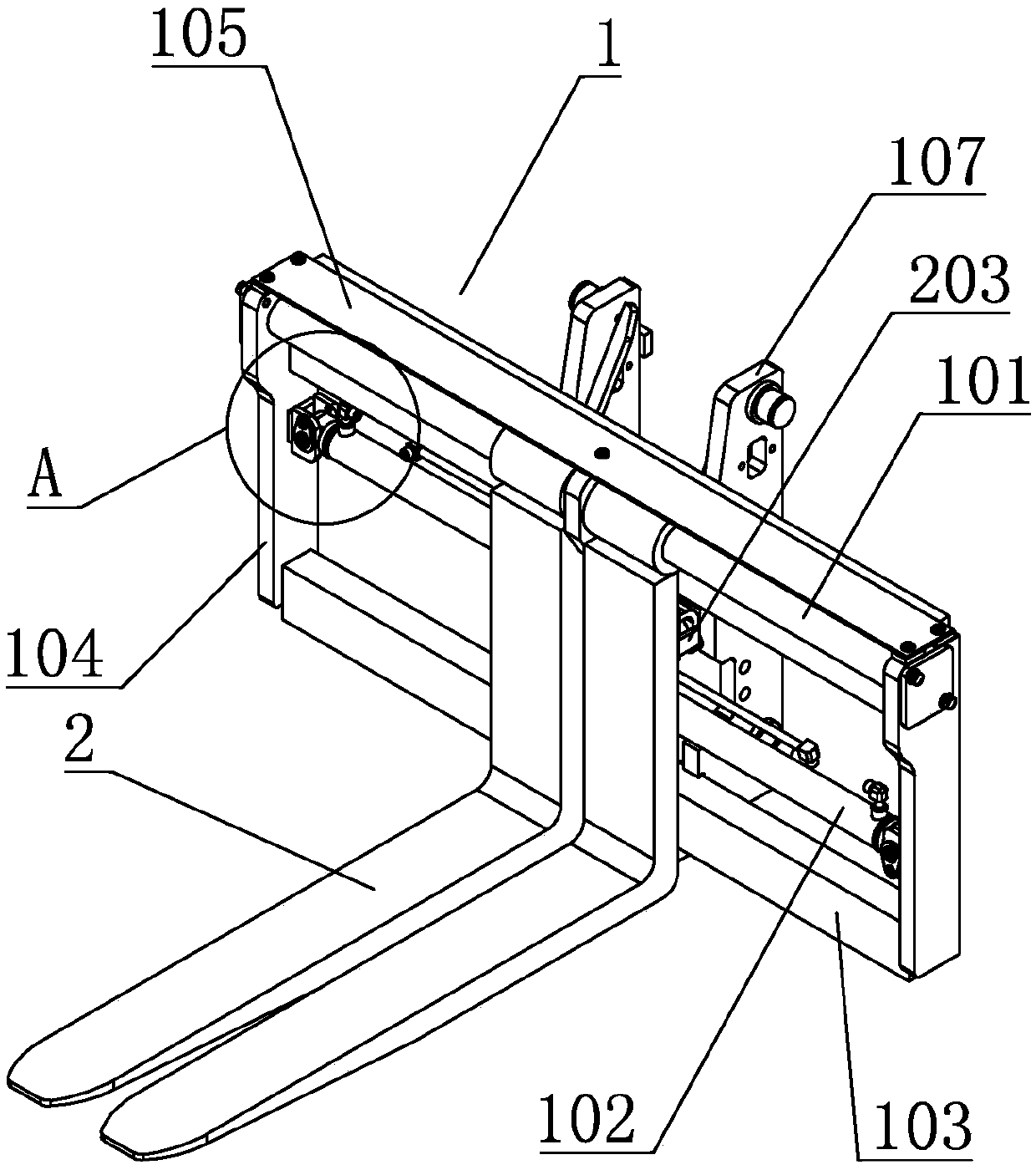

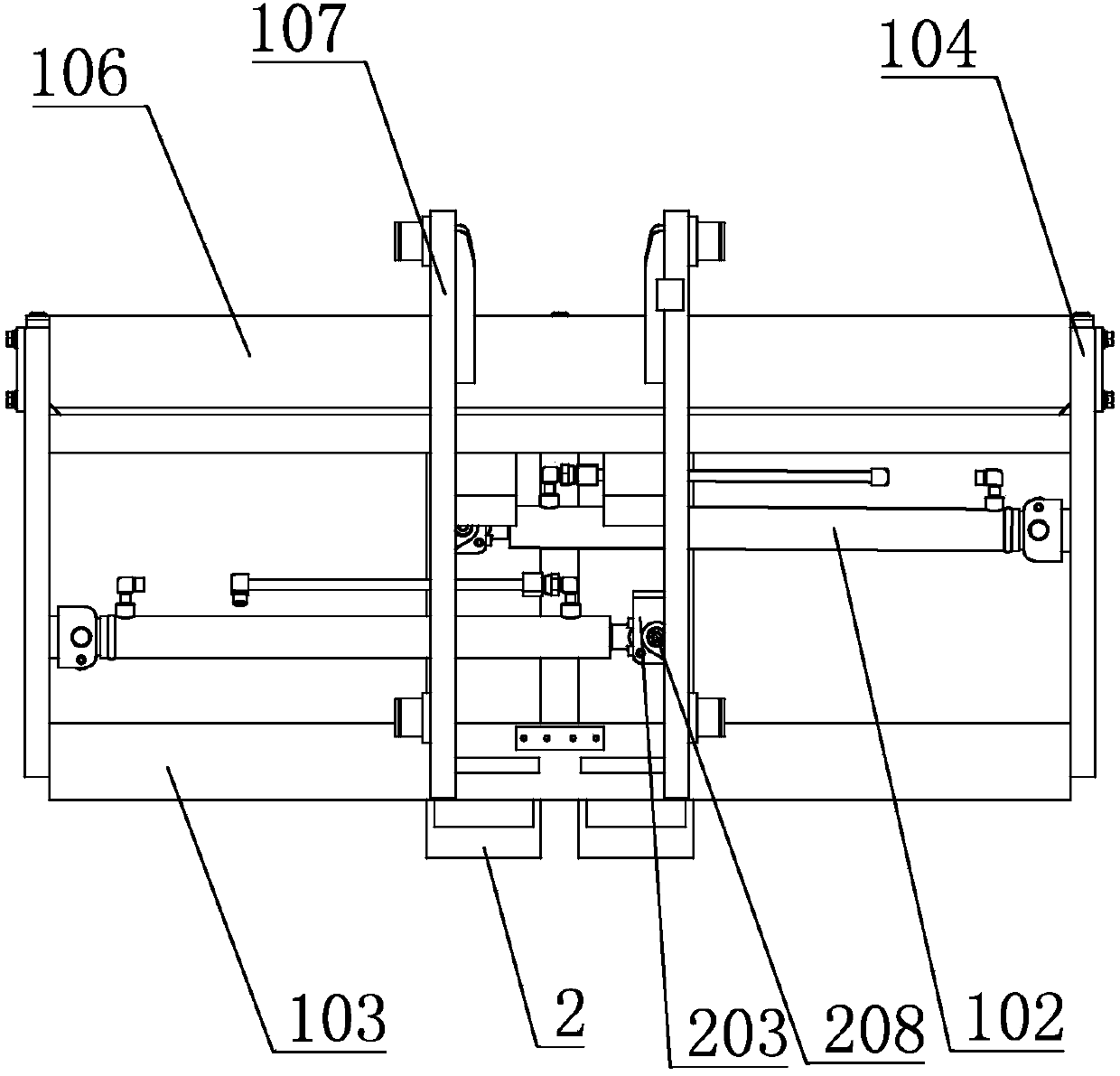

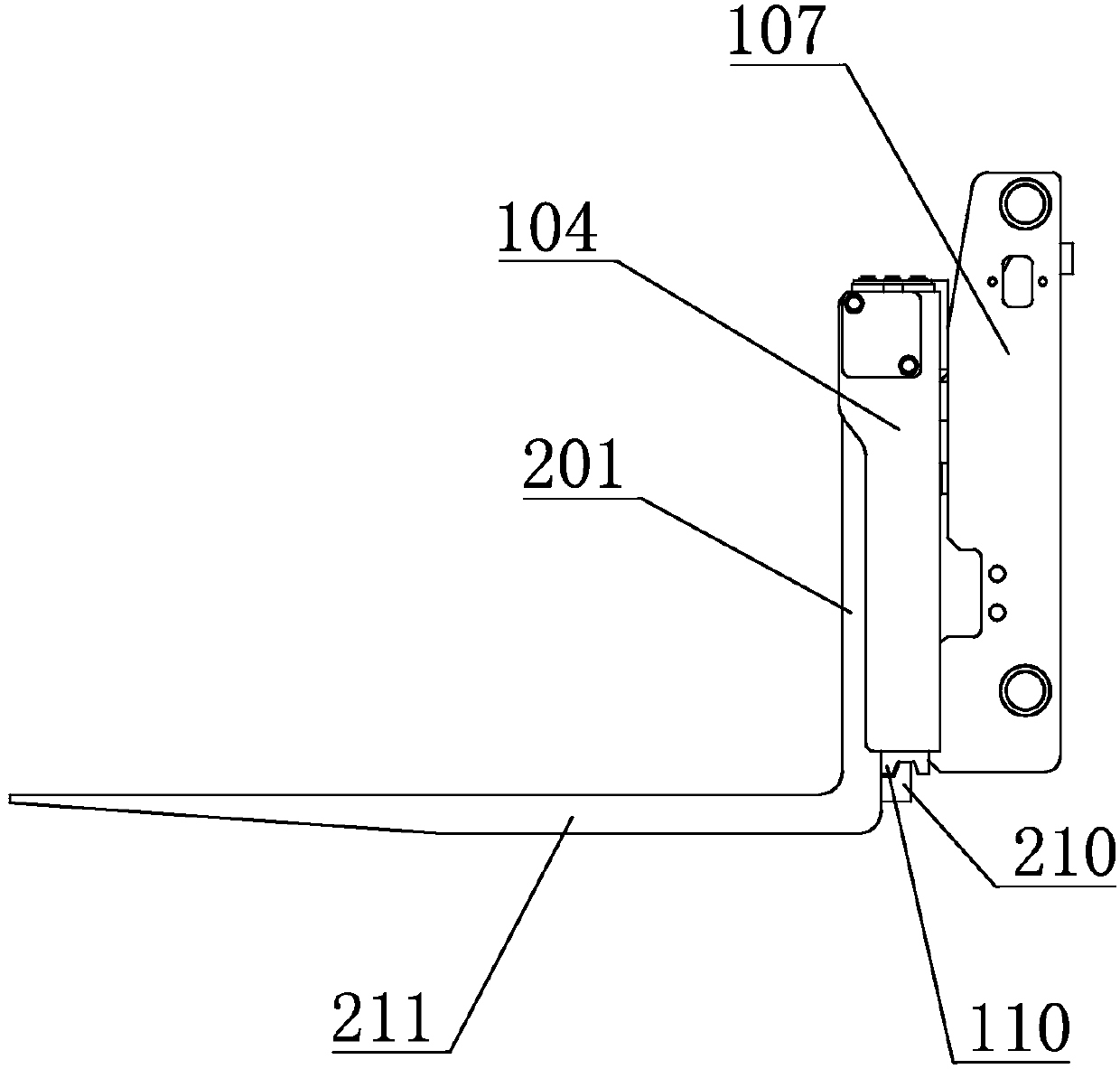

[0021] Reference Figure 1 to Figure 6 , A forklift hydraulic adjustable pitch fork, comprising a pitch adjustable frame 1 mounted on the front lifting frame of the forklift and two L-shaped forks 2 that can adjust the opening and closing distance on the adjustable frame 1. The adjustment The distance frame 1 is provided with a horizontally arranged guide rod 101, the top of the vertical part 201 of the fork 2 is fixed with a cylindrical guide sleeve 202 that is adapted to the guide rod 101, and the inner ring of the guide sleeve 202 and the guide rod 101 are coated with lubrication The vertical part 201 is provided with an upper hook 203 and a lower card slot 204 on the upper and lower sides of the vertical part 201. Both sides of the pitch adjusting frame 1 are equipped with horizontally opposed pitch adjusting cylinders 102, and the lower side is provided with a horizontal sliding rod 103. The end of the output rod from the cylinder 102 is hinged on the two upper hooks 203 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com