Fine-adjustment coining mechanism

A technology of embossing mechanism and pressing rod, which is applied in the field of stamping processing molds, and can solve problems such as tremors at the end of the stamping speed lever, inaccurate adjustment and positioning of the lever, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

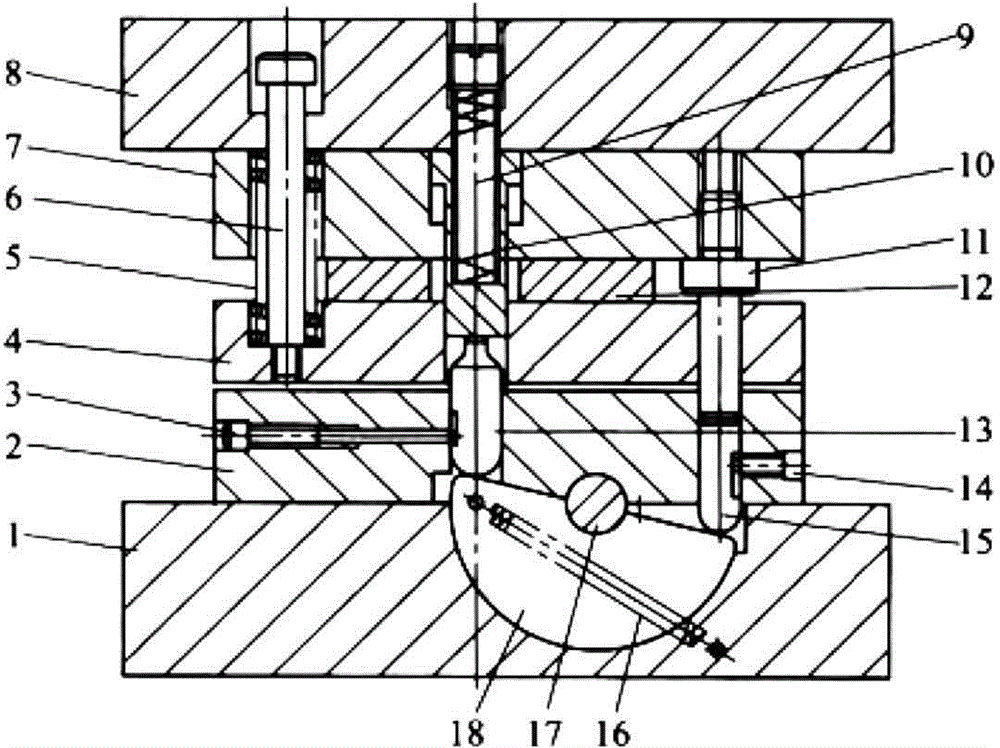

[0020] The reference signs in the drawings of the description include: connecting rod 9, compression spring 10, limit ring 11, elastic body 12, pressing rod 15, jacking wire 14, flanging punch 13, extension spring 16, mandrel 17, Rotate semicircle 18, lower die holder 1, lower die holder 2, bolt 3, stripper plate 4, upper extension spring 5, guide bar 6, upper die 7, upper die holder 8.

[0021] Such as figure 1 As shown, the fine-tuning embossing mechanism of the present invention includes an upper mold frame 8, an upper mold 7, a lower mold frame 1, a lower mold 2, and a discharge plate 4 arranged on the mold surface of the upper mold 7, and also includes sequentially connecting push rods 15. Rotate the semicircle 18 and the flanging punch 13. A guide rod 6 is provided between the upper die frame 8 and the stripper plate 4, the upper end of the guide rod 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com