Online automatic cleaning device of belt conveyor idler

A belt conveyor, automatic cleaning technology, applied in the direction of cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of material conveying line changes, idler rollers not fitting well, affecting the service life of the belt, etc., to avoid The effect of chipping, reducing the possibility of entering production raw materials, saving costs and human resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

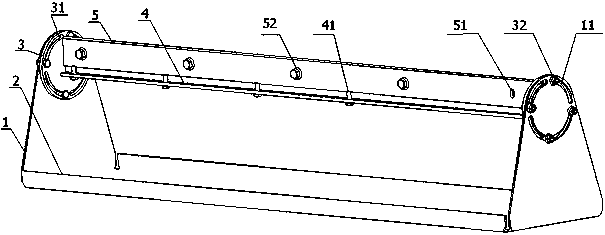

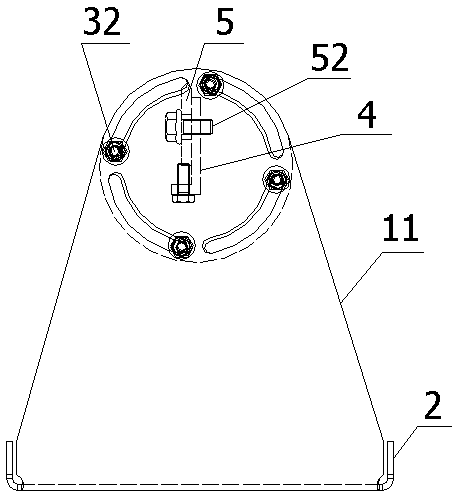

[0024] The invention provides an online automatic cleaning device for belt conveyor rollers, such as figure 1 and figure 2 shown.

[0025] The online automatic cleaning device for the idler roller of the belt conveyor includes a scraper 5 and a scraper adjustment bracket 4 for installing the scraper 5, and also includes a scraper base 3 arranged on both sides of the scraper adjustment bracket 4, and a corresponding set for installing the scraper. The fixed bracket 1 of the base 3, the two side walls of the scraper adjustment bracket 4 are fixed to the scraper base 3; the scraper base 3 is provided with a plurality of arc-shaped holes 31 along the circumference, and the fixed bracket 1 corresponds to the arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com