Method and device for detecting efficiency parameters of hydraulic system and engineering machinery having the device

A hydraulic system and efficiency technology, applied in the field of testing hydraulic system efficiency parameters, can solve the problems of inability to accurately control the hydraulic system flow, impair the quality of fine operation, and it is difficult for the control device to achieve the intended purpose, so as to increase the total flow of hydraulic oil. Cardinality, the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

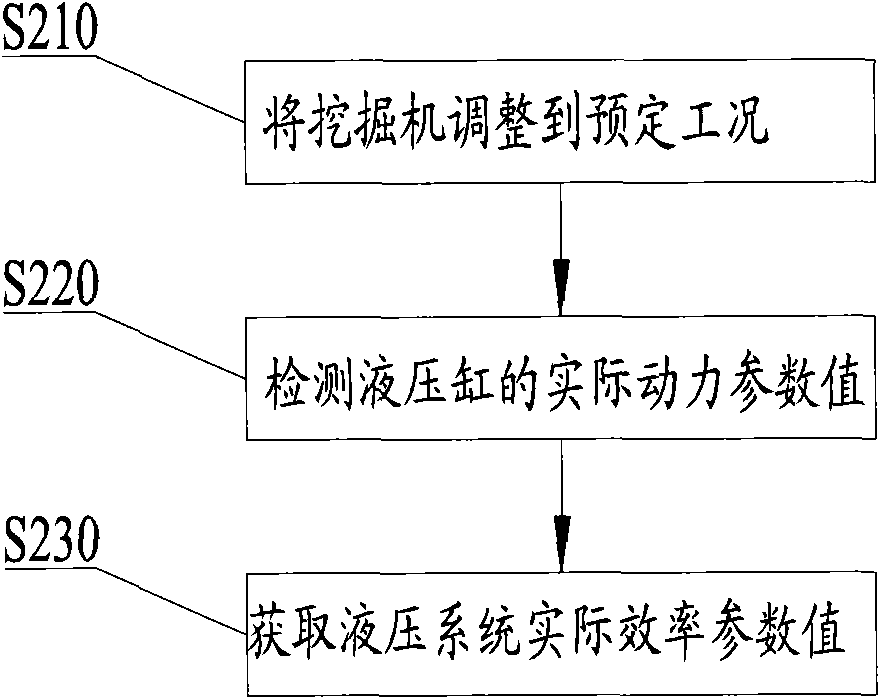

[0052] The method for detecting the efficiency parameters of the hydraulic system provided by Embodiment 1 includes the following steps:

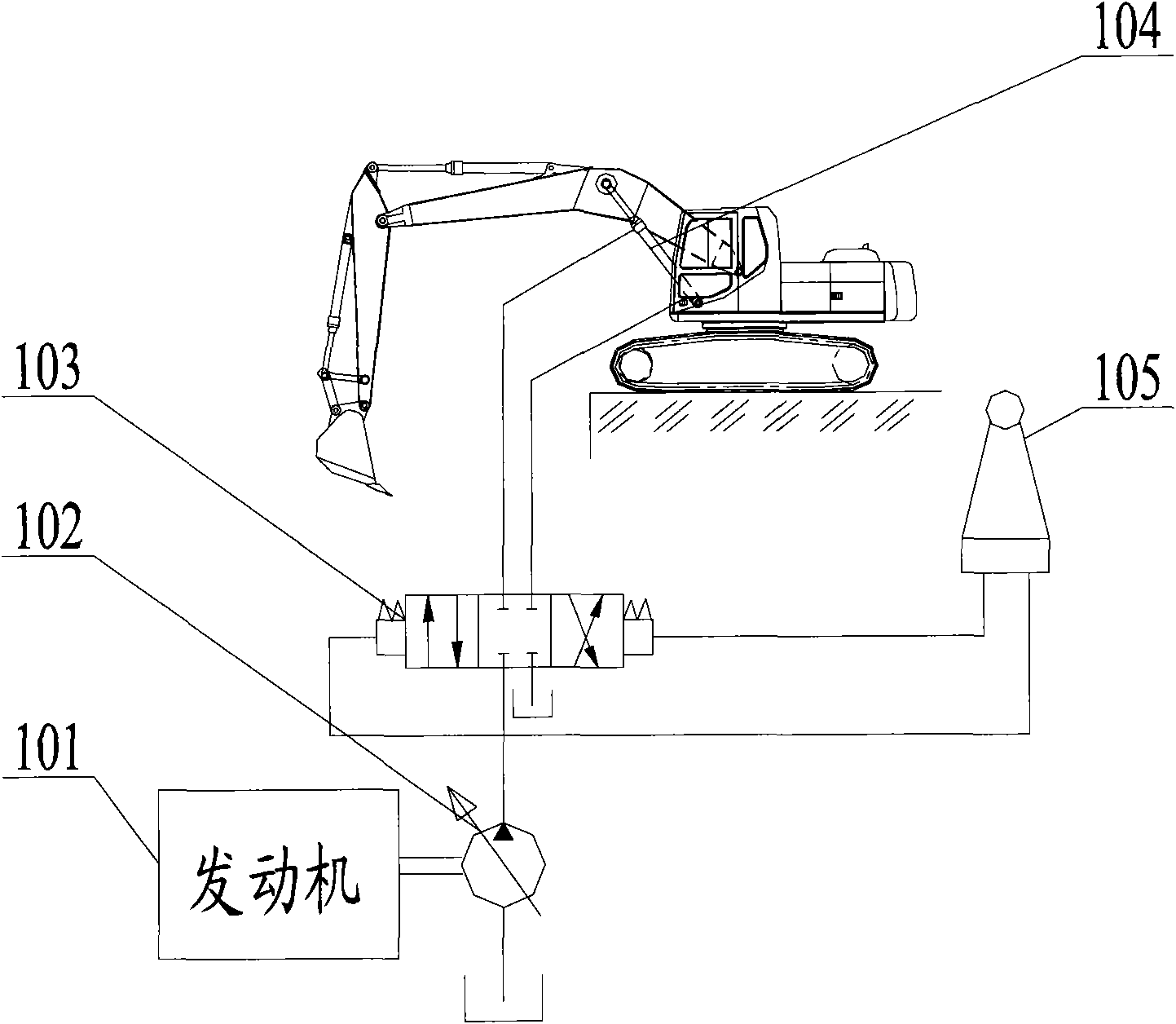

[0053] S210, adjusting the hydraulic system of the excavator to a predetermined working condition, including adjusting the rotational speed of the engine 101 to the rated rotational speed of the hydraulic pump 102, adjusting the displacement of the hydraulic pump 102 to the maximum displacement, keeping the external load of the excavator, and setting the hydraulic cylinder 104 Adjust to the shortest position.

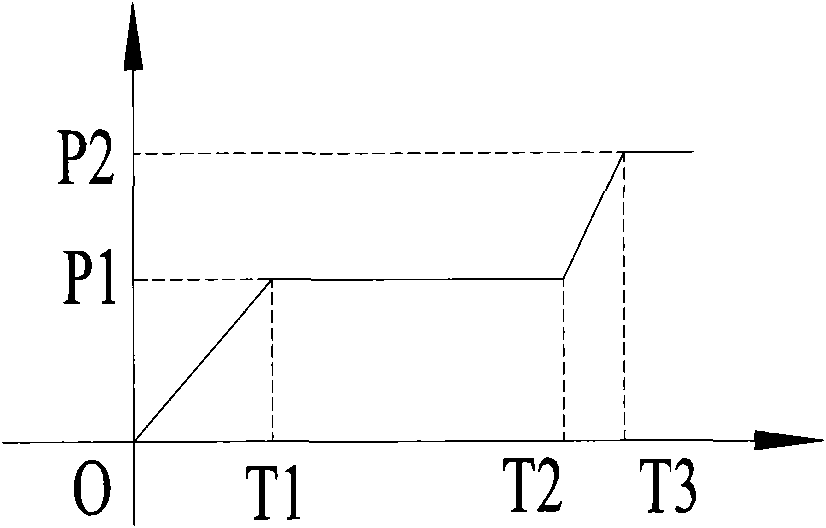

[0054] S220, make the hydraulic cylinder 104 extend at the fastest speed through the control device 105, detect the elongation time required for the hydraulic cylinder 104 to extend from the shortest position to the longest position, and use the elongation time as an actual power parameter value.

[0055] S230. Determine an actual efficiency parameter value of the hydraulic system according to the actual power parameter value and a p...

Embodiment 3

[0070] The device for detecting the efficiency parameters of the hydraulic system provided by Embodiment 3 also includes a sensor 601 and a controller 602. For the convenience of description, a hydraulic actuator 603 is also shown; the controller 602 stores predetermined power parameter values and predetermined efficiency parameters value, the predetermined power parameter value is the power parameter value output by the hydraulic actuator of the hydraulic system under the predetermined use state and predetermined working condition; the predetermined hydraulic system efficiency parameter value is the hydraulic system in the predetermined Efficiency parameter values for the state of use and predetermined operating conditions.

[0071] Under the predetermined working condition, the sensor 601 can transmit a power signal to the controller 602 according to the action of the hydraulic actuator 603, and the controller 602 can detect the actual power parameter value output by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com