X-Y micro-adjustment apparatus for optical element in lithographic projection objective

A technology of lithography projection and adjustment device, which is applied in the direction of optical components, microlithography exposure equipment, photolithography exposure device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

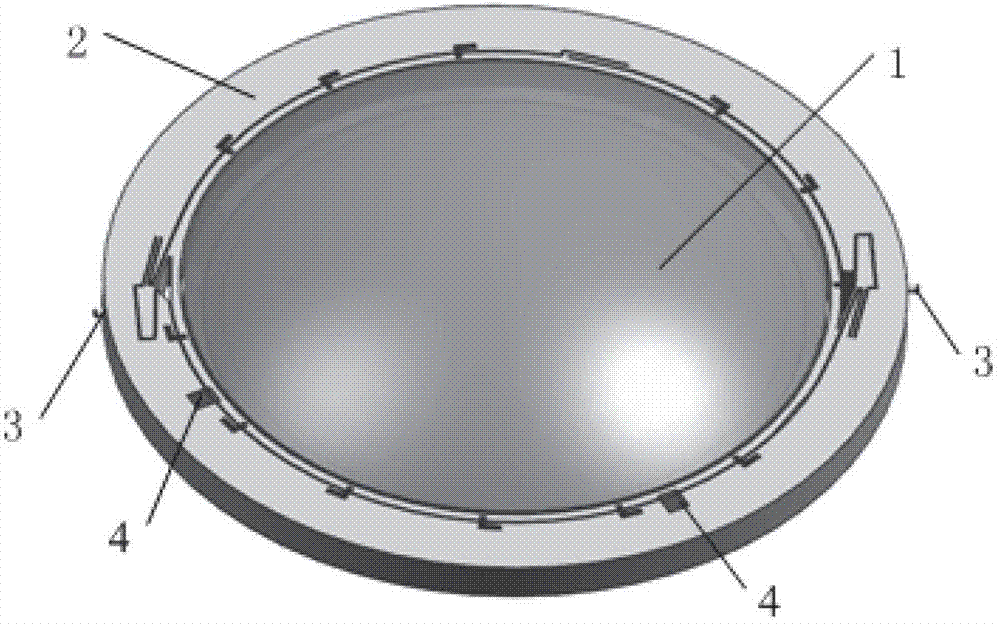

[0019] like Figure 1 to Figure 5 As shown, the optical element X-Y micro-adjustment device in the lithography projection objective lens includes a mirror frame 2, two drivers 3 and two capacitive sensors 4; the optical element 1 and the mirror frame 2 are connected by gluing, and the two drivers 3 and two capacitive sensors 4 are fixed on the mirror frame 2 respectively.

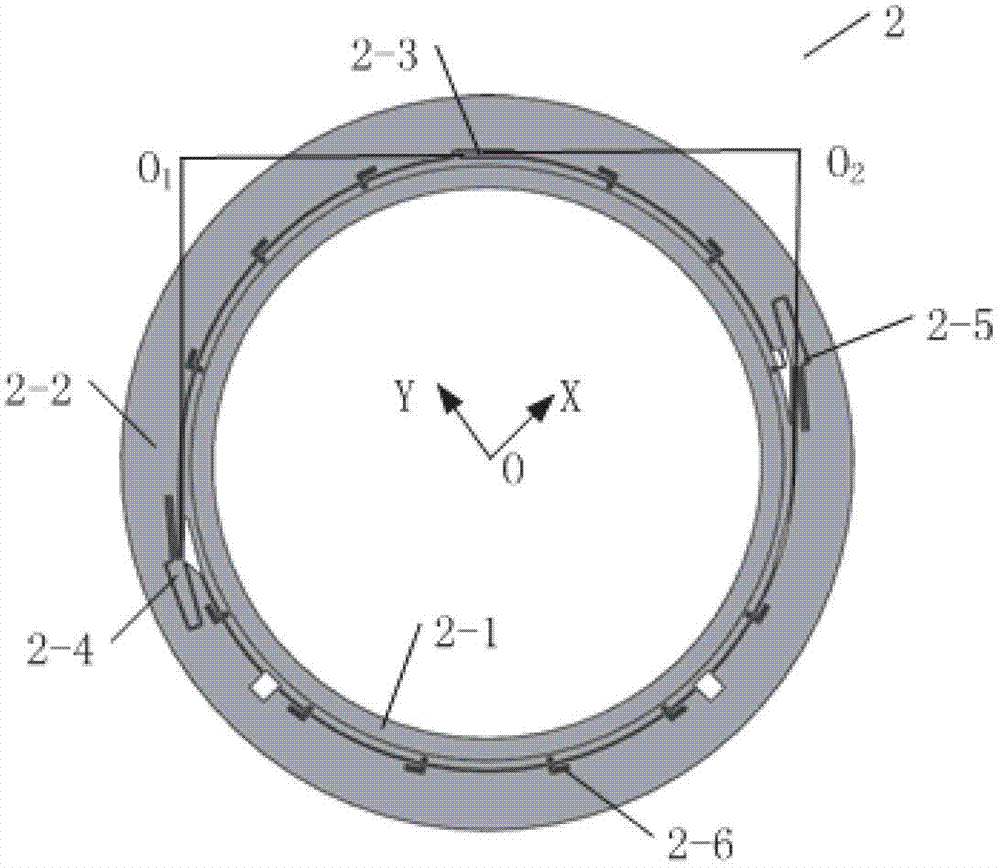

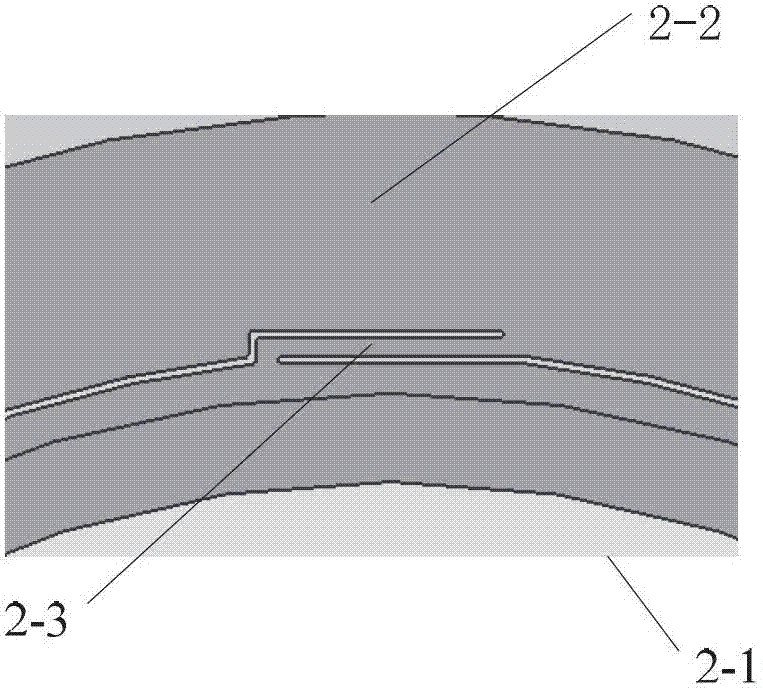

[0020] The picture frame 2 is an integrated structure composed of a picture frame inner ring 2-1, a picture frame outer ring 2-2, a straight elastic piece 2-3, a folding elastic piece 2-4, a folding elastic piece 2-5 and a plurality of auxiliary supporting elastic pieces 2-6. Processed by slow wire cutting or electrochemical corrosion. The inner ring 2-1 of the picture frame and the outer ring 2-2 of the picture frame are connected by a straight elastic piece 2-3, a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com