Sleeve valve with adjustable longitudinal flow

A vertical flow and adjustable technology, applied in the field of valves, can solve the problems of not meeting the vertical fluid flow direction, large leakage, inconvenient control of upper and lower water levels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

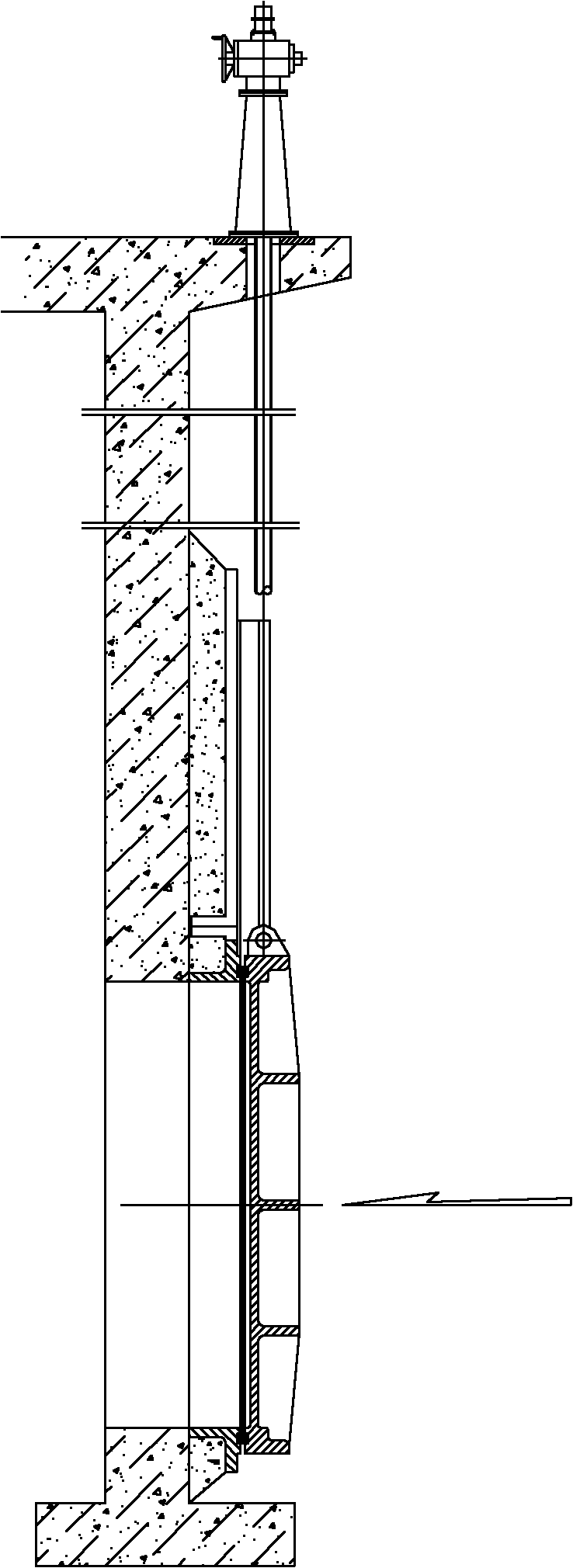

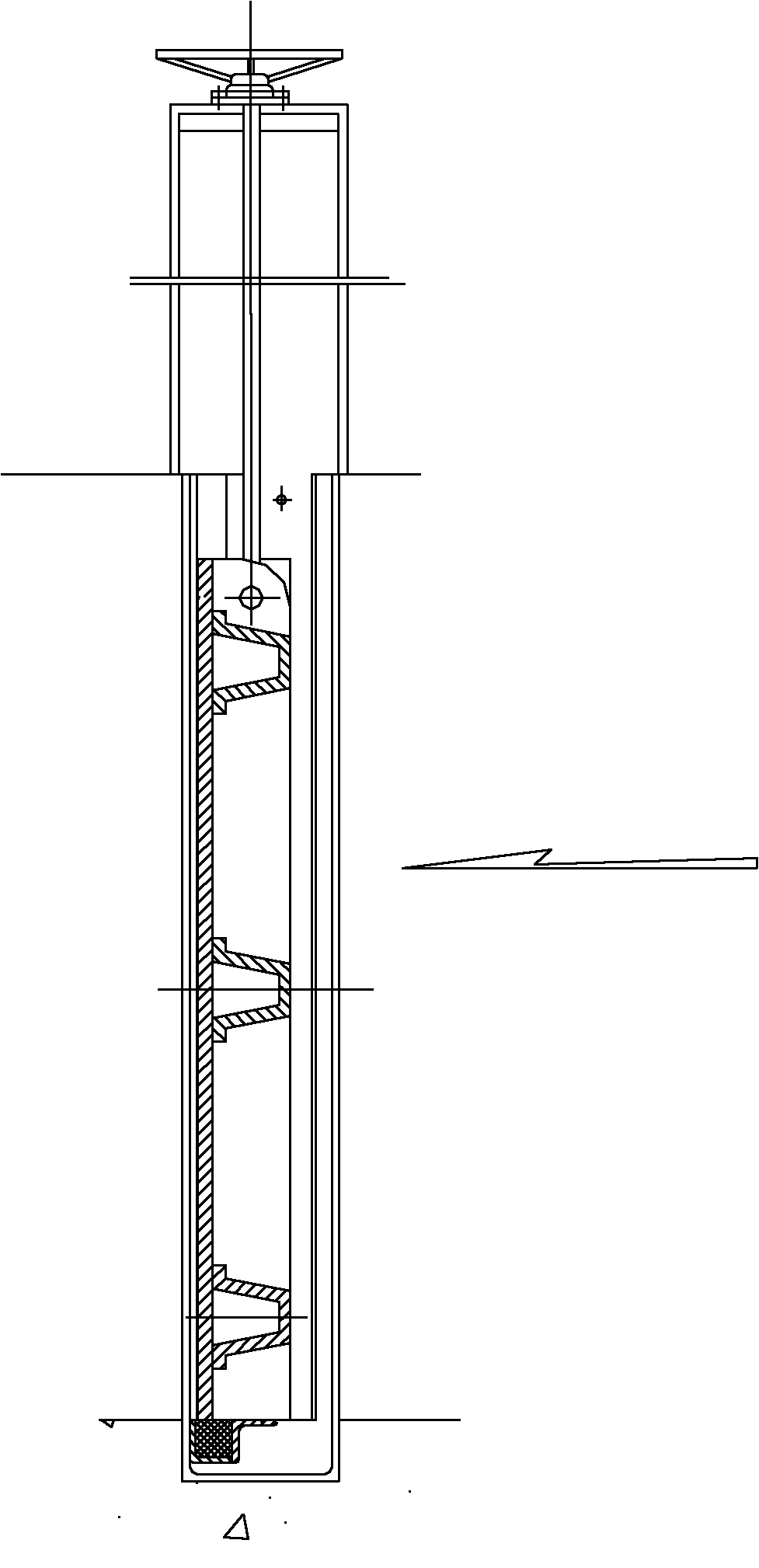

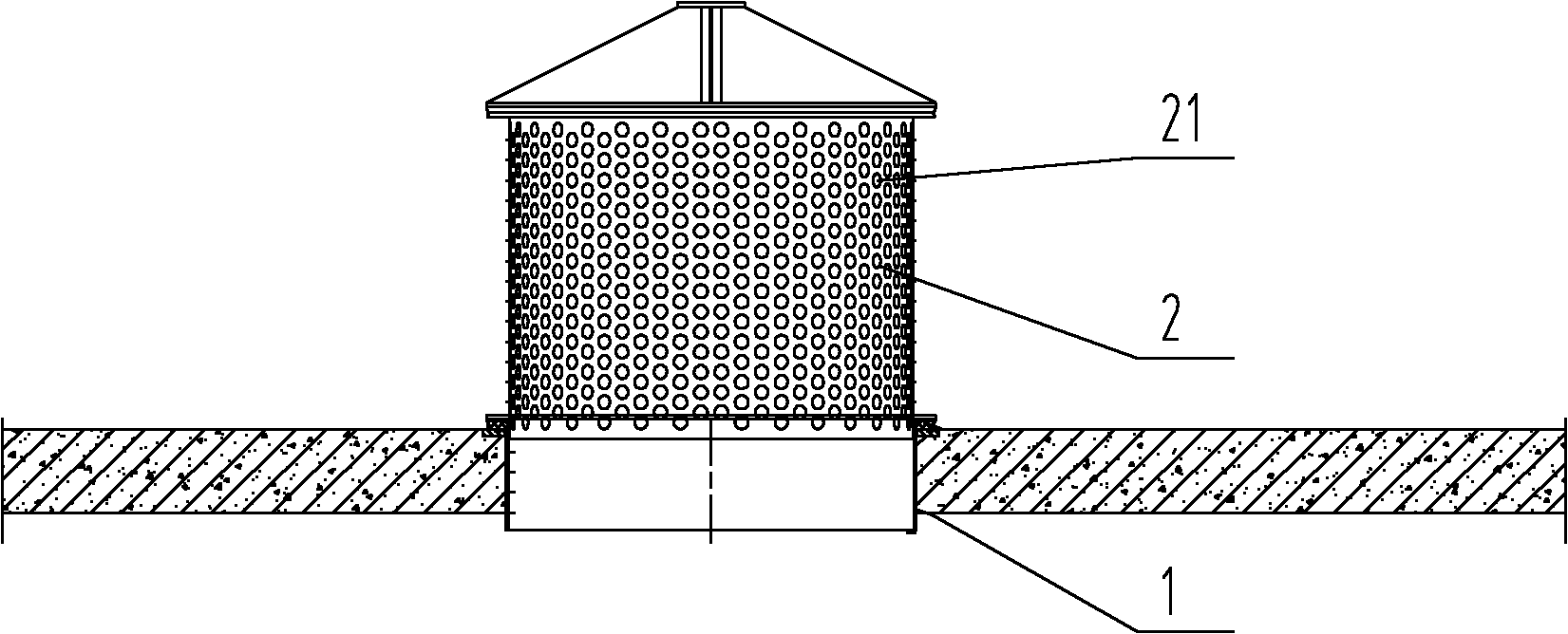

[0018] A sleeve valve with adjustable longitudinal flow, comprising: a valve sleeve 1, a piston cylinder 2 is arranged in the valve sleeve 1, and a sliding fit is formed between the piston cylinder 2 and the valve sleeve 1, and a guide is provided on the piston cylinder 2. Orifice 21. In this embodiment, considering the requirements of flow control and total flow (ie the maximum flow), the sum of the areas of all the diversion holes 21 on the piston barrel 2 is equal to the inner area of the valve sleeve 1 .

[0019] During specific use, the present invention is installed on the platform between the upper and lower pools of the stacked structure, and the piston cylinder 2 is connected to the lifting device 3, and the lifting device 3 is used to drive the piston cylinder 2 to move up and down. The lifting device 3 Including frame 32, frame 32 is provided with hoist 31, is screwed with drive screw mandrel 33 at hoist 31, hoist 31 can be purchased from the market, and drive scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com