Roller adjusting mechanism of small standard copper belt rolling machine

A technology of roll adjustment and small size, applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc. Low technical personnel requirements, compact structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

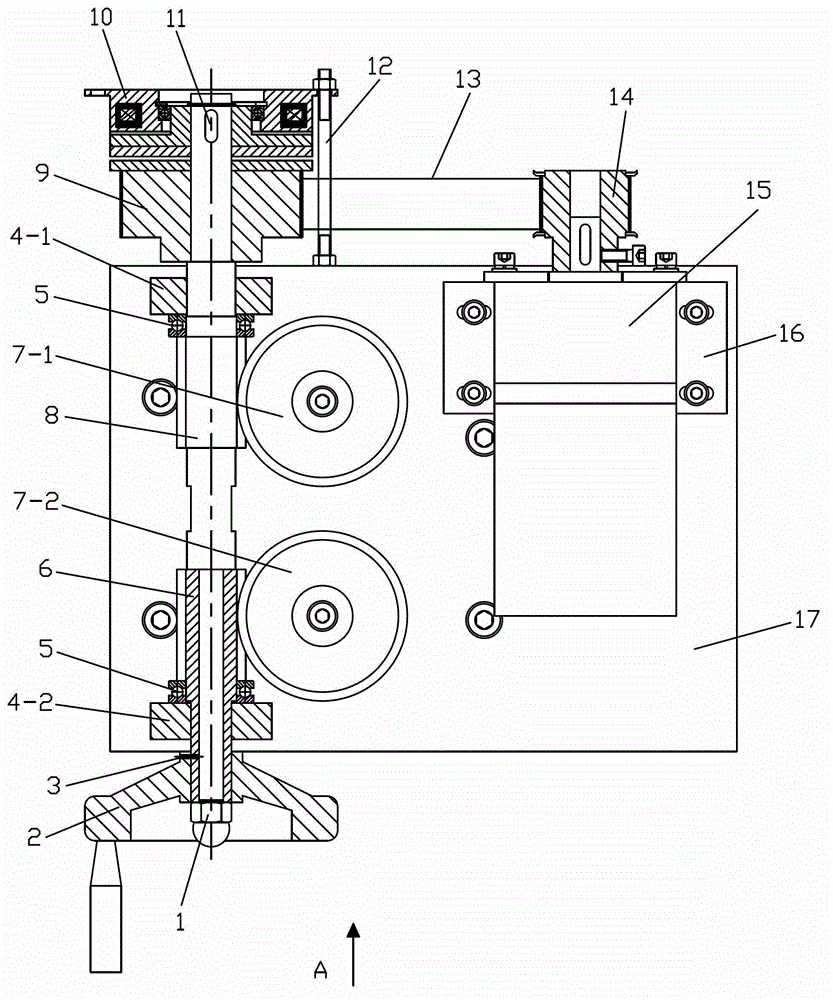

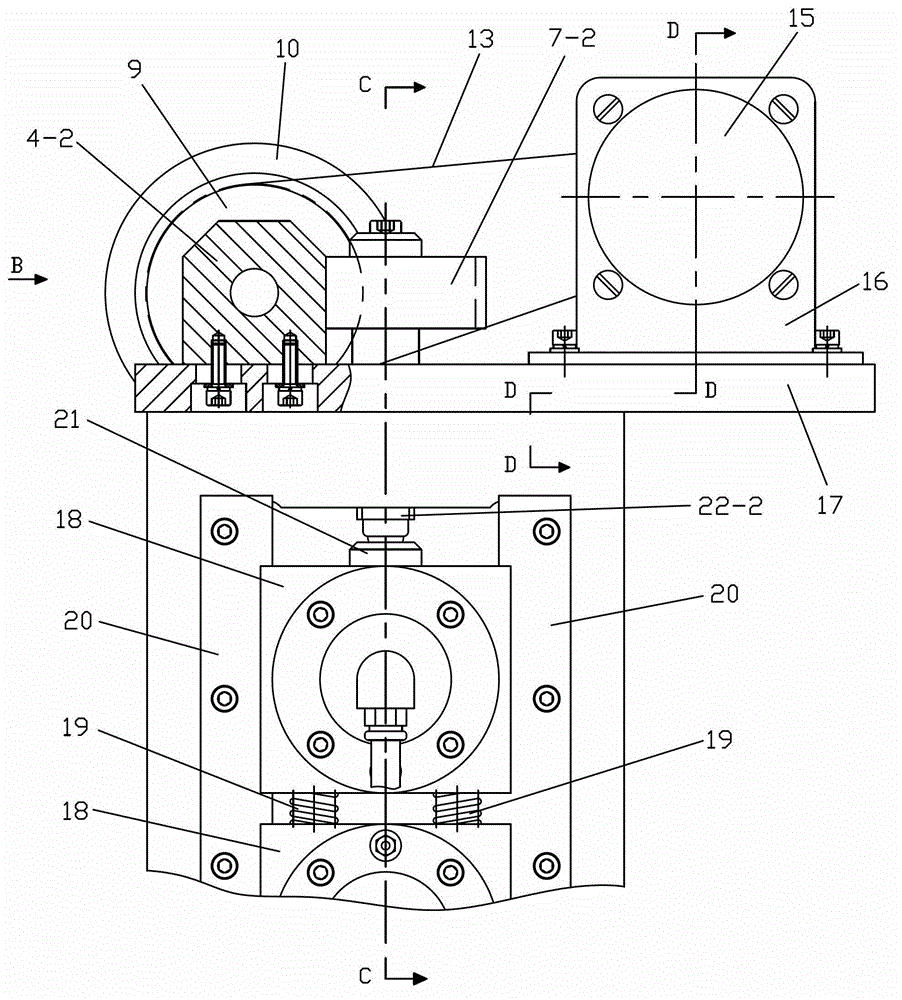

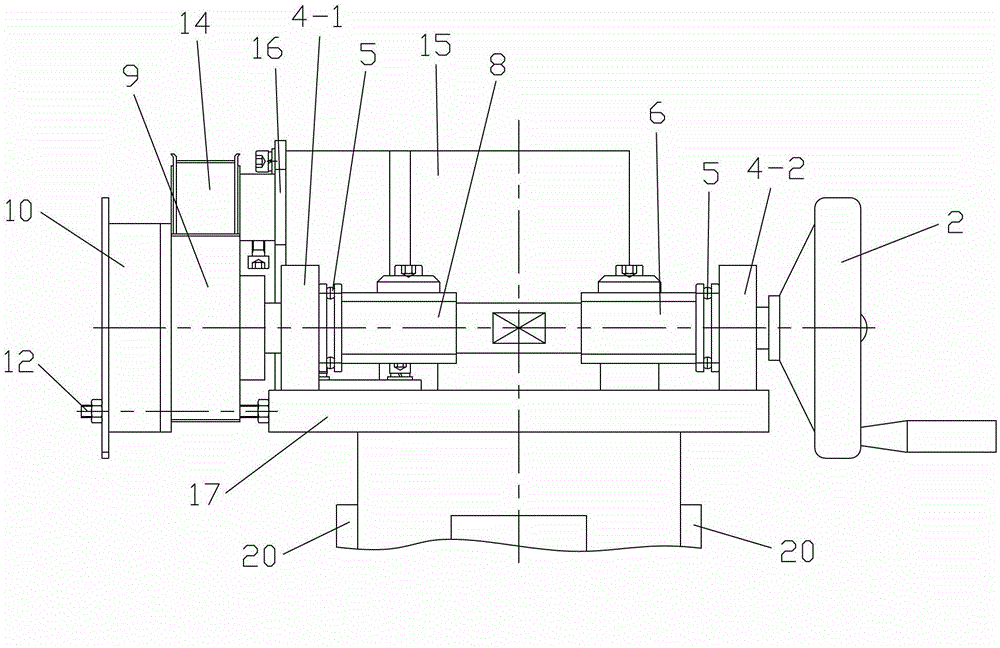

[0032] Such as Figure 1 to Figure 5 As shown, the present invention includes mounting plate 17, worm screw 8, worm screw cover 6, hand wheel 2, nut 1, helical gear one 7-1, helical gear two 7-2, timing pulley one 9, timing belt 13, timing belt Wheel two 14, reduction motor 15 and electromagnetic clutch 10, described installation plate 17 is fixed on the frame 26 that is used to support and install roll 23 to be adjusted, and described worm screw 8 passes through support plate one 4-1 that is sleeved on the worm screw 8 and the support plate two 4-2 are supported and installed on the mounting plate 17, the inner sides of the support plate one 4-1 and the support plate two 4-2 are all provided with thrust bearings 5, and the mounting plate 17 is provided with thrust bearings for pushing the Adjust the slide block 18 on the two ends of the roll 23 along the screw shaft one 22-1 and the screw shaft two 22-2 that slide up and down along the guide bar 20 installed on the frame 26, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com