Core pulling machine for smoke conveying pipes

The technology of conveying pipe and core-pulling machine is applied in the field of flue gas conveying pipe core-pulling machine, which can solve the problems of difficult core-pulling, large volume and heavy weight of flue gas conveying pipe, and achieves convenient sliding frame movement and high transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The present invention will be described in further detail below in conjunction with the accompanying drawings.

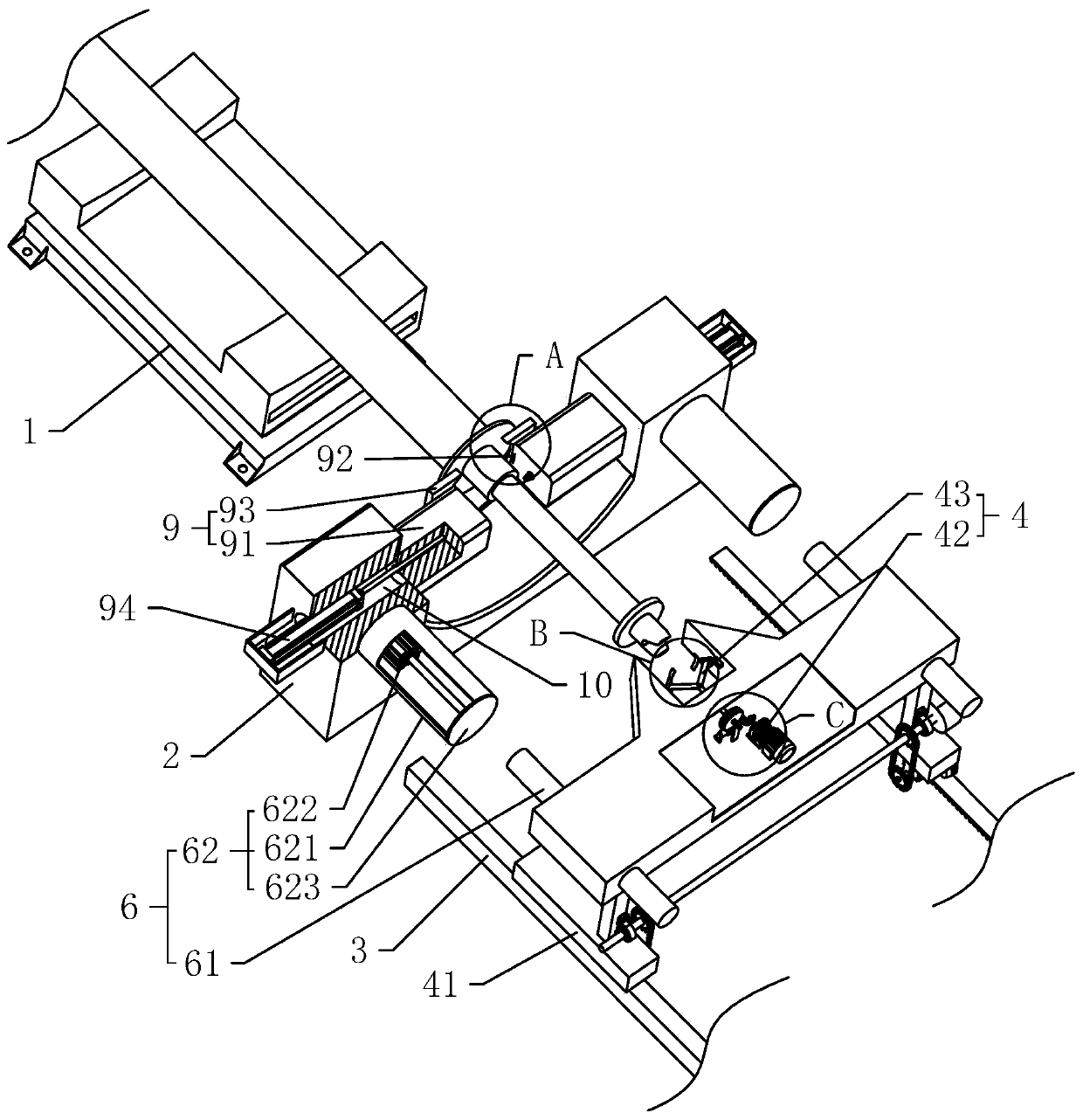

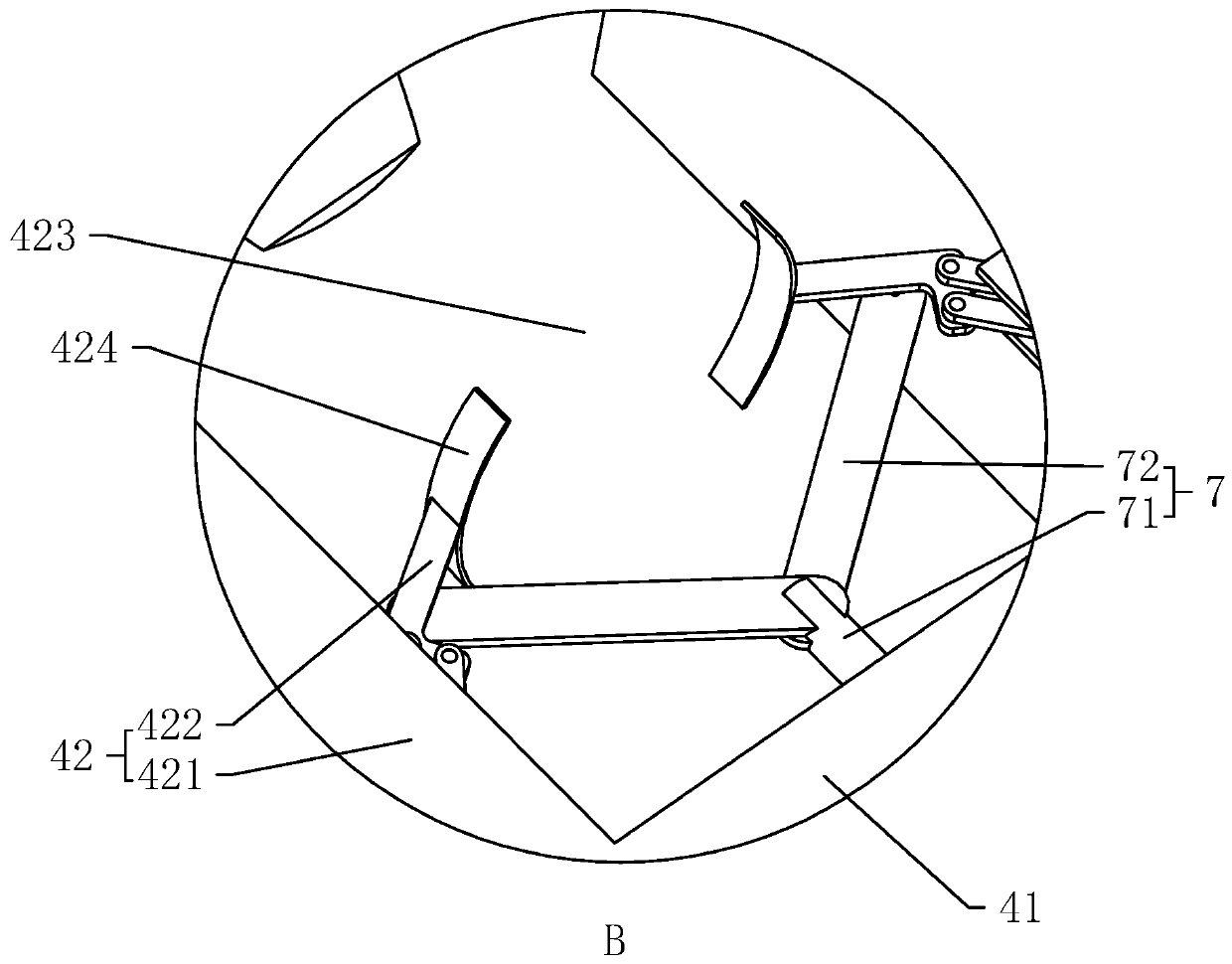

[0037] Such as figure 1 As shown, a core-pulling machine for flue gas conveying pipes includes a carrier frame 1, a positioning frame 2, a guide rail 3, and a core-pulling device 4. The carrier frame 1 is composed of a base and a lifting platform. The rubber hose is supported; the positioning frame 2 is fixed on the ground, and the positioning frame 2 remains fixed during the operation of the core pulling machine, and a positioning mechanism 9 for limiting the movement of the rubber hose is arranged on the positioning frame 2 .

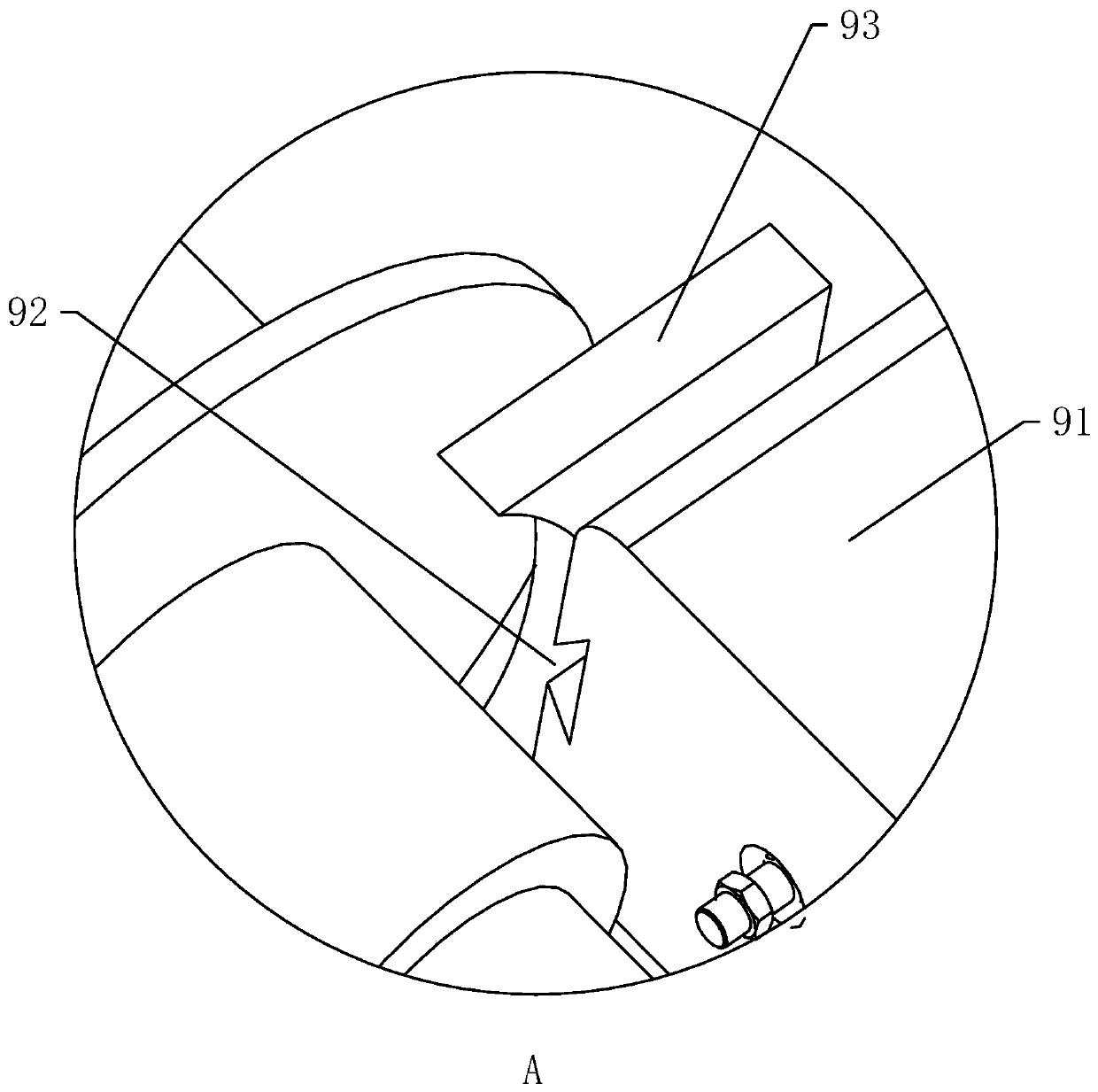

[0038] The positioning mechanism 9 comprises a positioning arm 91, a slideway 92, a positioning clamp 93, and a telescopic assembly 94. The positioning arm 91 is provided with two pieces, which are fixed on the positioning frame 2 and are respectively located on both sides of the positioning frame 2; the slideway 92 (see figure 2 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com