Planetary Mechanism Load Equalization System

A planetary mechanism, load-balancing system technology, applied in mechanical equipment, transmission, gear transmission, etc., can solve the problems of increasing noise, shortening service life, easy to generate vibration, etc., to avoid operation delay and eliminate meshing gap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

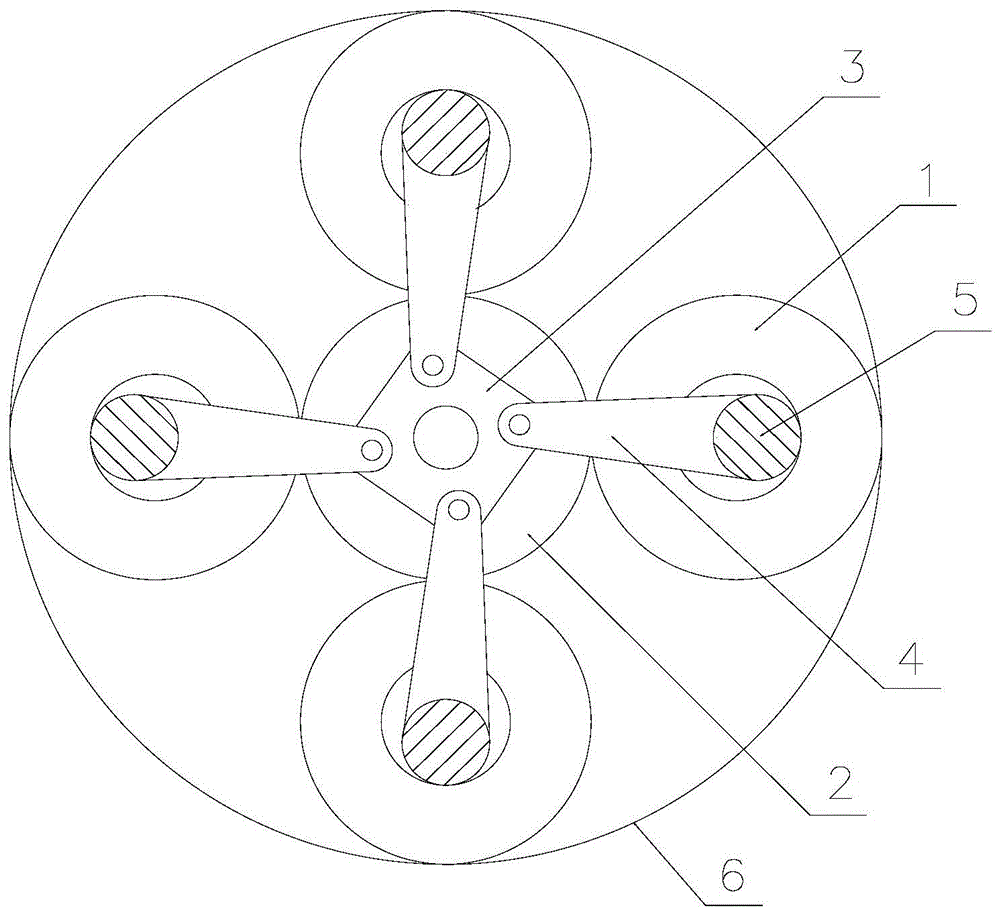

[0011] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the planetary mechanism load sharing system of this embodiment includes a synchronous load sharing system that is connected between each planetary gear 1 in the planetary mechanism and is used to synchronously adjust the position of the planetary gears to achieve load sharing Mechanism: Due to the influence of machining accuracy, there is a certain fit gap between the planetary gear 1, the sun gear 2 and the ring gear 6. After adjusting the rotation angle of the planetary gear 1 to eliminate the above gap, connect the synchronous load equalizing mechanism to each planet Between the wheels 1, each planetary gear 1 is mutually constrained to realize the synchronous rotation of each planetary gear 1, and avoid the operation delay of the planetary gear 1.

[0012] In this embodiment, the synchronous load equalizing mechanism includes a balancer 3 and a connecting rod 4; the balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com