High frequency precision harmonic reducer

A harmonic reducer, precise technology, applied in transmission parts, belt/chain/gear, mechanical equipment, etc., can solve the problem of hindering the development of high-frequency harmonic reducer, the vibration of the harmonic reducer is large, and it is not enough to reduce Vibration and other problems, to achieve the effect of improving precision transmission capacity, sufficient meshing, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

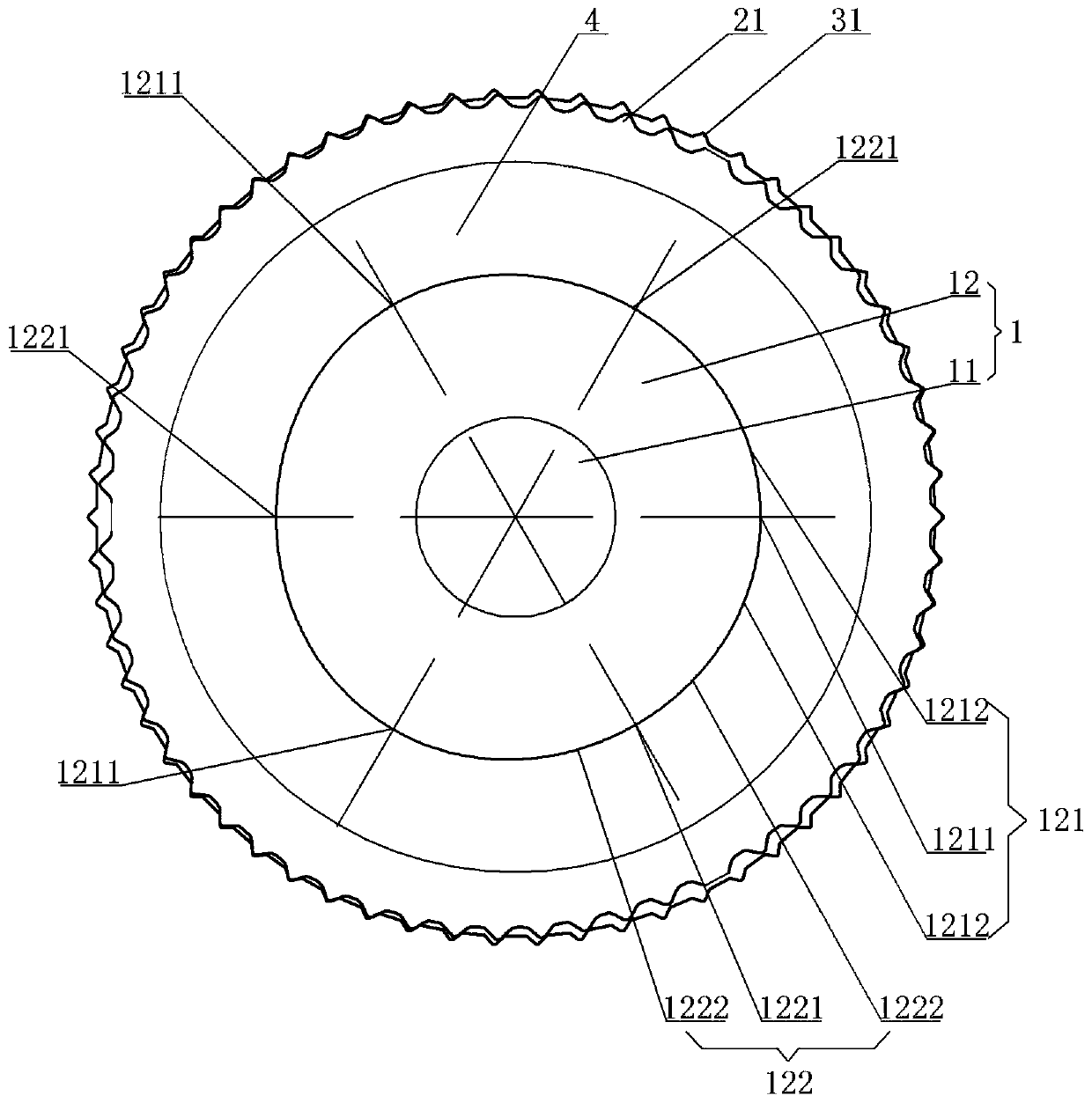

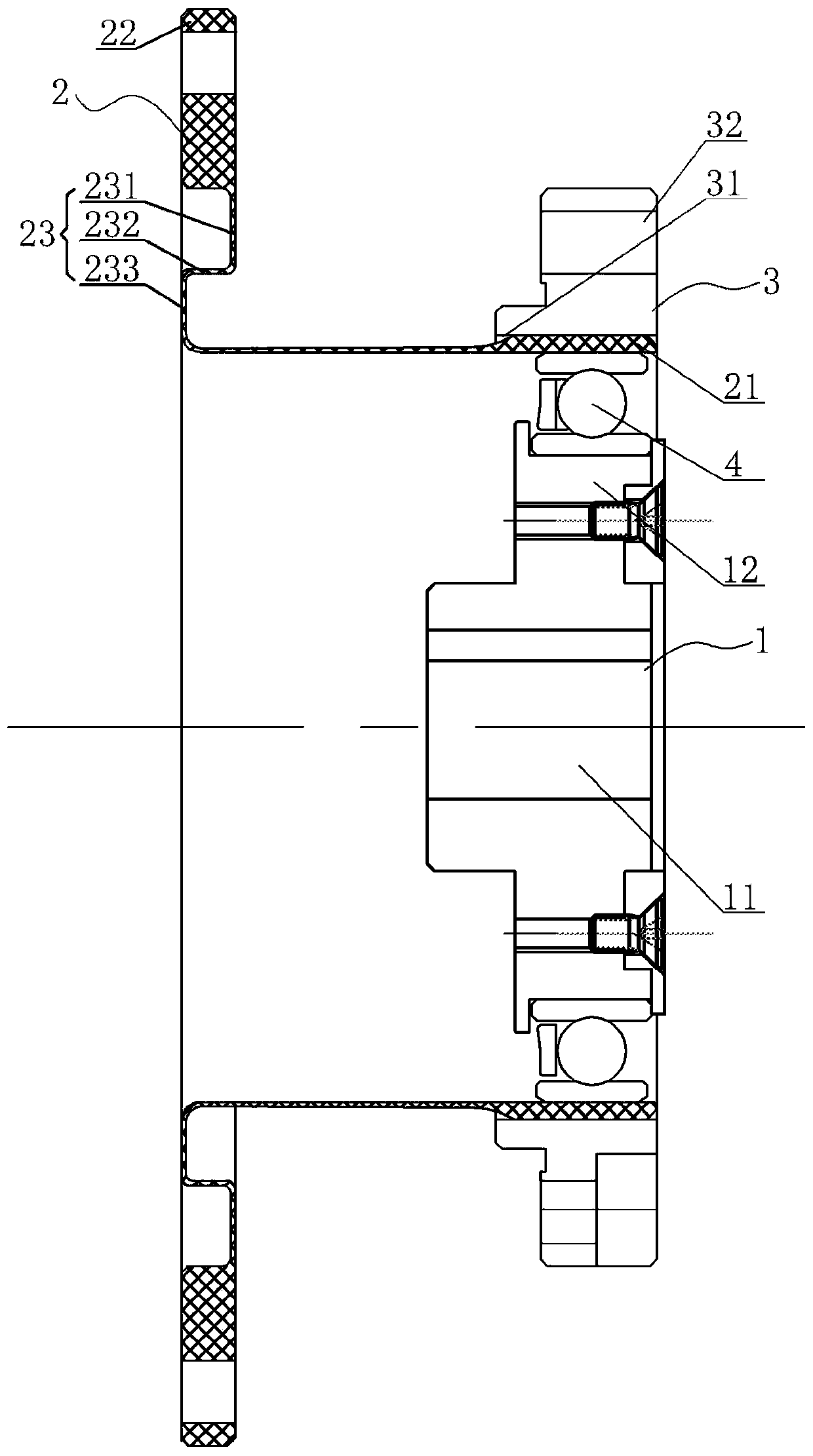

[0021] A high-frequency precision harmonic reducer, see Figure 1-Figure 2 : It includes a wave generator 1, a flex spline 2, and a rigid spline 3. The flex spline 2 includes a flexible internal gear 21, an output flange 22, and a radial connection part 23. The wave generator 1 is built into the internal installation cavity of the flexible internal gear 21 Arranged internally, the wave generator 1 includes an input shaft end 11, a cam 12, and a ring cloth flexible bearing 4 between the outer peripheral surface of the cam 12 and the inner peripheral surface of the flexible internal gear 21. The cam 12 of the wave generator 1 is specifically N convex structure, the outer circumference of the cam 12 is evenly distributed with N convex ring surfaces 121, wherein N is a natural number greater than or equal to 2, and a progressive transition ring surface 122 is provided between adjacent convex ring surfaces 121, flexible The teeth of the inner gear 21 mesh with the corresponding out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com