Sorting machine, sorting trolley, sorting system and article sorting method

A sorting trolley and sorting machine technology, applied in sorting, conveyor objects, conveyors, etc., can solve problems such as installation in areas that are not easy to install in small spaces, the use efficiency of belt conveyors is reduced, and there is no way to carry out sorting, etc. Sorting capacity, improve use efficiency, reduce the effect of space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

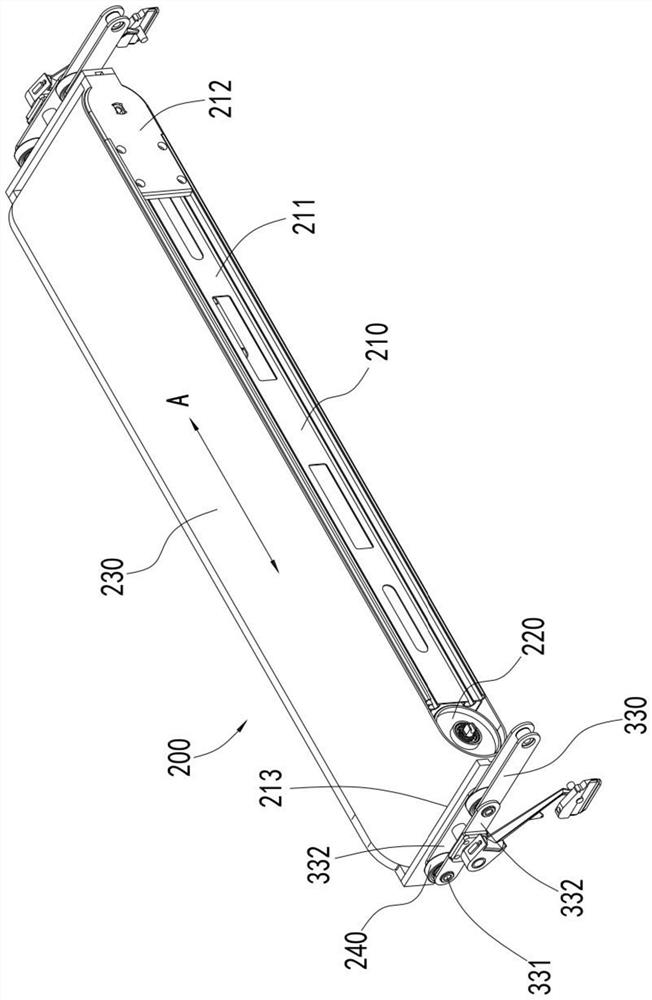

[0097] The overall structure of this embodiment is the same as that of the above-mentioned embodiment 1, the difference is that the sorting trolley is a roller conveyor or a chain conveyor instead of a belt conveyor, as shown in the attached Figure 13 As shown, when the sorting trolley is a roller conveyor, it includes a group of rollers 202 of equal height and arranged in parallel on the frame 201, the top of the rollers 202 is higher than the top of the frame 201, and the rollers bottom is lower than the bottom of the frame. One of the drums may be an electric drum, and the other drums may be driven by a transmission structure composed of a belt or a chain and a sprocket; or all the drums may be electric drums. Correspondingly, the vehicle frame 201 can adopt a simpler structure, that is, the vehicle frame can only have two vertical and parallel side plates 2011 and end plates 2012 connected at both ends of the two side plates, and the structure of the side plates 2011 can ...

Embodiment 3

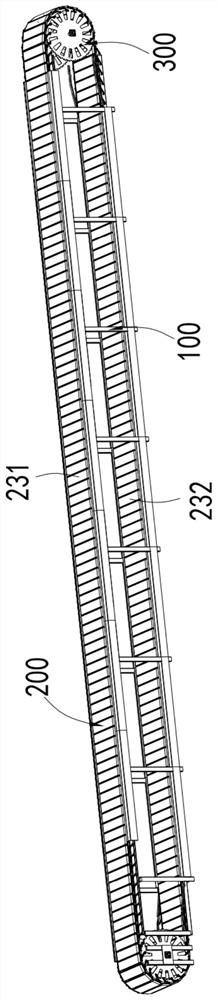

[0100] The overall structure of this embodiment is similar to that of the above-mentioned embodiment 1, the difference is that the chain-type drive mechanism is replaced by the linear motor and the secondary plate in the conventional cross-belt sorter to drive the sorting trolley. Specifically, as attached Figure 14 , attached Figure 15 As shown, a secondary plate 301 is provided on part or all of the end plates of the sorting trolley, and a linear motor 302 that drives the secondary plate to move linearly is provided on the outside of the secondary plate, and the linear motor 302 is fixed on the frame , the number of which can be designed according to the required power, which is not limited here. In addition, the linear motor can preferentially select the position of the turning section of the loop of the trolley, so that the corresponding installation requirements can be reduced. as attached Figure 14 As shown, the secondary plate 301 may be parallel to the first stra...

Embodiment 4

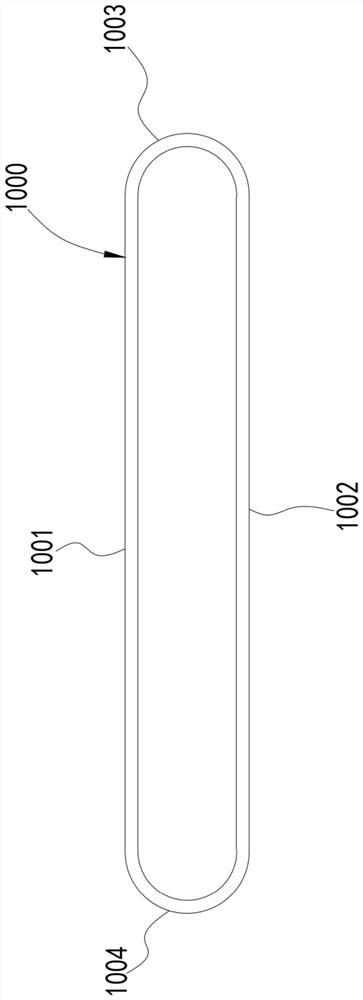

[0103] In the above-mentioned embodiments 1-3, the shape surrounded by the trolley loop line 1000 is a waist-shaped ring. At this time, the upper and lower straight sections can only be wrapped and wrapped at the upper straight section and the lower straight section. Such a structure does not It is beneficial to increase the sorting point. better, as attached Figure 16 - attached Figure 20 As shown, the trolley loop 1000 has more layers of straight segments (in the present invention, each layer of straight segments is counted in order from bottom to top, that is, the bottom straight segment of the trolley loop is the first layer, the bottom straight segment The upper layer of straight line is the second layer, and so on to the topmost straight line), specifically, the shape surrounded by the trolley ring 1000 is "I" or "Wang" or "日". Either "E" shape or "U" shape with opening on the side. as attached Figure 16 As shown, taking the "I" font as an example, at this time, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com