Automatic cutter for printer

An automatic cutter and printer technology, applied in metal processing, etc., can solve problems such as poor reliability, poor paper cutting, complex cutter reversing mechanism, etc., achieve long life and improve the quality of paper cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

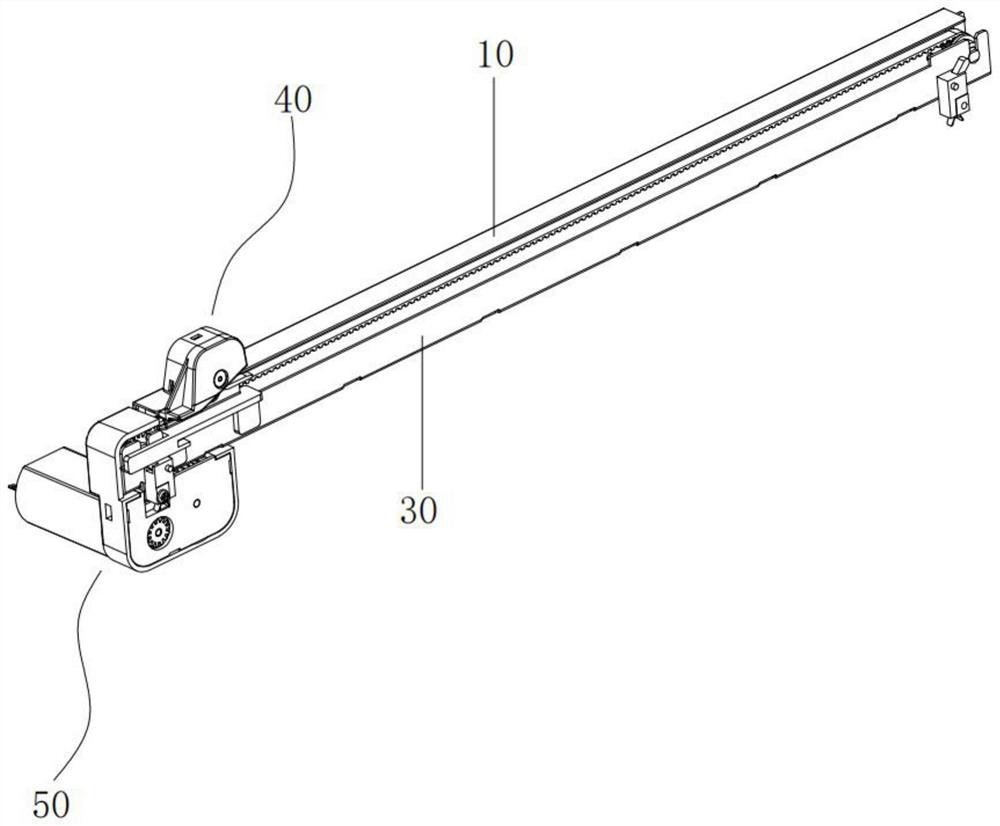

[0039] see Figures 1 to 12 , is an automatic cutter for a printer as Embodiment 1 of the present invention, comprising a horizontal fixed knife 10 and a circular cutter 20 slidingly connected with the fixed knife 10, the fixed knife 10 is inclined downward and vertically The angle formed by the direction is less than 90 degrees, and the front end of the circular cutter 20 along the paper cutting direction is attached to the cutting edge of the fixed knife 10, and its rear forms an included angle with the cutting edge of the fixed knife 10, and the included angle is an acute angle. ; Wherein, the angle formed by the fixed knife 10 and the vertical direction is α, and α is 87-89 degrees; the acute angle range is 1-3 degrees; a certain angle is formed between the circular cutter 20 and the fixed knife 10, Allowing the circular cutter 20 to mesh with the fixed knife 10 can more fully improve the quality of paper cutting and have a longer life.

[0040] The automatic cutter also ...

Embodiment 2

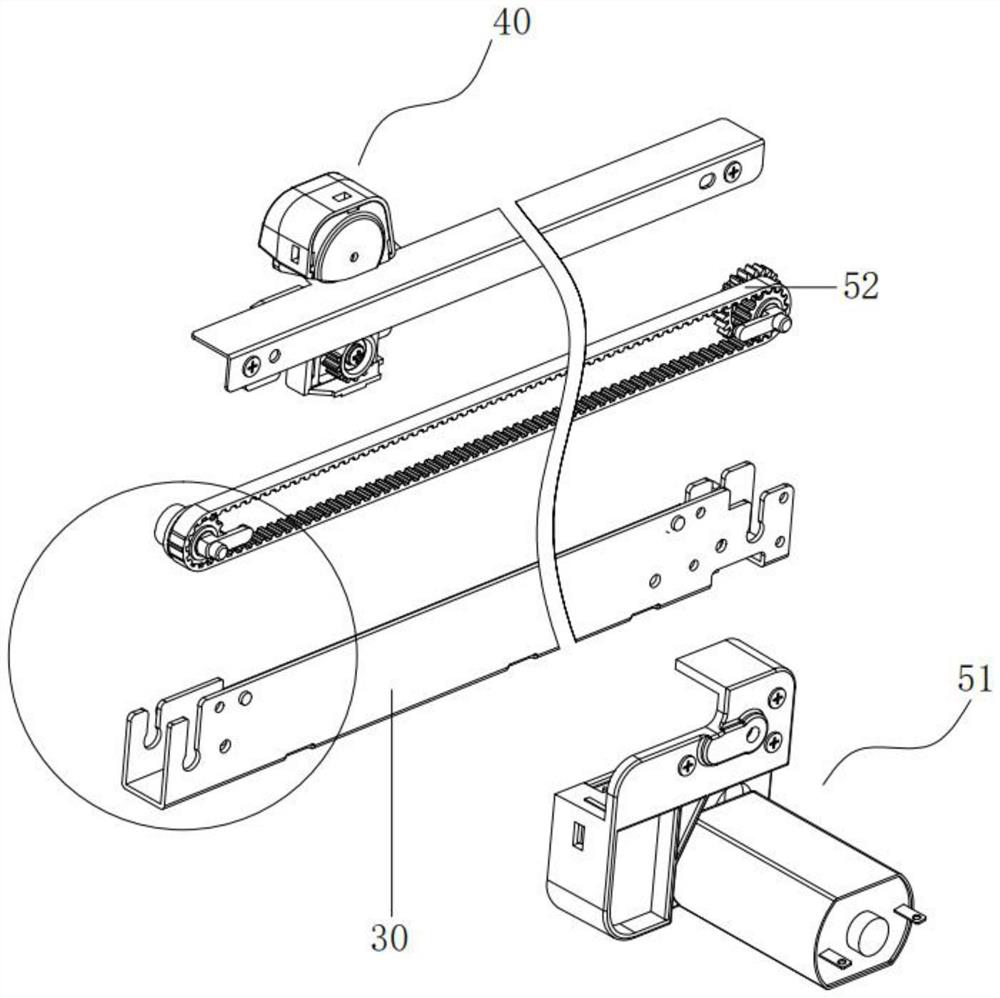

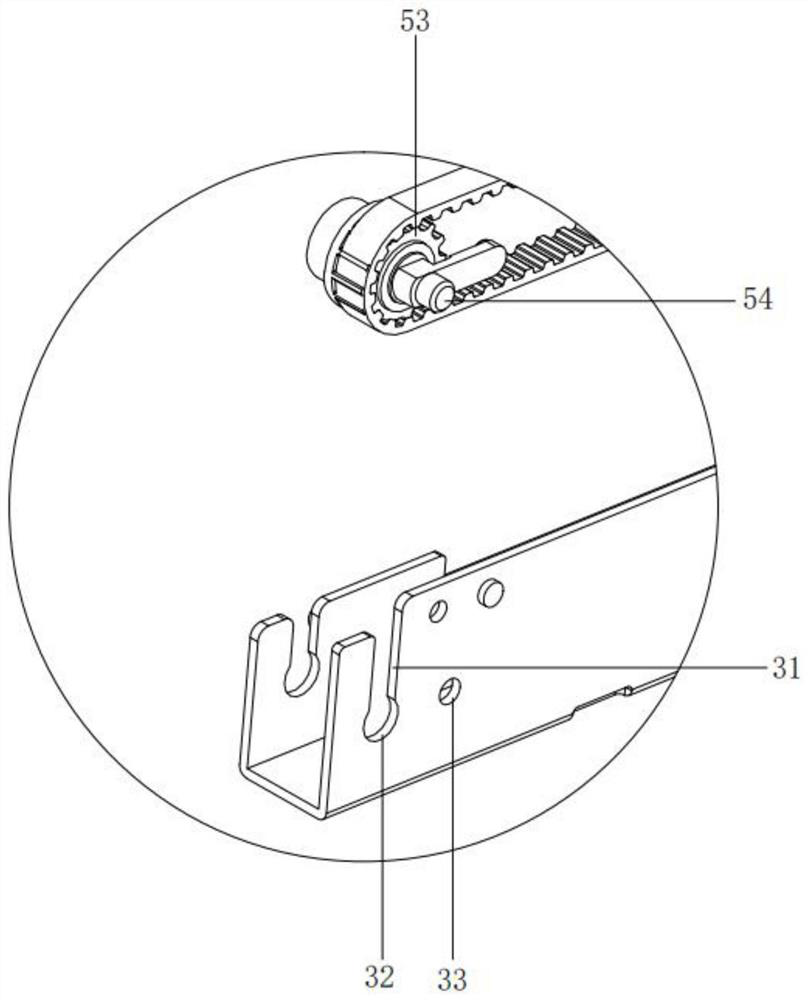

[0046] see Figure 13 , 14 , is an automatic cutter for a printer as Embodiment 2 of the present invention. The difference between this embodiment and the embodiment is that the plan adopted for the repeated movement of the bracket 41 is different; The connected bracket 41, the pressing block 46 for fixedly connecting the bracket 41 with the transmission belt 52, and the shaft detection switch 47 for sensing the position of the bracket 41 are arranged at both ends of the transmission belt 52, wherein the shaft detection switch 47 is fixedly arranged on the support On the seat 30, and on both sides of the bracket 41, there are extensions 412 for shaft detection and sensing; the motor drives the bracket 41 to slide, and when it is detected that the bracket 41 reaches one end of the conveyor belt 52, the motor reverses and drives the bracket 41 to the other end of the conveyor belt 52 Move, when the shaft detection switch at the other end detects that the bracket 41 is in place,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com