Double-layered casing windowing drillbit

A double-layer casing and drill bit technology, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of long window opening period, high casing steel grade strength, low window opening success rate, etc., to improve cutting performance and wear resistance, prolong service life, and solve the effect of low success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

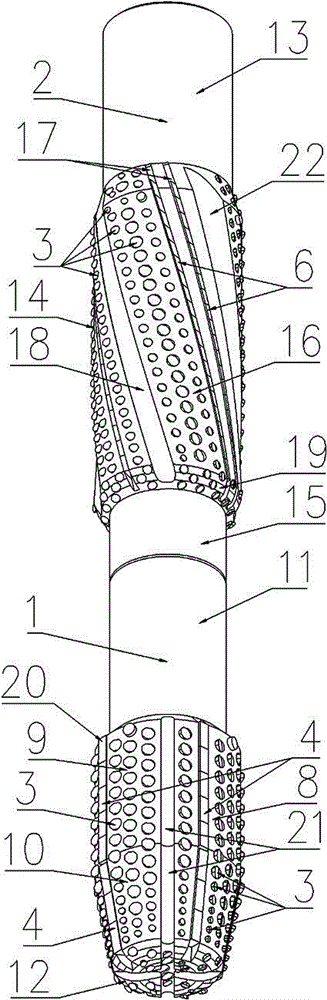

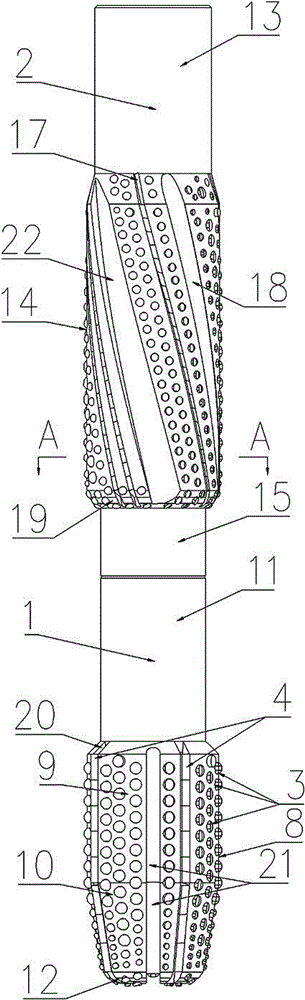

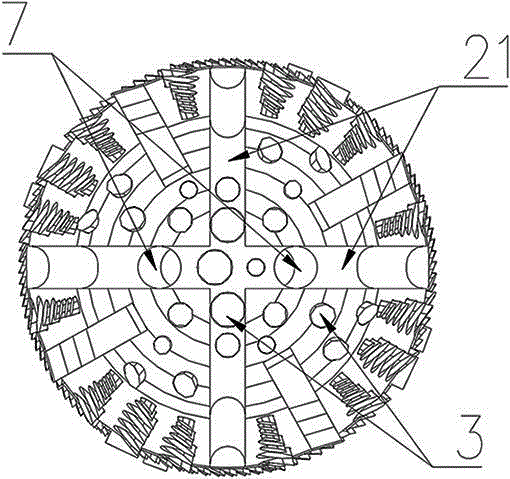

[0021] Such as figure 1 , figure 2 , Figure 4 As shown, a double-layer casing window opening drill bit includes a first-level drill bit base body 1, and a first-level drill bit base body 1 is provided with an upper joint 11 and a first-level cutting part 8 connected in sequence, and the first-level cutting part 8 includes a cylindrical The cloth tooth surface 9, the tapered tooth cloth surface 10 and the bottom end surface 12, the outer surface of the primary cutting part 8 are also provided with tooth grooves 20 and water grooves 21 extending in the axial direction, and it also includes a secondary drill base 2, two The base body 2 of the drill bit is provided with a joint 13, a secondary cutting part 14 and a lower joint 15 which are sequentially connected. The upper joint 11 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com