Special gear for optical fiber rotary connector

A technology of rotating connectors and gears, applied in the direction of belts/chains/gears, components with teeth, coupling of optical waveguides, etc., can solve the problems of large size and heavy weight of products, and reduce the number of parts and fixing parts, the effect of speeding up assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

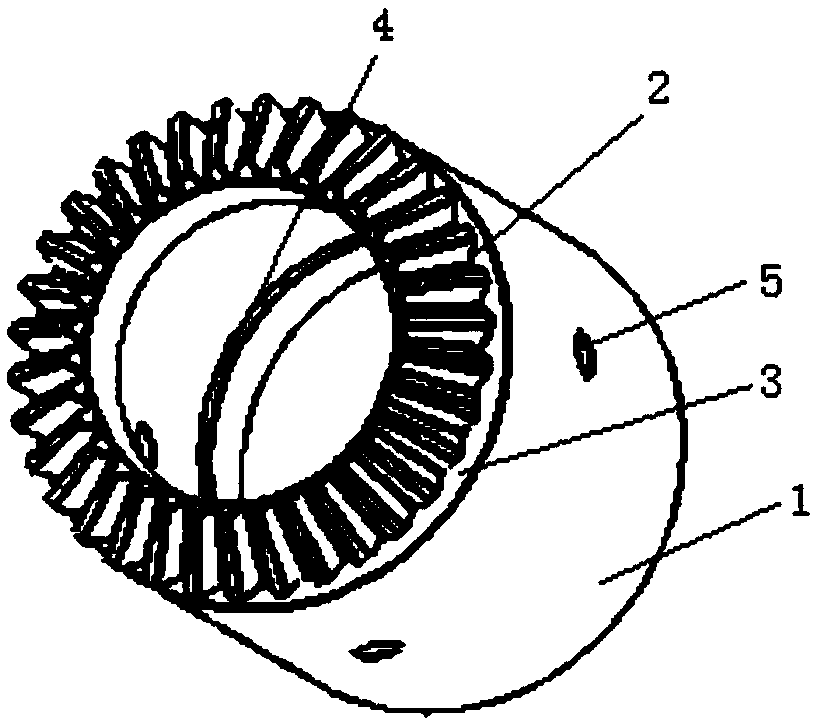

[0015] Such as figure 1 The shown special gear for optical fiber rotary connector includes a hollow cylinder 1, and a bevel tooth structure 2 is processed on one end surface of the cylinder 1 to form a bevel gear. An annular groove 3 is provided at the position of the tail of the bevel teeth in the circumferential direction of the cylinder body 1 . A card slot 4 is processed on the inner wall of the cylinder body 1, and the card slot is convenient for connecting with other parts. In the barrel 1, the inner diameter of the barrel at one end of the bevel gear is smaller than the inner diameter of the other parts of the barrel, and the inner wall of the barrel forms a stepped structure. A through hole 5 that runs through the cylinder is processed on the cylinder. The bevel gears are straight bevel gears or bevel bevel gears.

[0016] The basic principles, main features and advantage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com