Bevel gear tooth profile design method based on circular conical surface involute

A technology of bevel gear and tapered surface involute, applied in belt/chain/gear, mechanical equipment, components with teeth, etc., can solve problems such as difficulty in precise processing, and achieve the effect of avoiding large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to specific embodiments.

[0029] The bevel gear tooth profile design method based on the conical surface involute includes the following steps:

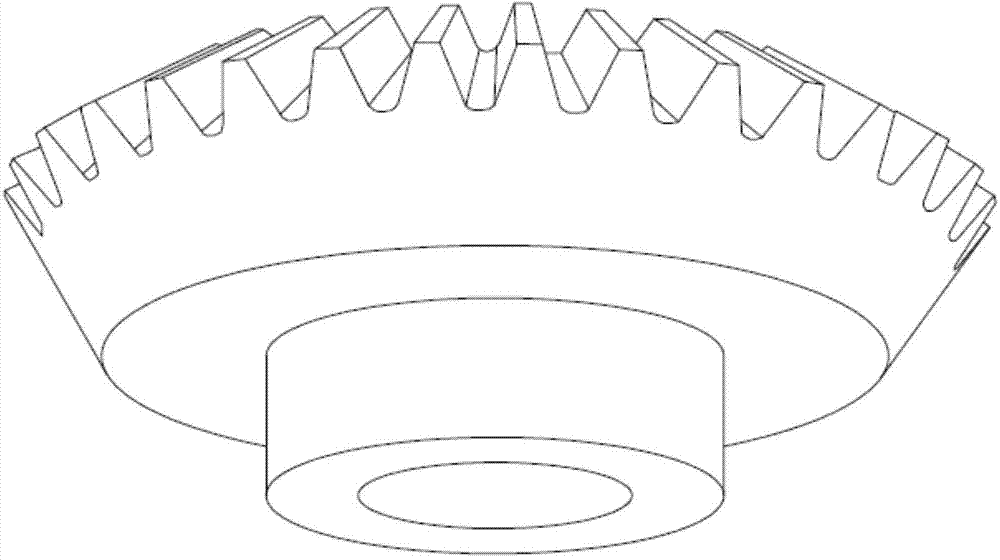

[0030] In the first step, take the following set of parameters as an example, as the known parameters of the bevel gear to be designed: the big end module m=2.75mm, the number of teeth z=30, the pressure angle α=20°, the tooth tip height coefficient h a =1, the tooth root height coefficient h f =1.2, taper angle δ=56.3017°, tooth width B=15mm, calculated back taper angle δ b =90°−δ=33.6983°, and the taper distance R=(mz / 2) / sinδ=49.58108mm.

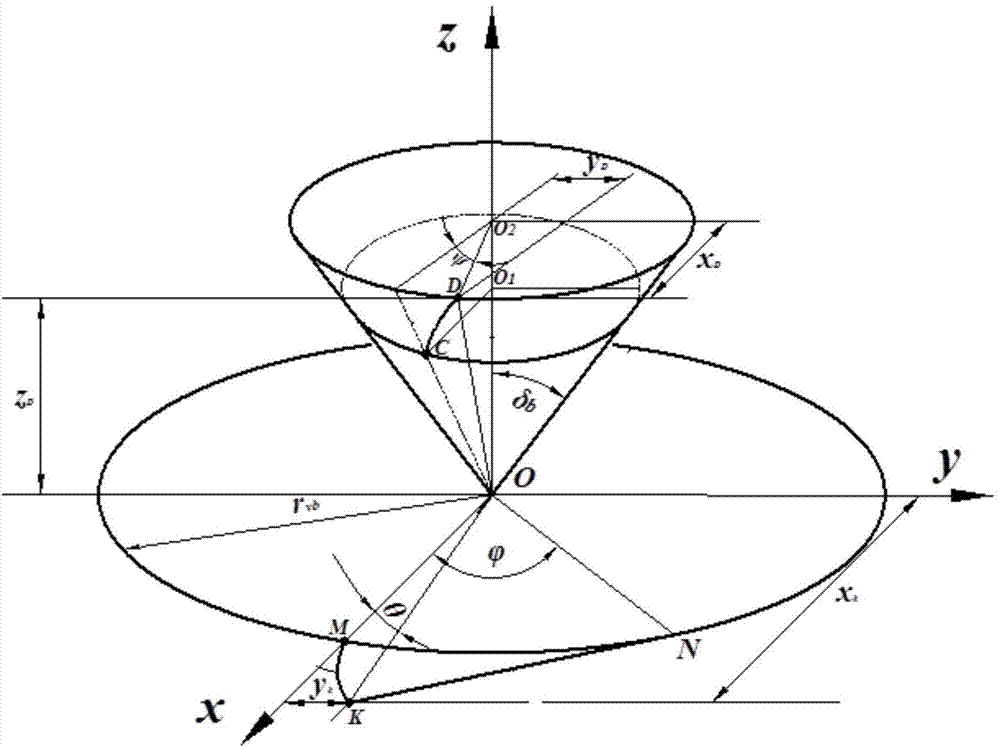

[0031] In the second step, take the back cone top of the bevel gear to be designed as the coordinate origin O, take the plane perpendicular to the axis of the bevel gear to be designed as the XY plane, and take the axis of the bevel gear to be designed as the Z axis, establish the OXYZ coordinate system, such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com