Nailing machine containing swinging type continuous nailing head

A nail box machine and swing-type technology, applied in container manufacturing machinery, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc., can solve the problems of expensive imported equipment, high maintenance rate of nail heads, and low production efficiency , to achieve the effect of easy maintenance, simplified structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

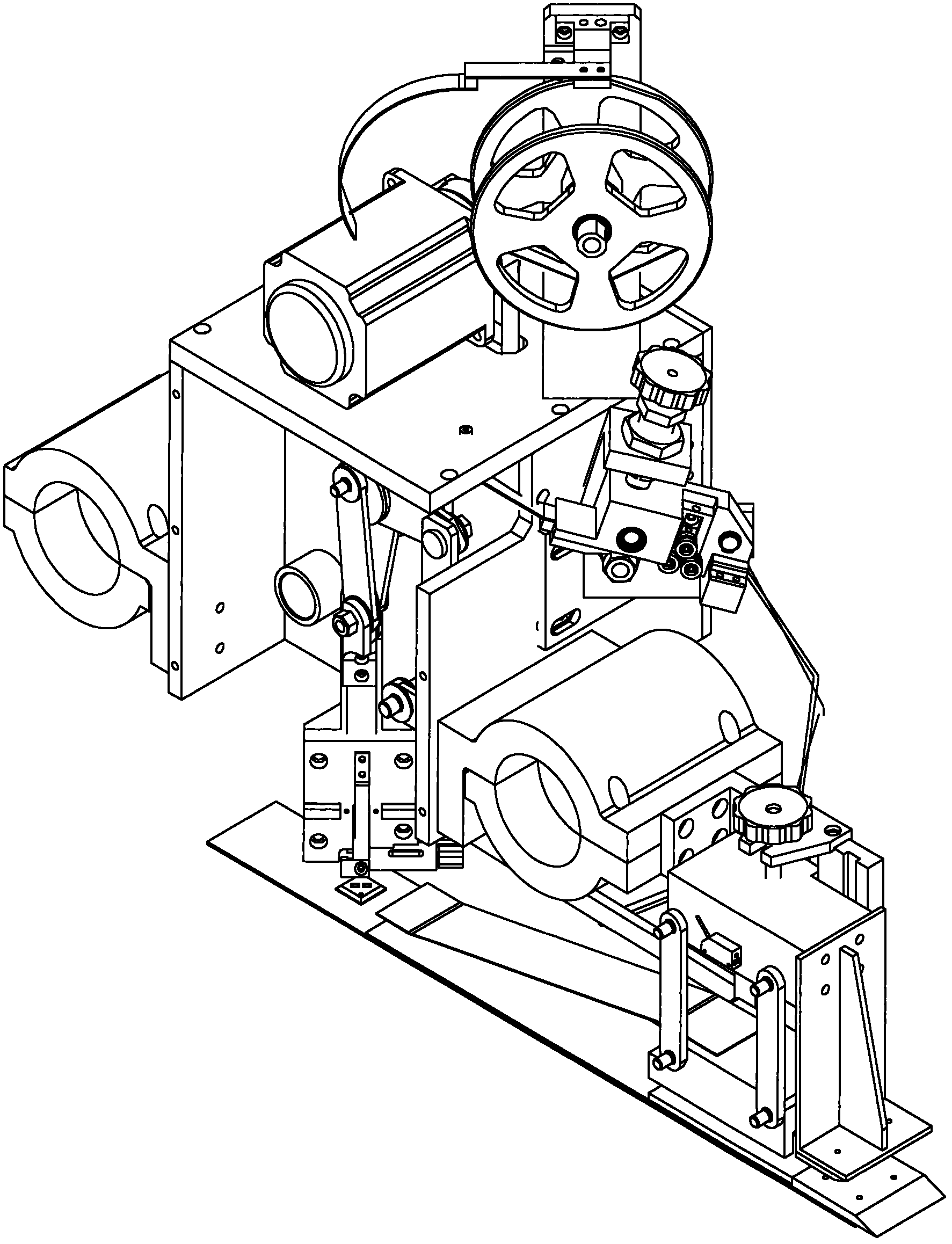

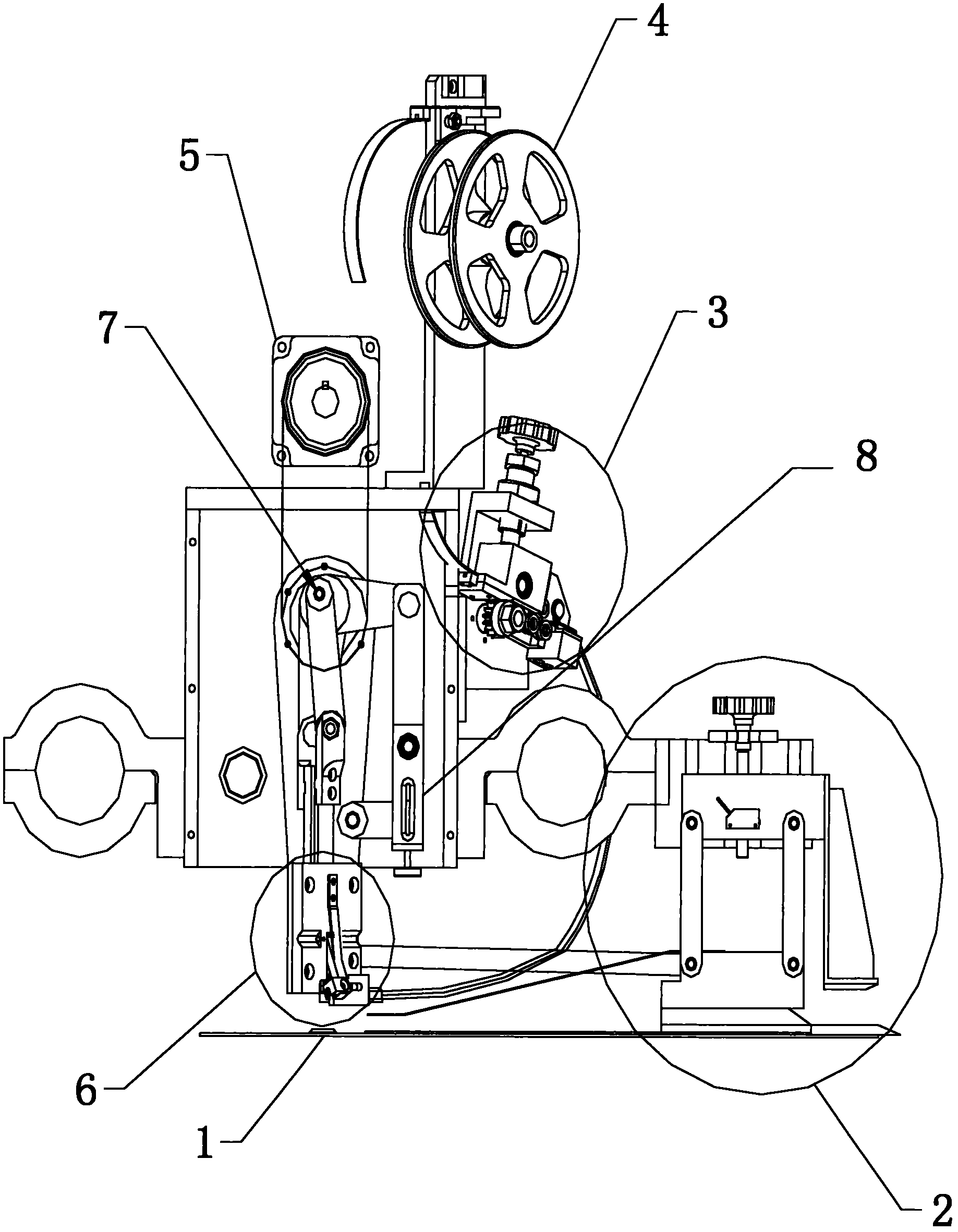

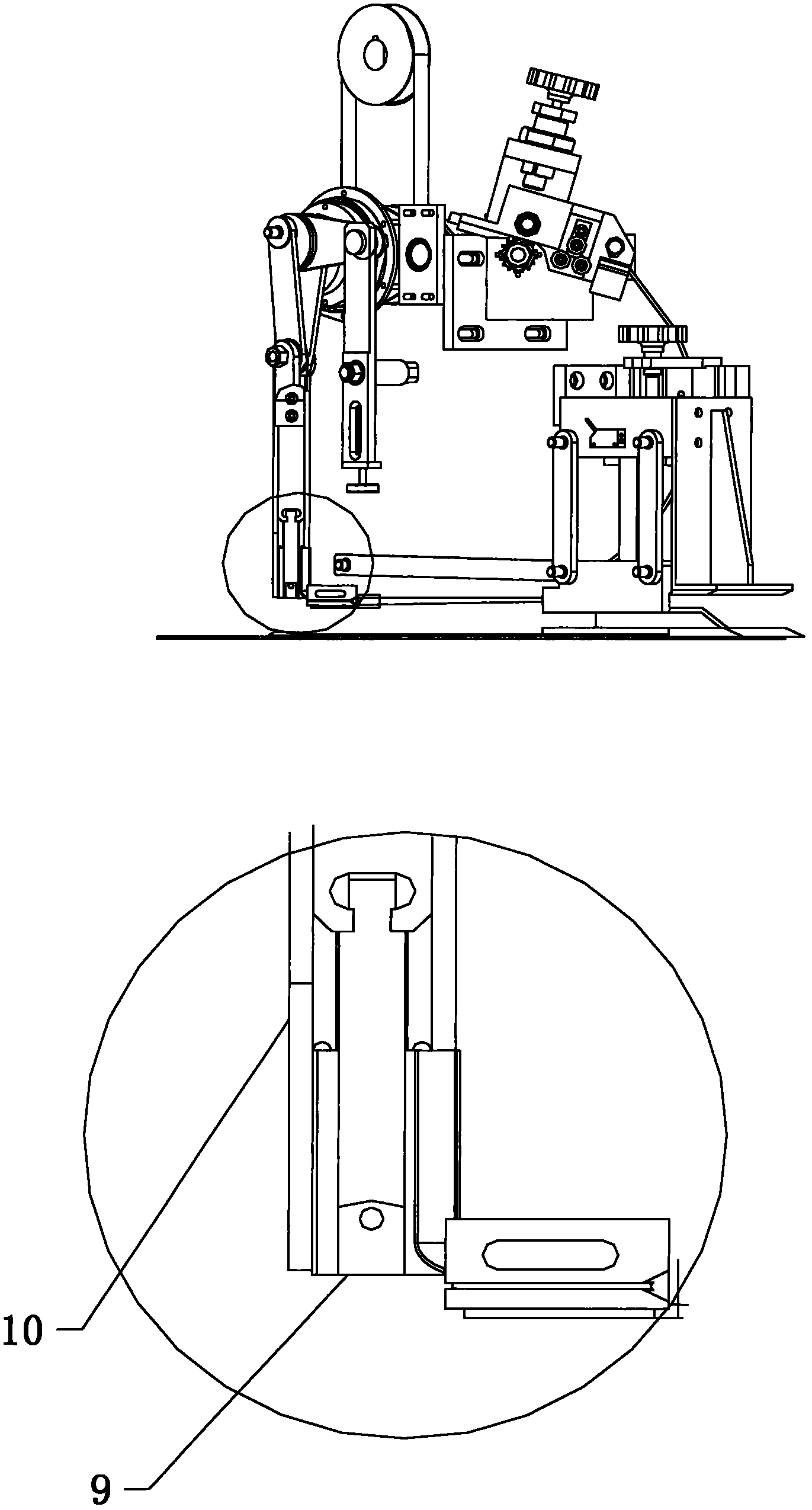

[0021] Such as Figure 1 to Figure 4 A nail box machine with a swinging non-stop nail head is shown, including a base 1 , a base linkage device 2 , a wire feeding mechanism 3 , a nailing disc 4 , a servo motor 5 and a nail head 6 . The nail wire dish 4 is put on the nail line flat wire and then enters the nail head 6 through the wire feeding mechanism 3 . The wire feeding mechanism 3 is connected with the main shaft 7 through a timing belt and a bevel tooth chain, and when the main shaft 7 rotates, it simultaneously drives the wire feeding mechanism to perform wire feeding work. The carton is sent into the nail head 6 through the paper feeding belt. When the sensor detects that the carton is on the shaft of the paper feeding belt, the encoder starts to operate. When the carton reaches the set position, the motor of the main shaft 7 detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com