Symmetrical arc swing mechanism of full position automatic double welding torch pipeline welder

An automatic welding machine and all-position technology, which is applied in the pipeline system, mechanical equipment, welding equipment, etc., can solve the problems of welding, increasing the control communication interface, and difficult calibration of the arc starting point and arc extinguishing point of the welding torch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

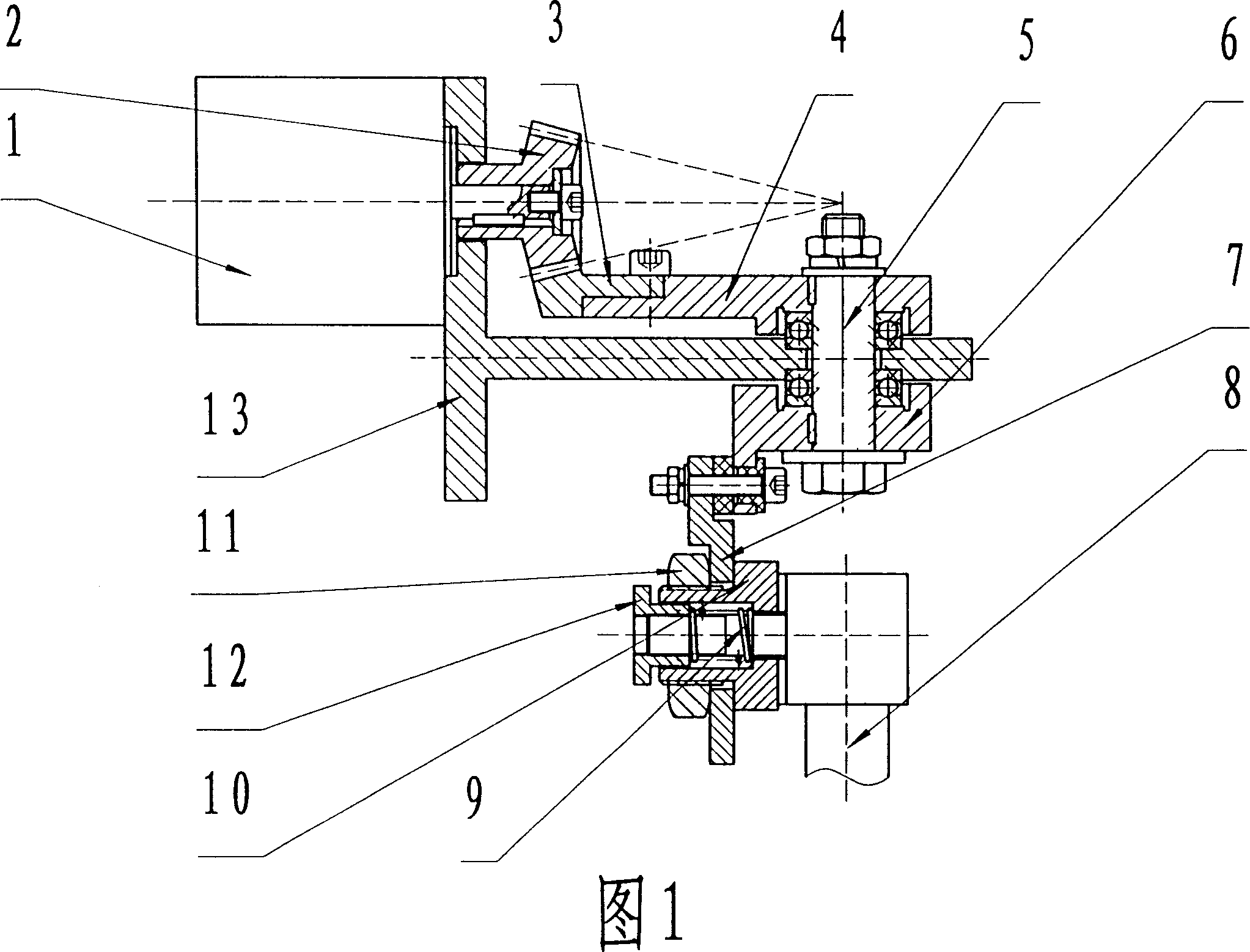

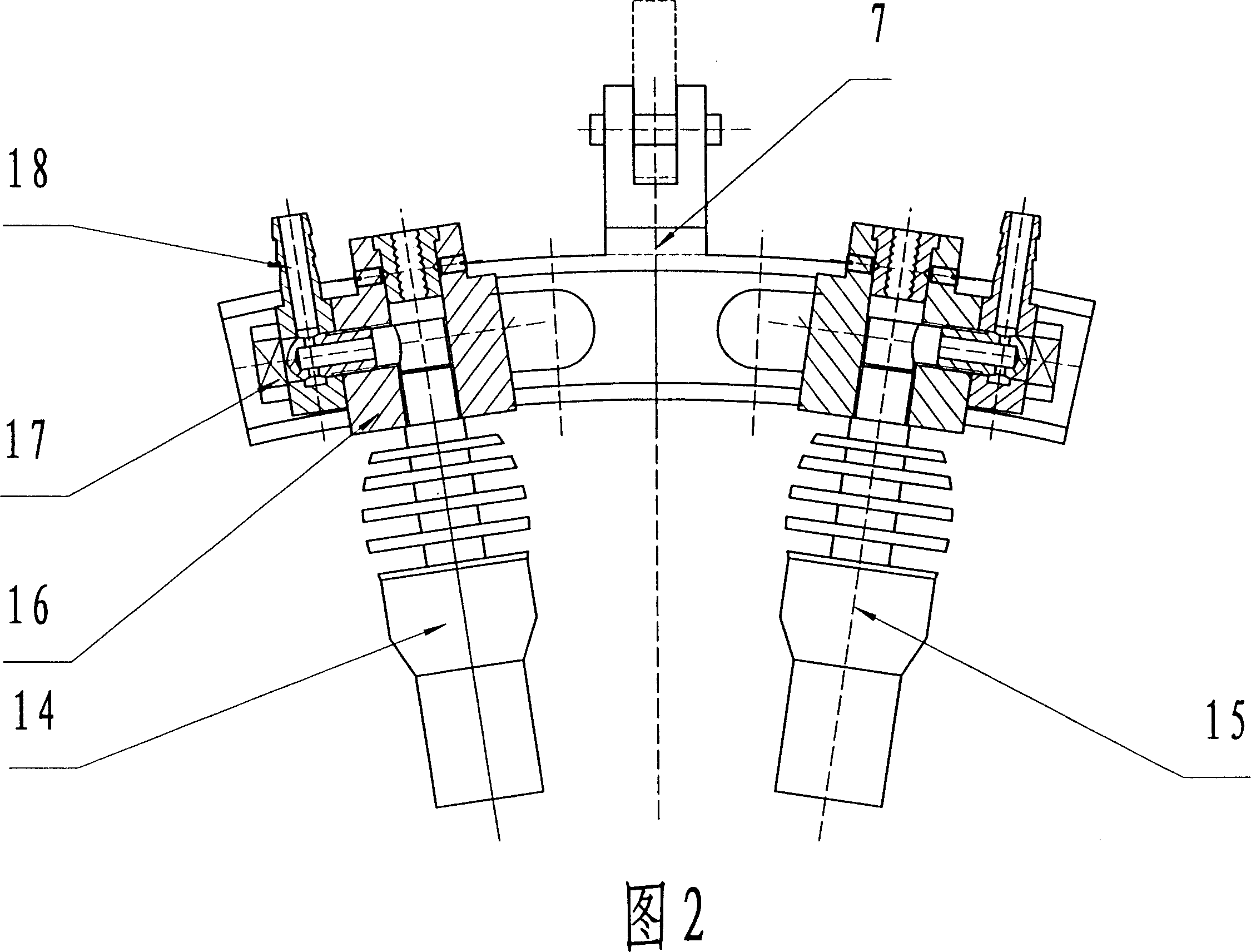

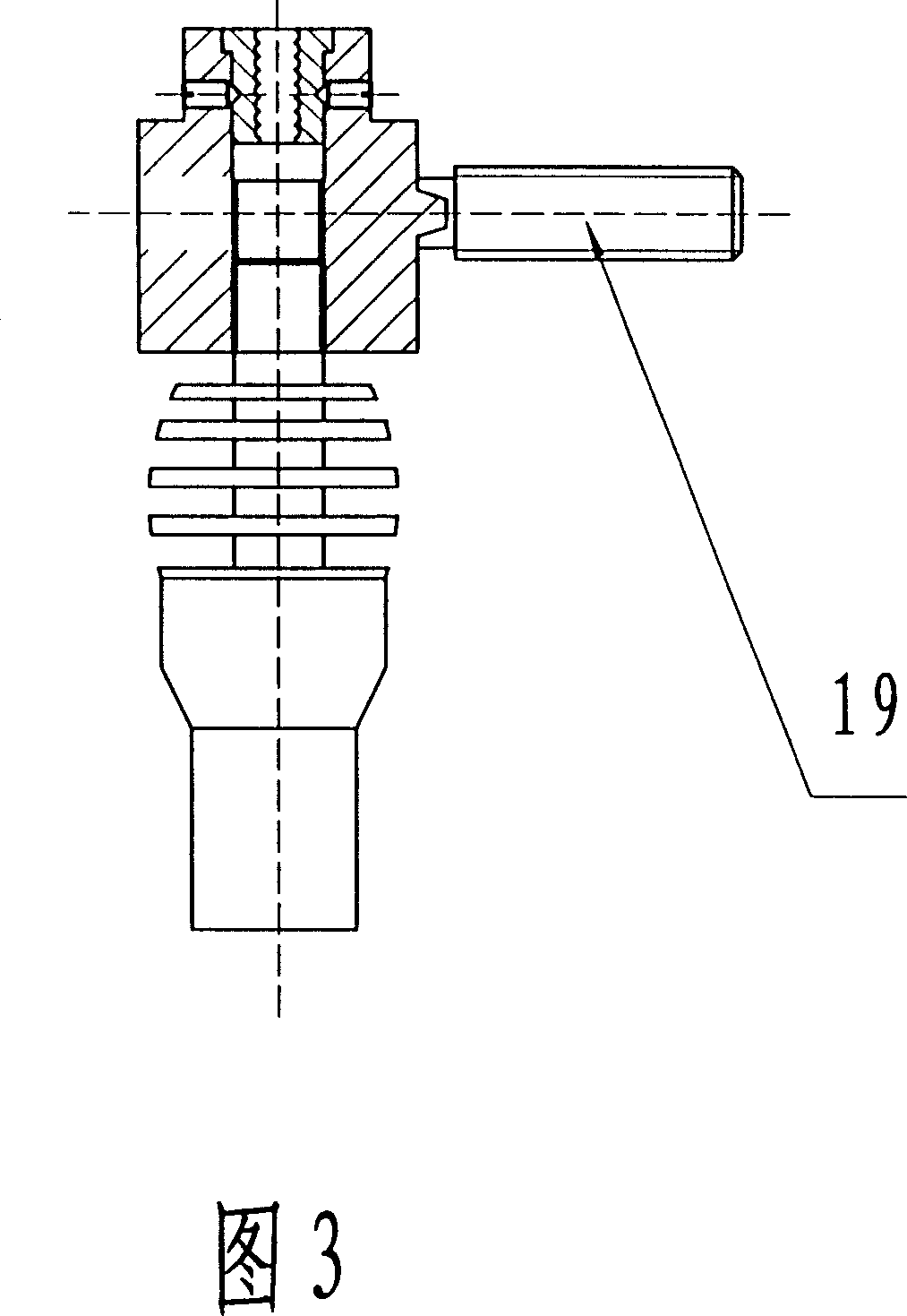

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0013] Please refer to Fig. 1 to Fig. 3, the output shaft of drive motor 1 in the figure is connected with the first transmission gear 2, and the second transmission gear 3 meshed with the first transmission gear 2 is fixed on the swing support main board 4, and the first transmission gear The gear 2 and the second transmission gear 3 are a pair of bevel gears, which are driven by the drive motor 1 to realize periodic reciprocating swing, and control the swing amplitude and swing frequency of the double welding torches by controlling the swing angle and swing frequency of the drive motor 1. Coupling shaft 5 is supported on the support 13, and swing support main board 4 and swing support sub-plate 6 are installed on the coupling shaft 5, and the motion of swing support main board 4, swing support sub-plate 6 and coupling shaft 5 is synchronous. The welding torch suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com