Motor stator structure

A motor stator and structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of wheel-shaped stator gear body deformation, stator teeth are difficult to absorb, and poor characteristics, etc., to achieve structural Stabilization and prevention of bad stator deformation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

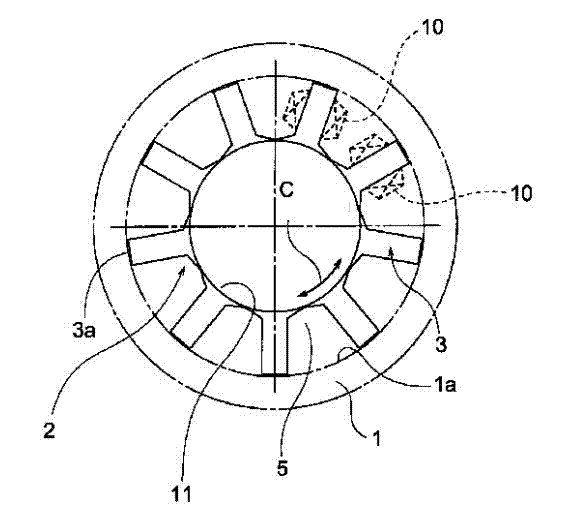

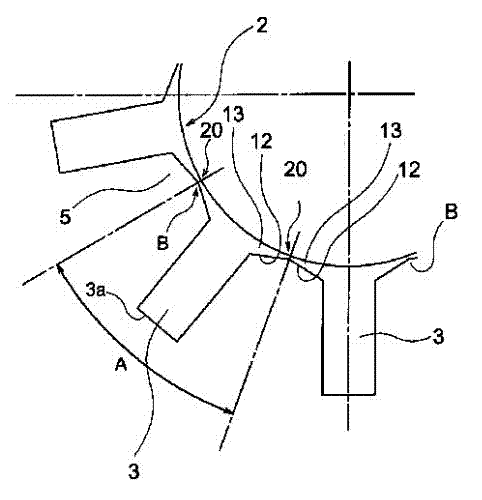

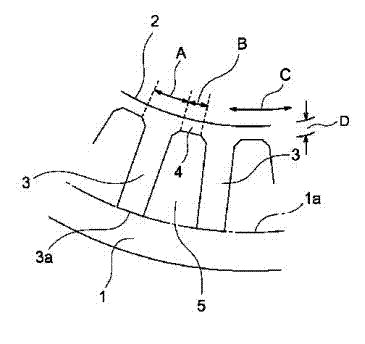

[0023] Next, suitable application forms of the motor stator structure invention will be described with reference to the drawings. In addition, the same or equivalent parts as conventional examples will be described using the same symbols. exist figure 1 and image 3 Among them, the part indicated by symbol 1 is the fixed part iron core composed of a wheel-shaped laminated structure, and the wheel-shaped stator gear body 2 having a plurality of stator teeth parts 3 is mounted on the fixed part iron core 1 by using a press-fitting process or the like. inside.

[0024] The outer peripheral surface 3a of each stator tooth part 3 of the above-mentioned wheel-shaped stator gear body 2 is connected to the inner peripheral surface 1a of the fixed part iron core 1, and a stator coil 10 is installed on the stator tooth part 3, and the stator coil 10 is located on each stator tooth. In the tooth groove 5 between parts 3 and 3.

[0025] On the inner peripheral position 11 of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com