Conical tooth clutch assembly and machining technology thereof

A processing technology and clutch technology, applied in clutches, mechanically driven clutches, clutches that mesh with each other, etc., can solve the problems of unqualified whole worm, braking lag, sideslip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

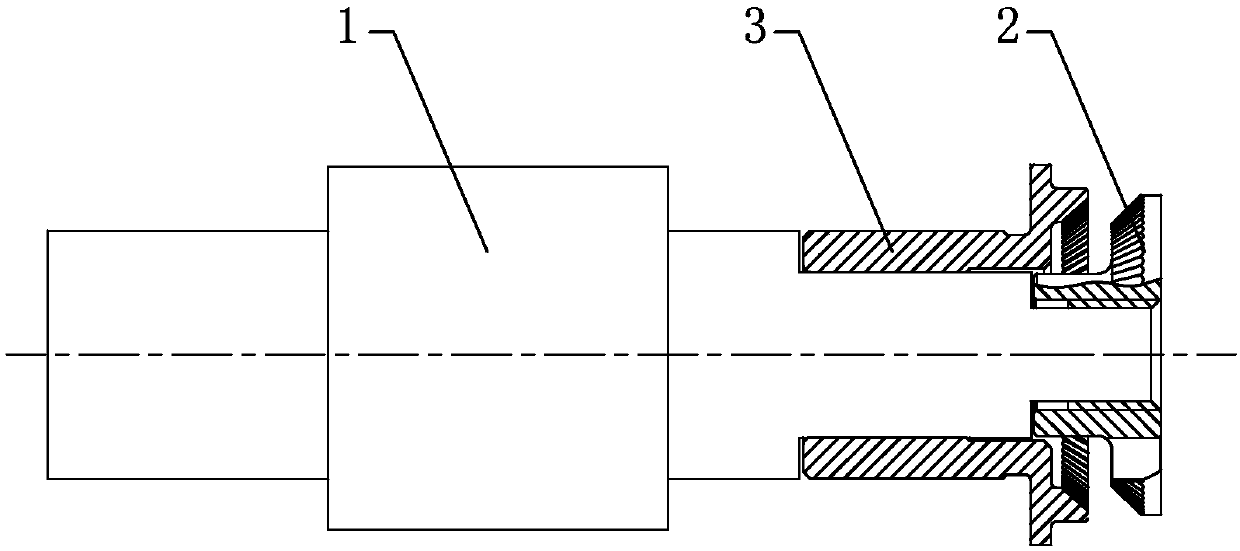

[0026] refer to Figures 1 to 4 The embodiment of a bevel clutch assembly of the present invention will be further described.

[0027] Such as figure 1 As shown, a bevel clutch assembly includes a worm shaft 1, an inner bevel clutch 3 sleeved on the worm shaft 1, an outer bevel clutch 2 detachably connected to the worm shaft 1, and an inner bevel clutch 3 is axially movably connected with the worm shaft 1, and the inner bevel clutch 3 is adapted to the outer bevel clutch 2.

[0028] The worm shaft 1 and the external bevel clutch 2 are separate structures. If one of the parts is worn or damaged, only the worn or damaged part needs to be replaced, and the cost is reduced, and the machining accuracy of the worm shaft 1 and the external bevel clutch 2 can be separated. Control, easy processing, improve processing accuracy, can improve transmission accuracy.

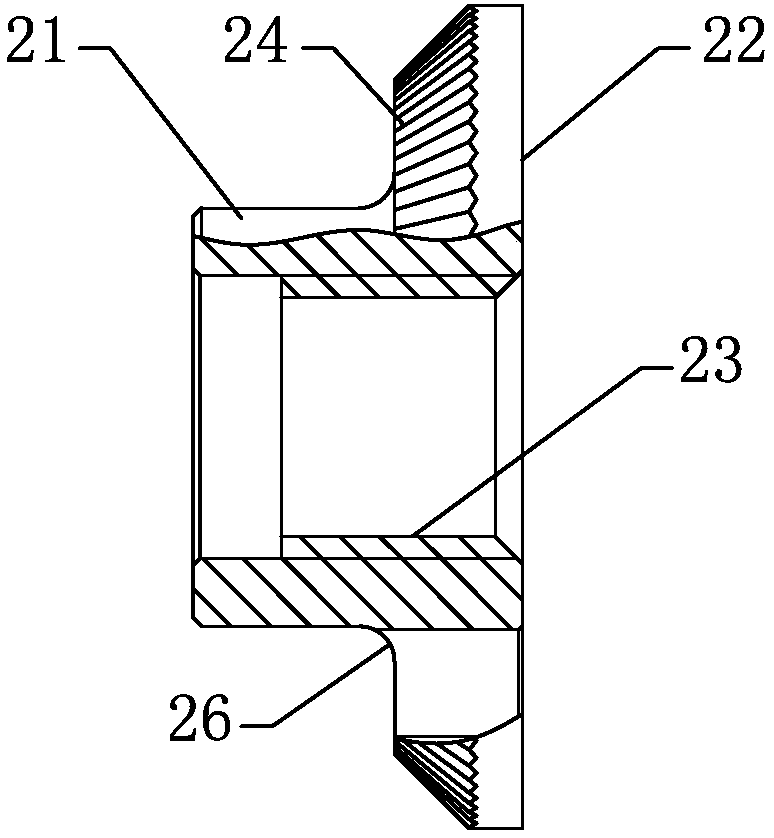

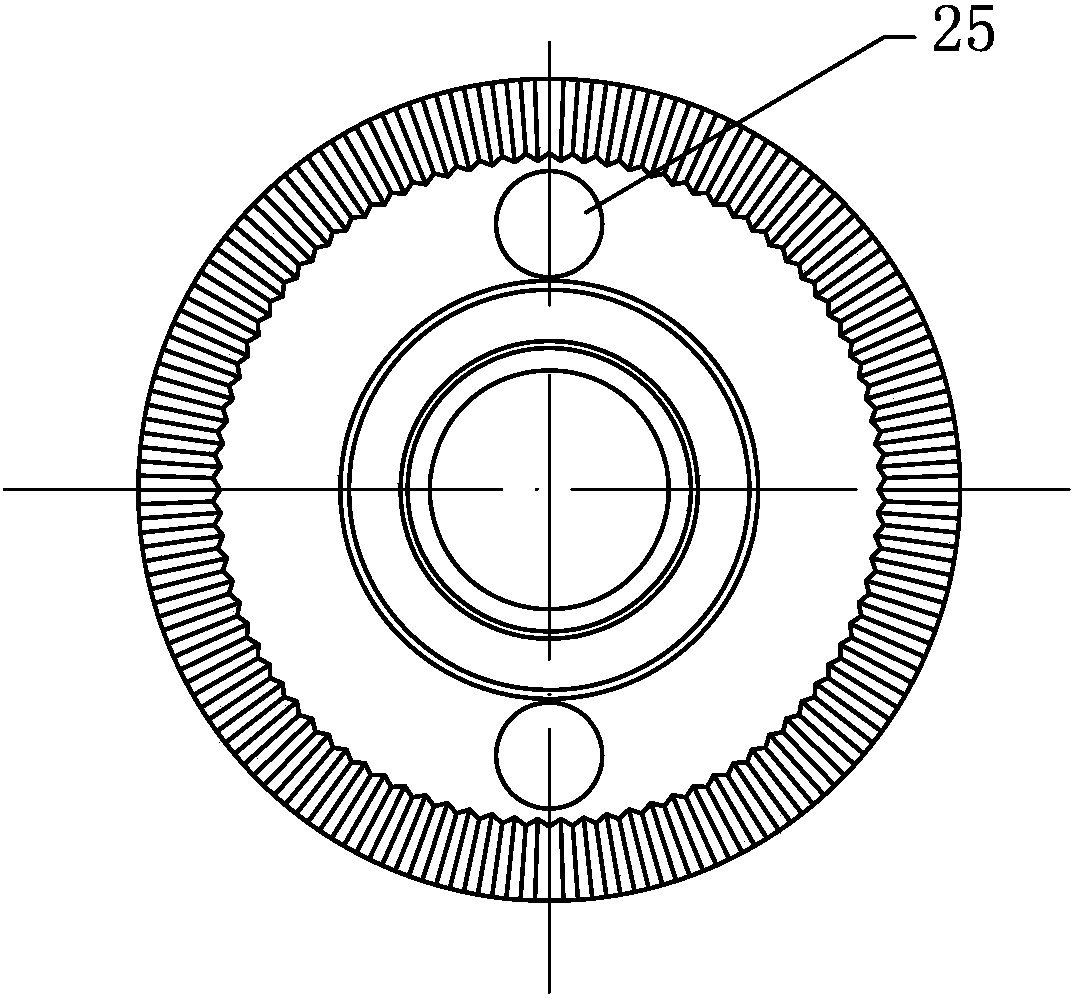

[0029] Such as Figure 2-3 As shown, the external bevel gear clutch 2 includes a first connecting sleeve 21 and a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com