Primary crushing method of coal-series needle coke and device thereof

A primary crushing and needle coke technology, applied in grain processing and other directions, can solve problems such as difficulty in selection, and achieve the effects of improving crushing work efficiency, convenient capture and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

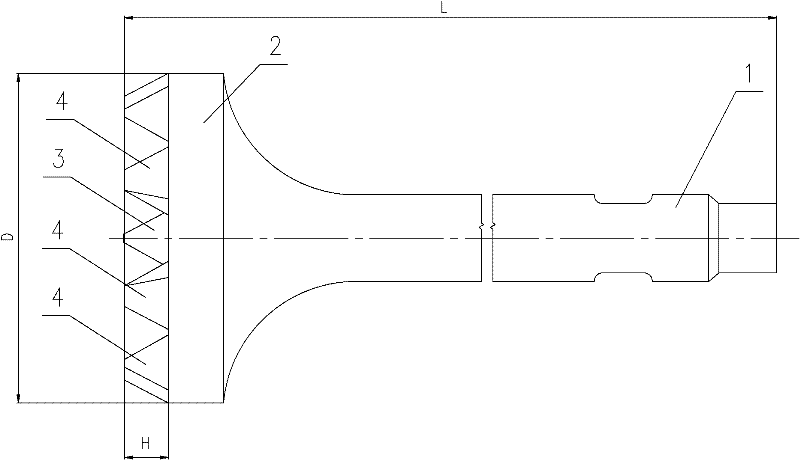

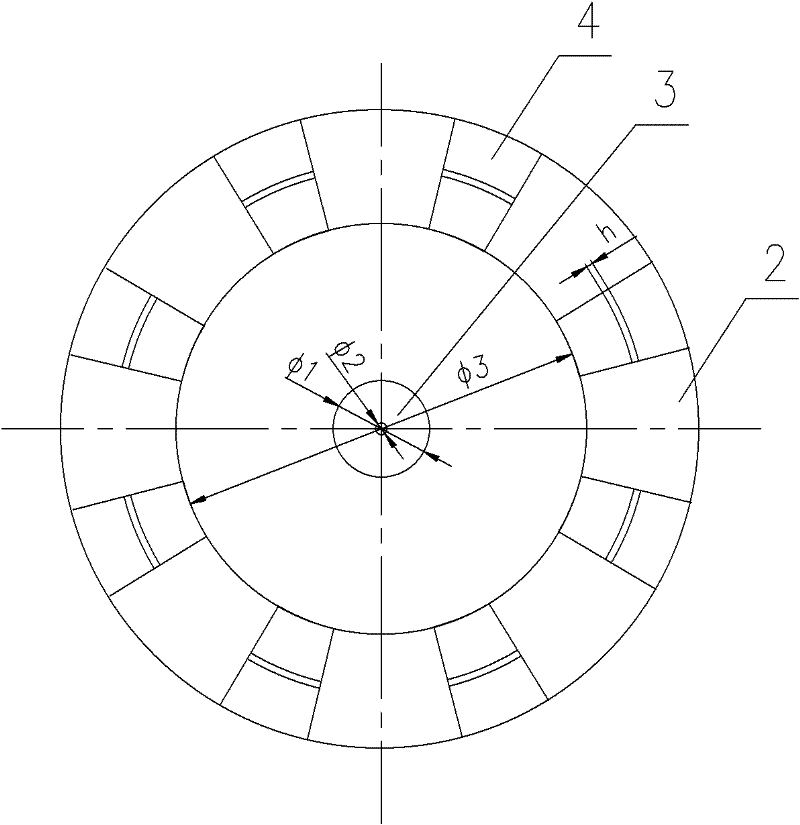

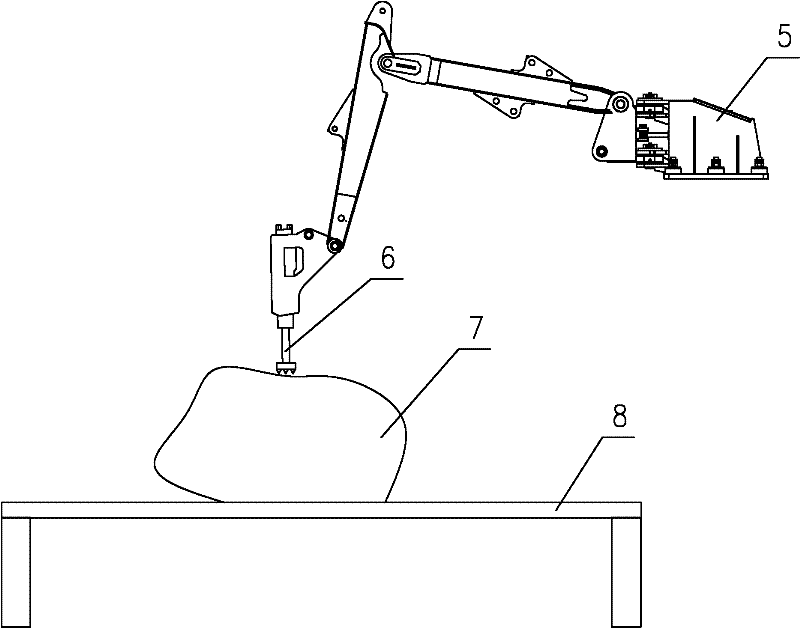

[0017] See figure 1 , figure 2 , is a structural schematic diagram of an embodiment of the multi-cone hammer head of the present invention. The multi-cone hammer head has an integrated structure, and the total length L is 700-750 mm. One end of the multi-cone hammer head is provided with a drill rod 1, and the size of the end of the drill rod 1 and The shape matches the clamping end of the impact hammer. The other end of the multi-cone hammer head is equipped with a crushing head 2. The crushing head 2 is disc-shaped. The diameter D of the disc is 300-350mm. The height H of the teeth 3 is 40-50mm, the root diameter φ1 is 60-65mm, and the top diameter φ2 is 6-10mm. The square bevel teeth 4 are concentrically arranged around the conical teeth 3. 4 is the same height as the conical tooth 3, the shape of the root of the square bevel tooth 4 is a fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com