Directional double-tooth self-balancing PDC drill bit suitable for soft and hard interlayers

A self-balancing, drill bit technology, used in drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of poor drilling stability, low drilling efficiency, and large lateral force, reducing impact wear and improving rock breaking efficiency. , the effect of reducing lateral vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

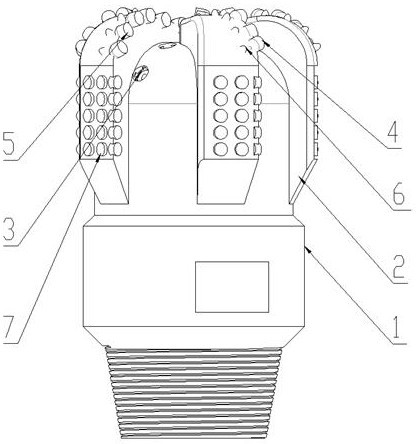

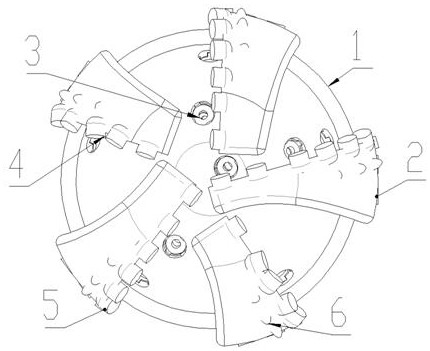

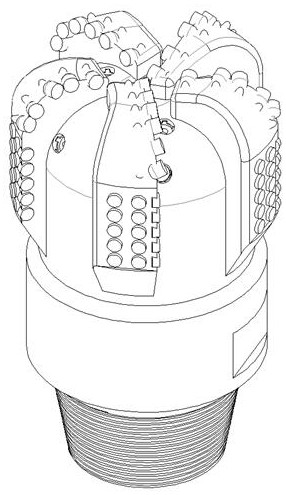

[0020] With reference to each figure, a kind of directional double-teeth self-balancing PDC drill bit suitable for soft and hard interlayers, the drill bit includes a drill body 1 and blades 2 and nozzles 3 arranged on the drill body 1; the number of blades 2 is 5, the blade 2 is equipped with a double-tooth structure 4, a front row of single teeth 5, a rear row of conical teeth 6 and a gauge tooth 7, and the rear row of conical teeth 6 is arranged on the same track behind the front row of single teeth 5; The nozzles 3 are arranged in the straight line area and the arc area of the crown of each blade 2; the crown of the blade 2 is a straight line-arc crown, and the cone depth of the crown is moderate; the drill body 1 The lower part is a male joint, and the lower end is provided with a screw thread, and the middle car has a groove for making up the well; the number of the nozzles 3 is 8.

[0021] Take the right horizontal blade as the initial blade, and the blades in the cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com