High-rise drainage bend tube

A curved, high-rise technology, applied in the field of pipeline systems, can solve problems such as affecting the work of drainage pipelines, large water flow potential, pipeline rupture, etc., to facilitate regular maintenance and replacement, enhance energy dissipation effect, and prevent impact damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

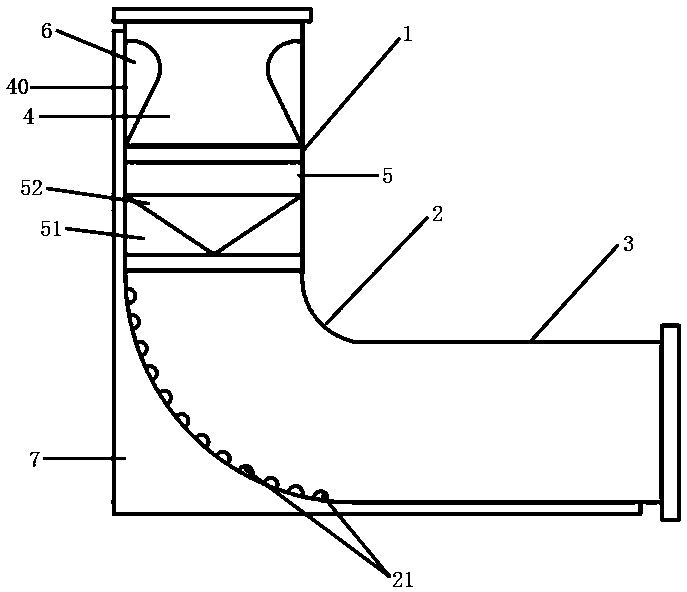

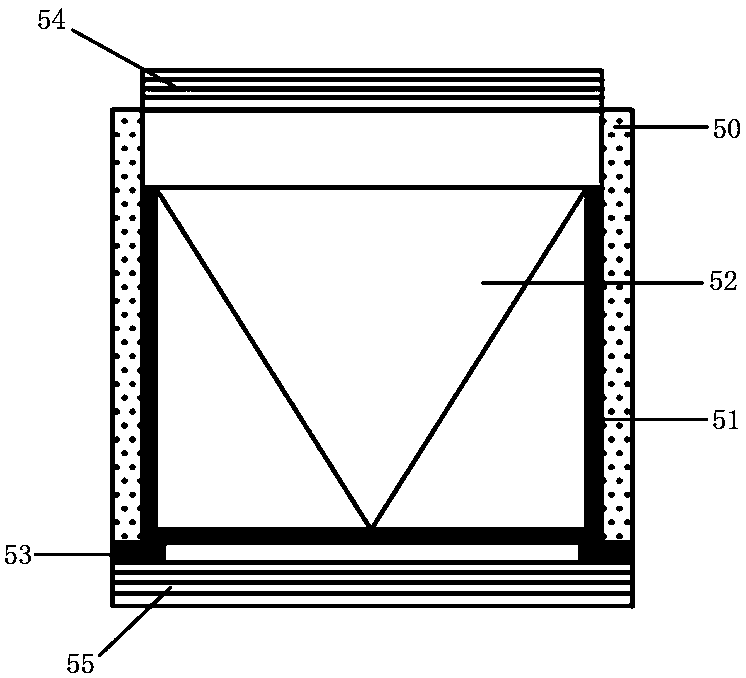

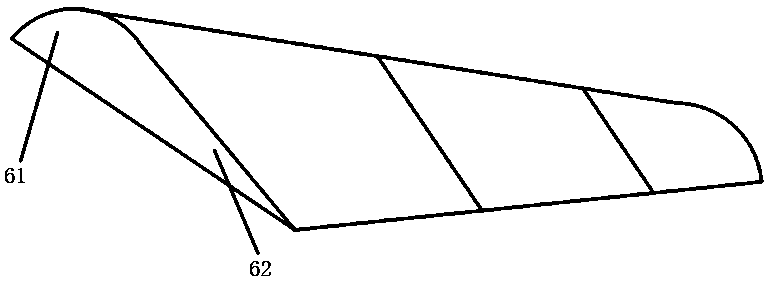

[0028] A high-rise drainage bend pipe, comprising a water inlet section 1, a bend section 2, and a water outlet section 3. The water inlet section is composed of an energy dissipation pipe 4 and a filter pipe 5 detachably connected to the lower end of the energy dissipation pipe; the energy dissipation pipe 4 includes a first The pipe body 40 and the energy dissipator 6 welded on the pipe wall in the first pipe body, the upstream surface of the energy dissipator 6 is a circular arc surface 61, and the back surface is an inclined surface 62, and the upstream surface is smoothly connected with the inclined surface for energy dissipation. The length of the filter is 1 / 4 of the length of the water inlet section, and the number is 2, which are symmetrically distributed on the inner wall of the first pipe; the filter pipe includes a second pipe body 50, an internal thread 54 arranged on the upper end of the second pipe body And the external thread 55 at the lower end of the second pi...

Embodiment 2

[0030] A high-rise drainage bend pipe, comprising a water inlet section 1, a bend section 2, and a water outlet section 3. The water inlet section is composed of an energy dissipation pipe 4 and a filter pipe 5 detachably connected to the lower end of the energy dissipation pipe; the energy dissipation pipe 4 includes a first The pipe body 40 and the energy dissipator 6 bonded to the pipe wall in the first pipe body, the upstream surface of the energy dissipator 6 is an arc surface 61, and the back surface is an inclined surface 62, and the upstream surface is smoothly connected with the inclined surface, forming a Airfoil, the length of the energy dissipator is 1 / 3 of the length of the water inlet section, and the number is 4, which are symmetrically distributed on the water inlet to the inner pipe wall; the filter pipe includes a second pipe body 50, which is arranged on the second pipe body The internal thread 54 at the upper end and the external thread 55 at the lower end o...

Embodiment 3

[0032] A high-rise drainage bend pipe, comprising a water inlet section 1, a bend section 2, and a water outlet section 3. The water inlet section is composed of an energy dissipation pipe 4 and a filter pipe 5 detachably connected to the lower end of the energy dissipation pipe; the energy dissipation pipe 4 includes a first The pipe body 40 and the energy dissipator 6 clamped on the pipe wall in the first pipe body, the upstream surface of the energy dissipator 6 is an arc surface 61, and the back surface is an inclined surface 62, and the upstream surface is smoothly connected with the inclined surface, forming a Airfoil, the length of the energy dissipator is 1 / 4 of the length of the water inlet section, and the number is 3, which are symmetrically distributed on the water inlet to the inner pipe wall; the filter pipe includes a second pipe body 50, which is arranged on the second pipe body The internal thread 54 at the upper end and the external thread 55 at the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com