Construction waste wind separation device

A technology for wind separation and construction waste, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve the problems of inability to meet fast and effective treatment, unsatisfactory separation effect, and low separation efficiency. , to achieve the effect of wide practicability, simple structure and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

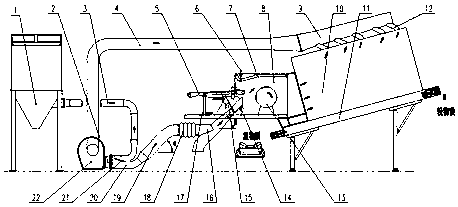

[0011] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] The construction waste wind separation device of the present invention is mainly composed of an air circulation system, a feeding and guiding device, and a collecting and conveying device. Among them, there are 2 sets of air circulation systems, each of which includes a blower 22, a dust removal device, an air supply pipe assembly, and a return air pipe 4. The air supply pipe assembly includes a three-way hard pipe 20, an air volume adjustment valve 21, and a left hard pipe 19. , soft connecting pipe 18, right hard pipe 16, large lead screw 15, wind speed regulating valve 14, the left end of three-way hard pipe 20 is connected and communicated with the air outlet of blower 22, and air volume regulating valve 21 is arranged in three-way hard pipe 20, three-way hard pipe 20 One of the two nozzles at the right end of the hard tube 20 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com