Side type powder feeding top blowing furnace and treatment method thereof

A top-blown furnace and powder technology, which is applied to the side-type top-blown powder feeding furnace and its processing field, can solve the problems of endangering the health of operators, large transportation flying losses, poor operating environment, etc., to avoid flying losses, Streamline the shipping process and improve the effect of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

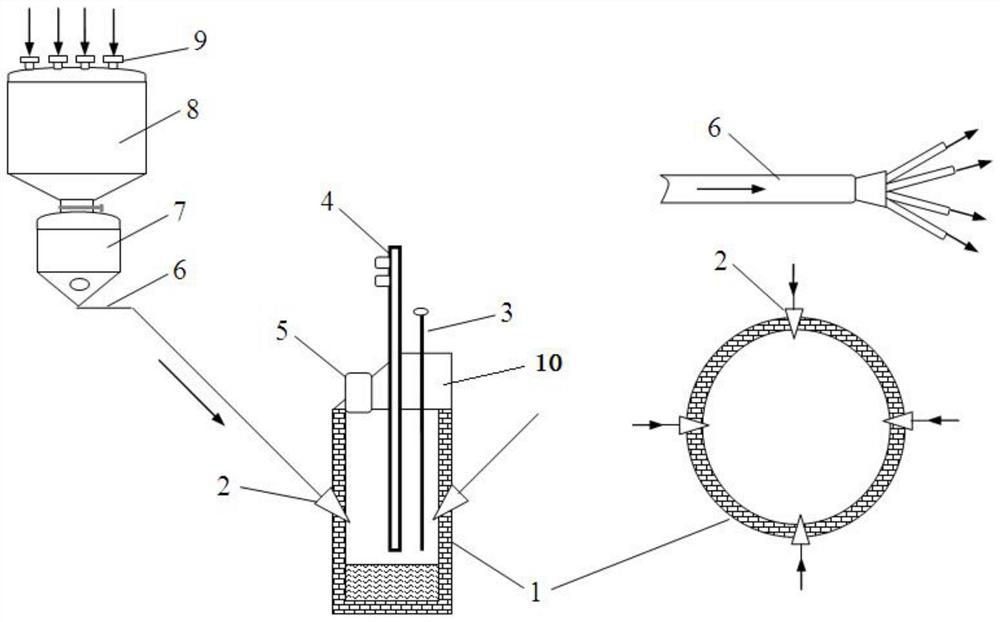

[0033] Embodiment 1 of the present invention provides a kind of processing method of side-type powder-feeding material top-blowing furnace, and described side-type powder-feeding material top-blowing furnace is such as figure 1 As shown, the working process of the side-type top-blown powder-feeding furnace is as follows:

[0034] In the tin smelting system, the powdered tin calcined sand produced by the desulfurization of the fluidized roaster Sn 35wt.%, S1.1wt.%, As 0.8wt.%, H 2 O≤3wt.%, powdered tin fume produced by fuming and enriching tin ore and tin slag in fuming furnace Sn 45wt.%, Pb 0.2wt.%, S 0.9wt.%, As 1.5wt.%, Fe 2wt.%, H 2 O≤4.5wt.%, powdered tin fume collected from waste heat boiler and electric dust collector of flue gas treatment system during top blowing furnace smelting Sn 38wt.%, Pb1.0wt.%, S 0.75wt.%, As 1.8wt.%, Fe 3wt.%, H 2 O≤4.5wt.%, powdered tin materials and pulverized coal from different sources in several tin smelters, are sent into the powdery m...

Embodiment 2

[0038] Embodiment 2 of the present invention provides a kind of processing method of side-type top-blown powder-feeding furnace, and working procedure is as follows:

[0039] In the tin smelting system, the powdered tin calcined sand produced by the desulfurization of the fluidized roaster Sn 38wt.%, S0.86wt.%, As 1.0wt.%, H 2 O ≤ 2wt.%, powdered tin fume produced by fuming and enriching tin ore and tin slag in fuming furnace Sn 42wt.%, Pb 0.5wt.%, S 0.8wt.%, As 2.0wt.%, Fe 3.5wt.%, H 2 O≤4.0wt.%, powdered tin fume collected from waste heat boiler and electric precipitator of flue gas treatment system during top blowing furnace smelting Sn40wt.%, Pb 2.1wt.%, S 0.68wt.%, As 1.5 wt.%, Fe 3.6wt.%, H 2 O≤5wt.%, powdery tin materials and pulverized coal from different sources in several tin smelters are simultaneously sent to the powdery material collection bin 8 through the corresponding quantitative pneumatic conveying device to complete the mixing, wherein the powdery tin is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com