Anti-backlash transmission comprising trochoid gears and roll pins with conical teeth

A pin-rolling gear and gear transmission technology, which is applied in the field of backlash-eliminating conical-tooth pin-trochoidal gear transmission, can solve the problem of not further considering the backlash and other problems, achieve low maintenance cost, eliminate backlash, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

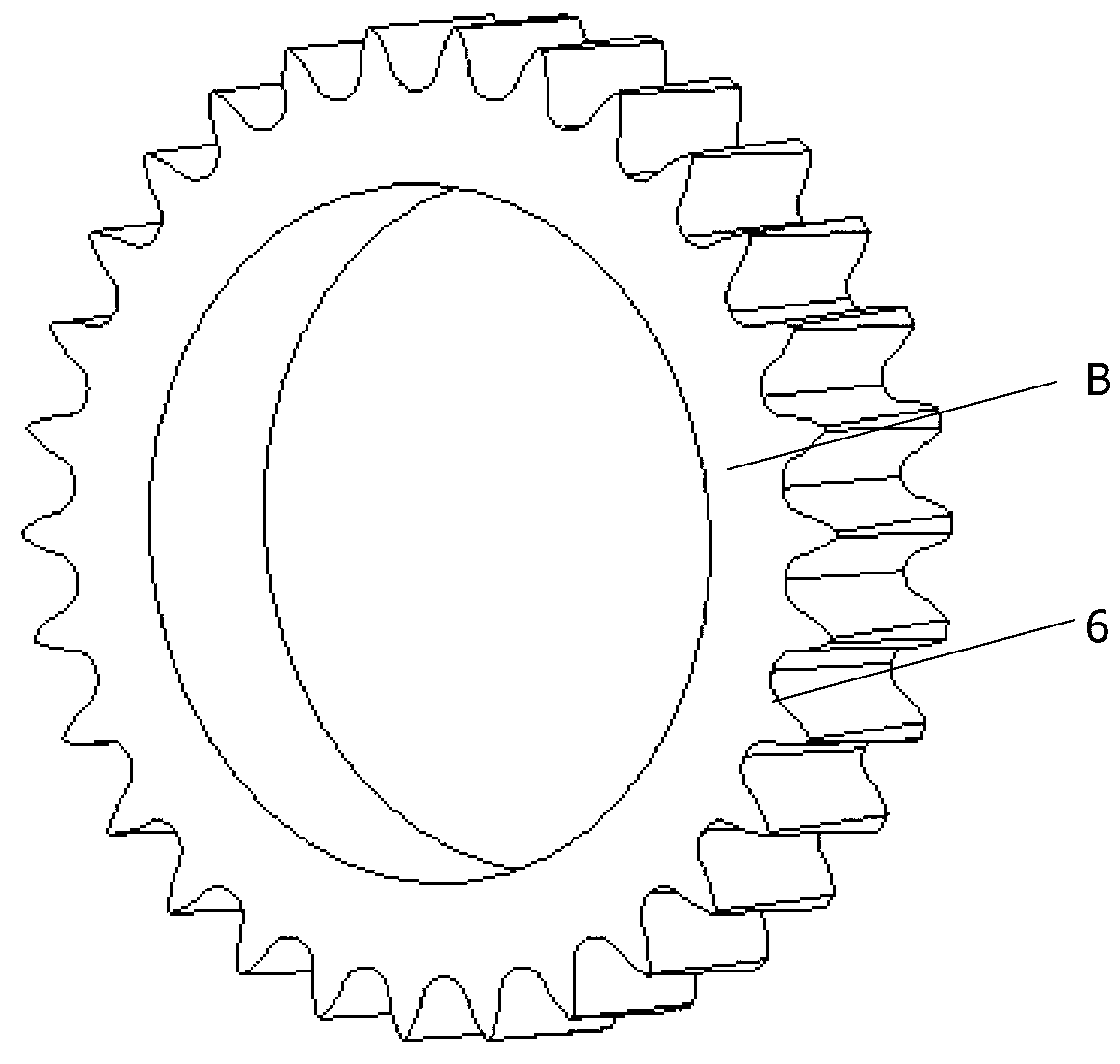

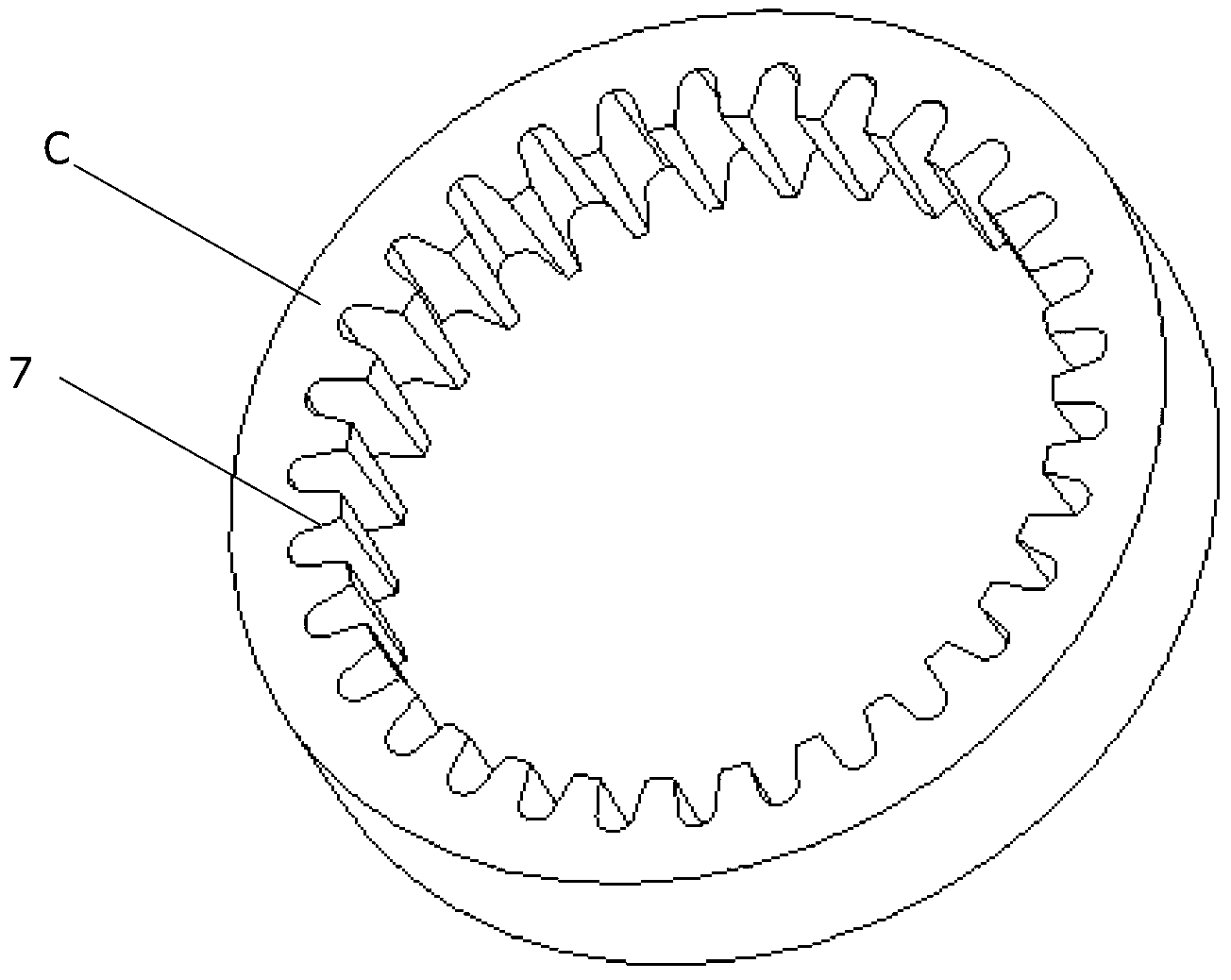

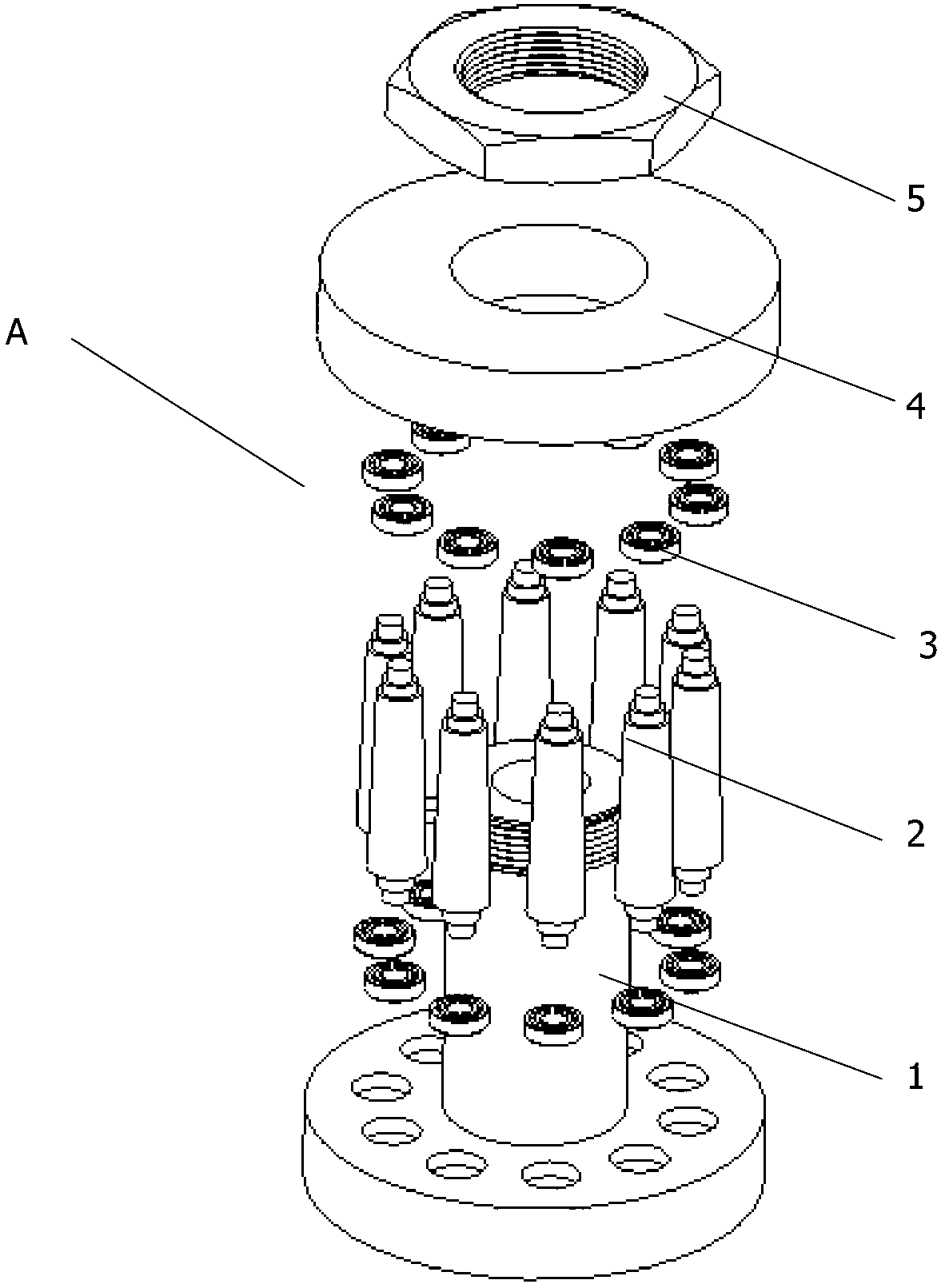

[0022] Figure 4 with Figure 5 Two transmission forms of external gearing and internal gearing according to the embodiments of the present invention are shown. During the installation process, in order to achieve zero backlash in meshing, a slight preload should be ensured between the external gear B (or internal gear C) and the rolling pin gear A, and the magnitude of the preload should be recorded as the predetermined preload. Tight force. When backlash occurs due to wear during transmission, push pin gear A toward the small end of the tapered pin until the pressure between external gear B (or internal gear C) and pin gear A reaches the predetermined preload. The backlash between the external gear B (or internal gear C) and the rolling pin gear A can be eliminated, thereby compensating the transmission error and ensuring the transmission accuracy.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com