Method used for automatic heat dissipation and dust removal of transformer box

A substation, automatic technology, applied in the cooling/ventilation of substation/switchgear, substation/distribution device shell, substation/switch layout details, etc., can solve the problems of intrusion cleaning range, fan consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Further detailed explanation through specific implementation mode below:

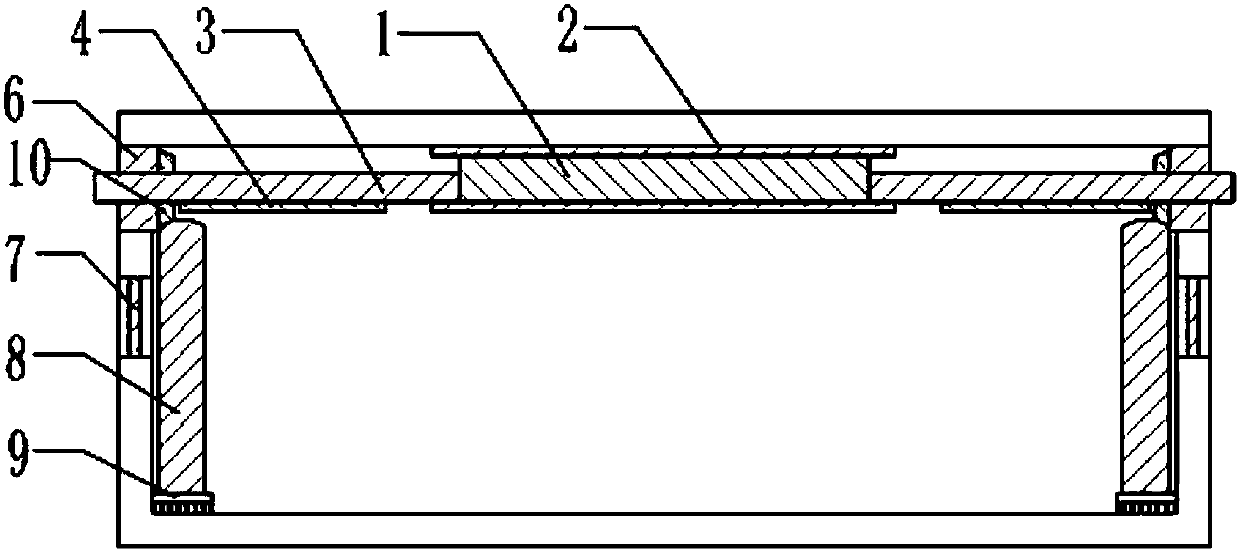

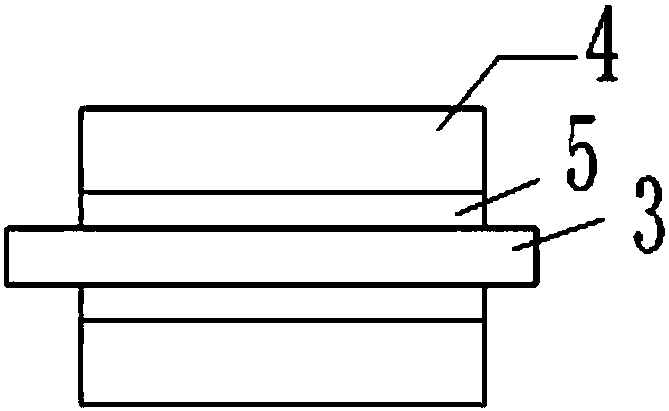

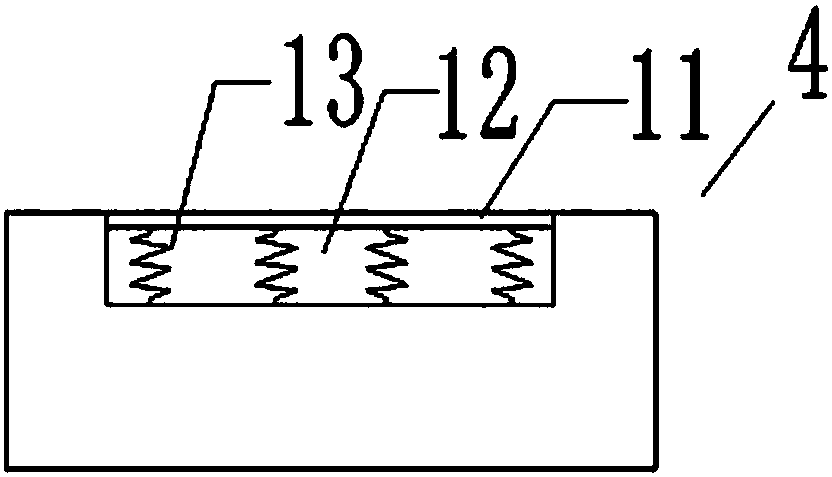

[0035] The reference signs in the accompanying drawings of the description include: airbag 1, limit tube 2, threaded rod 3, support plate 4, limit rod 5, spiral fan 6, louver 7, transmission rod 8, cleaning disc 9, tapered tube 10 , matte paper 11, groove 12, stage clip 13.

[0036] The method for automatic heat dissipation and dust removal of a transformer box includes the following contents:

[0037] S1, when the temperature rises, the inflatable airbag extends to both ends under the restriction of the limit tube, thereby driving the threaded rod fixed to both ends of the airbag to extend outward on the support plate; the diameter of the threaded rod is smaller than the limit tube When the temperature drops, the airbag shrinks, and under the restriction of the limit tube, the two ends of the airbag shrink toward the middle, driving the threaded rod to move toward the middle of the airbag on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com