Self-driven cooling and dedusting transformer box

A substation, self-driven technology, applied in substations, enclosed substations, substations/distribution device enclosures, etc., can solve the problems of fan consumption, intrusion into the cleaning range, etc., to accelerate gas flow and improve heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Further detailed explanation through specific implementation mode below:

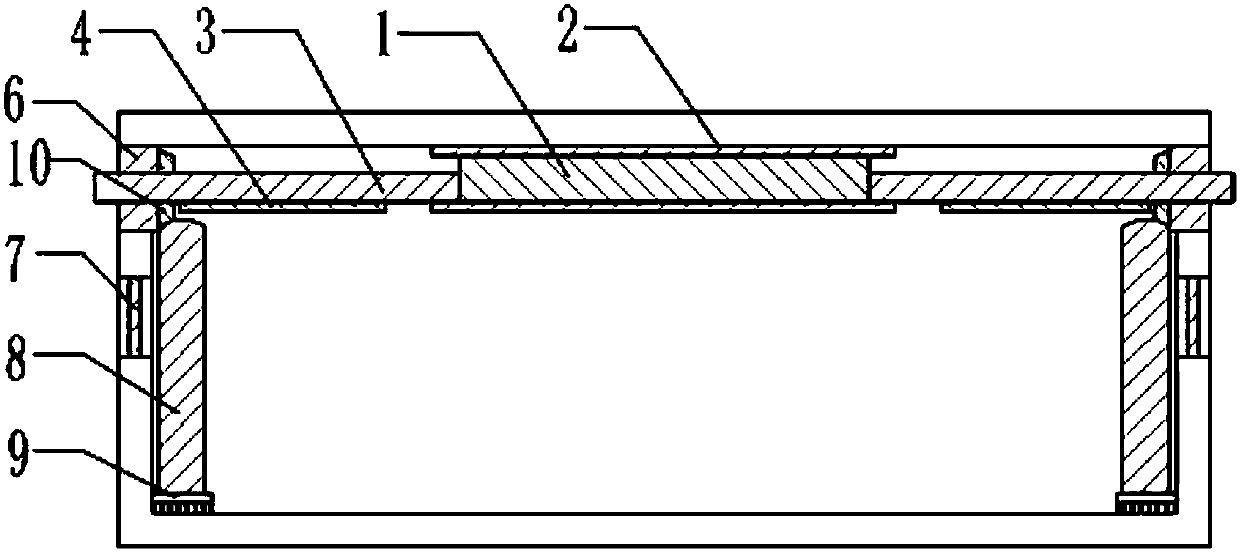

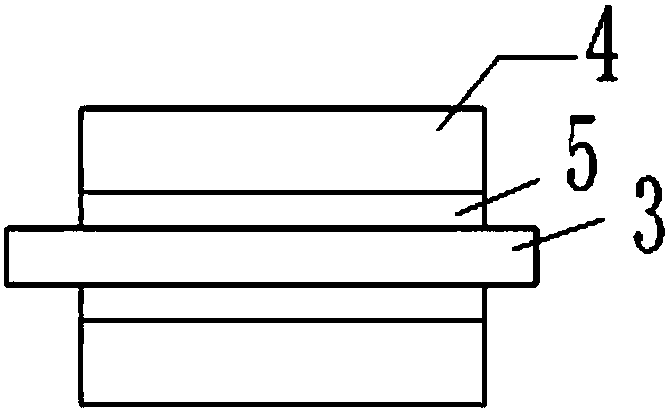

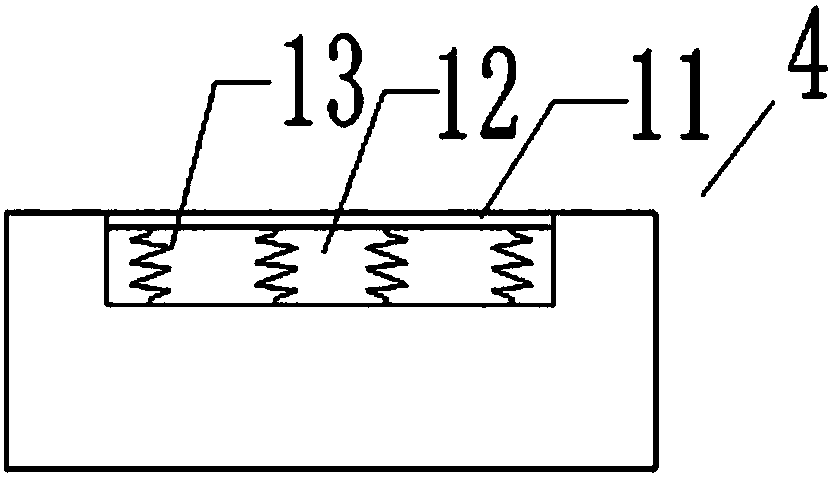

[0039]The reference signs in the accompanying drawings of the description include: airbag 1, limit tube 2, threaded rod 3, support plate 4, limit rod 5, spiral fan 6, shutter 7, transmission rod 8, cleaning disc 9, tapered tube 10 , matte paper 11, groove 12, stage clip 13.

[0040] Such as figure 1 As shown, the self-driven heat dissipation and dust removal transformer box of the present invention includes a box body, and the box body includes a box top wall, a box bottom wall, a box side wall and a heat dissipation and dust removal device; the heat dissipation and dust removal device includes a power mechanism, a cleaning mechanism and a ventilation mechanism;

[0041] The power mechanism includes an airbag 1, a limiting tube 2 and a threaded rod 3 sleeved on the airbag 1, the limiting tube 2 is fixed on the top wall of the box, the diameter of the threaded rod 3 is smaller than the inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com