Glass crushing device

A glass breaking and breaking box technology, applied in grain processing and other directions, can solve the problems of cumbersome operation steps and hidden dangers, and achieve the effect of reducing hidden dangers and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

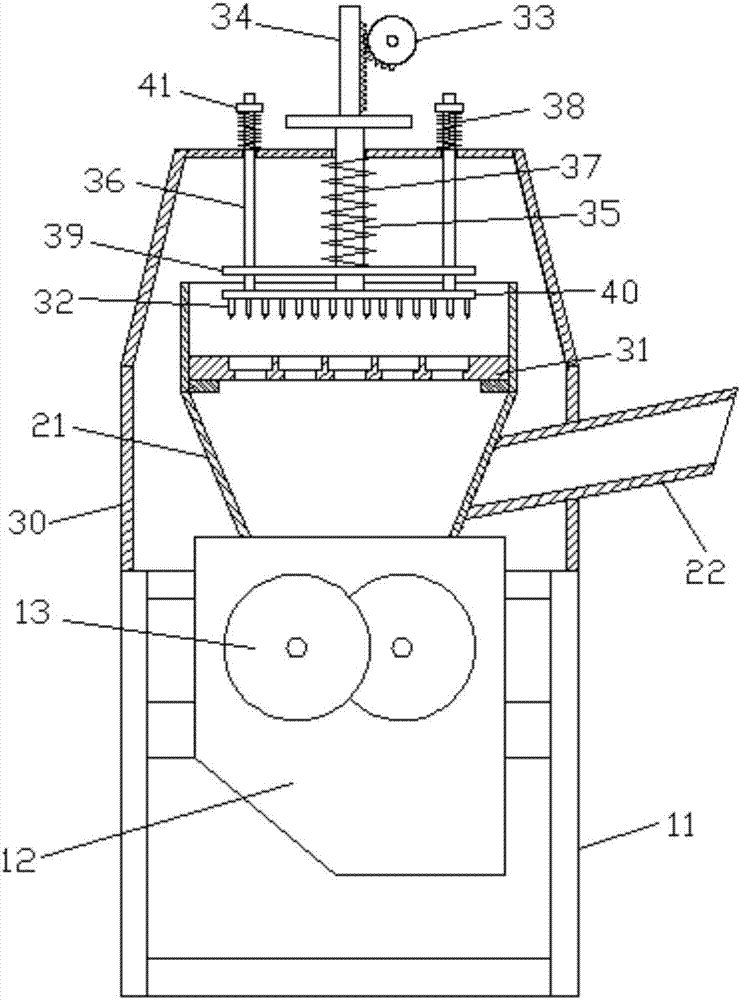

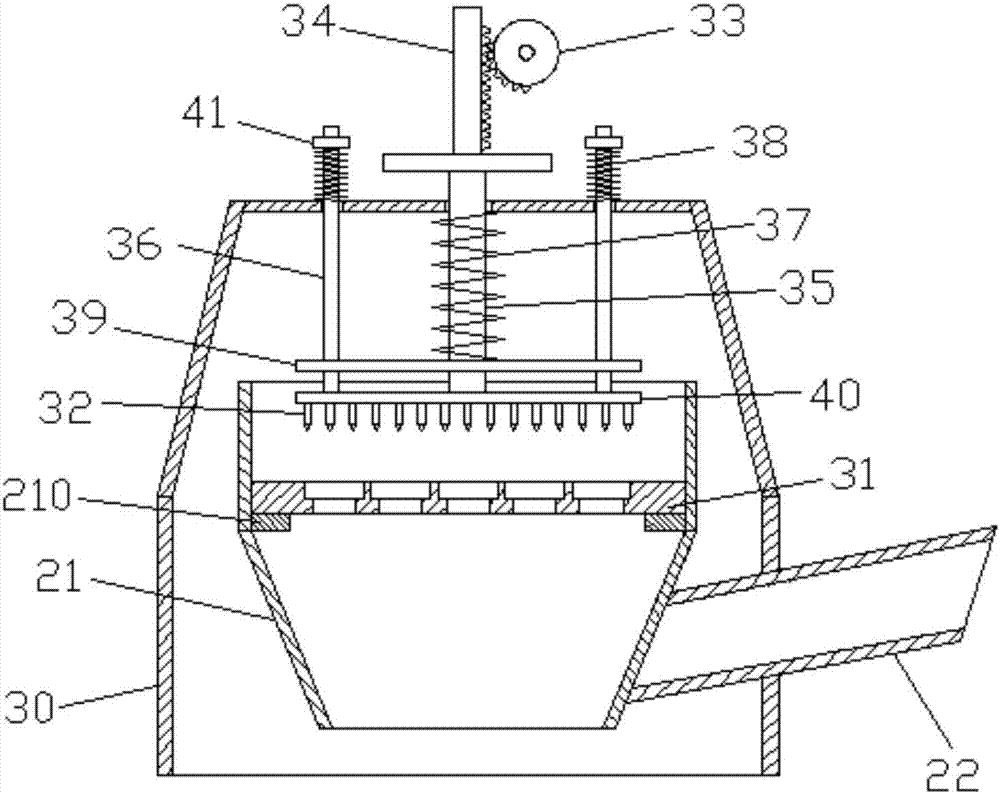

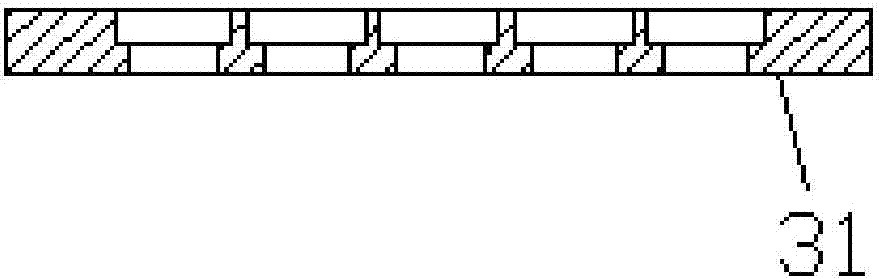

[0017] Such as Figure 1 to Figure 4 As shown, the present invention discloses a glass crushing device, which includes a frame 11, a crushing box 12, a crushing rotor 13, a feeding box 21, a mounting frame 30, a crushing plate 31, crushing cone teeth 32, an incomplete gear 33, and a rack 34 , the first guide rod 35, the second guide rod 36, the first spring 37, the second spring 38, the push plate 39, the mounting plate 40 and the positioning nut 41, the crushing box 12 and the mounting frame 30 are all fixed on the frame 11, The two crushing rotors 13 are rotated and installed in the crushing box 12, the feeding box 21 is fixed on the frame 11, and the discharge port of the feeding box 21 is connected with the feeding port of the crushing box 12, the first guide rod 35 and the second guide rod The rods 36 are all inserted into the mounting frame 30, the push plate 39...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com