Spiral-flow type blockage-free energy-efficient centrifugal fan

A centrifugal fan, non-clogging technology, applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problems of complex manufacturing process, non-optimal, loud noise, etc., achieve significant economic and social benefits, reduce energy Consumption, energy saving and emission reduction outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

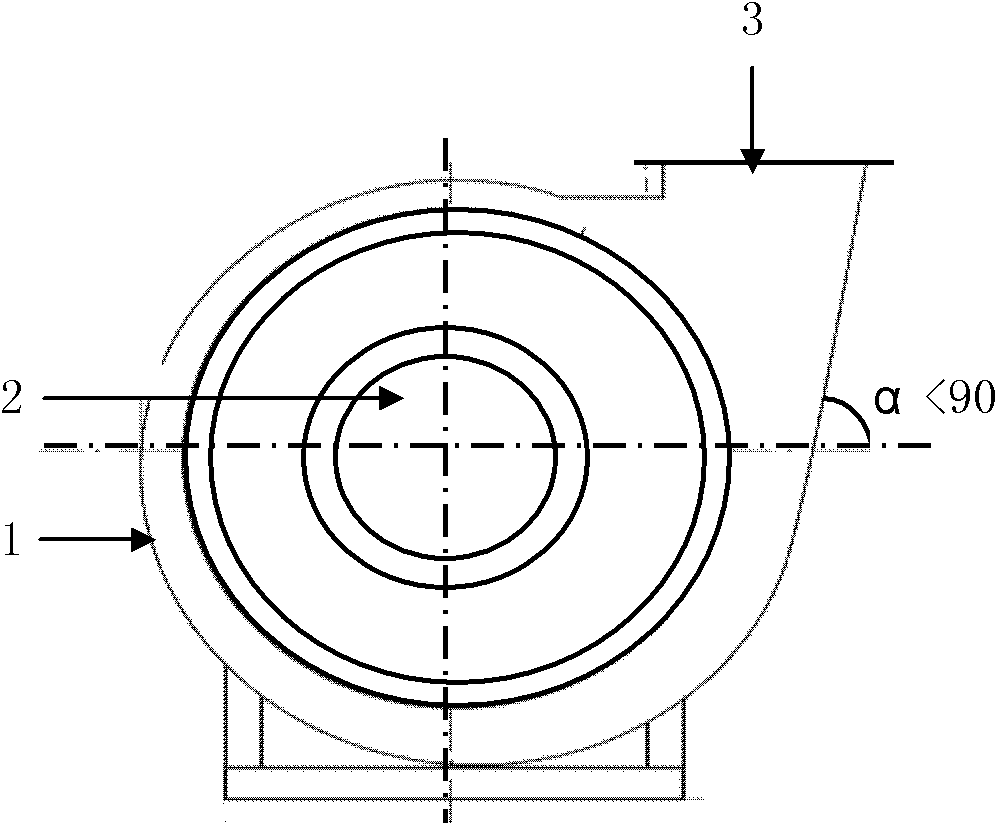

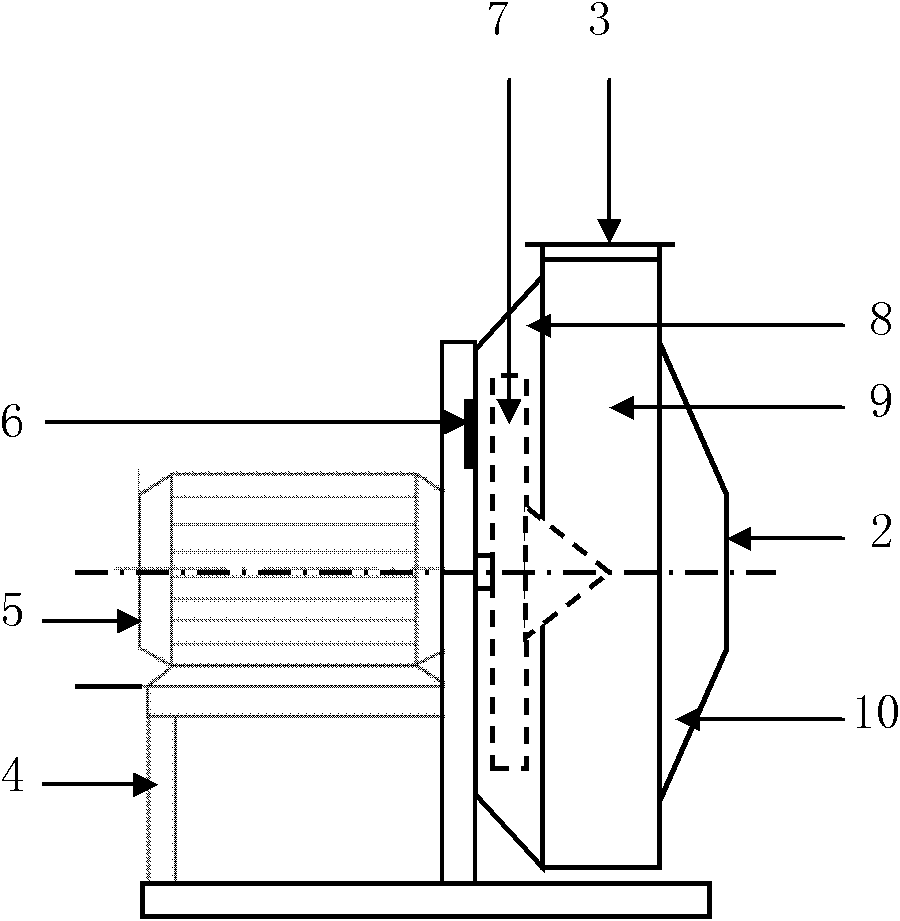

[0023] A swirling non-blocking energy-saving centrifugal fan, which includes a casing 1, an air inlet 2, an air outlet 3, a frame 4, a motor 5, an adjustable wheel guard hole 6, an impeller 7, a frustum-shaped induction chamber 8, Circular or volute-shaped swirl chamber 9, umbrella-shaped diffuser chamber 10, such as figure 1 , figure 2 shown.

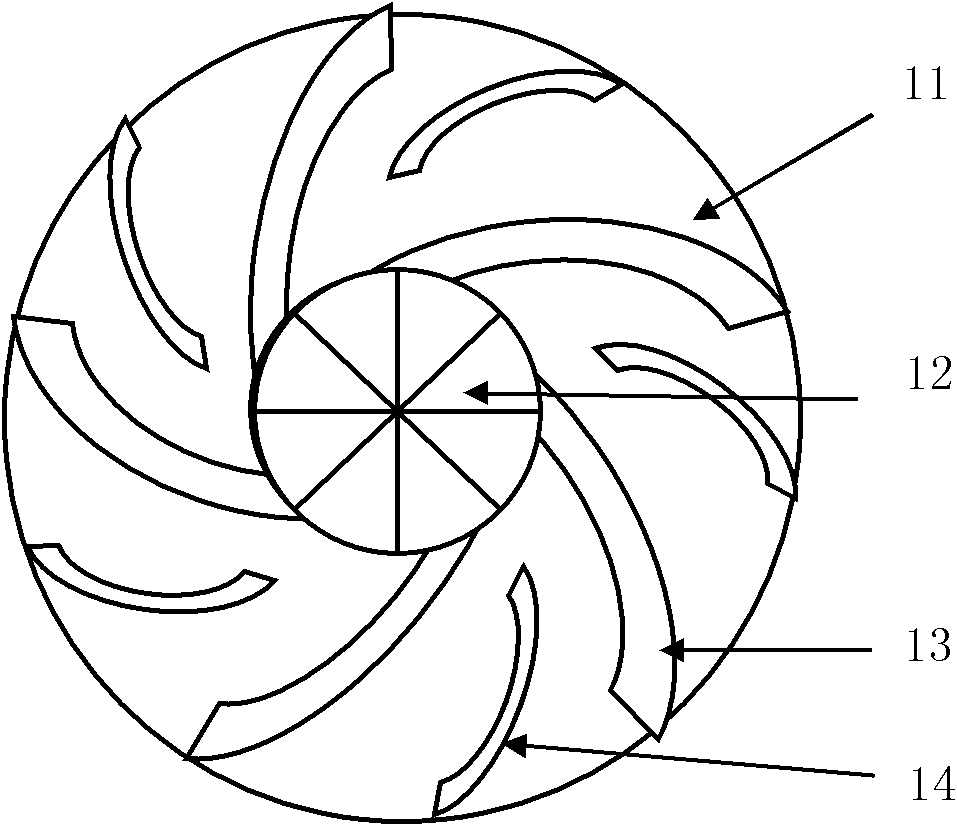

[0024] Install the motor 5 and the casing 1 on the frame 4, the casing 1 is provided with an air inlet 2 and an air outlet 3, and the casing 1 is composed of a frustum-shaped induction chamber 8, a circular or volute-shaped swirl chamber 9 and an umbrella-shaped diffuser chamber 10, the impeller 7 is installed in the frustum-shaped induction chamber 8, and is directly connected with the motor 5; the impeller 7 is a blade-type disc impeller and a bevel-toothed impeller with one side open in the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com